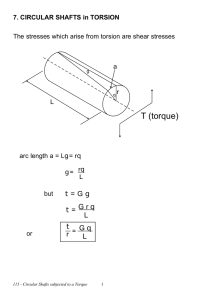

Equipment: WP500 Torsion Tester Title: Torsion Testing of Cast Iron Location: GF-051, MATERIALS LAB Torsion Testing of Cast Iron ENGINEERING MATERIALS LAB-III A. Theory In solid mechanics, torsion refers to the twisting action caused by a pair of externally applied equal and oppositely directed force couples acting on parallel planes or by a single external couple applied to a member that has one end fixed against rotation. It is expressed in newton meters (N.m) or foot-pound force (ft.lbf). In sections perpendicular to the torque axis, the resultant shear stress in this section is perpendicular to the radius. B. Equipment The Torsion Tester, 30Nm WP 500 is used for torsion testing of metal test bars loaded to destruction. The test moment and torsion angle are measured. C. Assumptions 1. The apparatus is error free in measurement of the force value. D. Procedure For Information Specimen Head: 17 mm Hexagon Head Permissible Specimen Length: 750 mm (Max) Specimen Drawing for Experiment General Procedure 1. Insert sockets into square connections. 2. Release clamping lever on torque measurement unit and push it backwards. 3. Place the specimen in the sockets and slide the torque measurement unit forwards again. Make sure the moving device is located in the center of its range of movement. 4. Fix the torque measurement unit in place with the clamping levers. 5. Carefully pre-tension the specimen until there is no more slack and the torque display begins to move. 6. Set the torque to display to zero using the tare function. 7. Set the pointers on the two angle scales to zero. 8. Set the dial gauge on the compensation device to zero by rotating the scale ring. 9. Reset the revolution counter. 10. Begin the experiment and complete the table as under. Equipment: WP500 Torsion Tester Title: Torsion Testing of Cast Iron Location: GF-051, MATERIALS LAB D. Observations S. No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 Input Angle Turns 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140 145 150 155 160 165 Torque, T (Nm) Angle of twist ɸ (°) Shearing Angle, ɼ (rad) Shear Stress, Ʈ (N/𝒎𝒎𝟐) Equipment: WP500 Torsion Tester Title: Torsion Testing of Cast Iron Location: GF-051, MATERIALS LAB E. Lab Discussion 1. Using the values, make the following graphs: a. Torque (Nm) against Specimen Torsion Angle (°) b. Shear Stress (N/𝑚𝑚2) against Shearing Angle (rad) c. Calculate the value of Modulus of Rigidity using the graph in part (b). 2. Discuss the breaking behavior being exhibited by the specimen. Please Note: Grace Marks would be awarded for cleanliness, finesse of handling lab equipment and presentation of work.