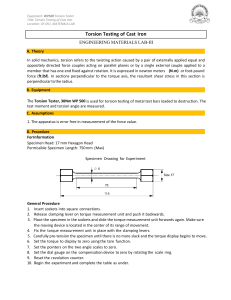

Material Torsiontest Mohammed Elmoursi Mohammed Autotronics Torsion test During a torsion test, a specimen is subjected to a twisting or torsional force, which induces a torque. This test is particularly useful for materials that are subjected to torque in their application, such as shafts, rods, and fasteners. How to perform a torsion test: 1. Specimen Preparation: Material: Select the material to be tested (metal, polymer, etc.). 2. Shape and Size: The specimen is usually a cylindrical rod or tube, with a uniform cross-section. Standard dimensions are specified in various testing standards such as ASTM E143. 3. Coding: Mark the length of measurement (distance between handles) on the specimen. 4. Preparation: Specimen Mounting: Clamp the specimen between the handles of the torsion testing machine. One end is held stationary, while the other end is fixed to the rotating handle. 5. Calibration: Ensure that the machine is properly calibrated according to the material and size of the specimen. Page 1 of 3 6. Test Procedure: Apply Torque: Gradually apply torque to the specimen by rotating the movable handle. The applied torque rate should be increased at a constant rate. 7. Data Recording: As the torque is applied, record the torsion angle and the corresponding torque. The data is usually captured by the machine software, which plots the torque-torsion curve. 8. Failure Note: Continue to apply torque until the specimen breaks or yields. Note the maximum torque applied and the corresponding torsion angle. 9. Post-test analysis: Fracture inspection: Examine the fracture surface to understand the failure mode (brittle or ductile). 10.Data interpretation: Use the torque-torsion curve to calculate the shear modulus, yield strength and ultimate shear strength of the material. Specifications for using a torsion testing machine Machine capacity: 1. The machine must have a torque capacity appropriate for the material and sample size. Common capacities range from a few Newton meters (Nm) for small samples to thousands of Newton meters for larger samples. 2. Rotation speed: The machine must be able to apply torque at a controlled rotational speed, typically ranging from 0.1 to 5 degrees per second, depending on the material being tested. Page 2 of 3 3. Grips: The grips must hold the sample securely without slipping. Different grips are used for different sample shapes and materials (e.g., flat grips for flat samples, V-shaped grips for cylindrical samples). 4. Torsion angle measurement: The machine must have a high-precision angle displacement measurement system, typically using encoders or digital angle sensors, with an accuracy within ±0.1 degrees. 5. Data acquisition system: The machine must be equipped with software to automatically record and analyze torque and torsion data. It should also provide a real-time display of the curve and allow data to be exported for further analysis. 6. Calibration and Maintenance: Regular calibration of the device is essential to ensure accurate measurements. The device should also be maintained according to the manufacturer's recommendations. Page 3 of 3