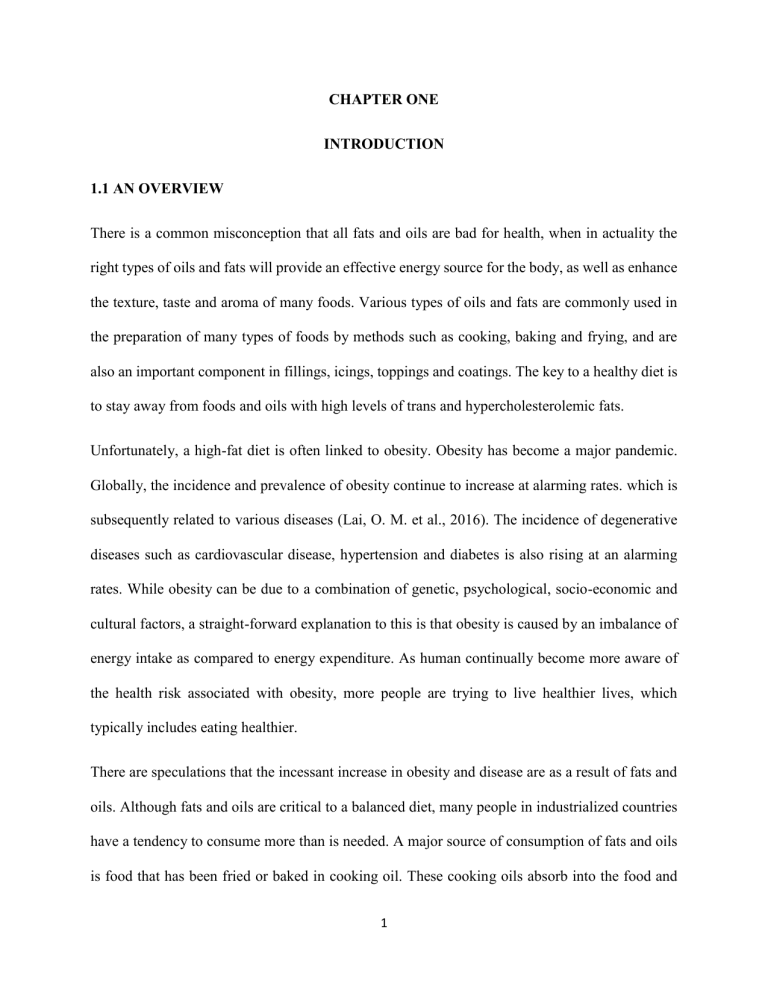

CHAPTER ONE INTRODUCTION 1.1 AN OVERVIEW There is a common misconception that all fats and oils are bad for health, when in actuality the right types of oils and fats will provide an effective energy source for the body, as well as enhance the texture, taste and aroma of many foods. Various types of oils and fats are commonly used in the preparation of many types of foods by methods such as cooking, baking and frying, and are also an important component in fillings, icings, toppings and coatings. The key to a healthy diet is to stay away from foods and oils with high levels of trans and hypercholesterolemic fats. Unfortunately, a high-fat diet is often linked to obesity. Obesity has become a major pandemic. Globally, the incidence and prevalence of obesity continue to increase at alarming rates. which is subsequently related to various diseases (Lai, O. M. et al., 2016). The incidence of degenerative diseases such as cardiovascular disease, hypertension and diabetes is also rising at an alarming rates. While obesity can be due to a combination of genetic, psychological, socio-economic and cultural factors, a straight-forward explanation to this is that obesity is caused by an imbalance of energy intake as compared to energy expenditure. As human continually become more aware of the health risk associated with obesity, more people are trying to live healthier lives, which typically includes eating healthier. There are speculations that the incessant increase in obesity and disease are as a result of fats and oils. Although fats and oils are critical to a balanced diet, many people in industrialized countries have a tendency to consume more than is needed. A major source of consumption of fats and oils is food that has been fried or baked in cooking oil. These cooking oils absorb into the food and 1 give it certain texture, colour, and palatable qualities to which people have become accustomed. Simply eliminating this cooking oils or fried foods from the diet often leaves people feeling unsatisfied, or decreases the flavor and palatability of foods to the customer, so that motivation to eat such foods for a potential health benefits is short lived. So far, low fat oil substitutes have generally proven to be unsuccessful. The public does not seem to be willing to compromise taste for health. Healthier, more palatable edible oils may be key to controlling the incidence of obesity and certain diseases. Although, Oils and fats are important components of our daily diet. However, health experts have warned that the number of fat or obese people worldwide has risen at an alarming rate. Doctors, scientists, and nutritionists are now investigating on the role of genetics, metabolism, and drugs in contributing to this weight-related problem, as well as new methods to treat it. This, in turn, has directly or indirectly enhanced the very lucrative global anti-obesity market, which currently is in excess of USD 240 billion. However, at the other end of the scale, the rapid growing rate of obesity may bankrupt national health organizations of certain countries (Lean et al. 2016). The functional oils and fats market has certainly benefited from all this publicity. In the past decade, rising consumer awareness and mandatory governmental legislations on unhealthful fats have partly surged the sales volume of functional oil and fat products. In the past two decades, the image of fats and oils has shifted from bad to healthful (Kennedy, 1991). As is often the case in the field of nutrition, there are always new products and new developments to stay on top of. United States Patent No. 6,004,611 discloses an edible oil composition having unique nutritional benefits. The majority of this edible oil composition is diglycerides, of which the 1,3 diglycerides (comprising more than 40% of the oil) are considered to be actual beneficial component. When edible oils of triglyceride nature are digested, they are 2 broken into fat components. The body packages the components into triglycerides, and transport them to the tissues while the liver handles the excess. Triglycerides are stored in adipose tissue until the body needs them for energy at a later time. However, the body does not package the digested components of 1,3-diglycerides as it does the triglycerides. Therefore, the components of 1,3-diglycerides are transported to the liver to be metabolized. One recent commercial development in functional edible oils and fats is a product named ‘Healthy Econa Cooking Oil’, developed and patented by Kao Corporation (Japan) in 1999. This novel oil contains at least 80% diacylglycerols (DAG), predominantly the 1,3-isoform, and can be used in the same way as conventional edible oils. The most important feature of this product is its ability to reduce and prevent fat accumulation in the body. This functional oil was a hit in the Japanese market when it was first launched in February 1999, with demand outstripping production. Currently, the oil is used as a key component in a variety of products such as phytosterol-enriched cooking oil, salad dressings, margarine, canned products and bread. Sales of ‘Healthy Econa Cooking Oil’ account for 80% of premium oils, which constitutes around 14% of the total Japanese edible oil market worth. Being designated as GRAS (generally recognised as safe) by the US Food and Drug Administration, the functional oil reached the US market at the end of 2002 through a joint venture with Archer Daniels Midland Co. called ADM Kao LLC (Decatur, Illinois). The patented process for the production of DAG in this oil involves hydrolysis of triacylglycerols in refined edible oils, followed by 1,3-position selective esterification using 1,3-position selective lipases (Lai O. M. et al., 2019). Researchers at Kao have found that DAG oil has metabolic characteristics that are distinct from triacylglycerol (TAG) oils. The consumption of DAG oil is claimed to reduce postprandial serum 3 TAG levels and thus is beneficial for the prevention and management of obesity. The physiological differences between DAG and TAG observed in animal and clinical trials are due to distinct metabolic fates of the oils after being absorbed via the gastrointestinal tract. Diacylglycerols (DAGs) in different degrees of purity are used as additives or carriers in the food, medicine and cosmetic industries (Ning, L., 2018). DAG oil has beneficial effects on obesity and weight-related disorders. Dietary DAGs exhibit anti-obesity activities and can prevent postprandial hypertriacylglycerolemia in experimental animals and humans. Numerous methods for the synthesis of DAG-particularly 1,3-DAG-enriched oils—have been reported. 1,3-DAGs can be synthesized using chemical and enzymatic methods. A detailed description on the metabolic fates of DAG and TAG is provided in this review. Unlike conventional TAG cooking oils that contains only up to 10% (w/w) DAG, these rather light-tasting healthful cooking oils are claimed to contain 80% (w/w) or more of DAG as the main functional component. In this review, we look into the properties and potential health benefits and highlight patented processes and product formulations of DAG oil. 4 CHATER TWO LITERATURE REVIEW 2.1 PALM OIL Palm oil is an edible vegetable oil whose color ranges from yellow-red to dark-red, and is obtained from the reddish pulp (mesocarp) of the fruits of the Oil Palm tree, especially the African Oil Palm-Elaeis guineensis (Composition of Palm Oil, 2019). Palm oil is a fat from the fruit flesh of species of the Oil Palm tree (Elaeis guineensis), which has a distinctive orange-red color as a result of the relatively high amount of carotenoids it contains (Palm Oil, 2020). The Crude Palm Oil (CPO) is used extensively in Nigeria for the cooking of soups, stews, African salad and also in frying; it represents a major source of vegetable fat (Nnadozie et al., 1989). Palm oil is different from Palm kernel oil (PKO), in that Palm kernel oil (PKO) is gotten from the kernels of the oil Palm fruit. Crude Palm oil (CPO) has a reddish color because of its high beta-carotene content. Though Palm oil and Palm kernel oil may be from the same oil Palm tree, Palm oil has a red color while Palm kernel oil does not because it lacks carotenoids and Palm oil contains low levels of saturated fat (49%) while Palm kernel oil (PKO) has about 81% of saturated fats (Palm oil, n.d.). However, when Crude Palm oil (CPO) has been refined, bleached and deodorized, it produces a common commodity called RBD Palm oil (Refined, Bleached and Deodorized Palm oil) which does not contain carotenoids. Fig. 2.1 Crude Palm Oil (PKO) (source: Palm oil, n.d.) 5 Fig. 2.2 Refined, Bleached and Deodorized Palm Oil (RBD Palm Oil) (source: Palm Oil, n.d.) Table 2.1 Composition of Crude Palm Oil and Refined Palm Oil (source: Composition of Palm oil, 2019). The Oil Palm tree (Elaeis guineensis) produces dense bunches having a large number of fruits and those bunches weigh 10kg and above. The tree is native to the West Africa region and was exported to South East Asia (firstly Malaysia) around the mid-19th century (Palm Oil, 2015). Oil 6 Palm grows more in humid tropics and yields more when grown at about 10 degrees north or south of the equator. Usually, the Oil Palm tree needs approximately 3m diameter clear around the base of each tree to allow full growth. The tree is a very productive crop that yields more oil per square meter of land than any other form of vegetable oil producing tree on earth. (Palm Oil, 2020). Fig. 2.3 Palm Fruits (source: Palm Oil, n.d..) Fig. 2.4 Palm Trees (Elaeis guineensis) (source: Palm Oil, n.d.) Palm oil is used in a many diverse ways which depends to a large extent on its form i.e. whether it is in its crude form or refined form. Crude Palm oil (CPO) is used in the preparation of many delicacies in Africa and Asia, it is also used in the production of some soap, animal fats and in the production of bio-fuel, it has now what is referred as a green fuel option. It is also used in the production of edible Palm oil cakes which is considered a medium grade protein feedstock used in the fattening of cattle and other livestock. The Refined Palm oil is used to make pastries, cakes, biscuits and other snacks. It can also be used to make personal care and beauty products as manufacturers of these brands prefer Palm oil because of its cheap price. It is also useful in industrial and home cooking and frying because of its refined color and taste and also because it has a high smoke (Njiribeakor & Nwanya, 2017). 7 2.1.1 COMPSOSITION OF PALM OIL Palm Oil, just like any other edible oils consists of Monoacylglycerols, Diacylglycerols and Triacylglycerols. Other components are tocopherols, tocotrienols, sterols, carotenes, phosphatides (gums), ubiquinone, moisture, Free Fatty acids (FFA), dirt and other minor constituents of non-oil fatty matter amongst others (Composition of Palm Oil, 2019). 2.1.1.1 TRIACYLGLYCEROLS (TRIGLYCERIDES) Triacylglycerols is the fundamental unit of fats and oils that determines their characteristics. The characteristics of the fats and oils are dependent on the type of fatty acid and the distribution of its molecules in position (Composition of Palm Oil, 2019). Triacylglycerols is a chemical compound found in Palm oil that consists of three constituting elements which are carbon, hydrogen and oxygen. The three constituent elements make up the molecules of fatty acids and glycerol, which on combination forms molecules of fat referred to as triacylglycerols. The term “Triacylglycerol” refers to the combination of three (tri-) molecules of the acyl group (from carboxylic acids) to one glycerol molecule. For fats and oils generally, the carboxylic acids consist of fatty acids (Dekker, 2016). Fig. 2.5 Structure of Triglycerides. (source: Composition of Palm Oil, 2019). 2.1.1.2 FATTY ACIDS 8 Fatty acids are compounds having carbon and hydrogen atoms in long chains (molecules of hydrocarbon), whereby each of the two ends have a moiety of the carboxylic acid group. When numbering carbons in fatty acids, it starts with the carbon contained in the carboxylic group. Fatty Acid hydrocarbons chain usually consists of carbons in even numbers (from 4 to 28) (Refining of Palm Oil, n.d..). While there are a large variety of fatty acids, only a select few amount of these acids are of commercial importance, they include: lauric, palmitic, stearic, oleic, myristic, linolic and linolenic acids. Palm oil is readily distinguishable from other oils by the high amount of palmitic acid C (16:0) it contains. Palm oil also differs from other vegetable oils in that, it consists of equal amounts of saturated acids (Palmitic and Stearic acids, 45% and 4% respectively) and unsaturated acids (Oleic and linoleic acids, 40% and 10% respectively) (Composition of Palm Oil, 2019). Fatty acids are usually used as animal feeds or can be sold to producers of oleochemicals for soaps production as well as the production of other specialized chemicals. Table 2.2 Composition of Fatty acids in some edible oils. (source: oilpalmblog.wordpress.com) 9 Table 2.3 Names and Properties of some saturated Fatty acids. (source: Composition of Palm Oil, 2019). 2.1.1.3 MONOACYLGLYCEROLS, DIACYLGLYCEROLS AND FREE FATTY ACIDS (FFA) The Triacylglycerol content in Palm oil usually gets broken down in the presence of water and heat in the process of hydrolysis to give more monoacylglycerols, diacylglycerols and free fatty acids (FFA). These monoacylglycerols and diacylglycerols are negligible contents in good grade oils, but they may be formed extensively in fruits that are stored badly as a result of hydrolysis. The breaking down (hydrolysis) reaction, may be catalyzed by lipase (an enzyme), some metals or it can even be autocatalytic. The very first step is partial hydrolysis, which produces diglycerides (glycerol attached with two molecules of fatty acids) and free fatty acids (Composition of Palm Oil, 2019). Hydrolysis can occur in different stages. The reaction can occur in pre-harvest preparations or in post-harvest handling and storage, in oil extraction, crude palm oil storage, and product shipping. This hydrolysis is unwanted because it results in increase in the free fatty acid (FFA) concentration in the unrefined crude oil. More attention need to be paid during the stages of the refining process so as to reduce the amount of free fatty acid in the Crude Palm oil (CPO) in the 10 starting as well as the finishing stages. The presence of elevated levels of free fatty acids in Crude Palm oil (CPO) will lead to increase in refining losses (Refining of Palm Oil, n.d..). Good grade oils with smaller amounts of monoglycerides and diglycerides are vital in fractionation because they inhibit the formation of crystals as emulsifying agents thus making filtration easier (Composition of Palm Oil, 2019). The industrial manufacture of monoglycerols and diglycerols is carried out through the process of partial hydrolysis. They are generally used as food grade emulsifier. 2.2 DIACYLGLYCEROLS DAGs are esters of the trihydric alcohol glycerol in which two of the hydroxyl groups are esterified with fatty acids. They can exist in two structural isomers namely, 1,2-DAG and 1,3-DAG (Fig. 1). These isomers will undergo acyl migration to form equilibrium at a ratio of 3–4:7–6 between 1,2and 1,3-DAG (Takano and Itabashi 2017) often in the presence of an acid, alkali, or heat. 1,3DAG is more thermodynamically stable because of the steric effect of the molecule. In general, the melting point of 1,3-DAG is approximately 10°C higher than TAG, and 1,2-DAG is approximately 10°C lower than 1,3-DAG, of the same fatty composition. The causes of these melting point differences are the strength of hydrogen bonding of the hydroxyl group and fatty acid chain arrangement of the DAG isomers. 1,3-DAG has a V-shaped fatty acid chain arrangement, while 1,2- DAG has a hairpin-shaped conformation. The type of molecular arrangement of the DAG isomer relates to its polymorphic form. Unlike TAG polymorphism, DAG exhibits two types of polymorphic forms. 1,2-DAG exhibits the α- and β′-forms but has no β-form, while 1,3-DAG has no α-form but exhibits two types of β-form, β1 and the more unstable β2 (Nakajima et al. 2016) 11 Fig 1.1 Structure of Diacylglycerol . The 1,2- DAG isoform is recognized as a metabolic intermediate that is formed after the ingestion of triacylglycerol (TAG). The DAG contained in refined edible oils is largely converted to the 1,3isoform by migration of the acyl group during the high-temperature manufacturing process. In most edible oils, ~70% (w/w) of the DAG is present as the 1,3-isoform as shown in Table 1.1. 12 TABLE 1.1 Contents of Acylglycerols in Edible Oils of Various Origina DAG TAG Total DAG 1,2- DAG 1,3- DAG MAG Others (g/100 g) Soybeanb 97.9 1.0 ND ND 0.0 1.1 Palmb 93.1 5.8 ND ND < DL 1.1 Cottonseedb 87.0 9.5 ND ND 0.2 3.3 Cornb 95.8 2.8 1.5 2.9 < DL 1.4 Safflowerb 96.0 2.1 1.2 2.7 < DL 1.9 Oliveb 93.3 5.5 ND ND 0.2 2.3 Olive (mol%)c 18– 41 8– 20 Rapeseedb 96.8 0.8 ND ND 0.1 2.3 Vegetable oild 98.3 1.7 0.6 1.1 < DL ND (Soy + Canola) Canolad 97.1 2.9 1.0 1.9 < DL ND Sesamed 95.2 4.1 1.2 2.9 0.8 ND Pure sesame 95.5 3.9 1.2 2.7 0.6 ND Rice germd 91.2 8.8 2.7 6.1 < DL ND 13 Corn germd 95.5 4.5 1.5 2.9 < DL ND Pure grapeseedd 94.2 5.8 2.1 3.7 < DL ND DAG oile 81.4 28.4 53.0 1.2 ND 17.3 a Abbreviations: ND, not determined; <DL, below detectable limit (<0.1 g/100g). b S o u r c e: Refs. 37 and 38. c Source: Ref. 39. d S o u r c e: Nishide, T., unpublished data. DAG in Nature DAG is a natural component of glycerides in various fats and oils at levels up to 10% (w/w). Table 1.1 shows the content of DAG and other acylglycerols in edible oils of In particular, olive oil has been used for a long time in the Mediterranean area. It was reported that some olive oil obtained in Major area in Spain contained a high content of DAG (39). DAG is also a main component of mono- and diglycerides, one of the popular emulsifiers used in foods. Therefore, DAG is normally present in plant oils and in fats and oil products that have been consumed by humans for a long period of time. 2.1 DAG Oil DAG oil contains >80% DAG, <20% TAG, <3% monoacylglycerol (MAG), and small amounts of antioxidants and emulsifiers to maintain quality. DAG is generally made from fatty acids derived from vegetable oil and glycerin by using an immobilized 1,3-regiospecific lipase. The ratio of the 1,3-isoform to the 1,2- or 2,3-isoform is ~7:3 due to acyl migration during the refining process. DAG oil as cooking oil is commercially 14 available in Japan and in the United States The main nutritional functions of DAG oil vs. TAG oil are as follows: I. II. A suppressive effect on postprandial serum triglyceride elevation, and A suppressive effect on body fat accumulation. DAG oil also has unique physicochemical properties caused by the presence of a free hydroxyl group in the structure compared with TAG oil. The cooking properties of DAG oil are similar to those of conventional cooking oil 2.2 Digestion, Absorption, and Metabolism DAG can be digested by the same gastrointestinal enzymes that hydrolyze TAG. However, upon digestion, DAG does not follow the resynthetic pathway of TAG, which includes the 2monoacylglycerol (2-MAG) pathway and the glycerol-3-phosphate (GP) pathway. In TAG digestion, the human pancreatic lipase hydrolyzes fatty acids from the terminal positions of the TAG molecule to form 1,2- and 2,3-DAG as intermediate products. These intermediate products can be further hydrolyzed by the pancreatic lipase to form 2-MAG. As such, the pancreatic lipase can also hydrolyze 1,3-DAG to form 1(3)-MAG and free fatty acids (Kondo et al. 2018). The key characteristic of DAG metabolism lies in the formation of 1(3)-MAG rather than 2-MAG as found in TAG metabolism. In TAG absorption, 2-MAG will undergo re-esterification with fatty acids via the 2-MAG pathway to reform TAG, which will then be transported as a chylomicron complex into the blood stream via the lymphatic system. In the case of DAG, however, 1(3)-MAG is poorly re-esterified via the 2-MAG pathway and thus has an insignificant contribution toward TAG 15 resynthesis (Lehner et al. 2019). Instead, substantial amounts of 1(3)-MAG are further hydrolyzed to free fatty acids and glycerol, which are precursors of the GP pathway, while some are reesterified to 1,3-DAG. The efficiency of DAG digestion products to convert into TAG in the small intestines was also found to be low. Another important difference between DAG and TAG metabolism is the substrate specificity of the DAG acyltransferase (DGAT) enzymes, DGAT-1 and DGAT-2, in the small intestines (Cases et al., 2020). DGAT is involved in the final synthetic step of TAG by catalyzing the acylation of 1,2 (2,3)-DAG, which are products from the 2-MAG pathway. However, DGAT has low substrate specificity toward 1,3 DAG and therefore does not significantly convert 1,3-DAG to TAG (Lehner and Kuksis 2019). Conclusions from these findings on the nature of DAG digestion and absorption may explain the reduction of postprandial TAG levels in the blood. Numerous animal and clinical studies have all shown that ingestion of DAG oil, in comparison with TAG oil, increases the rate of β-oxidation of fatty acids. Additionally, the activities of enzymes involved in fatty acid synthesis, such as glucose-6-phosphate dehydrogenase, malic enzyme, and fatty acid synthetase, were observed to significantly decrease in subjects fed with DAG oil. On the other hand, hepatic enzymes involved in the β-oxidation pathway, such as acylcoenzyme A (CoA) dehydrogenase, acyl-CoA oxidase, enoyl-CoA hydratase, carnitine palmitoyltransferase, 3- hydroxyacyl-CoA dehydrogenase, 2,4-dienoyl-CoA reductase, and δ3,δ2enoyl-CoA isomerase, were found to increase in activity on a dose-dependent manner with DAG intake. In a clinical study, it was interesting to note that the increase in β-oxidation occurred even without any change in daily energy expenditure resulting from resting activity or activity related 16 to physical exertion. It is believed that the increase in β-oxidation of DAG metabolism relates to the corresponding reduction in body fat and serum TAG levels. 2.3 Potential Health Benefits The ingestion of DAG oil has been shown to reduce body fat accumulation and lower serum TAG levels. Murase et al. (2016) reported a 70% reduction in body weight of mice after 5 months on a diet containing 30% DAG oil. Significant fat reductions surrounding the epididymal, mesenteric, retroperitoneal, and perirenal areas were observed. However, other animal tests revealed that the effect of DAG oil on reducing body weight was not found at low intakes (10% or less) of DAG. To compare the effects of DAG and TAG oil ingestion on human body fat, Nagao et al. (2018) had conducted a 16-week double-blind study on 38 healthy men with an average body mass index (BMI) of approximately 24 kg/m2. The subjects were randomly provided with food products that contain either DAG or TAG oil at a dosage of 10 g/day during the treatment period. The results revealed that reductions in body weight, BMI, waist circumference, and total fat area were more distinct in subjects consuming the DAG oil diet. In another related study, it observed similar findings in a 6- month investigation on the effect of diets rich in DAG and TAG oils on obese men and women with BMI of approximately 34 kg/m2. On the contrary, several studies did not find any significant change in body fat reduction of the subjects after the treatment period Studies investigating the effect of DAG oil on serum TAG levels in animals and humans also showed inconsistent results. Reductions in serum TAG levels were observed in some studies while in others, there was no change in serum TAG. It was investigated that the effect of feeding diets containing 10% DAG oil to rats and concluded that DAG has an ability to reduce serum TAG levels. Murata et al. (2017) suggested that the ingestion of 17 DAG oil decreased serum TAG levels by retarding the chylomicron assembly that is essential for TAG transportation. In another study, it was reported that TAG synthesis in DAG-infused rats was less pronounced than in TAG-infused rats. On the other hand, it did not find any decrease in serum TAG levels of rats fed with diets containing 30% DAG oil. It is interesting to note that it was found that the DAG oil suppressed it 2.4 Oil-in-Water Type Emulsion Foods Oil-in-water type emulsion (O/W) food products are commonly represented by mayonnaise and salad dressings. In general, mayonnaise and salad dressings contain oil, egg yolk, vinegar, and seasonings (salt, sugar, spices, flavors, etc.). The major difference between mayonnaise and salad dressings is in the oil content. Mayonnaise has an oil content of 65–85% (w/w), while salad dressing has less than 60% (w/w) oil. The application of DAG oil in O/W products was first patented by Nomura et al. (1992). According to the invention, the O/W product has an oil phase comprising of 30–100% (w/w) DAG with a melting point of 20°C or less. The O/W composition is claimed to exhibit a rich fatty savor even at a low fat content. Several years later, Kawai and Konishi (2000) describes an O/W composition that has excellent storage stability, good appearance, taste, and physical properties. The composition has an oil phase that is comprised of 30% (w/w) or greater of DAG oil and a yolk wherein the ratio of lysophospholipids to the whole phospholipids is at least 15% (w/w) based on phosphorous content. Shiiba et al. (2002) provided further improvements by disclosing an O/W composition that has excellent shelf stability at low temperatures comprising at least 20 (w/w) and 0.5–5% (w/w) of a crystallization inhibitor. The 18 crystallization inhibitor is a polyglycerol fatty acid ester, sucrose fatty acid ester, or sorbitan fatty acid ester. 2.5 Water-in-Oil Type Emulsion Foods The other form of emulsified food product has a water-in oil type emulsion (W/O). Examples of such products are margarine, spreads, butter cream fillings, and icings used in baking and the confectionery industry. Mori et al. invented a W/O-emulsified fat composition that has good stability and spreadability and is suitable for use as a margarine. The W/O composition is made up of 40 to less than 95% (w/w) of DAG and 5 to less than 60% (w/w) of TAG, wherein the DAG comprises of 0.5 to less than 20% (w/w) DAG containing two saturated C14–C22 fatty acid groups, 20 to less than 55% (w/w) DAG containing one saturated C14–C22 fatty acid group and one unsaturated C14–C22 fatty acid group, and 25 to less than 70% (w/w) DAG containing two unsaturated C14–C22 fatty acid groups, and the weight ratio of total C14 and C16 saturated fatty acid groups in DAG to total C18, C20, and C22 saturated fatty acid groups in DAG is in the range from 1 to 8. Another W/O composition claimed to have excellent flavor release during the time of ingestion was invented by Masui and Konishi (2001). According to this invention, it is claimed that 30% (w/w) of the W/O oil or fat composition is being able to reverse in phase within 1 min after coming into contact with water at 36°C, thereby releasing the flavor component. The W/O composition comprises of water as the aqueous phase, 15% (w/w) or more of DAG as the oil phase, and a demulsifier, which comprises at least a polyglycerol fatty acid ester having a hydrophilic–lipophilic balance (HLB) value of 8 or more, a water-soluble decomposed 19 protein, lysolecithin having a HLB value of 8 or more, a sucrose fatty acid ester having a HLB of 5 or more, a MAG organic acid ester having a HLB of 8 or more, and a sorbitan fatty acid ester having a HLB of 8 or more. A W/O composition by Masui and Yasunaga (2001) describes a W/O product that is stable in spite of containing a high water content and has good storage and mouth feel. The product composition comprises of water as the aqueous phase, 35– 95% (w/w) of DAG having a melting point of below 20°C, and the remainder as TAG, which is composed of 13–60% (w/w) palmitic acid and 5% (w/w) or less of fatty acid having 12 carbons or lower, as the oil phase. Additionally, the TAG has to possess a stable polymorphic form of β. 2.6 DAG Oil Composition Containing Phytosterols Phytosterols are lipid compounds that have been shown to lower serum cholesterol levels in humans (Ling and Jones 1995; Jones et al. 1997). Because of its limited solubility in oil (approx. 1% w/w) and insolubility in water, normal intake of phytosterols are not efficiently absorbed by the intestines and therefore ineffective in lowering serum cholesterol levels. Efforts were made to increase solubility of phytosterols in oil by converting it into phytosterol fatty acid esters (Hendriks et al. 1999). However, Meguro et al. (2001) reported that phytosterols can achieve higher solubility in DAG oil without the need of esterification. Several patent literatures were found on DAG oil composition containing dissolved phytosterols. Goto et al. (2000a, b) claimed that the solubility of phytosterol can be increased by 1.2–20% (w/w) when 15% (w/w) or more of DAG oil is used as solvent. Additionally, the authors claimed that 80% (w/w) or more of DAG oil can dissolve 0.05–20% (w/w) of phytosterols. However, 55% (w/w) or more of unsaturated fatty acids have to be present in the DAG oil for effective solubilization of the phytosterols. In another patent (Goto et al. 2001), an oil composition 20 containing 15% (w/w) or more of DAG and up to 2,000 ppm of tocopherol was reported to effectively dissolve 1.2–20% (w/w) of phytosterols. The DAG component is comprised of at least 70% (w/w) unsaturated fatty acids. Nakajima et al. made further improvements of phytosterol solubility in DAG oil in a disclosure whereby an oil composition containing 15–95% (w/w) is used to dissolve 2–10% (w/w) of phytosterol and the resultant oil composition remains a transparent liquid at temperatures of 0–30°C. 2.7 Practical Use of DAG Oil. DAG oil became commercially available as a cooking oil (Econa Cooking Oil, Kao Corporation, Tokyo, Japan) in March 1999 in Japan, and greater than100,000 tonnes were consumed, making it a top-selling brand as of December 2003. In the United States, it is sold in Chicago and Atlanta under the name Enova Oil as ofnDecember 2003. DAG is used in various fats and oil products in Japan. DAG has been applied to spreads (Snow Brand Milk Products Company), bread (Yamazaki Baking Company), and canned tuna (Hagoromo Foods Company) in 2000. DAG cooking oil containing phytosterols and DAG salad dressing (Kao Corporation) became commercially available in 2001, a mayonnaise-type product (Kao Corporation) and curry roux (House Foods Corporation) in 2002, fried tofu (Satonoyuki Company), fried noodles (Sanyo Foods Company), and chips (Calbee Foods Company) in 2003. 2.7.1 Shortenings DAG also finds an application in the formulation of shortenings. Doucet and Olathe (1999) invented a shortening composition comprising a nonhydrogenated vegetable oil and a stearine fraction containing 50–60 mol% of DAG. It is claimed that the shortening formulation has a 21 synergistic amount of solids and crystal matrices that imparts superior organoleptic properties to the food product, without the incorporation of trans-fatty acids commonly found in partially hydrogenated fats. Concomitantly, Doucet et al. (1999) claimed that the above effects can also be made possible with the addition of MAG composed predominantly of saturated fatty acids. 2.7.2 Frying Applications Because DAG has a lower molecular weight than TAG, DAG oil has a significantly lower smoke point (30–40°C) than TAG oil with similar fatty acid compositions. Therefore, frying applications with DAG oil will be problematic. Several DAG compositions suitable for use as frying oil have been reported. Sakai et al. (2002a) reported a fat composition containing at least 15% (w/w) of DAG, a fatty acid L-ascorbic ester, and a component such as catechin or a natural plant extract such as rosemary, sage, and turmeric extracts. The authors claimed that the DAG composition has excellent stability toward oxidation, while providing good flavor and appearance. Another DAG composition reported by Sakai et al. (2002b) contains 15% (w/w) or more of DAG and 70 ppm or more of one or more types of organic carboxylic acids such as two- to eight-carbon hydroxycarboxylic or dicarboxylic acids and their derivatives thereof. The composition is claimed to resist thermal oxidation or hydrolysis after prolonged heating or storage, as well as to reduce smoking when the oil composition is used for frying purposes. 2.7.3 Foods Containing DAG Oil Foods that are prepared with or contain DAG oil are summarized in this section. Mori et al. (1999b) disclosed fried food with a fat composition containing 55 to less than 95% (w/w) of DAG, which composed of 55 to less than 93% (w/w) of unsaturated fatty acids. The authors claimed that when the food is fried with DAG oil of such composition, the resultant fried food will have a low water 22 content and will not likely get moist and reduce in crispiness over a prolonged period of time. The fried foods that are covered in this patent are fried cakes, French fried potatoes, fried chicken, and doughnuts. A disclosure from Mori and Watanabe (2000) described a food that is comprised of 0.5–85% (w/w) DAG with C2–C10 fatty acids. When ingested, the food composition is claimed to possess good organoleptic properties, as well as to reduce body fat accumulation and provide energy at times of exhaustion and fatigue. Another DAG-containing food product as reported by Kudo et al. (2002) is fried or baked potatoes, which comprise of 3–50% (w/w) of oil or fat, wherein the DAG content is 15% to less than 50% (w/w). The fatty acids of the DAG oil are composed of 15–100% (w/w) of 5-3 unsaturated fatty acids of less than 20 carbon atoms. Similar to the findings of Mori et al. (1999b), potatoes fried or baked in such a DAG oil composition was reported to provide a product that has a low water content, favorable texture and taste, and good storage stability. 2.7.4 Ice Cream Coating Fats Ice cream coating fats are generally TAG of medium-chain fatty acids, such as lauric acid-rich coconut oil. The first use of DAG as an ice cream coating fat was reported by Cain et al. (1999). The fat composition is comprised of 50–90% (w/w) DAG and 10–50% (w/w) TAG of vegetable origin. The DAG oil is composed of 75–90% (w/w) di-unsaturated DAG, less than 5% (w/w) disaturated DAG, and 10–25% (w/w) DAG with one unsaturated and one saturated fatty acid. The TAG composition in this fat composition is such that the sum of tri-unsaturated and di-unsaturated TAG is at least 50% (w/w). According to this invention, the ice cream coating fat had resulted in a product that is softer and less brittle but had quicker and smoother meltdown, than cocoa butterbased coating fats. 23 2.8 Manufacturing Process. The performance requirements for the industrial manufacturing of DAG include high purity and low-cost production. DAG was prepared from fatty acids and glycerin by esterification using an immobilized 1,3-regiospecific lipase (Watanabe, T., et al. 2018). The manufacturing flow can be divided into two main processes, i.e., the production of DAG through enzymatic reactions and the refining process that is typically used in the production of edible oils. Enzymatic esterification is an efficient route for producing oil with a high DAG content. DAG obtained in the enzymatic reaction consists mainly of the 1,3-isomer; some of the 1,3-isomer is isomerized to the 1,2-isomer during the refining process in which some heat is generated. Finally, DAG consists of ~70% 1,3-isomer and 30% 1,2isomer. DAG is currently being produced in Japan and in the United States and the current production volume is >30,000 tonnes/year 2.9 Safety and Regulation. The safety of DAG has been established by various studies in humans, in vitro, and in animals. The Ministry of Health and Welfare of Japan approved DAG oil as Food for Specified Health Use (FOSHU) in 1999. In 2000, the Japanese Society of Human Dry Dock, a professional association of Japanese physicians, recommended that DAG play a role in improving human health. In the United States, DAG was submitted to the FDA as a Generally Recognized As Safe (GRAS) substance, and the FDA indicated that there was no question regarding safety. 24 CHAPTER THREE CONCLUSION 3.1 CONCLUSION DAG, a natural oil component that has unique nutritional properties, “less likely elevates postprandial serum triglycerides and is less likely to become body fat compared to TAG.” The physicochemical properties of DAG oil as a liquid oil are nearly the same as those of TAG oil. However, because DAG has a hydroxyl group in the molecule, some physicochemical properties differ from those of TAG. These specific properties, which are not associated with TAG, may require specific devices and technology to be able to apply DAG oil to food products; in some cases, however, this would be useful for the development of new products. DAG is an attractive new food material not only for its nutritional properties but also for its physicochemical properties. Scientific and practical information regarding the nutritional properties, clinical efficacy, safety, manufacturing, and application technologies of DAG oil is summarized in this book and will be useful in increasing our understanding of the nature of DAG and the use of DAG oil to maintain a healthy body weight and prevent lifestyle-related diseases caused by obesity. Numerous scientific reports have shown the effectiveness of DAG in preventing body fat accumulation and obesity related disorders. The commercial potential of DAG has prompted various patent publications on production technologies and product applications of DAG oil. However, greater emphasis is required to further reduce the overall cost of DAG oil to meet consumer expectations. 25 Further analysis is expected to allow more scientific evidence and information to be accumulated concerning the efficacy, safety, mechanism of action, and application technologies that may provide new insights for managing a lifestyle–related chronic disease such as the metabolic syndrome. At the current growth rate of obese population throughout the world, it can be expected that the global market demand for DAG oil will increase in the future. 26 REFERENCES Cases, S., Stone, S. J., Zhou, P., Yen, E., Tow, B., Lardizabal, K. D., et al. (2020). Cloning of DGAT2, a second mammalian diacylglycerol acyltransferase, and related family members. Journal of Biological Chemistry, 276, 38870–38876. Composition of Palm Oil. (2014). Retrieved from www.oilpalmblog.wordpress.com Dekker, Marcel (2002). Food lipids. 2nd Edition. pp 11. Retrieved from http://www.oilpalmblog.wordpress.com Dekker, Marcel (2002). Physical Properties of Lipids. Retrieved from http://www.oilpalmblog.wordpress.com Kondo, H., Hase, T., Murase, T., & Tokimitsu, I. (2018). Digestion and assimilation features of dietary DAG in the rat small intestine. Lipids, 38, 25–30. Lean, M., Gruer, L., Alberti, G., & Sattar, N. (2016). Obesity—Can we turn the tide? British Medical Journal, 333, 1261–1264. Lehner, R., Kuksis, A., & Itabashi, Y. (2019). Stereospecificity of monoacylglycerol and diacylglycerol acyltransferases from rat intestineas determined by chiral phase high-performance liquid chromatography. Lipids, 28, 19–34. Murase, T., Mizuno, T., Omachi, T., Onizawa, K., Komine, Y., Kondo, H., et al. (2016). Dietary diacylglycerol suppresses high fat and high sucrose diet-induced body fat accumulation in C57BL/6J mice. Journal of Lipid Research, 42, 372–378. Murata, M., Ide, T., & Hara, K. (2017). Reciprocal responses to dietary diacylglycerol of hepatic enzymes of fatty acid synthesis and oxidation in the rat. British Journal of Nutrition, 77, 107–121. Nakajima, Y., Fukasawa, J., & Shimada, A. (2017). Physicochemical properties of diacylglycerol. In Y. Katsuragi, T. Yasukawa, N. Matsuo, B. D. Flickinger, I. Tokimitsu, & M. G. Matlock (Eds.) Nagao, T., Watanabe, H., Goto, N., Onizawa, K., Taguchi, H., Matsuo, N., et al. (2018). Dietary diacylglycerol suppresses accumulation of body fat compared to triacylglycerol in men in a double-blind controlled trial. Journal of Nutrition, 130, 792–797. 27 Njiribeakor, J.A and Nwanya, L.N (2017). Enhancing the Adsorptive Performance of natural bleaching Earth's from limestone/Clay mixture. Journal of the Chemical Society of Nigeria. pp 25, 54. Diacylglycerol oil (pp. 182–196). Illinois, USA: AOCS. Nnadozie, N.N; Arowolo, T.A and Akpan, H.J (1989). Quality of Nigerian Palm Oil after bleaching with Local treated Clays. Journal of the Chemical Society of Nigeria. Vol. 66. No 2. pp 218-219. Palm Oil. (n.d.). Retrieved from http://www.wikipedia.com/palm-oil Palm Oil. (2015). Retrieved from http://www.palmoilinvestigations.com Seong, K. L., Chin, P. T. Kamariah, L., Mohd, S. A. Y., & Lai, O., M. (2018). Diacylglycerol Oil—Properties, Processes and Products: A Review. Food Bioprocess Technol (2008) 1:223–233Food Bioprocess Technol 1:223–233 Takano, H., & Itabashi, Y. (2017). Molecular species analysis of 1,3-diacylglycerols in edible oils by HPLC/ESI-MS. Bunseki Kagaku, 51, 437–442. Watanabe, T., Shimizu, M., Sugiura, M., Sato, M., Kohori, J., Yamada, N., and Nakanishi, K. (2018) Optimization of Reaction Conditions for the Production of DAG Using an Immobilized 1,3-Regiospecific Lipozyme RMIM, J. Am. Oil Chem. Soc. 80, 1201–1207. 28