Iron-Carbon Diagram Review: Phases, Allotropy, Solidification

advertisement

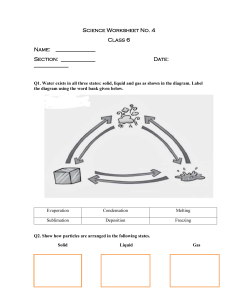

MPE 312 – Review of Iron-Carbon Diagram 1.1 Iron - Carbon Diagram The solidification of an alloy generally occurs as a continuous process over a range of falling temperature. Even after solidification, important constitutional changes may continue to take place e.g. age hardening, precipitation hardening, . The graph obtained by plotting temperature against constitution (Composition) is normally referred to as equilibrium diagram. Equilibrium diagrams are important in the understanding and controlling of processes such as casting and heat treatment. The Iron-Carbon thermal equilibrium diagram in strict sense represents an Iron- Iron carbide meta-stable system. This is due to the fact that iron- carbide is an unstable phase. Nevertheless iron carbide precipitates from austenite, during ordinary conditions of cooling in preference to the theoretically more stable graphite. Once formed, Iron - carbide (cementite) is quite stable and for this reason it can be regarded as an equilibrium phase. The diagram represents a case whereby the constituents are partially incompatible in the solid state hence the formation of a EUTECTIC of two solid solutions. Phase boundaries occur below the solidus indicating that phase changes can take place in the solid. Austenite (γ) This is the solid solution formed when carbon dissolves in FCC iron in amounts up to 2% Ferrite (α) This is a very dilute solid solution of carbon in body-centered cubic iron and containing at the most only 0.002% carbon Cementite (Iron carbide Fe3C) This is an interstitial compound of iron and carbon containing 6.69% carbon The progressive addition of carbon to pure iron results in a distinct difference in the structure. At low temperatures, pure iron may be regarded as ferrite (α). Additions of carbon yield a compound called cementite, which is hard, brittle and brilliantly white. Before the cementite composition is attained, an interstate compound occurring as wavy parallel plates of alternately dark (cementite) and light (ferrite) colour will be prominent. This eutectoid mixture is known as pearlite. After the eutectoid, any further increase in carbon gives rise to free cementite at the grain boundaries or as needles. The highest strength is obtained when the structure consists entirely of pearlite. Presence of free cementite increases hardness at the expense of strength. MPE 312 – Review of Iron-Carbon Diagram Fig 1.1 Phases in the Iron Carbon Diagram. MPE 312 – Review of Iron-Carbon Diagram Allotropy of Iron Certain substances can exist in two or more crystalline forms. Four changes occur in iron which gives rise to forms known as alpha (α), Beta (β), gamma (γ) and delta (δ). Of the above forms α, β and δ forms have the same atomic structure (BCC) while γ iron has an FCC structure. Iron can therefore be said to have two allotropic forms. The change at curie temperature (i.e. loss of magnetism) is of no much significance in the heat treatment process. Further up however, changes in structure are accompanied by thermal changes, together with discontinuities in other physical properties such as electrical, thermo-electric potential, magnetic, expansion and tenacity. The A3 change from BCC to FCC atomic structure at 937 oC (for pure iron) is accompanied by a marked contraction while the reverse occurs at These changes in structure are accompanied by re1400 oC. crystallisation followed by grain growth. Addition of carbon to pure iron produces another change at ≈ 723 oC (A1) which is associated with the formation of pearlite. The structural changes, which occur during cooling give rise to evolution of heat, which cause arrests on a cooling curve. The temperatures of the arrests are known as critical points or “A” points. The addition of carbon to iron not only gives rise to the A1 point but also influences the critical points in pure iron. The A4 point is raised; and the A3 point lowered until it coincides with A1. The α, β and δ forms of iron have only slight solubility for carbon, but up to 1.7% carbon dissolves in γ iron to form a solid solution called Austenite. Effect of Silicon on the Iron-Carbon Diagram Fig 1.2 Phase diagram of Fe-C-(2%)Si MPE 312 – Review of Iron-Carbon Diagram The solidification of hypoeutectic cast iron begins with precipitation of austenite. Assuming rapid diffusion in the liquid, the development of the solid fraction of the primary phase fs may be calculated as a function of temperature by the Scheil equation:- f s = 1− ⎡ T m −T ⎤ ⎢ − ⎥ ⎣T m T l ⎦ 1 k −1 where Tm is the temperature at which the extrapolations of the liquidus and the solidus curves intersect and is given by:-:Tm (oC) = 1618 - 15.033 x %Si Tl is the liquidus temperature which may also be estimated from:Tl (oC) = 1636 – 113(%C+1/4%Si+1/2%P) Despite the effectiveness of the cooling curve to yield accurate information on the solidus and liquidus points, other reactions occurring during processing of semi-solid grey cast iron and which consequently affect its behaviour may be difficult to identify from the cooling curve. The primary phase distribution coefficient k is determined as:- k= c c s l = 2.10 − 0.22 x% Si 4.26 − 0.32 x% Si Both silicon and phosphorous strongly reduce the eutectic carbon content and are traditionally equated with carbon in the carbon equivalent CE= %C +1/3 (%Si+%P). They strongly favour less proeutectic austenite formation and more eutectic solidification. In addition, silicon contributes to ferrite formation by creating a three-phase region in which ferrite and austenite coexist as illustrated in Fig 1.2. Furthermore, silicon reduces the solubility of carbon in austenite, thus increasing the rate of growth of free ferrite. Silicon additions also raise the threephase region to higher temperatures and increase the temperature interval between the α transformation temperature and the eutectoid temperature, thus allowing for more time for carbon to diffuse under given cooling conditions. Using the Scheil equation, one can estimate the solid fraction at different temperatures within the marshy zone hence determine the correct pouring temperature (to avoid early solidification) and the effect of alloying on the solidification characteristics. Assuming rapid cooling (where solid state transformation is minimal), it is also possible to determine the solid fraction of primary phase upon solidification. Further reading:The lever rule - Determination of composition at various temps Meaning of terms :- peritectic, pro-eutectoid, hyper-eutectoid, eutectic, eutectoid, e.t.c MPE 312 – Review of Iron-Carbon Diagram Solidification process Solid metals in bulk may be produced by a variety of ways but the melting and freezing of a liquid is by far the most common method of preparing metals used in engineering, either as castings, having the desired final shape or as ingots which may be subjected to subsequent machining or shaping processes. As a metal solution attains the solidification temperature at which it will begin to crystallise around ‘impurities’ (which in some cases may have significant secondary effects on solidification), finger-like protrusions appear, extending into the liquid solution The protrusions are referred to as dendrites. As they extend into cooler (i.e. under-cooled), regions, their growth will be accelerated. These grow outwards until contact is made with neighbouring growth. The contact surface then becomes a grain boundary. The dendrite arms become thickened until finally a solid crystal remains with no indication of the dendrite growth. Most often dissolved or insoluble impurities in the metal may be expelled to the grain boundaries as the crystals grow thus becoming trapped in-between the arms of the dendrites. The distribution of impurities in this manner betrays the dendritic growth.