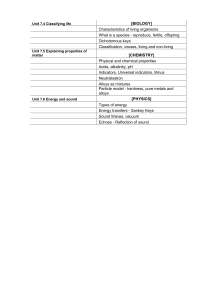

A criterion for evaluating glass-forming ability of alloys Guo-Hua Zhang and Kuo-Chih Chou Citation: Journal of Applied Physics 106, 094902 (2009); doi: 10.1063/1.3255952 View online: http://dx.doi.org/10.1063/1.3255952 View Table of Contents: http://scitation.aip.org/content/aip/journal/jap/106/9?ver=pdfcov Published by the AIP Publishing Articles you may be interested in Temperature dependence of the thermoplastic formability in bulk metallic glasses J. Appl. Phys. 110, 043518 (2011); 10.1063/1.3624666 Abnormal behavior of supercooled liquid region in bulk-forming metallic glasses J. Appl. Phys. 108, 053515 (2010); 10.1063/1.3465310 The correlation between shear elastic modulus and glass transition temperature of bulk metallic glasses Appl. Phys. Lett. 94, 091907 (2009); 10.1063/1.3093879 Noncontact measurement of high-temperature surface tension and viscosity of bulk metallic glass-forming alloys using the drop oscillation technique Appl. Phys. Lett. 86, 014104 (2005); 10.1063/1.1844596 Overheating threshold and its effect on time–temperature-transformation diagrams of zirconium based bulk metallic glasses Appl. Phys. Lett. 84, 5010 (2004); 10.1063/1.1763219 [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 132.204.37.217 On: Tue, 09 Dec 2014 14:57:27 JOURNAL OF APPLIED PHYSICS 106, 094902 共2009兲 A criterion for evaluating glass-forming ability of alloys Guo-Hua Zhang1 and Kuo-Chih Chou1,2,a兲 1 University of Science and Technology Beijing, Beijing 100083, China Shanghai University, Shanghai 200072, China 2 共Received 4 August 2009; accepted 29 September 2009; published online 9 November 2009兲 A criterion defined as = 共Tx + Tg兲 / Tl关共Tx − Tg兲 / Tl兴␣ 共where Tx is the onset crystallization temperature, Tg is the glass transition temperature, Tl is liquidus temperature, and ␣ is an exponent兲 is proposed to evaluate the glass-forming ability of alloy systems. Regression analysis between the logarithm of the critical cooling rate ln Rc and yields value of ␣ = 0.0728. There exists a fine linear relationship between criterion and ln Rc with a coefficient of determination R2 = 0.942. The obtained relationship can be expressed as: ln Rc = 共30.10⫾ 0.91兲 − 共27.93⫾ 0.97兲 . The comparisons of with all other relevant parameters: 兵=Trg关共Tx − Tg兲 / Tg兴0.143其, ␥关=Tx / 共Tl + Tg兲兴, Trg共=Tg / Tl兲, 关=TxTg / 共Tl − Tx兲2兴, ␦关=Tx / 共Tl − Tg兲兴 show that this criterion has the best ability for evaluating the GFA of alloys. © 2009 American Institute of Physics. 关doi:10.1063/1.3255952兴 I. INTRODUCTION II. THEORETICAL ANALYSIS With the rapid development of bulk metallic glasses, it is urgent to find a valid criterion to evaluate the glass-forming ability 共GFA兲 of alloys. The critical cooling rate Rc is the most direct and accurate parameter for evaluating the GFA, however, it is always very difficult to obtain this value for glass-forming alloys. The critical thickness Zc can also reflect GFA to some extent. In general, the higher the Zc, the lower the Rc, and then the higher the GFA will be. However, it is also difficult to obtain an accurate value of Zc in practice. Therefore, a valid and convenient criterion is required, based on which one can directly distinguish the GFA for various alloys. It can save lots of time in finding glassforming alloys. Inoue et al.1 have proposed a GFA parameter, supercooled liquid width ⌬Tx 共Tx − Tg, where Tx is the onset crystallization temperature of the glass, and Tg is the glass transition temperature兲, and concluded that a good glass-forming alloy system should have a large ⌬Tx. The critical cooling rate Rc is the characteristic of good glass forming alloys, and a low Rc means a high GFA. However, a high degree of scatter has been found in a number of cases when ⌬Tx is plotted against Rc.2 Recently, many criteria have been proposed in terms of some combination of the characteristic temperatures, such as, glass transition temperature Tg, onset crystallization temperature Tx, peak crystallization temperature T p, onset melting point Tm, liquidus temperature Tl, and so forth: 兵=Trg关共Tx − Tg兲 / Tg兴0.143其,3 ␥ = Tx / 共Tl + Tg兲,2 reduced glass transition temperature Trg共=Tg / Tl兲,4 关=TxTg / 共Tl − Tx兲2兴,5 ␦关=Tx / 共Tl − Tg兲兴.6 Those criteria have been widely used and obtained good results in exploring the metal glass materials.7–9 In this paper, a criterion , defined as 共Tg + Tx兲 / Tl关共Tx − Tg兲 / Tl兴␣ has been suggested, and its validity has been checked. The comparisons of this criterion with other ones are also given in this article. It has been well recognized that the glass formation is a competing process between supercooled liquid and crystalline phase that is thermodynamically stable. Based on the classical theories of nucleation and crystal growth, the homogeneous nucleation rate, I, and the growth rate, U, of the crystalline phase forming at the supercooled liquid can be expressed as follows:10,11 a兲 Author to whom correspondence should be addressed. Tel.: 86-10-62332646. Electronic mail: kcc126@126.com. 0021-8979/2009/106共9兲/094902/4/$25.00 I= 1035 U= 冋 冋 冉 册 3 2 T − 16 ⌬S f ␣m , 3 NAk共Tl − T兲2 exp 共Tl − T兲⌬S f kT 1 − exp − 2 R gT 3 a 0 共1兲 冊册 共2兲 , where , k, ␣m, a0, NA, ⌬S f , and Rg are viscosity, the Boltzmann constant, a constant of 0.86, mean atomic diameter, Avogadro’s number, the molar fusion entropy, and the gas constant, respectively. The critical cooling rate required for glass formation is determined as12 Rc = 再 4 3f c 冕 Tg Tl I共T⬘兲dT⬘ 冋冕 Tg T⬘ 册冎 3 U共T⬙兲dT⬙ 1/4 , 共3兲 where f c is the crystallized volume fraction 共commonly, 10−6兲. From Eqs. 共1兲–共3兲, it can be seen that the viscosity has an inverse proportion to the nucleation rate I and the crystalline growth rate U. An increase of the viscosity will lead to rapid decreases of I and U, which decreases the critical cooling rate Rc, and therefore, enhances the GFA. By convention, the viscosity at glass transition temperature Tg is a constant 共=1012 Pa s兲.13 Therefore, a high value of Tg / Tl 共Trg, for short兲 means a rapid increase of viscosity of supercooled liquid when it is cooling from liquidus temperature, which dramatically lowers the diffusion ability of atoms. Besides, the high value of Trg also implies a lower degree of super- 106, 094902-1 © 2009 American Institute of Physics [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 132.204.37.217 On: Tue, 09 Dec 2014 14:57:27 094902-2 J. Appl. Phys. 106, 094902 共2009兲 G.-H. Zhang and K.-C. Chou cooling. The nucleation rate I is small when the degree of supercooling is low. All above analyses indicate that the following relationship should be kept: GFA ⬀ Tg/Tl . 共4兲 The reason why using liquidus temperature Tl rather than the onset temperature of melting 共Tm兲 is that GFA is more closely related to Tg / Tl rather than Tg / Tm.14 According to the analysis of Wakasugi et al.,15 the Tx / Tl ratio increases with increasing viscosity of the supercooled liquid, fusion entropy, and activation energy of viscous flow. It can be seen from Eqs. 共1兲–共3兲 that increasing the viscosity of supercooled liquid, the fusion entropy, as well as the activation energy of viscous flow will dramatically decrease the nucleation frequency and growth rate of crystal, thus decrease Rc, which means an enhancement of GFA. Therefore, Tx / Tl can reflect the GFA either. It can be expressed as GFA ⬀ Tx/Tl . 共5兲 Since both Tg / Tl and Tx / Tl can reflect the GFA of alloys, adding them together, a dimensionless parameter 共Tg + Tx兲 / Tl will be generated to characterize the GFA GFA ⬀ 共Tx + Tg兲/Tl . 共6兲 The stability of a glass can be qualified by the width of the supercooling liquid region when it is reheated. The large Tx − Tg reflects that the undercooled liquid can be kept in a wide temperature range without crystallization and has strong resistance against the nucleation and growth of crystalline phase.1 Thus, Tx − Tg may be related to GFA of alloys, a large Tx − Tg means high GFA. In order to make it comparable for different alloys, normalizing Tx − Tg by Tl is necessary. Therefore the GFA should be proportional to the factor of 共Tx − Tg兲 / Tl, expressed as follows: GFA ⬀ 共Tx − Tg兲/Tl . = 共Tx + Tg兲/Tl · 关共Tx − Tg兲/Tl兴0.0728 . 共9兲 From Fig. 1, it can be seen that there exists a fine linear relationship between the logarithm of the critical cooling rate ln Rc and parameter , with a coefficient of determination R2 = 0.942. In order to compare the parameter with any other parameters mentioned above, all the parameters are plotted against ln Rc 共figures are not given here兲, and coefficients of determination R2 are listed in Table II. It can be seen that the criterion possesses the highest R2. It is known to us, the value of the R2 that varies from 0 to 1 can statistically reflect how strong the linear correlation is. The higher the value of R2, the better the linear relationship is. Therefore, it can be concluded that the parameter is valid for evaluating the GFA of alloys. The obtained relationship can be expressed as follows: LnRc = 共30.10 ⫾ 0.91兲 − 共27.93 ⫾ 0.97兲 . 共10兲 共7兲 As discussing both cooling and reheating processes for an undercooled liquid, the GFA of an alloy could be proportional to both factors: 共Tx + Tg兲 / Tl and 共Tx − Tg兲 / Tl. Therefore, a product of them, as shown in Eq. 共8兲, is adopted for evaluating the GFA of alloys = 共Tx + Tg兲/Tl · 关共Tx − Tg兲/Tl兴␣ , shows the glass transition temperature Tg, onset crystallization temperature Tx and liquid temperature Tl of Mg-, Zr-, La-, Ti-, Ni-, Fe-, Pd-, and Ca-based metallic alloys. The used data were measured by differential thermal analysis 共DTA兲 at a heating rate of 20 K/min.2,16 In Table I, parameters , , ␥, Trg, , and ␦ are also calculated. From the definition of and , it can be seen that both of them are proportional to the width of supercooled liquid region, ⌬Tx. Many metallic alloys do not show a supercooled liquid region calorimetrically as ⌬Tx → 0. In order to have a meaningful value for the statistical treatment of all related data, ⌬Tx is set to be unity in their calculation, which is exactly the same as what Fan et al. did.5 Through the linear regression analysis between ln Rc and , the value of ␣ is generated to be 0.0728. Therefore the parameter can be expressed as 共8兲 where ␣ is a positive parameter that can be obtained by regressing the experimental data. The validity of the parameter will be checked in the next section. III. VALIDITY OF THE CRITERION The critical cooling rate Rc is much better than the critical thickness Zc in reflecting the GFA of alloys since Zc has a weaker relation with the GFA. It is noted that, except for the inherent glass-forming ability, many other factors can affect the value of Zc either, for example, the large casting variations for glass formation and different approaches to the maximum casting sizes.2 Besides, most of values of Zc are integer. Therefore it is more reasonable to evaluate GFA with Rc rather than Zc. In the following paragraph, the data of Rc will be used to check the validity of the criterion . Table I IV. COMPARISON AMONG ⌰, ⌽, ⌫, TRG, ⟩, ⌬ From Table II, it can be seen that parameters Trg, , and ␦ have weaker linear relationships with ln Rc, R2 of which are 0.724, 0.49, 0.722, respectively. The parameter of  is not a good criterion with a coefficient of determination R2 = 0.49, and the authors have also pointed out that the  criterion cannot evaluate the GFA for La-, Fe-, and Ni-based alloys very well.5 Parameter ␥ proposed by Lu and Liu is very good17 and has been used widely now in the literatures, the coefficient of determination of which can reach high to 0.914. Followed Lu and Liu’s idea, the criterion suggested in this paper, , can also reach a very high value with R2 = 0.942. It is expected that it may be useful in evaluating the GFA for alloys in future. V. CONCLUSION A criterion is proposed for evaluating the GFA of alloys, the application of which to 53 groups of metallic alloy systems shows that an excellent linear relationship between [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 132.204.37.217 On: Tue, 09 Dec 2014 14:57:27 094902-3 J. Appl. Phys. 106, 094902 共2009兲 G.-H. Zhang and K.-C. Chou TABLE I. Characteristic temperatures and critical rate Rc as well as calculated parameters. Composition Tg共K兲 Tx共K兲 Tl共K兲 Rc共K / s兲 ␥ Trg  ␦ Pd82Si18 Pd75Si25 Pd95Si5 Pd79.5Cu4Si16.5 Pd77.5Cu6Si16.5 Pd77Cu6Si17 Pd40Ni40P20 Pd42.5Cu30Ni7.5P20 Pd40Cu30Ni10P20 Pd42.5Cu27.5Ni10P20 Pd40Cu32.5Ni7.5P20 Pd40Cu25Ni15P20 Pd45Cu25Ni10P20 Pd45Cu30Ni5P20 Pd37.5Cu30Ni12.5P20 Mg80Ni10Nd10 Mg75Ni15Nd10 Mg65Ni20Nd15 Mg65Cu25Y10 Mg77Ni18Nd5 Mg70Ni15Nd15 Mg90Ni5Nd5 Mg65Cu25Gd10 Mg65Cu7.5Ni7.5Zn5Ag5Y10 Zr65Be35 Zr66Al8Ni26 Zr66Al8Cu7Ni19 Zr66Al8Cu12Ni14 Zr66Al9Cu16Ni9 Zr65Al7.5Cu17.5Ni10 Zr57Ti5Al10Cu20Ni8 Zr38.5Ti16.5Ni9.75Cu15.25Be20 Zr39.88Ti15.12Ni9.98Cu13.77Be21.25 Zr41.2Ti13.8Cu12.5Ni10Be22.5 Zr42.63Ti12.37Cu11.25Ni10Be23.75 Zr44Ti11Cu10Ni10Be25 Zr45.38Ti9.62Cu8.75Ni10Be26.25 Zr46.25Ti8.25Cu7.5Ni10Be27.5 La55Al25Ni20 La55Al25Ni15Cu5 La55Al25Ni10Cu10 La55Al25Ni5Cu15 La55Al25Cu20 La55Al25Ni5Cu10Co5 La66Al14Cu20 Ti34Zr11Cu47Ni8 Ti63Be37 Ni Ni59Zr16Ti13Si3Sn2Nb7 Fe91B9 Au77.8Si8.4Ge13.8 Ni60Nd40 Ca65Mg15Zn20 648 656 647 635 637 642.4 590 576 576.9 584 568 596 595 577 572 454.2 450 459.3 424.5 429.4 467 426 423 426 623 672 662.3 655.1 657.2 656.5 676.7 630 629 623 623 625 623 622 490.8 473.6 467.4 459.1 455.9 465.2 395 698.4 673 425 845 600 293 933 375 648 656 647 675 678 686.4 671 658 655.8 665 654 668 675 659 647 470.5 470.4 501.4 479.4 437.2 489 449 484 464 623 707.6 720.7 732.5 736.7 735.6 720 678 686 672 712 739 740 727 555.1 541.2 547.2 520 494.8 541.8 449 727.2 673 425 885 600 293 933 410 1071 1343 1688 1086 1058.1 1128.4 991 884 836 871 932 910 884 861 929 878 789.8 804.9 770.9 886.9 844 919 740 717 1238 1251 1200.8 1172.1 1170.6 1167.6 1145.2 1003 1006 996 1057 1206 1239 1185 941.3 899.6 835 878.1 896.1 822.5 731 1169.2 1353 1725 1301 1628 629 1484 630 1800 1 ⫻ 106 5 ⫻ 107 500 100 125 0.167 0.067 0.1 0.083 0.133 0.15 0.1 0.083 0.133 1251.4 46.1 30 50 4.9⫻ 104 178.2 53 000 1 50 1 ⫻ 107 66.6 22.7 9.8 4.1 1.5 10 1.4 1.4 1.4 5 12.5 17.5 28 67.5 34.5 22.5 35.9 72.3 18.8 37.5 100 6.3⫻ 106 3 ⫻ 1010 40 2.6⫻ 107 3 ⫻ 106 1400 20 0.759 0.604 0.467 0.968 1.000 0.948 1.076 1.191 1.259 1.206 1.102 1.154 1.206 1.210 1.092 0.807 0.913 0.980 0.983 0.712 0.888 0.744 1.037 1.002 0.625 0.869 0.941 0.987 0.995 0.996 0.980 1.064 1.079 1.063 1.070 0.966 0.940 0.968 0.929 0.949 1.039 0.939 0.860 1.045 0.970 0.952 0.614 0.300 1.032 0.450 0.606 0.772 1.027 0.240 0.193 0.152 0.394 0.407 0.388 0.448 0.493 0.519 0.505 0.465 0.484 0.505 0.507 0.460 0.321 0.366 0.405 0.411 0.273 0.357 0.305 0.433 0.420 0.200 0.353 0.390 0.412 0.415 0.415 0.399 0.435 0.444 0.435 0.446 0.406 0.396 0.407 0.390 0.398 0.435 0.392 0.358 0.437 0.406 0.379 0.196 0.104 0.420 0.148 0.207 0.236 0.424 0.377 0.328 0.277 0.392 0.400 0.388 0.424 0.451 0.464 0.457 0.436 0.444 0.456 0.458 0.431 0.353 0.379 0.397 0.401 0.332 0.373 0.334 0.416 0.406 0.335 0.368 0.387 0.401 0.403 0.403 0.395 0.415 0.420 0.415 0.424 0.404 0.397 0.402 0.388 0.394 0.420 0.389 0.366 0.421 0.399 0.389 0.332 0.198 0.412 0.269 0.318 0.386 0.408 0.605 0.488 0.383 0.585 0.602 0.569 0.595 0.652 0.690 0.670 0.609 0.655 0.673 0.670 0.616 0.517 0.570 0.571 0.551 0.484 0.553 0.464 0.572 0.594 0.503 0.537 0.552 0.559 0.561 0.562 0.591 0.628 0.625 0.626 0.589 0.518 0.503 0.525 0.521 0.526 0.560 0.523 0.509 0.566 0.540 0.597 0.497 0.246 0.650 0.369 0.466 0.629 0.595 2.347 0.912 0.386 2.537 2.989 2.257 3.866 7.420 11.650 9.152 4.806 6.798 9.194 9.319 4.654 1.287 2.075 2.500 2.395 0.928 1.812 0.866 3.124 3.088 1.026 1.610 2.071 2.483 2.572 2.588 2.695 4.044 4.214 3.9884 3.727 2.118 1.851 2.156 1.827 1.995 3.088 1.862 1.401 3.199 2.230 2.600 0.980 0.107 4.321 0.341 0.760 2.867 3.177 1.532 0.955 0.622 1.497 1.610 1.412 1.673 2.136 2.531 2.317 1.797 2.127 2.336 2.320 1.812 1.110 1.384 1.451 1.384 0.956 1.297 0.911 1.527 1.594 1.013 1.222 1.338 1.417 1.435 1.439 1.537 1.818 1.820 1.802 1.640 1.272 1.201 1.291 1.232 1.270 1.488 1.241 1.124 1.516 1.336 1.545 0.990 0.327 1.941 0.584 0.872 1.693 1.608 [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 132.204.37.217 On: Tue, 09 Dec 2014 14:57:27 094902-4 J. Appl. Phys. 106, 094902 共2009兲 G.-H. Zhang and K.-C. Chou 25 ACKNOWLEDGMENTS LnRc=30.10-27.93 θ 2 R =0.942 The authors wish to thank the Chinese Natural Science Foundation for their kind support under the Contract No. 50774004, and the “Changjiang Scholars and Innovative Research Team in University,” “PCSIRT” support under the Grant No: IRT0708. Thanks are also given to the Key Laboratory of Ecologic & Recycle Metallurgy, Ministry of Education. LnRc/(K/s) 20 15 10 5 0 -5 0.2 1 0.4 0.6 0.8 1.0 1.2 1.4 0.0728 θ, (Tx+Tg)/Tl ((Tx-Tg)/Tl) FIG. 1. The logarithm of the critical cooling Rc as a function of parameters . ln Rc and 共value of ␣ is 0.0728兲 can be reached. Comparisons among parameters , , ␥, Trg, , and ␦ are also given, and the results show that this criterion is the best one among them. It is anticipated that the criterion will play a useful role in exploring BMG materials. TABLE II. Comparison among different criterion. Criteria R2 ␥ Trg  ␦ 0.942 0.924 0.914 0.724 0.49 0.722 A. Inoue, T. Zhang, and T. Masumoto, J. Non-Cryst. Solids 156–158, 473 共1993兲. 2 Z. P. Lu and C. T. Liu, Acta Mater. 50, 3501 共2002兲. 3 G. J. Fan, H. Choo, and P. K. Liaw, J. Non-Cryst. Solids 353, 102 共2007兲. 4 D. Turnbull, Contemp. Phys. 10, 473 共1969兲. 5 Z. Z. Yuan, S. L. Bao, Y. Lu, D. P. Zhang, and L. Yao, J. Alloys Compd. 459, 251 共2008兲. 6 Q. J. Chen, J. Shen, D. L. Zhang, H. B. Fan, J. F. Sun, and D. G. McCartney, Mater. Sci. Eng., A 433, 155 共2006兲. 7 K. Ziewiec, J. Alloys Compd. 387, 179 共2005兲. 8 O. N. Senkov and J. M. Scott, J. Non-Cryst. Solids 351, 3087 共2005兲. 9 M. Calin, M. Stoica, J. Eckert, A. R. Yavari, and L. Schultz, Mater. Sci. Eng., A 392, 169 共2005兲. 10 C. V. Thompson, A. L. Greer, and F. Spaepen, Acta Metall. 31, 1883 共1983兲. 11 L. E. Tanner and R. Ray, Acta Metall. 27, 1727 共1979兲. 12 D. H. Xu and L. Johnson, Phys. Rev. B 74, 024207 共2006兲. 13 S. Sastry, Nature 共London兲 409, 164 共2001兲. 14 A. Inoue, W. Zhang, T. Zhang, and K. Kurosaka, J. Non-Cryst. Solids 304, 200 共2002兲. 15 T. Wakasugi, R. Ota, and J. Fukunaga, J. Am. Ceram. Soc. 75, 3129 共1992兲. 16 Z. P. Lu, H. Bei, and C. T. Liu, Intermetallics 15, 618 共2007兲. 17 Z. P. Lu and C. T. Liu, Phys. Rev. Lett. 91, 115505 共2003兲. [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 132.204.37.217 On: Tue, 09 Dec 2014 14:57:27