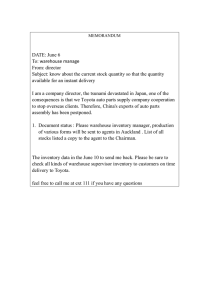

Physical distribution is one of the oldest aspects of commercial enterprise, has historically been one of the most overlooked business topics. Since the mid-1950s, there has been a frenzy of interest in the concept of integrated physical distribution. Physical distribution is an organised group of components linked according to a strategy for achieving specific goals with the components of customer service, transportation, inventory control that is how much inventory a firm should maintain at each location, protective packaging and material handling that is how the firm can efficiently handle goods in the factory, warehouse and transport terminals, order processing, warehousing," according to Boon and Kurtz (2003). Essentially, physical distribution aims to get products to consumers quickly and cheaply. It emphasises the importance of achieving righteousness in all significant aspects of physical distribution, namely, the right product, at the right time, at the right place, in the right manner, for the right people, and at the right price/cost. It strikes a balance between price and service. Order processing refers to the communication message that starts the physical distribution process (Croxton, 2003). It includes tasks like product delivery planning, execution, communication, and specification (Zhang, Lee & Xu,2010). To ensure a smooth flow of operations, order processing is linked to information system technologies (Schlesinger et al., 2001). The order processing function connects the warehouse to allow stock visibility and delivery scheduling. However, in order for information to flow seamlessly, the information systems of multiple channel members must be compatible (EspinoRodrguez & Rodrguez-Daz, 2014). Physical distribution information systems are used to improve the organization's flexibility and responsiveness, and they are frequently the glue that holds everything together (Lau & Lee,2000) "Inventory management is critical in physical distribution," says Buell (1970). Inventory control aims to decrease both financing and inventory variations while also filling customer orders quickly and accurately. Inventory costs include acquisition and storage costs. Management must decide how much stock to order when it is time to replenish it. This is facilitated by the notion of economic customer demand, which is defined as the volume with the lowest inventory carrying costs and purchase processing costs. The primary function of a warehouse is to store raw materials and finished goods (Gu, Goetschalckx & McGinnis 2010).The main activities carried out in the warehouse are as follows: Receiving, storage, order picking, accumulation, sorting, and shipping are all steps in the process (Gu et al.,2010). The warehouse's location has an effect on the organization's responsiveness and lead time to customers (Esper et al., 2007). Inadequate warehousing locations can result in delivery delays, inefficient distribution, and higher logistics costs (Chan, Kumar & Choy, 2007). An efficient warehouse improves the organization's service levels, resulting in shorter delivery times and higher customer satisfaction (Shang et al., 2009). The warehouse should be designed in such a way that it allows for a continuous flow of goods. Transportation is the physical transportation of goods from one location to another, customarily from the point of origin to the point of destination, and it becomes significant when it spans countries and continents (Villarreal, Garcia & Rosas, 2009). According to the logistics barometer, transportation is the most expensive aspect of physical distribution. (Havenga et al., 2016).Transportation activities include route planning, cargo tracking, and shipment notifications (Zhang et al., 2010). Using transport systems, schedules, and bundling orders to achieve scale economies improves the physical distribution of the organisation by reducing travel distances and increasing load capacity (Lu & Yang, 2010). Material Handling encompasses all activities related to moving products after they have left the manufacturing plant but before they are loaded onto a transport vehicle. This activity has existed for a long time and has now evolved into a system. It entails using various modes of transportation to transport goods from the plant to the warehouses and from the warehouses to the point of loading. Proper material handling management aids in the avoidance of unnecessary goods movement, the prevention of product damage, the facilitation of order processing, and the efficient movement of goods. Material handling is a part of the whole physical distribution systems that contributes to cost reduction and improved customer service. Material handling system management that is effective increases the system's effectiveness. According to Chan & Choy, 2006 “packaging logistics is defined as the interaction and relations between the logistics and the packaging system that improve “add on” values to the whole supply chain from raw material producer to end-user, and the disposal of the empty package”. Protective packaging supplies, simply put, are materials designed to protect and buffer a product from potential harm or destruction during shipping or warehousing. Protective packaging can be made of any material, including but not limited to cardboard, plastic, metal, and so on. Depending on the product contained within, protective packaging is frequently used as the primary component of a product's packaging or as a secondary form of packaging supply. It is useful for a variety of applications, but all forms of protective packaging serve the same purpose: to ensure that a product arrives in pristine condition, free of damage or other issues. Just-in-time (JIT) is a materials management system which aims to work with zero inventories and to ensure materials when they are required. JIT has been written about since the early 1970s. If one search would be made on the researches, dissertations, papers and manuscripts that were written about JIT, it is clear that a significant amount of study will be noticed over the past three decades. JIT takes advantages of minimum resources and responses in minimum time to the customers with having minimum waste and using all the factors of production. JIT management approach has been proven effective in the manufacturing sector in increasing productivity, quality and efficiency, decreasing costs and waste and improving communication (Kee-Hung and Cheng 2009:1). JIT also started to grow in the service sector around the mid-1990s (Yasin, Small and Wafa, 2003). Firms are forced to implement a wide variety of innovative managerial tools and philosophies to react to external and internal pressures. Over the past three decades just in time has been one of the most popular business revitalization for the firms. The early development of JIT was initiated by Taiichi Ohno in Toyota’s manufacturing plants in an attempt to meet customer demands precisely with minimum delays (Kee-Hung and Cheng 2009:9). In opinion of Nikolaidis (2013) TQM is a system approach that works backwards and forwards along the supply chain. At the heart of TQM lies the concept of a continuous improvement and “customer value”. Value is delivered to the customer during the “use process”, which includes all the activities that customer goes through in using a product: find, acquire, transport, use, dispose. The implementation of TQM philosophy promotes the integration of the supply chain, builds positive relationships with customers, improves the level of logistics customer service and develops logistics subsystems Containerization is an intermodal freight transport method that uses weathering steel intermodal containers (also known as shipping containers and ISO containers) to move products. Containers have fixed dimensions and can be loaded and unloaded, stacked, transported economically over long distances, and transferred without being opened from one method of transport to another, such as container ships, rail ships, rail transport, flat cars, and semi-trailer vehicles. The handling method is highly mechanised, with cranes and special forklift trucks handling everything. Computerized methods are used to number and trace all containers. GPS-secured container seals are being used for freight tracking in recent advancements. The essential purpose of a shipping container is to contain and protect its contents during transport from manufacturer to consumer. Where an industrial package is involved, the consumer could be another manufacturer, and not the ultimate user of the finished goods. The function of the consumer container or retail unit is to provide for a convenient quantity or number of articles in one unit, which will be purchased by the ultimate user in a retail shop or store. It is obvious, however, that to some extent the outer or shipping container will be complementary to the inner or retail units. THANK YOU