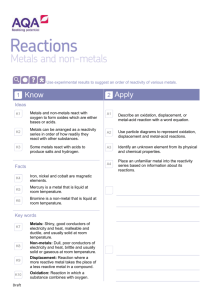

METALS A metal is an element which has the ability to lose electron(s) and became positively charged. There are about 105 different elements. Of these 84 are metals and 21 are non metals. GENERAL PROPERTIES Metals generally have the following properties. i. ii. iii. iv. v. vi. vii. viii. ix. x. xi. Have high melting and boiling points Are good conductors of heat and electricity Have a high density – metal atoms are parked very closely Are solids at rtp, except for mercury which is a liquid. Are Malleable i.e can be beaten into sheets Are Ductile i.e can be made into wires. Are Sonorous i.e produce sound when beaten Are Lustrous i.e can be polished or have a shining surface. They are strong under tension and compression. That means they can withstand stretching and crushing without breaking React with oxygen to form basic oxides Form positively charged ions (Cations) by losing electrons. WHY METALS ARE USED AS ALLOYS Pure metals are usually too soft and weak for most uses. A gold chain is never made of pure gold, as the chain would be too soft and would break easily. Instead, it is alloyed with other elements to make it more shiny and stronger. Metals are mainly used as alloys for the following reasons To improve on their properties. To improve on their appearance. To make metals to be less brittle. To Make metals strong and harder. A comparison between pure metals and alloys is shown below. Pure metal Alloy Are usually Soft and can easily bent Are Strong and hard, not easily bent Have higher melting points Have lower melting points than the melting points of their components Atoms can slide over each other easily as atoms are of the same size Diagramatic representaion of a pure metal Atoms cannot slide over each other easily as foreign atoms are of different size and disrupt the orderly arrangement of the metal atoms Diagrammatic representation of an alloy METAL ALLOYS An alloy is a mixture of a metal with another element. Alloys mainly consist of two or more metals mixed together or they may be largely a metal with a non-metal. An alloy is usually made by melting the main metal and then dissolving the other substances in it. Alloys have certain properties that differ from those of their components and make them more suitable for particular purposes than their parent metals. There are thousands of different alloys; here are the examples of common ones; Alloy Composition Special Properties Aluminium alloys Duralumin Uses Aluminium, copper and magnesium Aluminium, cobalt and and nickel harder and corrosive resistance Retains magnetism Aircraft bodies Copper alloys Brass Copper and zinc Sonorous, Stronger, highly ductile and malleable Bronze Copper and tin Monel Copper, nickel and manganese Corrosion resistance and harder Corrosion resistance Make musical instrument, pins of electrical plugs, Deep drawn materials ,hot rolled materials Money coin, trophies, Alnico Iron alloys Mild steel Permanent magnets Chemical plant Iron(95.5%) and carbon(o.5%) Iron(99%) and carbon(1%) Iron(84%) ,silicon(15%) and carbon(1%) harder and strong High speed steel Iron and tungsten Heat resistance, very hard Stainless steel Iron,chromium and nickel Corrosion resistance, very hard Hadfields steel Iron and manganese Abrasion resistant Lead alloys Common solder Lead and tin Wide liquid range and sharp low melting point Metal joints (joining wires and pipes) Lead, Tin, Bithmuth, and mercury Hardens quickly, abrasion resistant Filling dental cavities Hard steel Duriron Dental amalgam Very hard, stronger Acid resistance, corrosion resistance, hard Construction works, machinery tubings, window grills, car bodies Blades for cutting tools (e.g razor blades/ saws) sand paper, drill bits Tanks and pipes for chemical plants, industrial equipment that comes into contact with corrosive chemicals Making high speed cutting tools, ball bearing and drill bits Making of cutlery e.g knives), surgical instruments, kitchen sink, chemical plants and cutting tools Heavy drill bits, rock crusher jaws, railway points REACTIVITY SERIES OF METALS This is the arrangement of elements in order of their chemical reactivity. The numbers of different reactions have been used to compare the reactions of the elements. To come up with the reactivity series, chemists compared the reactions of different metals with; i. Air (oxygen) ii. Cold water iii. Steam iv. Dilute acids etc In the reactivity series the most reactive metals are placed on top while the least reactive at the bottom, as shown Potassium K Sodium Na Calcium Ca Magnesium Mg Aluminium Al Zinc Zn Iron Fe (Hydrogen) H Copper Cu Silver Ag Gold Most reactive Decreasing reactivity * Au Least reactive * Hydrogen although is not a metal has been included in the series to act as a reference point to indicate its position Any metal higher than hydrogen in the series will displace hydrogen from an acid where as those below it will not. USEFUL INFORMATION TO REMEMBER ABOUT THE REACTIVITY SERIES 1. The metal at the top of the series generally, react more vigorously than those that are at below the series 2. The more reactive the metal is, the more compounds it forms so only metals below the series e.g. gold, silver platinum are found as elements in the earth’s crust. The other reactive metals are found as compounds. 3. When a metal reacts, it gives up electrons to form ions. The more reactive the metal, the more easily it gives up electrons. 4. The more reactive the metal, the more stable its compounds. Stable means difficult to break down. Compounds of metals high in the reactivity series are difficult to split because they form strong bonds (stable compounds) 5. All metals in the reactivity series undergo displacement reactions. Metals higher in the reactivity series will displace from aqueous solution of its salt any metal below it. The greater the gaps separating the metal the more easily does the displacement take place. 6. The more reactive the metal , the more it is difficult to extract from its compounds since the compounds are stable. Hence, for more reactive metals , you need a tough method of extraction; Electrolysis. 7. If you place two metals in an electrolyte and join them up, you’ll get the current! Electrons flow from a more reactive metal to a least reactive one. In an electrolytic cell, The further apart the metals are in the reactivity series , the higher the voltage of the cell. REACTIONS RELATED TO THE REACTIVITY SERIES Knowing the position of the reactivity series will help us determine the type of chemical reaction that may occur and the rate of such a chemical reaction. The following are the reactions; A. DISPLACEMENT REACTIONS OF METALS. i. Displacement of a one metal by another in aqueous solution. Metals high in the reactivity series will displace the least reactive metals in solution. e.g Zn (s) + CuSO4 (aq) ZnSO4 (s) + Cu (s) BUT, a less reactive metal cannot displace a more reactive metal from its solution e.g Fe (s) + CaCO3 (aq) Fe (s) + CaCO3 (aq) ; No reaction takes place (NO reaction takes place, Fe cannot displace Ca from its solution) ii. Reduction of metal oxides by a more reactive metal. A metal high in the reactivity series has a high affinity for oxygen .hence, a more reactive metal will remove oxygen from the a less reactive metal and bond with the oxygen instead. e.g Fe (s) + CuO (aq) FeO (s) + Cu (s) iii. Reduction of metal oxides by carbon. At high temperature, carbon behaves as a reducing agent and reduces metal oxides to metals, removing the oxygen from the metal oxides. e.g C (s) + 2 PbO (s) CO2 (s) + 2 Pb (s) NB Carbon cannot reduce oxides of reactive metals like potassium, calcium, magnesium and aluminium. Carbon reduces oxides of metals lower in the reactivity series i.e Zinc and those metals below. iv. Reaction of metal oxides with hydrogen Hydrogen is also a good reducing agent, it can reduce metal oxides to metals. BUT hydrogen can only reduce oxides below zinc in the reactivity series. e.g H2 (g) + CuO (aq) H2O (l) + Cu (s) v. Reaction of metals with acids Metals above hydrogen in the reactivity series will displace hydrogen from acids forming a salt and hydrogen gas. e.g Zn (s) + H2SO4 (aq) ZnSO4 (aq) + H2 (g) 2 Mg (s) + HNO3 (aq) Mg(NO3)2 (aq) + H2 (g) Cu (s) + HCl (aq) (Cu cannot displace H from its solution) Cu (s) + HCl (aq) ; NO reaction takes place B. REACTION OF METALS WITH OXYGEN. Metals react with oxygen to form metal oxides i. Potassium, sodium and calcium react with oxygen in the air to form metal oxide e.g 4Na (s) + O2 (g) 2Na2O (s) ii. Magnesium, Aluminium, Zinc and Iron burns when heated to form a metal oxide. e.g 2Mg (s) + O2 (g) 2MgO (s) iii. Tin, lead, copper and mercury form metal oxides slowly on heating. e.g 2Cu (s) + O2 (g) 2CuO (s) NB; Silver and Gold do not react with oxide. C. REACTION OF METALS WITH DILUTE HYDROCHLORIC ACID Metals above hydrogen in the reactivity series react with acids to form a salt and hydrogen gas. e.g K (s) + HCl (aq) KCl (aq) + H2 (g) React explosively Ca (s) + 2 HCl (aq) CaCl2 (aq) + H2 (g) React vigorously Mg (s) + 2 HCl (aq) MgCl2 (aq) + H2 (g) React rapidly in warm acids 2Al (s) + 6 HCl (aq) 2 AlCl3 (aq) + H2 (g) React slowly; warming may be required. Cu (s) + HCl (aq) Cu (s) + HCl NO Reaction takes place NB; The more reactive the metal , the more vigorously the reaction D. REACTION OF METAL WITH WATER i. Potassium, Sodium and calcium react readily with cold water. The products are metal hydroxide and hydrogen gas. e.g 2Ca (s) + 2H2O (l) 2Ca(OH)2 (aq) E. ii. Magnesium, aluminium, zinc ,and iron do not react with cold water but react with steam to producemetal oxides and hydrogen gas. e.g 2Mg (s) + 2H2O (g) 2Mg(OH)2 (s) iii. Metals below hydrogen do not react with cold water or stem. ACTION OF HEAT ON METAL CARBONATES i. Potassium and sodium carbonates cannot be decomposed be heating. e.g heat Na2CO3 (s) Na2CO3 (s) NO Decomposition ii. Metals below sodium form carbonates that can be decomposed by heating. e.g heat CaCO3 (s) CaO (s) + CO3(g) EXTRACTION OF METALS Metals high in the reactivity series do not exist in their free state, but combined withother elements to form metal ores or salts. Metal ores are usually in the form of oxides, sulphides or carbonates. The extraction of metals depends on their reactivity. There are two basic methods of extraction of metals from their ores. These are; i. Electrolysis and ii. Reduction. The method used to extract the metal depends on the reactivity of the metal. Metals high in the reactivity series are extracted by electrolysis. These metals include potassium, sodium, calcium, magnesium and aluminium. The moderately reactive metals are extracted by the Reduction process. These include iron, copper, lead, tin and zinc. The unreactive metals are are found as pure and uncombined elements as their ores occur naturally. RUSTING OF IRON When a metal is attacked by air, water or other substances in its surroundings the metal is said to corrode. Corrosion of iron and steel is called RUSTING. Rusting occurs when iron comes into contact with water and oxygen. Rust is actuall hydrated iro(ii) oxide, Fe2O3.H2O. CONDTION FOR RUSTING The diagrams below show conditions for rusting. HOW TO PREVENT RUSTING To prevent iron from rusting water and/or air(oxygen) must be prevented from coming into contact with the metal surface. Below are some of the methods; They mostly involve coating the metal with something to keep out air and water. 1. 2. 3. 4. 5. 6. PAINTING: Paints that contain lead or zinc are mostly used OILING ( or greasing): this prevents air(oygen) from coming into contact with the metal surface GALVANIZING: Coating the iron with a zinc metal. SACRIFICIAL PROTECTION: Coating the metal with a more reactive metal e.g magnesium ELECTROPLATING: Coating the iron with a less reactive metal. It is deposited on the iron by electrolysis process. e.g Tin plating and chromium plating ALLOYING: When iron is made into stainless steel or chromium steel it does not rust.