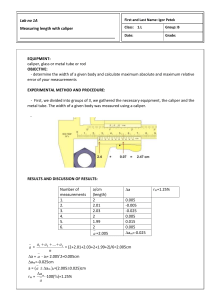

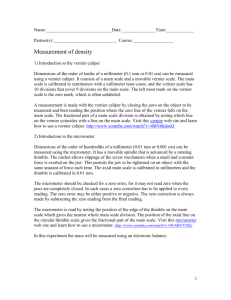

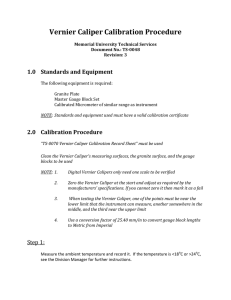

Activity 1: Measurement of Length SCORE Date Performed Activity No. 1 MEASUREMENT OF LENGTH INTRODUCTION /20 1|Page Activity 1: Measurement of Length Measurement is the process of comparing an unknown quantity with a known quantity. Because of human and mechanical limitations, every measurement is an approximation. Every measurement has a limit of accuracy and precision beyond which certainty exists. Accuracy is a way of describing how close a stated number to that of the actual quantity it represents. A scientific measurement consists of a number and a dimensional unit. Since the metric system is generally used in scientific word, all the instruments provided in these illustrations have a scale graduated in metric units. A. The Vernier Scale The vernier scale is a movable auxiliary scale attached to a main scale that accurately determines the fractional part of a division on the main scale as shown in see Figure 1.1. This auxiliary scale has divisions that are slightly smaller than a division on the stationary main scale along which it slides. When the zero mark of the vernier coincides on any main scale division, then the n divisions of the vernier caliper will correspond to n-1 divisions on the main scale. If S is the length of the smallest main scale division and D is the length of the smallest vernier scale division, then nD = (n -1) S. Figure 1.1: The vernier caliper The least count LC of the instruments with the vernier scale is the term applied to the smallest value that can be read directly from the vernier scale. It is equal to the difference between a main scale division and the vernier scale division: LC = S - [ (n-1) / n ] S = S / n B. The Micrometer Caliper A micrometer caliper is another precision instrument used to determine lengths. The value of the measured quantity is accurately indicated by the use of a pitched screw as shown in Figure 1.2. It measures length by translating distance into revolutions and fractions of a revolution of a known pitch. One complete revolution of the pitched screw is equivalent to 0.5 mm, which is the smallest division indicated on the graduated reference line found on the sleeve of the caliper. Graduations touching the reference line are 1- mm apart. Activity 1: Measurement of Length Figure 1.2: The micrometer caliper C. The Ruler A rule (see Figure 1.3) is an instrument consisting of a smooth straight edge strip of material with mark off units, used to measure the distance between two points. Figure 1.3: The ruler OBJECTIVE To study the principles of vernier caliper scale and micrometer caliper and how to use these precision instruments in the measurement of length. APPARATUS Vernier caliper, micrometer caliper, ruler, 4 different solids PROCEDURE A. The Vernier Scale 1. In making measurement with a vernier scale, the following procedure may be followed: (a) Determine first the least count of the caliper by noting the number of vernier divisions n, the length of the smallest main scale division S and the length of the smallest vernier scale division D. (b) Determine the zero reading of the caliper by closing the jaws and noting the vernier division which coincides with a mark on the main scale division. (c) Read the number of divisions on the main scale before the zero mark of the vernier scale and then note which vernier division coincides with a mark on the main scale Multiply the number of the coinciding vernier mark by the least count LC to obtain the fractional part of the main scale division to be added to the main scale reading. Activity 1: Measurement of Length Final reading = Main scale reading + LC ( vernier reading) + LC (zero reading) Example: fixed scale vernier scale final reading : : : 3.7 cm .03 cm 3.73 cm fixed scale : vernier scale : final reading : 51.0 mm .9 mm 51.9 mm 2. Use the vernier caliper to measure the dimension of all four objects provided in the measurement set. (a) Use the outside caliper to measure the length, width, and the height of the metal block, and the diameter of the metal sphere. (b) Use the inside caliper to measure the inner diameter of the hollow metal cylinder and use the depth gauge to measure the inside depth of the hollow metal cylinder. (c) Record all measurements for the metric scales in Table 1.1 B. The Micrometer Caliper 1. The micrometer caliper in the measurement set has a pitch of 0.5 mm. This means that the screw advances 0.5mm when turned through one revolution. Fraction revolution of the screw is indicated by the graduation on the circumference of the thimble. The scale around the circumference of the thimble is divided into 50 parts. Each division represents 1/50 of revolution. When the thimble is turned through one division, the screw advances 1/50 of the pitch, i.e., 1.50 mm or 0.01 mm. 2. Use the micrometer caliper to measure the dimensions of the objects in Step 1. (REMINDER: Micrometer measurement limit is 2.58 cm. Measurement beyond this limit may damage the device. Just put N/A (not applicable) to any measurement beyond 2.58 cm). Record your measurements in Table 1.2. Compare your readings with the ones obtained in Step 1. Measure the diameter of the sphere at several points. When measuring the diameter of the sphere, only the center of the faces of both anvil and spindle should touch the sphere. 3. In making measurements with the micrometer caliper: (a) Determine the zero reading of the caliper by closing the jaws and noting what graduation lines are after the thimble coincides with the reference line. (b) Read and record the number of graduation lines before the thimble and determine the line on the thimble that coincides with reference line. If the reference line does not coincide with a line on the thimble but between two lines, do an interpolation. Activity 1: Measurement of Length Example: Sleeve : Thimble : Interpolation : Final reading : 8.00 mm 0.11 mm 0.005 mm 8.115 mm C. The Ruler 1. Use the ruler to measure the dimensions of the objects specified in Table 1.3. Make the following comparison for the thickness of the rectangular block: a. Ruler vs. vernier caliper (1 pt.) b. Ruler vs. micrometer caliper (1 pt.) c. Vernier caliper vs. micrometer caliper (1 pt.) Activity 1: Measurement of Length TABLE 1.1 VERNIER CALIPER S = _____ cm, n = _____, LC = _____ cm; S = _____ mm, n = _____, LC = _____ mm (2 pts) Fixed Scale Vernier Scale Reading mm mm mm Object Rectangular Block Length Height Width Inner diameter of hollow cylinder Diameter of metal ball Activity 1: Measurement of Length Sketch of Scale Rectangular Block Length Height width Inner diameter of hollow cylinder Diameter of metal ball Activity 1: Measurement of Length TABLE 1.2 MICROMETER CALIPER S = _____ mm, n = _____, LC = _____ mm (2 pts) Object Sleeve Thimble Reading Thickness of rectangular block Diameter of solid cylinder Diameter of metal ball There’s no Interpolation since there were no scale that goes in between two lines of the Thimble. Activity 1: Measurement of Length Sketch of the Scale Thickness of rectangular block Diameter of solid cylinder Diameter of metal ball Activity 1: Measurement of Length TABLE 1.3 RULE Rectangular Block Actual Reading (mm) Length Width Thickness Sketch of Scales