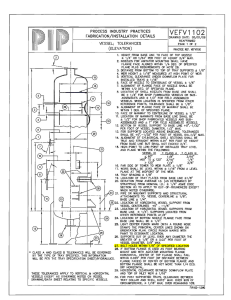

ARAMCO EQUIPMENT INTERVIEW QUESTIONS Date: 28‐11‐ϮϬϭϲ 1. MDMT: Minimum design metal temperature 2. High - Alloy Steels: Steels with a total alloying content more than 5%. 3. Low - Alloy Steels: Steels with a total alloying content of less than 5% but more than specified for carbon steels 4. Nominal Thickness: The value of the design thickness required to withstand all primary loads, and includes allowance for corrosion. 5. PFD: Process Flow Diagram. 6. Utility Services: Water, air and nitrogen services. 7. Equipment Davit A davit for the lifting of equipment shall be specified for vessels containing removable internals such as trays, packing and relief valves. 8. Vortex Breaker: The use of vortex breakers or guying devices in order to maintain internal stresses, due to wind-induced vibration within allowable limits, is prohibited. 9. Telltale Holes Telltale holes in reinforcing pads shall be protected with wooden plugs or packed with rust preventative grease such as Denso paste. 10. VPCI The interior surfaces of vessels, including internals, shall be protected from corrosion by use of a nontoxic vapor phase corrosion inhibitor such as COTEC VCI-309 or 307 or equivalent, (depending on the metallurgy of the vessel) applied at a rate of 0.1 kg/m³. 11. Nozzle 1|Page Threaded nozzle connections shall be protected with threaded plugs. Vessels waiting for installation have the flanged connections and all other machined surfaces protected by a coating such as MIL C16173 Grade IV, which is easily removed in the field and fitted with steel or Wood cover, 3 mm thick and neoprene gaskets. 12. Pad plate Leveling shims are installed with a minimum top elevation of 25 mm from the top of concrete foundation. This is to allow a minimum thickness of 25mm of non-shrink cement based grout. 13. Anchor bolt The minimum anchor bolt diameter shall be 20 mm (¾"), except when specified otherwise by the vendor for small equipment 14. What is the Equipment? Transfer the process fluids from one place to another place it is called equipment. Two types of equipment are there, 1. Static equipment 2. Rotary equipment 15. What is a Static Equipment? 16. What is a Heat Exchanger? Heat transfer between two different liquid media. 17. Types of Reactor Pressurized water reactor Pressurized heavy water reactor Sodium cooled water reactor High temperature gas cooled reactor Valve Tray Sieve Tray Chimney tray Bubble cap tray Seal tray 18. Types of Trays 19. Types of Heat exchanger Shell and Tube heat exchanger Air cooled heat Exchanger 2|Page Double pipe Plate frame heat exchanger Electric Heat exchanger Spiral heat exchanger 20. Types of packaging Structured Packaging Random Packaging Ball rings Catalyst and Desiccant packaging 21. What is pressure vessel? A container designed to withstand internal or external pressure, which can be imposed by an External source, by the application of heat from a direct or indirect source, or by any combination thereof. This definition includes unfired steam generators and other vapor generating vessels, which use heat from the operation of a processing system or other indirect heat source Equipment include strainers, pressure containers used for Transferring liquids as an integral part of a piping system and devices that serve The purposes of mixing, separating, distributing, metering and controlling flow. 22. What is drum? 23. What is column? It is the vertical equipment with internal trays and packaging are used for process application Column is using for separation of gases or liquids 24. What are drum internals? Demister pads, Baffles, Vortex breakers, Distribution piping. 25. What are drum elevation requirements? NPSH, minimum clearance, common plat forming, maintenance, operator access. 26. What are drum supports? Skirt for large drums, legs, lugs, saddles for horizontal drums. 27. What are necessary nozzles for non-pressure vessel? Inlet, outlet, vent, manhole, drain, overflow, agitator, temperature element, level instrument, and steam out connection. 28. What are necessary nozzles for pressure vessel? 3|Page Inlet, outlet, manhole, drain, pressure relief, agitator, level gauge, pressure gauge, temperature element, vent and for steam out. 29. What is preferred location for level instrument nozzles? Away from the turbulence at the liquid outlet nozzle, although the vessel is provided with a vortex breaker, instrument should be set in the quiet zone of the vessel for example on the opposite side of the weir or baffle or near the vapor outlet end. 30. What is preferred location for process nozzles on drum? Minimum from the tangent line. 31. What is preferred location for steam out nozzle on drum? At the end opposite to the maintenance access. 32. What is preferred location for vent? AT the top section of drum at the end opposite the steam out connection. 33. What is preferred location for pressure instrument nozzle on drum? Must be anywhere in the vapor space, preferable at the top section of drum 34. What is preferred location for temperature instrument? Must be in liquid space, preferably on the bottom section of drum. 35. What is preferred location for drain? Must be located at the bottom section of drum. 36. What is NPSH? NET POSITIVE SUCTION HEAD: It is measure of the pressure drop of the liquid as it moves form the inlet of the pump to the eye of the impeller, determined by testing and expressed in feet of water by pump manufacturer. 37. Tell about reactor? Heart, mixing, chemical reaction, heat generated-absorbed, agitation, jacket, heating coils, cooling. 38. Where furnaces shall be located? Furnaces shall be located upwind or side wind of process units to blow any combustible leaks away from the open flame, Min 90M away from tanks and 30M away from control room. 39. What should be stack height? Stack height shall be minimum 6M above working platform in the vicinity of 25m radius. 40. Where spiral heat exchangers are used? 4|Page Generally in chemical plants 41. How piping is positioned for spiral heat exchangers? Piping positioned to allow opening of covers and the removal plates. 42. What are the types of tube arrangements? U-tube, Fixed tube, kettle arrangement. 43. What is full form of TEMA? Tubular exchanger’s manufacturers Association. 44. Which fluids to be sent through tubes? Fouling and/or corrosive fluids (Easy cleaning and cheaper to replace tubes than shell), hotter fluid: To reduce heat loss to the surroundings except steam. refrigerant, cooling fluid. 45. What should be clearance between flanges of exchangers? 1000 MM. 46. Where plate exchangers are used? Low pressure, low temperature applications. 47. Where used DOUBLE PIPE OR FIN TUBE EXCHANGERS? Used when liquid has a greater resistance to heat flow than another or when the surface area is small. 48. Where used AIR COOLER EXCHANGERS? To cool tower overhead vapors. 49. What insulating materials are used? Asbestos, calcium silicate, cellular glass, cellular silica, diatomaceous silica plus asbestos, Mineral fiber, mineral wool, magnesia, polyurethane foam. 50. Where jacked screwed flange is used? For spectacle discs, one flange is jacked screw flange. This flange has two jacked screws 180 degree apart which are used to create sufficient space between flange for easy removal and placement of line blind or spectacle blind. 51. Where blind flange is used? It is used with view to future expansion of the piping system, or for cleaning, inspection etc 52. What are types of towers? Stripper, Vacuum tower, trayed, packed towers. 5|Page 53. What is batch shell process? Feed, heat, condense, heat more, and condense low quality. 54. What is chimney tray? It’s a solid plate with central chimney section, used at draw off sections of the tower. 55. What factors to consider while setting tower elevation? NPSH, Operator access, Maintenance access, Minimum clearance, re boiler type, common area, type of support, Tower dimensions, type of head, bottom outlet size, foundation details, and minimum clearances. 56. How to located tower maintenance access nozzles? At bottom, top and intermediate sections of tower, must not be at the down comer section of tower and in front of internal piping. 57. How to locate feed nozzle? Must be oriented in specific area of tray by means of internal piping. 58. How to located temperature and pressure instruments? Temperature in liquid space, at down comer side and pressure in vapor space, in area except down comer sector. 59. What will be check during torqueing? Before Torqueing? A. Before Torqueing Check the Flange faces and Cleanliness Verify the Gasket type, size, color code and ratings Sequence of torqueing and Torque value Calibration of Torque wrench Flange Alignment Bolt Details and Specifications B. During Torqueing Sequence of Torqueing Procedure of Torqueing Check the Cap between matting flanges 60. What is the Inspection required before Box-Up? All nozzles should be reinstated All internal man ways should be closed and inspected Final internal installation and cleanliness inspection to be completed Verify the open NCR’s Check the Flange faces Verify the Gasket type, size, color code and ratings Sequence of torqueing and Torque value Calibration of Torque wrench 61. How many types of gasket using for pressure vessel? Spiral Wound gasket 6|Page O ring gasket RTJ gasket Spiral wound with PTFE Teflon gasket Compressed asbestos gasket PIKOTEK gasket 62. Main parts of Pressure vessel? Inlet, outlet, vent, manhole, drain, overflow, agitator, temperature element, level instrument, and steam out connection. Saddle, Skirt, Leg, Lug, Support, Demister pad, Baffle plate, Vortex breaker, Davit arm 63. How many types of internal inspection? Tray Test Leak test Cleanness test Visual inspection 64. What is the document required for material Receiving? Aramco approved documents RFI Purchase order Delivery note Mill test certificate IRC-Inspection release certificate 65. How you will find Equipment was in Preservation? All nozzles should be end blinded with temporary gasket Installed the pressure gauge to ensure the nitrogen filled Marking on the equipment which shows VpCI is present ( Vapor phase Corrosion Inhibitors ) 66. Which type of grout using for Static equipment? Non-Shrink cement based grout 67. What is the purpose of blank nut are welded on equipment skirt? The bottom heads of vertical vessels that are externally insulated are provided with 12 mm blank nuts. Blank nuts are welded on edge and located on 300 mm square centers. Fire proofing 68. Where you get reference from verticality Tolerance? 32-SAMSS-004 / 13 Page / Para 14 PIP VEFV 1100/1102 69. What is the External Inspection on vessel? 7|Page Orientation to be check Elevation Verticality ( Plumpness ) Centering (Foundation center to Equipment center ) Anchor Bolt tightness Visual inspection of equipment to ensure that damages 70. What is Peaking? Banding? Peaking Deviation at vertical weld joints shall not exceed 13 mm.peaking at vertical weld joint shall be determined using a horizontal sweep board 900 mm long. Banding Deviation at horizontal weld joints shall not exceed 13 mm.peaking at horizontal weld joint shall be determined using a vertical sweep board 900 mm long. 71. Types of Air cooled heat Exchanger? Forced Draft (Fan – Top and Bundle – Bottom ) Induced Draft ( Fan - Bottom and Bundle - Top ) 72. Main parts of Air cooled heat Exchanger? Plenum, Fan, Pulley, Tube Bundle, Motor, Structural Attachment, Inlet and Outlet 73. Sliding side Bolt full Tight Required? True or false False 74. What are the tools required at the time of Inspection? Measuring Tape, Sprit Level, Feller gauge, Right angle Theodolite and Dumpy level Plumpness 75. How to measure belt thickness of driver and driven 76. What is your responsibility during Installation? Verify the pre installation inspection status Plant drawing to be verify Check the orientation Check the Foundation cleanliness Check and verify the anchor bolt condition 77. What are the inspections to be done before installation? Verifying foundation release Pad plate elevation Projection of anchor bolt 8|Page Distance between anchor bolt dimensions PCD Visual Inspection Of Equipment 78. What are the two types of static equipment? Vessels, exchangers, drum, reactors, boilers etc., 79. What is Horizontal Equipment tolerance? Equipment Center to Bottom of base plate 0,-3 mm Centering of Equipment 3 mm Levelness of base plate ± 3 mm Diagonal ± 6 mm BCD ± 6 mm 80. Which type of equipment is using Saddle? Horizontal vessels & Exchangers 81. What is the inspection to be check during PRE INSTALLATION? Verifying foundation release report Pad plate elevation Padding voids Projection of anchor bolt Distance between anchor bolt dimensions PCD 82. Maximum Tolerance for Vertical Equipment? 0.8mm / 1 M (Max 19 mm) 83. What is the Inspection point of TWO MATING FALANGES? Check the Flange faces Check the flange alignment Check the bolt hole are going freely moving Check the flange offset Verify the Gasket type, size, color code and ratings Sequence of torqueing and Torque value Calibration of Torque wrench 84. What is Qc Roles and responsibility? Monitoring the process as per the ITP, Data sheet and approved drawings Eliminate the defects during process Ensure the execution of work as per Specified requirement Should be vigilant Convey the irregularities found to the concern authorities 85. What is the Difference between Tank & Pressure Vessels? Tank 9|Page Pressure Vessels 86. What is Plumpness Tolerance for API 650 Tank? 1/200 mm 87. API 650 Tank tolerance? Radii measured at 0.3 m above the bottom corner Tank Diameter 12m 12m to 45m 45m to 75m Above 75m Radius Tolerance ±1/2 in ±3/4 in ±1 in ±1 ¼ in 88. PIP drawing attached for RFI? Yes or No YES 89. DEGREE calculation 0° 2m diameter of ANCHORBOLT foundation? 90. Tell about API 650 tank and usage? 91. Types of Tray testing? Leak test Tightness test Levelness Deflection 92. Write the name of five International stds? 10 | P a g e API 510-Presure vessel inspection code-In- service, alteration, Re rating API560-Rules for construction of fired heater API 530-Calculation of tube thickness of fired heater API 661-Shell and Tube heat exchanger for general refinery service API 662-Plate frame heat exchanger for general refinery service API 572-Inspection of pressure vessel ASME SEC II-Material ASME SEC VIII-Rule for construction of pressure vessel ARAMCO EQUIPMENT INTERVIEW QUESTIONS Date: 28‐11‐ϮϬϭ 1. MDMT: Minimum design metal temperature 2. High - Alloy Steels: Steels with a total alloying content more than 5%. 3. Low - Alloy Steels: Steels with a total alloying content of less than 5% but more than specified for carbon steels 4. Nominal Thickness: The value of the design thickness required to withstand all primary loads, and includes allowance for corrosion. 5. PFD: Process Flow Diagram. 6. Utility Services: Water, air and nitrogen services. 7. Equipment Davit A davit for the lifting of equipment shall be specified for vessels containing removable internals such as trays, packing and relief valves. 8. Vortex Breaker: The use of vortex breakers or guying devices in order to maintain internal stresses, due to wind-induced vibration within allowable limits, is prohibited. 9. Telltale Holes Telltale holes in reinforcing pads shall be protected with wooden plugs or packed with rust preventative grease such as Denso paste. 10. VPCI The interior surfaces of vessels, including internals, shall be protected from corrosion by use of a nontoxic vapor phase corrosion inhibitor such as COTEC VCI-309 or 307 or equivalent, (depending on the metallurgy of the vessel) applied at a rate of 0.1 kg/m³. 11. Nozzle 1|Page Atmospheric Caustic Embrittlment Hydrogen blistering Soil corrosion 103. What is galvanic corrosion'? When two different metals are electrically connected, either by direct contact or by an electrical conductor 104. What is contact corrosion (crevice corrosion)? A type of corrosion that occurs at the point of contact 105. Types of tube arrangement U tube Fixed tube Kettle arrangement 106. What is Preservation? Preservation is the activity to preserve the material, components and equipment’s from physical condition and from the climatic condition. Preservation started when the material or equipment arrived at laydown area To cover the nozzle by blind flange to prevent dust entry and cover the polythene covers where ever it is possible Nitrogen purging is required to avoid inside corrosion and maintain the pressure 5 PSI To check the pressure twice in a month Should be keep in 150mm above the ground 107. Four main parts of gasket Inner ring Outer ring Filler and Hoop 108. Steps of Preservation Transportation Storage Construction phase Commissioning phase ( From pipe tight conditions onwards ) 109. What is Gauge Ring? OD or ID of gasket the ring provide Mechanical stability, Safe guard against unraveling of windings. 110. Before Tray installation inspection 12 | P a g e Internal Cleaning Manhole face should be protect from mechanical damages Reference line and location marking to be done Ring levelness check Mockup should be done and recorded 111. after tray installation inspection Orientation and measurement to be check Check the no loose hardware’s is left Ensure that All parts are fitted properly Tray must be clean Check the down comers clearance Weir plate level and height Bolt torqueing to be check Final check before closing of man way is necessary 112. Which fluids to be sent through tubes and shell Fouling and/or corrosive fluids ( easy cleaning and cheaper to replace tubes then sheet) Hotter fluids (To reduce heat loss to the surrounding except steam, refrigerant) Cooling fluids 13 | P a g e