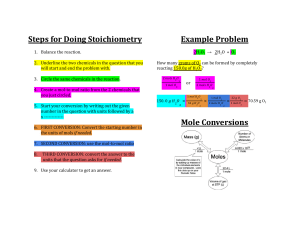

2.1 Identify the chemicals used on board the ship based on their general classification. Fuel additives, cooling towers, electric motor cleaners, biological cleaners, boiler water and evaporator chemicals, seaweed inhibitors, tank, carbon, acid, cement cleaners, cooling water and sea water chemicals are world-class products used in the required areas. Segregate chemicals by hazard class (flammable compressed gases, nonflammable compressed gases, flammable liquids, combustible liquids, flammable solids, corrosive acids, corrosive bases, oxidizers, organic peroxides, spontaneously combustible reactives, water reactives, explosives and radioactives). 2.2 Identify the chemicals used on board the ship according to degree of polymerization. Many simple hydrocarbons, such as ethylene and propylene, can be transformed into polymers by adding one monomer after another to the growing chain. Polyethylene, composed of repeating ethylene monomers, is an addition polymer. It may have as many as 10,000 monomers joined in long coiled chains What are the chemical used on board ship? Fuel additives, cooling towers, electric motor cleaners, biological cleaners, boiler water and evaporator chemicals, seaweed inhibitors, tank, carbon, acid, cement cleaners, cooling water and sea water chemicals are world-class products used in the required areas. 2.3 Explain the risks of the various chemicals used on board the s Ships that carry chemicals are also in danger of causing chemical spills that harm other people and the environment. Flammable chemicals may cause ship fires if exposed to excess heat, open flame, or electric sparks, which can injure or kill workers on board, especially when out to sea. 2.4 Explain the risks of handling refrigerants. The risks associated with the use of refrigerants in refrigeration and air-conditioning equipment can include toxicity, flammability, asphyxiation, and physical hazards. Which are the dangers to personnel when handling refrigerant gas? Contact with gas or liquefied gas may cause burns, severe injury and/or frostbite. At room temperature, most of refrigerant vapors have little or no effect on the skin or eyes. However, in liquid form, they can freeze skin or eyes on contact causing frostbite. 2.5 Explain the safety procedures in handling refrigerants. Always use with adequate ventilation. Most fatal accidents involving refrigerant are due to oxygen deprivation; Never expose refrigerants to flames, sparks or hot surfaces; Never trap liquid refrigerants between valves where there is no pressure relief device. What are the common safety practices procedure in handling the refrigeration and airconditioning system? Wear safety goggles and gloves at all times when handling refrigerants or servicing a refrigeration system. Wear the proper respiratory protection while working with refrigerants. Check the MSDS for the 2.6 Explain safety procedures in chemicals as per safety data sheet ( MSDS ) and / or best industry practices. The MSDS lists the hazardous ingredients of a product, its physical and chemical characteristics (e.g. flammability, explosive properties), its effect on human health, the chemicals with which it can adversely react, handling precautions, the types of measures that can be used to control exposure, emergency and first 2.7 Explain the mitigation procedures in handling chemicals as per MSDS and / or best industry practices Controlling Exposure 1.Change process to minimize contact with hazardous chemicals. 2.Isolate or enclose the process. 3.Use of wet methods to reduce generation of dusts or other particulates. 4.General dilution ventilation. 5.Use fume hoods.