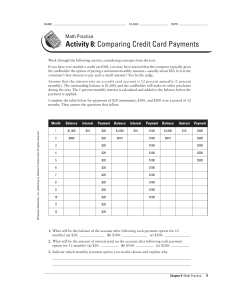

Material Requirements Planning (MRP) and ERP 14 PowerPoint presentation to accompany Heizer and Render Operations Management, Global Edition, Eleventh Edition Principles of Operations Management, Global Edition, Ninth Edition © 2014 Pearson Education 14 - 1 Outline Dependent vs. Independent Demand What is MRP? The benefits and requirements of MRP Inputs, outputs, and nature of MRP processing How to translate the requirements in a Master Production Schedule into material requirements for lower-level items (components) Lot Sizing Techniques Extensions of MRP (MRP II, ClosedLoop MRP, ERP) © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 2 Wheeled Coach Largest manufacturer of ambulances in the world 12 major ambulance designs 18,000 different inventory items 6,000 manufactured parts 12,000 purchased parts © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 3 Hierarchy of Production Decisions Long-range Capacity Planning 14 - 4 Dependent vs Independent Demand 12-5 14 - 5 Dependent Demand For any product, all components of that product are dependent demand items. Given a quantity for the product, the demand for all parts and components can be calculated. © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 6 What is MRP Material requirements planning (MRP) is a dependent demand production planning and inventory control system. MRP integrates data from production schedules (MPS) with inventory records, scheduled receipts and the bill of materials (BOM) to determine purchasing and production schedules for the components required to build a product. © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 7 Trumpet and Subassemblies 14 - 8 Bill-of-Material for Trumpet 14 - 9 MRP A computer-based information system that translates master production schedule (MPS) requirements for end items into timephased requirements for subassemblies, components, and raw materials. 12-10 14 - 10 MRP The MRP is designed to answer three questions: What is needed? How much is needed? When is it needed? © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 11 Benefits of MRP 1. Better response to customer orders 2. Faster response to market changes 3. Improved utilization of facilities and labor 4. Reduced inventory levels © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 12 Inputs to MRP MRP is a dependent demand technique that uses Bill-of-Material (BOM) On-hand inventory data Expected receipts (outstanding purchase orders) Master Production Schedule (MPS) Lead Time information to determine material requirements. 14 - 13 Overview of MRP 14 - 14 Master Production Schedule (MPS) Time-phased plan specifying how many and when the company plans to produce each end item Aggregate Plan (Product Groups) MPS (Specific End Items) 14 - 15 Master Production Schedule (MPS) MPS is established in terms of specific products The MPS is a statement of what is to be produced, not a forecast of demand Must be in accordance with the aggregate production plan Before it is executed, MPS must be tested for feasibility (Capacity Requirements Planning) © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 16 MPS Example – 1 One possible MPS… Product Month Week Tricycle Wagon Scooter Totals 41 300 300 October 42 43 44 45 300 300 300 300 300 300 300 2,400 300 November 46 47 300 300 300 300 2,400 48 49 300 250 250 300 December 50 51 250 250 250 250 52 250 250 2,000 14 - 17 MPS Example – 2 Months Aggregate Production Plan (Shows the total quantity of amplifiers) Weeks Master Production Schedule (Shows the specific type and quantity of amplifier to be produced 240-watt amplifier 150-watt amplifier 75-watt amplifier January 1,500 1 2 100 3 February 1,200 4 100 500 6 100 500 300 5 7 8 100 450 450 100 Figure 14.2 © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 18 Bills of Material (BOM) List of components, ingredients, and materials needed to make product Provides product structure Items above given level are called parents Items below given level are called children © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 19 Assembly Diagram and Product Structure Tree 12-20 14 - 20 BOM Example (Determine requirements for all components to satisfy demand for 50 Awesome Speaker Kits) Level Product structure for “Awesome” (A) 0 A E(2) 2 3 12” Speaker kit w/ C(3) Std. amp-booster B(2) Std. 12” Speaker kit 1 D(2) F(2) Std. 12” Speaker E(2) Packing box and installation kit of wire, bolts, and screws booster assembly G(1) D(2) Amp-booster 12” Speaker © 2011 Pearson Education, Inc. publishing as Prentice Hall 12” Speaker 14 - 21 BOM Example Level Product structure for “Awesome” (A) 0 A 1 2 3 D(2) Part B: 2 x number of As = (2)(50) =Std. 12” Speaker100 kit w/ BPart 12” Speaker kit C (2) Std. (3) C: 3 x number of As = (3)(50) =amp-booster 150 Part D: 2 x number of Bs + 2 x number of Fs = (2)(100) + (2)(300) = 800 E(2) 2 x number of Bs E(2) F(2) Std. 12” Speaker Part E: booster assembly + 2 x number of Cs = (2)(100) + (2)(150) = 500 Part F: 2 x Packing numberbox ofand Cs = (2)(150) = 300 kit of wire, G(1) D(2) Part G: 1installation xbolts, number of Fs = (1)(300) = 300 and screws Amp-booster 12” Speaker © 2011 Pearson Education, Inc. publishing as Prentice Hall 12” Speaker 14 - 22 Accurate Records for Outstanding Purchase Orders (Scheduled Receipts) Accurate inventory records are absolutely required for MRP (or any dependent demand system) to operate correctly Generally MRP systems require more than 99% accuracy Outstanding purchase orders must accurately reflect quantities and scheduled receipts © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 23 Lead Times The time required to purchase, produce, or assemble an item For production – the sum of the order, wait, move, setup, store, and run times For purchased items – the time between the recognition of a need and the availability of the item for production © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 24 Time-Phased Product Structure Must have D and E completed here so production can begin on B Start production of D 1 week D 2 weeks to produce B 2 weeks E A 2 weeks 1 week E 1 week 2 weeks G C 3 weeks F 1 week D | | | 1 2 3 | | 4 5 Time in weeks © 2011 Pearson Education, Inc. publishing as Prentice Hall | | | 6 7 8 Figure 14.4 14 - 25 MRP Outputs: Primary Planned orders A schedule indicating the amount and timing of future production and/or purchasing orders 14 - 26 MRP Outputs: Secondary Secondary Outputs Performance-control reports e.g., missed deliveries and stockouts Planning reports Data useful for assessing future material requirements e.g., purchase commitments Exception reports excessive scrap rates, 14 - 27 MRP Processing MRP processing takes the end item requirements specified by the master production schedule (MPS) and “explodes” them into timephased requirements for assemblies, parts, and raw materials offset by lead times 14 - 28 MRP Record Week Number 1 2 3 4 5 6 Gross Requirements Scheduled Receipts Projected on hand Net requirements Planned-orderreceipt Planned-order release Gross requirements • Total expected demand Scheduled receipts • Open orders scheduled to arrive Projected On Hand • Expected inventory on hand at the beginning of each time period 14 - 29 MRP Record Week Number 1 2 3 4 5 6 Gross Requirements Scheduled Receipts Projected on hand Net requirements Planned-orderreceipt Planned-order release Net requirements • Actual amount needed in each time period Planned-order receipts • Quantity expected to be received at the beginning of the period offset by lead time Planned-order releases • Planned amount to order in each time period 14 - 30 MRP: Processing The MRP is based on the product structure tree diagram Requirements are determined level by level, beginning with the end item and working down the tree The timing and quantity of each “parent” becomes the basis for determining the timing and quantity of the “children” items directly below it. The “children” items then become the “parent” items for the next level, and so 12-31 on 14 - 31 Example MRP Shutter Frames (2) Wood sections (4) 12-32 14 - 32 Example MRP 14 - 33 Updating the MRP System An MRP is not a static document As time passes Some orders get completed Other orders are nearing completion New orders will have been entered Existing orders will have been altered Quantity changes Delays Missed deliveries 14 - 34 Updating the System Two basic systems Regenerative system: MRP records are updated periodically Essentially a batch system that compiles all changes that occur within the time interval and periodically updates the system Net-change system: MRP records are updated continuously The production plan is modified to reflect changes as they occur 12-35 14 - 35 Safety Stock Theoretically, MRP systems should not require safety stock Variability may necessitate the strategic use of safety stock A bottleneck process or late delivery of raw materials may cause shortages in downstream operations When lead times are variable, the concept of safety time is often used Safety time: Scheduling orders for arrival or completions sufficiently ahead of their need so that the probability of shortage is eliminated or significantly reduced 12-36 14 - 36 Lot Sizing Rules Lot-for-Lot (L4L) ordering The order or run size is set equal to the demand for that period Minimizes investment in inventory It results in variable order quantities A new setup is required for each run Economic Order Quantity (EOQ) Can lead to minimum costs if usage of item is fairly uniform This may be the case for some lower-level items that are common to different ‘parents’ Periodic Order Quantity (POQ): Provides coverage for some predetermined number of periods 12-37 14 - 37 Lot-for-Lot Example Gross requirements 1 2 3 4 5 6 7 8 9 10 35 30 40 0 10 40 30 0 30 55 0 0 0 0 0 0 0 0 0 0 0 30 40 0 10 40 30 0 30 55 30 40 10 40 30 30 55 40 30 Scheduled receipts Projected on hand Net requirements 35 Planned order receipts Planned order releases 30 40 10 30 55 Holding cost = $1/week; Setup cost = $100; Lead time = 1 week © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 38 Lot-for-Lot Example Gross requirements 1 2 3 4 5 6 7 8 9 10 35 30 40 0 10 40 30 0 30 55 0 0 0 0 0 0 0 0 0 0 0 30 40 0 10 40 30 0 30 55 30 40 10 40 30 30 55 40 30 Scheduled receipts Projected on hand Net requirements 35 Planned order receipts Planned order releases 30 40 10 30 55 Holding cost = $1/week; Setup cost = $100; Lead time = 1 week © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 39 Lot-for-Lot Example No on-hand inventory is carried through the system Total holding cost1 = $0 2 3 4 5 6 7 8 9 10 Gross 30 40 this 0 10 30 0 30 There are seven 35 setups for item40in this plan requirements Total ordering cost = 7 x $100 = $700 Scheduled 55 receipts Projected on hand Net requirements 35 35 0 0 0 0 0 0 0 0 0 0 30 40 0 10 40 30 0 30 55 30 40 10 40 30 30 55 40 30 Planned order receipts Planned order releases 30 40 10 30 55 Holding cost = $1/week; Setup cost = $100; Lead time = 1 week © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 40 EOQ Lot Size Example Gross requirements 1 2 3 4 5 6 7 8 9 10 35 30 40 0 10 40 30 0 30 55 0 0 43 3 3 66 26 69 69 39 0 30 0 0 7 0 4 0 0 16 Scheduled receipts Projected on hand Net requirements 35 Planned order receipts Planned order releases 73 73 73 73 73 73 73 73 Holding cost = $1/week; Setup cost = $100; Lead time = 1 week Average weekly gross requirements = 27; EOQ = 73 units © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 41 Calculating EQO Annual demand (D): (270/10)*52=1404 Setup Cost (S)= $100 Holding Cost (H) = $1*52= $52 EOQ= 73 units © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 42 EOQ Lot Size Example Gross requirements 1 2 3 4 5 6 7 8 9 10 35 30 40 0 10 40 30 0 30 55 0 0 43 3 3 66 26 69 69 39 0 30 0 0 7 0 4 0 0 16 Scheduled receipts Projected on hand Net requirements 35 Planned order receipts Planned order releases 73 73 73 73 73 73 73 73 Holding cost = $1/week; Setup cost = $100; Lead time = 1 week Average weekly gross requirements = 27; EOQ = 73 units © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 43 EOQ Lot Size Example Total cost = setup cost + holding cost Total Cost = D/Q x S + Q/2 x H Total cost = (1,404/73) x $100 + (73/2) x ($1 x 52 weeks)=$3,798 Cost for 10 weeks = $3,798 x (10 weeks/52 weeks) = $730 OR Total Cost = 4*100 + 375(including 57 units for week 11) = $775 © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 44 Periodic Order Quantity The EOQ attempts to minimize the total cost of ordering and carrying inventory and is based on the assumption that demand is uniform. Often demand is not uniform, particularly in material requirements planning, and using the EOQ does not produce a minimum cost. The period-order quantity lot-size rule is based on the same theory as the economic-order quantity. It uses the EOQ formula to calculate an economic time between orders. This is calculated by dividing the EOQ by the demand rate. © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 45 Periodic Order Quantity • Periodic order quantity (POQ) method sets: • the size of each production lot equal to the requirements for a fixed number of periods • Interval (period) = EOQ / average demand per period • Order quantity is set to cover the interval 14 - 46 POQ Lot Size Example WEEK Gross requirements 1 2 3 4 5 6 7 8 9 10 35 30 40 0 10 40 30 0 30 55 0 0 40 0 0 70 30 0 0 55 0 30 0 0 10 0 0 30 0 85 0 Scheduled receipts Projected on hand Net requirements 35 Planned order receipts Planned order releases 70 70 80 80 0 85 EOQ = 73 units; Average weekly gross requirements = 27; POQ interval = 73/27 ≅ 3 weeks 14 - 47 POQ Lot Size Example Setups = 3 x $100 = $300 Holding cost = (40 + 70 + 30 + 55) units x $1 = $195 Total cost = $300 + $195 = $495 © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 48 Lot-Sizing Summary For these three examples Lot-for-lot EOQ POQ © 2011 Pearson Education, Inc. publishing as Prentice Hall $700 $730 $495 14 - 49 BOM Example (Determine requirements for all components to satisfy demand for 50 Awesome Speaker Kits) Level Product structure for “Awesome” (A) 0 A E(2) 2 3 12” Speaker kit w/ C(3) Std. amp-booster B(2) Std. 12” Speaker kit 1 D(2) F(2) Std. 12” Speaker E(2) Packing box and installation kit of wire, bolts, and screws booster assembly G(1) D(2) Amp-booster 12” Speaker © 2011 Pearson Education, Inc. publishing as Prentice Hall 12” Speaker 14 - 50 Awesome Speaker Kits © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 51 Awesome Speaker Kits © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 52 Gross Requirements Plan (Note that components with multiple parents are only processed once, see component E) Week 1 A. B. C. E. F. D. G. 2 3 4 5 6 Required date Order release date 8 Lead Time 50 50 Required date Order release date 1 week 100 100 Required date Order release date 2 weeks 150 150 Required date Order release date 200 200 Required date Order release date 1 week 300 300 2 weeks 300 300 Required date Order release date Required date Order release date 7 3 weeks 600 600 200 200 1 week 300 300 2 weeks Table 14.3 © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 53 Determining Gross Requirements Starts with a production schedule for the end item – 50 units of Item A in week 8 Using the lead time for the item, determine the week in which the order should be released – a 1 week lead time means the order for 50 units should be released in week 7 This step is often called “lead time offset” or “time phasing” © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 54 Determining Gross Requirements From the BOM, every Item A requires 2 Item Bs – 100 Item Bs are required in week 7 to satisfy the order release for Item A The lead time for the Item B is 2 weeks – release an order for 100 units of Item B in week 5 The timing and quantity for component requirements are determined by the order release of the parent(s) © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 55 Determining Gross Requirements The process continues through the entire BOM one level at a time – often called “explosion” By processing the BOM by level, items with multiple parents are only processed once, saving time and resources and reducing confusion Low-level coding ensures that each item appears at only one level in the BOM © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 56 Net Requirements Plan The logic of net requirements Gross Allocations requirements + Total requirements – On Scheduled hand + receipts Net = requirements Available inventory © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 57 Allocations Allocated items refer to the number of units in inventory that have been assigned to specific future production but not yet used or issued from the stock room. The following slide illustrates how allocated items increase gross requirements 14 - 58 Awesome Speaker Kits © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 59 Awesome Speaker Kits © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 60 Net Requirements Plan (Awesome Speaker Kits) © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 61 Net Requirements Plan © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 62 Determining Net Requirements Starts with a production schedule for the end item – 50 units of Item A in week 8 Because there are 10 Item As on hand, only 40 are actually required – (net requirement) = (gross requirement - onhand inventory) The planned order receipt for Item A in week 8 is 40 units – 40 = 50 - 10 © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 63 Determining Net Requirements Following the lead time offset procedure, the planned order release for Item A is now 40 units in week 7 The gross requirement for Item B is now 80 units in week 7 There are 15 units of Item B on hand, so the net requirement is 65 units in week 7 A planned order receipt of 65 units in week 7 generates a planned order release of 65 units in week 5 © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 64 Determining Net Requirements A planned order receipt of 65 units in week 7 generates a planned order release of 65 units in week 5 The on-hand inventory record for Item B is updated to reflect the use of the 15 items in inventory and shows no on-hand inventory in week 8 This is referred to as the Gross-to-Net calculation and is the third basic function of the MRP process © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 65 MRP Evolution MRP Schedule Materials Closed Loop MRP Schedule Materials Incorporate Feedback MRP II Schedule & Purchase Materials Coordinate w/ Mfg Resources ERP 14 - 66 Closed-Loop MRP Production Planning Master Production Scheduling Material Requirements Planning Capacity Requirements Planning No Feedback Realistic? Feedback Yes Execute: Capacity Plans Material Plans 14 - 67 Manufacturing Resource Planning (MRP II) Goal: Plan and monitor all resources of a manufacturing firm (closed loop): manufacturing marketing finance engineering Simulate the manufacturing system 14 - 68 Enterprise Resource Planning (ERP) A computer system that integrates application programs in accounting, sales, manufacturing, and other functions in the firm This integration is accomplished through a common database shared by all the application programs Produces information in real time and ties in customers and suppliers 14 - 69 Typical ERP System 14 - 70 Enterprise Resource Planning (ERP) ERP modules include Basic MRP Finance Human resources Supply chain management (SCM) Customer relationship management (CRM) © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 71 Risks Associated with ERP Implementation High Cost and Cost Overruns Common areas with high costs: Training Testing and Integration Database Conversion Disruptions to Operations ERP is reengineering--expect major changes in how business is done 72 14 - 72 ERP Products SAP: largest ERP vendor modules can be integrated or used alone J.D. Edwards flexibility: users can change features; less of a pre-set structure than SAP’s 73 14 - 73 ERP Products Oracle tailored to e-business focus PeopleSoft open, modular architecture allows rapid integration with existing systems Baan use of “best-of-class” applications 74 14 - 74 Leading ERP Vendors Worldwide SAP Oracle PeopleSoft Sage J.D.Edwards Lawson Microsoft Dynamics AX Great Plains/Solomon Invensys (BaaN) IFS © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 75 Advantages of ERP Systems 1. Provides integration of the supply chain, production, and administration 2. Creates commonality of databases 3. Improves information quality 4. May provide a strategic advantage © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 76 ERP Drawbacks 1. Very expensive to purchase and even more so to customize 2. Implementation may require major changes- Resistance to change 3. So complex that many companies cannot adjust to it 4. Involves an ongoing, possibly never completed, process for implementation 5. Training is an on-going activity © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 77 ERP in the Service Sector ERP systems have been developed for health care, government, retail stores, hotels, and financial services Also called efficient consumer response (ECR) systems Objective is to tie sales to buying, inventory, logistics, and production © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 78 Distribution Resource Planning (DRP) Using dependent demand techniques through the supply chain Expected demand or sales forecasts become gross requirements Minimum levels of inventory to meet customer service levels Accurate lead times Definition of the distribution structure © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 79 #3 in the 10th edition;(#3) in the 11th edition © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 80 #5 in the 10th edition;(#5) in the 11th edition © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 81 #10 in the 10th edition;(#10) in the 11th edition © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 82 #10 in the 10th edition;(#10) in the 11th edition © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 83 #10 in the 10th edition;(#10) in the 11th edition © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 84 17-18-19 in 10th and in 11th editions © 2011 Pearson Education, Inc. publishing as Prentice Hall 14 - 85