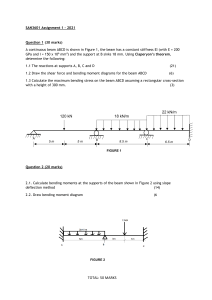

BENDING STRESS IN A BEAM INSTRUCTION MANUAL Email:- finitetechno@gmail.com BENDING STRESS IN A BEAM Aim Aim of this experiment is to study the effect of force of different magnitude on the bending stress in beam. Theory Bending of beam When an external load or the structure load applied in a beam is large enough to displace the beam form its present place, then that deflection of beam forms its resent axis is called bending stress of a beam. Bending stresses The applied force which produce bending moment in a beam also produces stresses in a beam these stresses are called as bending stresses. The cross-section of a structural element affects its stiffness. The elements of a thicker cross section resist the bending, better than those of a thinner cross section. However, the direction of the applied force is important. For example - a rectangular cross-section beam is thick in one plane, but thin in the other. So it will resist bending in one plane much better than in the other. This cross-sectional property in the direction of the force is known as the second moment of area (I). 𝑏𝑑 3 𝐼𝑥𝑥 = 12 As the upper part of the beam becomes compressed by the load, the lower part becomes stretched by the load (tension). At some point in the beam cross-section, the compressive and tensile forces are at equilibrium. This is the neutral axis defined as the axis in the cross section where there are no longitudinal stresses or strains. The neutral axis of a simple beam lies at mid-point through its cross-section, so y = d/2. Note: This is the position of the elastic neutral axis, while the beam is stressed in its elastic region. As a shape becomes stressed into its plastic region, the neutral axis moves to the plastic neutral axis. As with the elastic neutral axis, the crosssectional shape determines the position. However, for the rectangular crosssection, the elastic and plastic neutral axis remain in the same position. Description of Bending Stress in a Beam A standalone experiment for determining the bending stresses and strains across the surface of a T-beam. An inverted aluminium T-beam is mounted between two simple extrusion channel supports. The load onto the T-beam is applied using a fine screw mechanism with S-type load cell. The load cell arrangement and supports create point loading. A number of precision strain gauges are arranged on the T-beam specimen. The strain gauges connect to a strain gauge amplifier, which connects (with the load cell) to the USB interface hub of the Structures platform for computer display and data acquisition. BENDING STRESS IN A BEAM APPARATUS Experimental Capabilities of Bending Stress in a Beam 1. 2. 3. 4. 5. 6. 7. Bending Stresses across a T-Beam section Comparison of theory with experimental results Working with Strain gauges Bending equation Neutral axis Working with stresses and strains and their conversion Second Moment of Area Specification of Bending Stress in a Beam 1. 2. 3. 4. 5. T-Beam to have strain gauges attached in measuring Load cell to apply load with integral cable for connection to Interface Strain gauge outputs to be made available to Interface by amplifier Must be used with universal Frame and Stand Must be used with Interface Experiment This experiment is about to studying the effect of force of different magnitude on the bending stresses in a beam. To perform this experiment a structure hardware (BENDING STRESS IN A BEAM) will be used. A T shape beam is used in this experiment which has been supported on the frame with the help of two rectangular channel.in this experiment load is applied with the help of special mechanism attached to the apparatus (S type load cell). There are strain gauges attached to the beam at different locations and these strain gauges are used to collect the data of stress produce in a beam. Bending stress are produce in a beam when an external force is applied on the beam and produce deflection in a beam. Bending stresses main depends on the shape of beam, length of beam and magnitude of the force applied on the beam. In order to calculate the bending stresses in the beam following formula can be used Moment (M) and stress (σ) relationship 𝑴 𝛔 𝑬 = = 𝑰 𝒚 𝑹 Here, E is the young modulus M is the bending moment I is the second moment of inertia of beam. σ is the bending stress (Nm) ε is the bending Strain Y is the distance from the neutral axis PROCEDURE The apparatus involve in this experiment use an electronic system intrigued with software and calculate the bending moment. Due to which it is very important to follow the steps involve in this experiment in following presented order The strain gauges connect to a strain gauge amplifier, which connects (with the load cell) to the USB interface hub of the Structures platform for computer display and data acquisition. 1. Set the T-beam aluminium channel on the base frame and connect all the connecting wire to the channel as per the numbering is mentioned on the connecting wires all well as with the amplifier. 2. Adjust the distance as 800 mm from one end to the other end of the supported ends. 3. This distance is 800 mm because when we apply load to the beam then it will produce stress in middle of the T- channel. 4. As the load is applied then it will show the strain reading on the display because the gauges are at their desired positions. 5. Connect the connecter wire 1, 2, 3 with display panel on the back side of the panel with the amplifier 1, 2, 3 respectively. 6. Connect the supply cable for amplifier and display panel with the main supply and make sure that it’s in off position before starting the experiment. After all connection then switch on the supply button for starting the experiment. And all the values are displaying the display for bending stress in a beam. 7. Measure and record all necessary dimensions of the T-beam, load and support points, and the location of all the strain gauges with respect to the bottom of the beam. Do not remove the beam from the test fixture as the strain gauges are easily damaged. 8. Calculate the location of the centroid theoretically and the moment of inertia of the cross sectional area with respect to the neutral axis. 9. Calculate the maximum load P that can be applied to the beam given an allowable bending stress. 10.Calculate the bending stress at each position for a load P = 0 or for another load. Calculate the corresponding strain, which will allow you to check the experimental result you measure later. 11.Connect the power supplies to the Display and the Strain values will Display on the screen. Make sure they are “on”. Leave the system for 1 minutes to warm up and reach a steady state. 12.Read the initial strain values and, if necessary, adjust the Load Adjust Screw to make sure the strain values are in the range of 1000 . Then, turn the small black knob on the Load Cell to adjust the load reading to zero or press the tare on the display on the panel. 13.Record the strain values for each gauge for P = 0 load case. Then, use the Load Adjust Screw to increase the load, recording the strain values in each gauge for 100, 200, 300, 400 N loads. Do NOT exceed 400 N. 14.The strain data you recorded for the four load cases must be adjusted or calibrated. 15.Check the theoretical strain value you calculated in section with the experimental value to see if your measurement is reasonable. DATA:- TABLE 1 : BEAM SPECIFICATIONS Position of Neutral Axis, y (mm) 13.02 mm Second Moment of Inertia, I (mm4) 34614 mm 4 Length of the Beam, L (mm) 800 mm Modulus of Elasticity, E (Gpa) 69 x 109 Pa (GPa) Allowable Stress, σ (MPa) FIQURE: MOMENT DIAGRAM AND SYSTEMATIC VIEW TABLE 2: STRAIN GAUGE LOCATIONS Gauge No. 8,9 Position of Gauge (mm) From Bottom of Beam 0 mm 1,7 4 mm 2,6 15.5 mm 3,5 38.5 mm 4 50 mm TABLE 3: CALCULATED STRESS AND STRAIN FOR 100 N LOAD CASE Gauge No. Bending Stress (MPa) Strain (µ) 8,9 1,7 2,6 3,5 4 TABLE 4: RECORDED STRAIN VALUES Load (N) Gauge No. 0 100 200 300 400 1 2 3 4 5 6 7 8 9 TABLE 5: AVERAGE STRAIN DATA Gauge No. 8,9 Gauge Position (mm) 0 1,7 4 2,6 15.5 3,5 38.5 4 50 Bending Moment (N·m) 500 Calculations: According to the equation shown above for calculating bending stresses and strain, there are certain quantities like area of cross section of beam sections and second moment of inertia of beam needed to be known. Following are the equation which will be used for solving these quantities. 1. For bending moment M=PxA P =W/2 A = distance from the loading point 2. For calculating the centroid: y̅ = (A1. Y1 x A2. Y2) / (A1 + A2) Here, A1 = b1.h1 = __________ mm2 A2 = b2.h2 = ___________ mm2 Y1 = h2 x h1/2 = __________ mm Y2 = h2 / 2 =__________ mm 3. Second moment of inertia IXX = A. h2 + 𝒃𝒅𝟑 𝟏𝟐 = _________ mm4 (Area) × (y̅ -y2)2 + (bd^3)/12 4. Bending stress theortical M/I × σ/y = ___________ (Nm) 5. Bending stress experimental E = σ/ε = ____________ (Nm) Procedure for data acquisition. 1. Start the data acquisition software. For starting this software you have to connect the USB wire with the CPU then other end with back side of the display panel of bending stress apparatus for connection with software. Then open the software in the computer and you will see the preface as shown above in screenshot view. 2. Then click on the resource & then select the COM. 3. All dimensions of the beam are inbuilt in the structures software, which will automatically calculate the second moment of area (I) and the theoretical position of the neutral axis (y). 4. Check that there is not load is applied on the T beam (if some reading is showing on the display then zero the load cell reading by click on the tare on the display panel and you will see there is no reading will be shown after pressing it and readings will get zero of all strains gauges and also load in structures software. 5. Now apply the load from the knob screw mechanism Carefully wind the load cell down, until the load cell create some tension in the beam and the load cell just begins to read between 1N and 2 N (effectively zero). 6. Now apply some more load from the knob screw mechanism and you will get the load value in the load box and bending moment reading in respective box and all the 9 strain gauge readings in their respective box. 7. As same from the above process you will get the gauges readings and load, bending moment for other loads. (Take an initial reading (zero load and zero strain guage) and then carefully increase the load to achieve a readings for 50 N or 100 N.) 8. Allow the load reading to settle, then this load reading and bending moment is automatically calculated and also this strain gauges reading 9. After getting the reading or to get data to be record (click on the record data you will get recorded data of every load at all distance where the strains gauges are placed in the table form and also be recorded in the excel form by clicking on the export to CSV. 10.Carefully release the load back to zero. 11.Unplug all the connection wires of gauges and amplifier and also main supply wires.