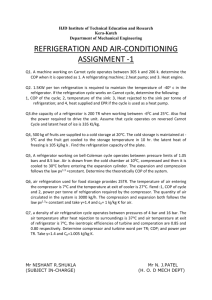

Ejector-Expansion Refrigeration & Heat Pump Systems Review

advertisement