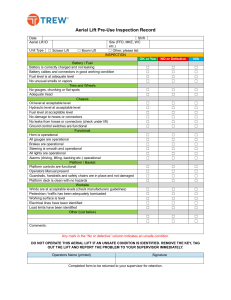

AERIAL LIFT PRE-USE INSPECTION FORM Inspector Name Aerial Lift Desc/ID# Unit Type (Scissor, Articulating Boom, Man Lift, Other) Date STARTING HOURS Jobsite/P# # ENDING HOURS Signed 2 3 4 Inspection Item and Description Operating and emergency controls are in proper working condition, EMO button or Emergency Stop Device Functional upper driver control interlock (i.e. foot pedal, spring lock, or two hand controls) Emergency Lowering function operates properly Lower operating controls successfully override the upper controls 5 6 7 8 9 10 Both upper and lower controls are adequately protected from inadvertent operation Control panel is clean & all buttons/switches are clearly visible (no paint overspray, etc.) All switch & mechanical guards are in good condition and properly installed All safety indicator lights work Drive controls function properly & accurately labeled (up, down, right, left, forward, reverse) Motion alarms are functional 11 12 13 Safety decals are in place and readable All guard rails are sound and in place, including basket chains Work platform & extension slides are clean, dry, & clear of debris Work platform extension slides in and out freely, and has safety locking pins in place to lock setting on models with extension platforms Inspect for defects such as cracked welds, fuel leaks, hydraulic leaks, damaged control cables or wire harness, etc. Tires and wheels are in good condition, with proper air pressure for pneumatic tires Braking devices are operating properly 1 14 15 16 17 18 19 20 21 P | F | N/A The proper operater’s manual is stored on machine Oil, hydraulic fluid, coolant, and fuel levels are all to proper fill Battery is charged Outriggers in place or functioning. Associated alarms operate properly Other Safety Precautions Check to Confirm Personal Protective Equipment in use Know manufacturer’s guidelines for operating in windy conditions. If manufacturer’s guidelines unknown or not available, do not operate in wind above 20 MPH or if lift begins to rock Be aware of ground or floor surface conditions within entire operating area. Holes, obstructions, uneven terrain, etc. General Housekeeping: Debris, cords and hoses, materials and supplies Electrical power cables or panels at a minimum of 10 foot distance from working area. Use proper lockout/tagout procedures as necessary Overhead obstructions Know and adhere to working load limit Use appropriate barriers/tape to secure area from vehicular and pedestrian traffic IF THE AERIAL LIFT FAILS ANY PART OF THIS INSPECTION, REMOVE THE KEY AND REPORT THE PROBLEM TO YOUR SUPERVISOR. DO NOT ATTEMPT TO MAKE REPAIRS UNLESS YOU ARE A TRAINED AND AUTHORIZED SERVICE PERSON. ALL SERVICE MUST BE DOCUMENTED. FULLY INSPECT ALL RENTAL MACHINES UPON DELIVERY OR PRIOR TO INITIAL USE.