Name

UCID

:

:

Udish Doorganah

30162199

Lab section

: B06

LAB 4 REPORT

BENDING

Objectives:

The objective of this lab is to study how the buckling load of simple columns depend on specimen

length and method of support. Moreover to prove Euler’s theory by comparing experimental values

and theoretical values and to determine maximum bucking force for different materials.

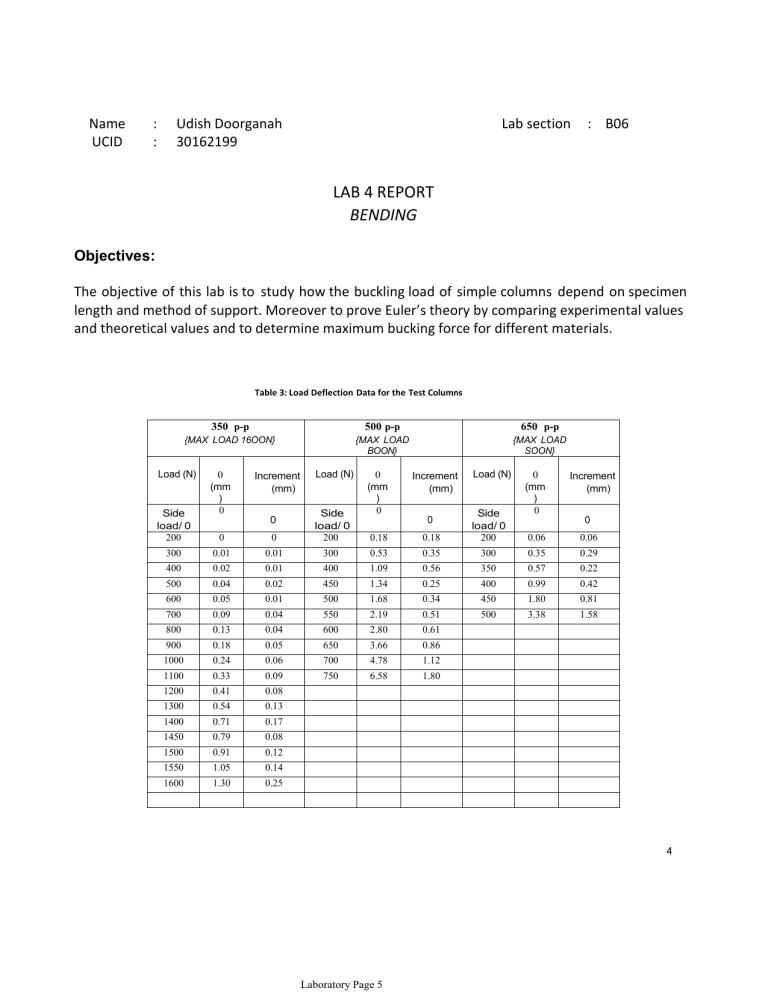

Table 3: Load Deflection Data for the Test Columns

350 p-p

500 p-p

650 p-p

{MAX LOAD 16OON}

{MAX LOAD

BOON}

{MAX LOAD

SOON}

Load (N)

Side

load/ 0

200

0

(mm

)

0

Increment

(mm)

Load (N)

0

0

Side

load/ 0

200

300

400

0.01

0.02

0.01

0.01

500

0.04

600

0.05

700

800

0

(mm

)

0

Increment

(mm)

Load (N)

0.18

0.18

Side

load/ 0

200

300

400

0.53

1.09

0.35

0.56

0.02

450

1.34

0.01

500

1.68

0.09

0.13

0.04

0.04

550

600

0

0

0

(mm

)

0

Increment

(mm)

0

0.06

0.06

300

350

0.35

0.57

0.29

0.22

0.25

400

0.99

0.42

0.34

450

1.80

0.81

2.19

2.80

0.51

0.61

500

3.38

1.58

900

0.18

0.05

650

3.66

0.86

1000

0.24

0.06

700

4.78

1.12

1100

0.33

0.09

750

6.58

1.80

1200

1300

0.41

0.54

0.08

0.13

1400

1450

0.71

0.79

0.17

0.08

1500

1550

0.91

1.05

0.12

0.14

1600

1.30

0.25

4

Laboratory Page 5

650 f-p

{MAX LOAD 1000N}

650 f-f

{MAX LOAD 1800N}

Table 3 Continued:

200

0.18

0.18

Load (N)

Side load/

O

200

300

0.39

0.21

400

0.72

0.33

500

1.21

600

1.74

650

700

Load (N)

Side load/ O

o(mm)

0

Increment (mm)

0

o(mm)

0

Increment (mm)

0

0.05

0.05

300

0.13

0.08

400

0.23

0.10

0.49

500

0.39

0.16

0.53

600

0.52

0.13

2.35

0.61

700

0.71

0.19

2.78

0.43

800

1.0

0.29

750

3.59

0.81

900

1.27

0.27

800

4.73

1.14

1000

1.59

0.32

850

6.09

1.36

1100

2.04

0.45

900

9.38

3.29

1200

2.52

0.48

1300

3.45

0.93

1350

4.04

0.59

1400

4.56

0.52

1450

4.98

0.42

1500

5.67

0.69

1550

6.41

0.74

1600

7.69

1.28

ANALYSIS OF RESULTS

4

Laboratory Page 5

The red point on the graph identify the point at which the relationship becomes clearly

nonlinear as the experimental critical buckling load

Column Identifier

cross-sectional area

of the columns(m^2)

critical buckling load

critical buckling divided by the crosssectional area of the

load(L)

columns

350 p-p

8E-5

1600N

20E6

500 p-p

8E-5

800N

10E6

650 p-p

8E-5

5OON

6.25E6

650 f-p

8E-5

1000N

12.5E6

650 f-f

8E-5

1800N

22.5E6

4

Laboratory Page 5

Sample Calculation for 350 p-p at l=800N

Where:

𝑃𝑐𝑟 = 𝜋 2 (210𝑥109 )((0.02𝑋(0.004^3))/12)/(0.352 )

Pcr =1804 N

Column identifier

Pcr(N)( Experimental)

critical buckling load(L)(given) Percentage difference%

350 p-p

1804

1600

12.75

500 p-p

884

800

10.5

650 p-p

523

500

4.60

650 f-p

1068

1000

6.80

650 f-f

2093

1800

16.27

As percentage difference for all Columns is less than 20 percent

the values are valid.

Errors

there was systematic error in the experiment for the fixed-fixed

pin. The clamping restraint did not tighten completely as some of

thread had been stripped due to wear.This prevented the strut

from being held securely and may have given it some lateral

freedom, possibly accounting for the experimental buckling load

being so far below from the theoretical.

Other systematic error included the precision of the magnetic

ruler, which measured to the nearest millimetre. This gives an

uncertainty of ‡0.5mm in the readings..

The measurements from the magnetic ruler also had to be read by

eye and, of course there may have been some error in this reading

Laboratory Page 5

4

4

Laboratory Page 5