Things to know about the 3D laser picture engraving process

advertisement

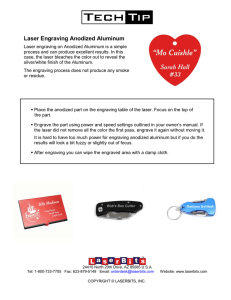

Things to know about the 3D laser picture engraving process Three-dimensional laser engraving is one of the popular techniques that helps to create high-quality 3D designs, images, and logos with perfection. Unlike traditional 2D picture engraving, the 3D laser picture engraving process takes more time but it delivers highly impressive results that you never expect. This process is effective, proficient, and ideal for making complex designs. In this blog, we are going to focus on the materials used in 3d laser picture engraving & its major benefits. What types of material are used in 3D laser engraving? 3D laser engraving is ideal for all kinds of materials. However, the stone is not the best choice for an engraving project. Here are some materials that are mostly used for threedimensional engraving applications: Hardwood: No doubt, hardwood is a very important material for 3D laser engraving. Common hardwood species such as cherry, maple, birch, & walnut are good for engraving as they come with an excellent grain structure. Medium-density fiberboard or MDF: Medium-density fiberboard is another popular material for 3D laser engraving. This material is less-inexpensive, soft & widely available. Once the laser engraving process is over, you can also clean the whole surface using a damp cloth or an air hose. Acrylic: Last but not the least, acrylic is also widely used in several 3D laser engraving projects. In comparison to wood, this material is quite harder & comes with a high melting point. Through acrylic material, premium quality 3D images can be designed perfectly. Why did you choose 3D laser engraving? If you go for three-dimensional laser engraving, you will definitely expect endless possibilities. It mainly offers several advantages & brings a new path for both small-scale and home-based businesses. 4 major perks of 3D laser engraving include: 1. Highly flexible One of the important perks of this process is that it provides very smooth engravings on nonflat & rough surfaces like conical shapes, round shapes, convex or concave portions, cylindrical shapes, triangular shapes, sloped surfaces, and more. Moreover, the heavy-duty laser engraving machine engraves objects seamlessly at different heights. Apart from that, the beam position and laser focal length can be easily adjusted through this machine. No doubt, this 3D engraving process offers higher flexibility as compared to 2D systems. 2. High marking value The heavy-duty 3D laser engraving machine comes with a number of features and functionalities. In comparison to traditional 2D engravers, 3D engraving machines are compact, powerful, and designed with high production capacity. According to professionals, 3D laser engraving machines employ an optical mode that offers lens deflection. These machines are also suitable for enhancing the marking effect integrity as well as high focus accuracy. 3. Ideal for deep engraving: With the 2D engraving process, engraving on a non-flat surface is difficult. Fortunately, 3D laser engraving solves this problem as it makes the non-flat surface engraving process very easier. This is one of the obvious choices for deep and accurate engraving applications. Moreover, it also supports multi-color engraving. Final words The three-dimensional laser engraving brings a perfect way to make high-quality custom 3D gifts, images, and photos. If you would like to get personalized 3D laser picture engraving products, contact Sweden Crystal Design today. With years of industry experience and skills, Sweden Crystal Design has been manufacturing high-quality 3D glasswork, photo crystal gifts, & customized office & home decor. As the most promising handmade glasswork supplier, they assure guaranteed products at a very reasonable price and build a good reputation by offering the finest craftsmanship to their customers. What are you waiting for? Visit their website to know more.