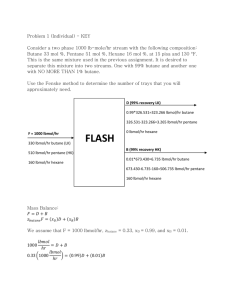

Mass balance in a fixed bed reactor is similar to that of a plugflow reactor (eq. 1.1): dX rA dV FA 0 (1.1) Recalling dW = B dV, then dX rA dW B FA 0 (2.1) For a reaction: A + bB cC + dD Species A B C D I TOTAL EFFLUENT Feed Rate Change within Reactor – FA0 X – b FA0 X c FA0 X d FA0 X Effluent Rate FA0 = FA0 FA = FA0 (1 – X) FB0 = B FA0 FB = FA0 (B – bX) FC0 = C FA0 FC = FA0 (C + cX) FD0 = D FA0 FD = FA0 (D + dX) FI0 = I FA0 FI = FI0 I FT = FT0 + (d + c – b – 1) FA0 X = FT0 + FA0 X For the above reaction, (1 + b) mol of reactants give (c + d) mol of product. In flow systems where this type of reaction occurs, the molar flow rate will be changing as the reaction progresses. Because only equal numbers of moles occupy equal volumes in the gas phase at the same temperature and pressure, the volumetric flow rate will also change. Assuming ideal gas behavior: PV P0 V0 NTRT NT 0RT0 P0 T NT V0 V P T0 NT 0 (2.2) Recalling the last row in the previous table: NT NT 0 NA 0 X FT = FT0 + FA0 X NT NT 0 NA 0 X 1 y A0X NT 0 NT 0 The above equation is further simplified by letting: change in total number of moles for complete conversion total number of moles fed to the reactor NA 0 d c b 1 y A0 NT 0 (2.3) Equation (2.2) now becomes: P0 T V 1 X V0 P T0 (2.4) Kalau reaksinya berlangsung sempurna (X = 1): NT * NT 0 NA 0 X NT 0 NA 0 Perubahan jumlah mol kalau reaksinya berlangsung sempurna (X = 1): NT * NT 0 NT 0 NA 0 NT 0 NA 0 d c b 1NA 0 d c b 1NA 0 NT 0 y A0 To derive the concentrations of the species in terms of conversion for a variable-volume flow system, we shall use the relationships for the total concentration. The total concentration at any point in the reactor is FT NT P CT v V RT (2.5) At the entrance of the reactor: FT 0 NT 0 P0 CT0 v 0 V0 RT0 (2.6) Taking the ratio of eq. (2.6) to eq. (2.5), we have upon rearrangement P0 T FT v v 0 P T0 FT 0 (2.7) From the above table: FT FT 0 FA 0 X (2.8) Substituting eq. (2.8) in eq. (2.7): P0 T FT 0 FA 0 X P0 T FA 0 v 0 1 X v v 0 FT 0 FT 0 P T0 P T0 P0 T FA 0 P0 T v v 0 1 X v 0 1 y A 0 X FT 0 P T0 P T0 P0 T v v 0 1 X P T0 (2.9) We can now express the concentration of species j for a flow system in terms of conversion: Fj Cj v Fj FT 0 Fj P T0 FT P0 T v 0 FT P0 T v0 FT 0 P T0 Fj P T0 C j C T 0 FT P0 T (2.10) Substituting F and FT in terms of conversion in eq. (2.10) yields FA 0 j jX P T0 C j CT0 FT 0 FA 0 X P0 T FA 0 j jX P T0 C T 0 FT 0 1 FA 0 FT 0 X P0 T j jX P T0 CT0 y A0 1 y A 0 X P0 T j jX P T0 Cj CA0 1 X P0 T (2.11) Energy balance in a fixed bed reactor is similar to that of a plug-flow reactor (eq. 1.56): dT Ua Ta T rA HRx T dV FA 0 X Cp iCpi (1.56) Recalling dW = B dV, then dT Ua Ta T rA HRx T dW B FA 0 X Cp iCpi (2.12) The majority of gas-phase reactions are catalyzed by passing the reactant through a packed bed of catalyst particles. We now must determine the ratio P/P0 as a function of volume V or the catalyst weight, W, to account for pressure drop. We then can combine the concentration, rate law, and design equation. However, whenever accounting for the effects of pressure drop, the differential form of the mole balance (design equation) must be used. The equation used most to calculate pressure drop in a packed porous bed is the Ergun equation: dP G 1 150 1 1.75G 3 dz g c Dp Dp (2.13) Where P : pressure, lb/ft2 : porosity (volume of void / total bed volume) Dp : diameter of particle in the bed, ft : viscosity of gas passing through the bed, lbm/ft h z : length down the packed bed of pipe, ft u : superficial velocity = volumetric flow : cross sectional area of pipe, ft/h : gas density, lb/ft3 G : u = superficial mass velocity, (g/cm2 s) or (lbm/ft2 h) In calculating the pressure drop using the Ergun equation, the only parameter that varies with pressure on the right-hand side of eq. (2.13) is the gas density, . We are now going to calculate the pressure drop through the bed. Because the reactor is operated at steady state, the mass (kg/s), is equal flow rate at any point down the reactor, m 0 (i.e., equation of to the entering mass flow rate, m continuity), 0 m m 0 v 0 v Recalling eq. (2.9), we have P0 T v v 0 1 X P T0 (2.9) P T0 1 v0 0 0 v P0 T 1 X (2.14) Combining eqs. (2.13) and (2.14) gives: P0 T G1 150 1 dP 1.75G 1 X 3 dz 0 g c Dp Dp P T0 Simplifying yields: dP P0 T 0 1 X dz P T0 (2.15) where: G1 150 1 0 1.75G 3 0 g c Dp Dp (2.16) For tubular packed-bed reactors we are more interested in catalyst weight rather than the distance z down the reactor. The catalyst weight up to a distance of z down the reactor is: weight of volume of density of catalyst solids solid catalyst W 1 A c z C (2.17) where Ac is the cross-sectional area. The bulk density of the catalyst, B (mass of catalyst per volume of reactor bed), is just the product of the solid density, C , the fraction of solids, (1 – ) : B C 1 (2.18) Using the relationship between z and W [eq. (2.17)] we can change our equation (2.15) into: dP P0 T 0 1 X dz P T0 dP 0 P0 T 1 X dW A c 1 C P T0 (2.15) (2.19) Further simplification yields: dP P0 T 1 X dW 2 P P0 T0 (2.20) where: 2 0 A c C 1 P0 (2.21) We note that: when is negative, the pressure drop P will be less than that for = 0. When is positive, the pressure drop P will be greater than when = 0. dX rA dW B FA 0 rA r' A B (2.1) dT Ua Ta T rA HRx T dW B FA 0 X Cp iCpi (2.12) dP P0 T 1 X dW 2 P P0 T0 (2.20) EXAMPLE 2.1 Calculate the pressure drop in a 60 ft length of 1 1/2-in. schedule 40 pipe packed with catalyst pellets 1/4-in. in diameter when 104.4 lb/h of gas is passing through the bed. The temperature is constant along the length of pipe at 260°C. The void fraction is 45% and the properties of the gas are similar those of air at this temperature. The entering pressure is 10 atm. SOLUTION dP P0 T 1 X dW 2 P P0 T0 T T0 0 P02 dP P0 dW 2 P P0 2P 2P dP dW 2 P0 W 2 P PdP dW 2 P0 P 0 0 1 2P 2 P P W P0 P2 1 W 2 P0 2 P 1 W P0 0 1 2 2 2 P P0 W P0 P 12 1 W P0 P 1 W 1 2 P0 2 0 A c C 1 P0 W 1 A c z C P 2 0 z 1 P0 P0 12 2 0 1 A C z C W A c C 1 P0 2 0 z W P0 2 0 A c C 1 P0 G1 0 0 g c Dp 3 150 1 1.75G Dp For 1½-in. schedule 40 pipe, A = 0.01414 ft2 104.4 lbm h lbm G 7383.3 2 0.0141 ft h. ft2 For air at 260C and 10 atm: = 0.0673 lbm/ft.h 0 = 0.413 lbm/ft3 Dp = ¼ in = 0.0208 ft lbm . ft g c 4.17 10 lb f .h2 8 7383.3 1 0.45 0 8 3 0.413 4.17 10 0.0208 0.45 150 1 0.45 0.0673 1.757383.3 0.0208 1 atm lb f 1 ft2 164.1 3 2 ft 144 in 14.7 lb f in2 atm kPa 0.0775 25.8 ft m P 2 0 z 1 P0 P0 12 1 P 0.265P0 2.65 atm P P0 P 7.35 atm 12 2 0.0775 60 10 0.265 EXAMPLE 2.2 Ethylene oxide is made by the vapor-phase catalytic oxidation of ethylene with air: O C2H4 + ½ O2 CH2 CH2 We want to calculate the catalyst weight necessary to achieve 60% conversion. Ethylene and oxygen are fed in stoichiometric proportions to a packed-bed reactor operated isothermally at 260°C. Ethylene is fed at a rate of 0.30 Ib mol/s at a pressure of 10 atm. It is proposed to use 10 banks of 1½-in.-diameter schedule 40 tubes packed with catalyst with 100 tubes per bank. Consequently, the molar flow rate to each tube is to be 3 10–4 Ib mol/s. The properties of the reacting fluid are to be considered identical to those of air at this temperature and pressure. The density of the a ¼-in.-catalyst particles is 120 lb/ft3 and the bed void fraction is 0.45 The rate law is: rA' k PA1 3 PB2 3 lbmol lb cat .h lb mol k 0.0141 at 260C atm.lb cat .h SOLUTION Reaction: A+½BC Mole balance: dX rA' dW FA 0 Rate law : rA' k PA1 3 PB2 3 k C ART 1 3 CBRT 2 3 kRTC1A 3CB2 3 Stoichiometry: gas phase, isothermal P0 T v v 0 1 X P T0 (2.9) j jX P T0 Cj CA0 1 X P0 T (2.11) For an isothermal gas phase reaction: P0 v v 0 1 X P j jX P Cj CA0 1 X P0 Ethylene and air are fed to the reactor where ethylene and oxygen are in stoichiometric proportions: A 1 A 1 FB 0 B 0.5 FA 0 B 0.5 FI0 79 21FB 0 I 1.88 FA 0 FA 0 C 1 NA 0 1 y A0 1 0.5 1 0.148 NT 0 1 0.5 79 / 210.5 j jX P Cj CA0 1 X P0 A AX P 1X P C A 0 CA CA0 1 X P0 1 X P0 B B X P 0.5 0.5X P C A 0 CB C A 0 1 X P0 1 X P0 C CX P X P C A 0 CC C A 0 1 X P0 1 X P0 rA' kRTC1A 3CB2 3 13 rA' C A 0 1 X P kRT 1 X P0 rA' kRTC A 0 P 1 X 1 3 0.5 2 3 1 X 2 3 1 X P0 rA' kRTC A 0 P 1 X 0.63 1 X P0 rA' 1X 0.63kRTC A 0 1 W 1 X 1X 12 r k' 1 W 1 X ' A C A 0 0.5 0.5X P 1 X P0 23 j jX P Cj CA0 1 X P0 1 2 where k’ = 0.63 kRTCA0 = 0.63 kPA0 dX rA' dW FA 0 dX 1 1 X 12 k' 1 W dW FA 0 1 X W FA 0 X 1 X 12 dX 1 W dW k' 0 1 X 0 FA 0 1 2 1 ln X 1 1 W 3 2 3 k' 1X 1 1 1 3FA 0 2k' 1 ln X 1X W 23 (a) w 2 12 32 1 W dW 1 W 3 0 0 W 2 2 32 1 W 1 0 3 2 3 3 2 2 32 1 W 3 3 2 1 1 W 3 2 3 Parameter evaluation per tube (i.e., divide feed rates by 1000): Ethylene FA0 = 3 10-4 lbmol/s = 1.08 lbmol/h Oxygen FB0 = 1.5 10-4 lbmol/s = 0.54 lbmol/h 79 mol N2 4 FI 1.5 10 lbmol s 21 mol O2 Inert (N2) = 5.64 10-4 lbmol/s = 2.03 lbmol/h Jumlah FT0 = FA0 + FB0 + FI = 3.65 lbmol/h FA 0 1.08 y A0 0.30 FT 0 3.65 y A 0 0.31 0.5 1 0.15 PA 0 y A 0 P0 0.3 10 atm 3.0 atm lbmol k' 0.63 kPA 0 0.63 0.0141 3 atm atm.lb cat.h lbmol 0.0266 h.lb cat For 60% conversion, eq. (a) becomes 1 1 3FA 0 W 1 2k' 1 ln X 1X 1 1 1.303FA 0 k' 2 3 W 23 lbmol lb lb A 0 1.08 m 28 30.24 h lbmol h lbmol lb lb B 0 0.54 m 32 17.28 h lbmol h lbmol lb lb I0 2.03 m 28 56.84 h lbmol h lb T 0 104.4 m h T 0 104.4 lb h m lb G 2 7383.3 A c 0.01414 ft h.ft2 For air at 260C and 10 atm: = 0.0673 lbm/ft.h 0 = 0.413 lbm/ft3 Dp = ¼ in = 0.0208 ft lbm . ft g c 4.17 10 lb f .h2 8 G1 0 0 g c Dp 3 150 1 1.75G Dp 7383.3 1 0.45 0 8 3 0.413 4.17 10 0.0208 0.45 150 1 0.45 0.0673 1.757383.3 0.0208 1 atm lb f 1 ft2 atm 164.1 3 2 2 0.0775 ft 144 in 14.7 lb f in ft 2 0.0775 2 0 A c C 1 P0 0.01414 120 1 0.45 10 0.0166 lb cat 1 1 1.303FA 0 k' 2 3 W 0.0166 lbmol 1.303 lb cat 1.08 h 1 1 lbmol 0.0266 lb cat . h 0.0166 lb cat = 45.4 lb of catalyst per tube = 45,400 lb of catalyst total 23 P 1 W 1 2 P0 0.0166 45.4 lb cat 1 lb cat 12 P = 0.496 P0 = 4.96 atm P = P0 – P = 10 – 4.96 = 5.04 atm 0.496