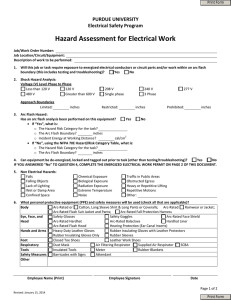

A R C - F L A S H P R OT E C T I V E C L OT H I N G F O R N F PA 7 0 E NFPA 70E is the national consensus standard for electrical safety in the workplace. The scope of this standard is to address safety-related work practices for the practical safeguarding of employees relative to the hazards associated with working around electrical energy. It specifically covers those electrical work practices performed by electricians and maintenance workers within a facility. Nearly all industries fall under the practices outlined in NFPA 70E. Manufacturing industries using high-voltage electrical equipment, such as aerospace, automotive, food processing, pulp and paper, industrial equipment, electronics, pharmaceuticals, and many others, are all covered by NFPA 70E. However, NFPA 70E does not cover electrical work performed outside of the facility that is under the exclusive control of an electric utility. This industry is covered by the National Electrical Safety Code (NESC). Many state OSHA agencies use NFPA 70E as their guideline for evaluating the protection of electrical workers. Those companies not protecting their employees from electric arc-flash hazards as described by this standard are at risk for potential fines should a safety inspection take place or an accident occur. So compliance with NFPA 70E not only protects workers but reduces the risk of OSHA fines. This informational guide will give you a brief overview of the NFPA 70E sections related to arc-flash protective clothing and other personal protective equipment (PPE). Arc- Flash Protective Clothing FOR NFPA 70E – 1 NFPA 70E Article 130 – Work Involving Electrical Hazards Section 130.5 Arc-Flash Risk Assessment This is the section within NFPA 70E that addresses the conditions under which PPE is required and the type and level of protection needed for various work conditions. It starts by stating, “Energized electrical conductors and circuit parts…shall be put into an electrically safe work condition before an employee performs work…”With that said, the standard goes on to state that“ energized work shall be permitted where the employer can demonstrate that de-energizing introduces additional hazards or increased risk.” It also states that “energized work shall be permitted where the employer can demonstrate that the task to be performed is infeasible in a de-energized state due to equipment design or operational limitations.” A critical piece of the hazard assessment is performing an arc-flash hazard analysis. This analysis is required in order to establish the arc-flash boundary, the incident energy at the working distance and the PPE that people within the arc-flash boundary shall use. PLUS: Equipment operating at less than 50 volts is not required to be de-energized. This section allows for the selection of the protective clothing and other PPE to be established by either performing an incident energy analysis or by using the PPE tables established in the standard. You can determine the PPE category by comparing the desired job with common tasks found in NFPA 70E table 130.7 (C)(15) (A) (b). Once the task has been identified on the table, one of five PPE category numbers will be identified as appropriate for that task. Each of these categories requires garments with the minimum associated arc rating and other PPE to be worn. Hazard Assessment In order to determine the proper type and protection level of PPE, a hazard assessment must be performed. In addition, federal OSHA requires employers to conduct hazard assessments in accordance with 29 CFR 1910.132(d). If an arc-flash hazard is present, OSHA deems the employer to be in compliance if NFPA 70E is the basis of determining the arc-flash protection boundary and the necessary PPE. Fig. 1 ARC FLASH BOUNDARY = The distance at which the incident energy equals 1.2 cal/cm². This is the energy level that will generate a second-degree burn on exposed skin. Energized Component Flash Boundary 2 – Workrite Uniform Company, Inc. Within the flash boundary, a person could receive at least a second-degree burn from an arc flash. 70E Arc-Flash Hazard PPE Categories for Alternating Current (ac) Systems Table 130.7 (C)(15)(A)(b) PPE Category Arc-Flash Boundary Panelboards or other equipment rated 240V or below. Maximum of 25kA short-circuit current available; maximum of 0.03 sec (two cycles) fault clearing time; working distance 455 mm (18 in.). 1 485 mm (19 in.) Panelboards or other equipment rated > 240V and up to 600V. Parameters: Maximum of 25kA short-circuit current available; maximum of 0.03 sec (two cycles) fault clearing time; working distance of 455 mm (18 in.). 2 900 mm (3 ft.) 2 1.5m (5 ft.) 4 12m (40 ft.) Equipment Other 600 V class (277 V through 600 V, nominal) equipment. Parameters: Maximum of 65 kA short-circuit current available; maximum of 0.03 sec (two cycle) fault clearing time; minimum 18 in. working distance. Metal-clad switchgear, 1kV through 15 kV. Parameters: Maximum if 35 kV shirt-circuit current available; maximum of up to 0.24 sec (15 cycles) fault clearing time; working distance 910 mm (36 in.). Once the HRC number has been identified from the task table, the PPE table 130.7 (C)(16) (see page 4) shall be used to determine the requirements for the specific protective clothing and other PPE based on that HRC number. HRC 1 and 2 are typically standard work clothes that have been arc rated from between a minimum of 4 cal/cm² for HRC 1, and a minimum of 8 cal/cm² for HRC 2. When the incident energy potential reaches 25 cal/cm², HRC 3 is required; at 40 cal/cm² and greater, HRC 4 garments are required. Arc- Flash Protective Clothing FOR NFPA 70E – 3 70E Hazard/Risk Category Classification Table (Cont.) Table 130.7 (C)(16) PPE Category 1 Clothing & PPE Description Arc-Rated Clothing: Arc-rated long-sleeve shirt and pants or arc-rated coverall, arc-rated face shield or arc-flash suit hood, arc-rated jacket, parka, rainwear or hard hat liner as needed Minimum Arc Rating 4 cal/cm² Protective Equipment: Hard hat, safety glasses or goggles, hearing protection, leather gloves, leather footwear 2 Arc-Rated Clothing: Arc-rated long-sleeve shirt and pants or arc-rated coverall, arcrated face shield and arc-rated balaclava or arc-flash suit hood, arc-rated jacket, parka, rainwear or hard hat liner as needed 8 cal/cm² Protective Equipment: Hard hat, safety glasses or goggles, hearing protection, leather gloves, leather footwear 3 Arc-Rated Clothing: Arc-rated long-sleeve shirt, arc-rated pants, arc-rated coverall, arc-rated flash suit jacket, arc-rated flash suit pants, arc-rated flash suit hood, arc-rated gloves, arc-rated jacket, parka, rainwear or hard hat liner as needed 25 cal/cm² Protective Equipment: Hard hat, safety glasses or goggles, hearing protection, leather gloves, leather footwear 4 Arc-Rated Clothing: Arc-rated long-sleeve shirt, arc-rated pants, arc-rated coverall, arc-rated flash suit jacket, arc-rated flash suit pants, arc-rated flash suit hood, arc-rated gloves, arc-rated jacket, parka, rainwear or hard hat liner as needed Protective Equipment: Hard hat, safety glasses or goggles, hearing protection, leather gloves, leather footwear 4 – Workrite Uniform Company, Inc. 40 cal/cm² Section 130.7 Personal and Other Protective Equipment This is the section that provides specific requirements for those employees working in areas where electrical hazards are present. Those employees are required to be provided with and use protective equipment designed for the specific part of the body to be protected at the incident energy level, as established in the arc hazard analysis or as specified in the HRC tables. The specific parts of the body required to be protected include: Head, Face, Neck and Chin (Head Area) Protection Non-conductive head protection whenever there is a danger from shock, contact burns or flying objects from electrical explosions. The face, neck and chin shall be protected from exposure to electric arcs or flashes and flying objects. If hairnets or beardnets are used, they must be arc-rated. Eye Protection Eye protection when there is a danger from electric arcs, flashes or flying objects. Hearing Protection Hearing protection whenever working within the arc-flash boundary. Body Protection Arc-rated clothing whenever there is a possibility of exposure to an electric arc flash above an incident energy level of 1.2 cal/cm². Hand and Arm Protection Hand and arm protection as appropriate for either shock and/or arc flash as detailed in other sections. Factors in Selection The specific factors in the selection of protective clothing are stated as: “If arc-rated clothing is required, it shall cover associated parts of the body as well as all flammable apparel.” It goes on to state that “garments that are not arc-rated shall not be permitted to be used to increase the arc rating of a garment or of a clothing system.” Layering, Coverage and Fit General non-melting, flammable fiber garments are permitted to be used as under layers in conjunction with arc-rated garments for added protection. The arc rating of the system must be sufficient to prevent break-open of the innermost arc-rated layer. Outer Layers The outermost layer, such as jackets or rainwear, must be made of arc-rated material. Under Layers Meltable fibers such as acetate, nylon, polyester, polypropylene and spandex are not permitted in fabric under layers (underwear) next to the skin. Coverage Clothing must cover potentially exposed areas as completely as possible. Shirts and coverall sleeves shall be fastened at the wrist, shirts shall be tucked into pants, and shirts, coveralls and jackets should be closed at the neck. Fit Tight-fitting clothing should be avoided. Loose-fitting clothing provides additional insulation because of air spaces. Interference The garment should have the least interference with the task but still provide the necessary protection. Arc- Flash Protective Clothing FOR NFPA 70E – 5 Simplified Choices with Two Clothing Sets Though different clothing is specified for each arc-rating minimum, many companies simplify their needs by choosing just two sets of clothing for their people to handle all electrical tasks: (a) A garment set with an arc rating of at least 8 cal/cm² for the more routine tasks of PFE category 1 and 2 (b) A garment set with an arc rating of at least 40 cal/cm² for more specialized tasks of PFE category 3 and 4 Standards on Protective Equipment Table 130.7(C)(14) lists the various performance standards, to which the protective clothing and PPE needs to conform. PPE Type Apparel – Arc-Rated Eye and Face – General Document Number Document Title ASTM F1506 Standard Performance for Flame-Resistant and Arc-Rated Textile Materials for Wearing Apparel for Use by Electrical Workers Exposed to Momentary Electric Arc and Related Thermal Hazards ANSI/ASSE Z87.1 Practice for Occupational and Educational Eye and Face Protection Face – Arc-Rated ASTM F2178 Standard Test Method for Determining the Arc Rating and Standard Specification for Face Protective Products Gloves – Leather Protectors ASTM F696 Standard Specification for Leather Protectors for Rubber Insulating Gloves and Mittens Gloves – Rubber Insulating ASTM D120 Head Protection – Hard Hat ANSI/ISEA Z89.1 Rainwear – Arc-Rated 6 – Workrite Uniform Company, Inc. ASTM F1891 Standard Specification for Rubber Insulating Gloves Personal Protection – Protective Headwear for Industrial Workers Standard Specification for Arc- and Flame-Resistant Rainwear So What Role Can Arc-Rated Clothing Play? • Clothed areas can be burned more severely than skin that is exposed directly to the arc flash, because the initial exposure is of a short duration while the burning clothing continues to apply heat to the skin until it either goes out or is removed Arc-rated clothing: • Does not ignite or continue to burn • Provides a protective barrier against the arc flash • The long-term cost of a single burn injury can exceed the cost of an entire FR clothing program • Insulates the wearer from heat Why is this important? • Most severe burns are caused by ignited clothing rather than by the original hazard • Rehabilitation for burn injuries can be extremely long and painful Arc-rated clothing is worn as insurance. In the unlikely event of an arc flash, these garments: • Minimize or reduce burn injury • Increase chances of survival Surviving a Burn Injury Burn Survival Rate 100 % Survival 75 25% Body Burn 50 50% Body Burn 75% Body Burn 25 0 20-29 30-39 40-49 50-59 Age Groups Summary Each year, more than 2,000 employees are admitted to burn centers with severe burns resulting from arc-flash accidents. Manufacturing facility workers within the arc-flash boundary are at risk of being exposed to an arc-flash event while performing common electrical work on energized parts or equipment. Because of that, being in compliance with the NFPA 70E safety standard not only protects those workers but reduces the risk of fines to the company should an accident occur. Arc- Flash Protective Clothing FOR NFPA 70E – 7 Our mission is to protect today’s workers by delivering trusted, innovative An Affiliate of Williamson-Dickie Manufacturing Company 1701 North Lombard Street, Suite 200 Oxnard, California 93030 1.800.521.1888 / 805-483-0175 Fax 805.483.0678 Monday–Friday / 6 a.m.–4 p.m. PST workrite.com 1700-01-05-15 | © Workrite Uniform Company and market-leading, flame-resistant branded apparel solutions.