110.15 High-Leg Marking On a 4-wire, delta

advertisement

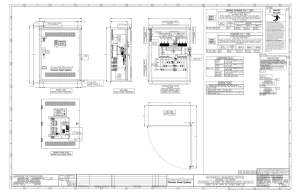

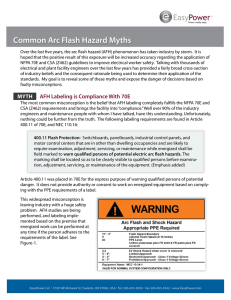

110.15 High-Leg Marking On a 4-wire, delta-connected system where the midpoint of one phase winding is grounded, only the conductor or busbar having the higher phase voltage to ground shall be durably and permanently marked by an outer finish that is orange in color or by other effective means. Such identification shall be placed at each point on the system where a connection is made if the grounded conductor is also present. The high leg is common on a 240/120-V 3-phase, 4-wire delta system. It is typically designated as “B phase.” The high-leg marking, which is required to be the color orange or other similar ]effective means, is intended to prevent problems caused by the lack of standardization where metered and nonmetered equipment are installed in the same installation. Electricians should always test each phase relative to ground with suitable equipment to determine exactly where the high leg is located in the system. 110.16 Arc-Flash Hazard Warning Electrical equipment, such as switchboards, switchgear, panelboards, industrial control panels, meter socket enclosures, and motor control centers, that are in other than dwelling units, and are likely to require examination, adjustment, servicing, or maintenance while energized, shall be field or factory marked to warn qualified persons of potential electric arc flash hazards. The marking shall meet the requirements in 110.21(B) and shall be located so as to be clearly visible to qualified persons before examination, adjustment, servicing, or maintenance of the equipment. This section requires switchboards, panelboards, motor control centers, and other equipment to be individually field or factory marked with proper warning labels to raise the level of awareness of electrical arc-flash hazards and to decrease the number of accidents that result when electricians do not wear the proper type of protective clothing when working on “hot” (energized) equipment. Exhibit 110.8 is one example of an equipment warning sign as required by this section. EXHIBIT 110.8 One example of an arc-flash warning sign. (Courtesy of the International Association of Electrical Inspectors) Exhibit 110.9 shows an electrical employee wearing personal protective equipment (PPE) considered appropriate flash protection clothing for the flash hazard involved. Suitable PPE appropriate to a particular hazard is described in NFPA 70E®, Standard for Electrical Safety in the Workplace®. EXHIBIT 110.9 An electrical worker clothed in personal protective equipment (PPE) appropriate for the hazard involved. (Courtesy of KTR Associates/ArcFlashPPE.com) Accident reports confirm the fact that workers responsible for the installation or maintenance of electrical equipment often do not turn off the power source before working on the equipment. Working on electrical equipment that is energized is a major safety concern in the electrical industry. This requirement alerts electrical contractors, electricians, facility owners and managers, and other interested parties to some of the hazards present when personnel are exposed to energized electrical conductors or circuit parts, and emphasizes the importance of turning off the power before working on electrical circuits. This section does not apply to equipment in dwelling units. However, dwelling occupancies include multifamily dwellings, which include multiple dwelling units and could have the same electric service as a commercial office building. The intent is to provide warnings to electricians working on these larger services. Employers can be assured that they are providing a safe workplace for their employees if safety-related work practices required by NFPA 70E have been implemented and are being followed. (See also the commentary following the definition of qualified person in Article 100.) In addition to the standards referenced in the informational notes and their individual bibliographies, additional information on electrical accidents can be found in the 1997 report “Hazards of Working Electrical Equipment Hot,” published by the National Electrical Manufacturers Association. Informational Note No. 1: NFPA 70E-2012, Standard for Electrical Safety in the Workplace, provides guidance, such as determining severity of potential exposure, planning safe work practices, arc flash labeling, and selecting personal protective equipment. Informational Note No. 2: ANSI Z535.4-1998, Product Safety Signs and Labels, provides guidelines for the design of safety signs and labels for application to products.