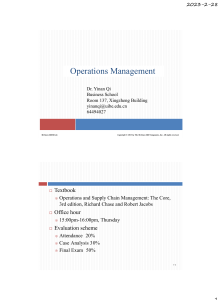

OM 300- Exam Notes Chapter One: Introduction -Op Mgr. Decisions: *Strategic Decisions: set direction for entire company, broad in scope, long-term *Tactical Decisions: specific and short-term, bound by strategic decisions. -Transformation process of a business: Transform a company’s inputs into the finished goods or services. - Identify the two major differences between service and manufacturing organizations: Low/High Customer Contact, Tangible/Intangible. Chapter Two: Op. Strategy and Competitiveness Explain the importance of a business strategy: The role of operations strategy is to provide a plan for the operations function so that it can make the best use of its resources. Order qualifiers and order winners: Order qualifiers Competitive priorities that must be met for a company to qualify as a competitor in the marketplace. Order winners Competitive priorities that win orders in the marketplace. Describe the three types of technologies: Product, Process, and Info Technology. Describe the meaning of productivity. Output/Input=Productivity, Output/1 Input, Output/Labor+Materials Explain the three types of productivity measures. (Total, Partial, and Multifactor) Chapter Three: Product Design and Process Selection Define product design and explain its relationship to business strategy: The process of defining all of the product’s characteristics. What are the differences between product and service design? Service package A grouping of physical, sensual, and psychological benefits that are purchased together as part of the service. Describe the stages of the product life cycle. What are demand characteristics at each stage? There are typically four stages of the product life cycle: introduction, growth, maturity, and decline. Identify the two general types of operations. What are their characteristics? Give examples of services that have a good match between customer expectations and service delivery. Give examples of services that do not have a good match. Chapter Five: Describe the four dimensions of quality. Which do you think is most important? Describe each of the four costs of quality: prevention, appraisal, internal failure, and external failure. Next, describe how each type of cost would change (increase, decrease, or remain the same) if we designed a higher-quality product that was easier to manufacture. Explain the meaning of the plan–do–study–act cycle. Why is it described as a cycle? Plan–do–study–act (PDSA) cycle A diagram that describes the activities that need to be performed to incorporate continuous improvement into the operation. Plan, Do, Study, Act, Describe the seven tools of quality control. Are some more important than others? Would you use these tools separately or together? Give some examples of tools that could be used together. Cause-and-effect diagrams identify potential causes of particular quality problems A flowchart is a schematic diagram of the sequence of steps involved in an operation or process. A checklist is a list of common defects and the number of observed occurrences of these defects. Control charts are a very important quality control tool. We will study the use of control charts at great length in the next chapter. Scatter diagrams are graphs that show how two variables are related to one another. Pareto analysis is a technique used to identify quality problems based on their degree of importance. A histogram is a chart that shows the frequency distribution of observed values of a variable. This is called reliability, the probability that a product, service, or part will perform as intended for a specified period of time under normal conditions.