Uploaded by

manalojustinealdrei

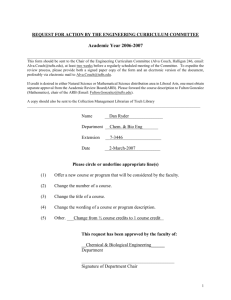

Materials Science & Engineering: Intro & Classifications

advertisement

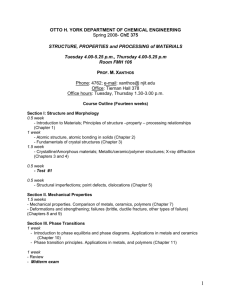

Introduction to Materials Science and Engineering Learning Objectives : Upon completion of this chapter, the student should be able to: • List six different property classifications of materials that determine their applicability. • Cite the four components that are involved in the design, production, and utilization of materials. • Cite three criteria that are important in the selection process. Materials Science and Engineering Materials Science – investigating relationships that exist between the structure and properties of materials. Materials Engineering – is, on the basis of these structure-property correlations, designing or engineering the structure of a material to produce a pre-determined set of properties Materials in day to day life Materials: The Milestones of Progress • Development and advancement of Human societiesclosely related with materials • Civilizations have been named based on the level of their materials development – Stone age, Bronze age etc. Quest for newer materials: The driving force for the progress- stone age to modern age Quest for more advanced materials needs as the civilization progressed. to meet the growing Stone age Stone age – People living in caves and hunting with stone-made weapons 200,000 BC Discovery of fire – Said to be the most significant discovery in human civilization. However, till the time the fire was controlled to contain and utilize the heat, it was not significant. Containing the fire – Was not possible without materials. Started with clay (a ceramic material) pots and now we have all kinds of means to control and contain fire. Introduction of metals First metals to be discovered – Copper and Gold Material processing - Annealing and Shaping. Throwing copper into camp fire and hammering in early days Melting and casting of metals. Melting of Gold to give it different shapes Reduction of copper from its ore – Nile Valley The dawn of metallurgy. Perhaps discovered by chance much before by early potters Discovery of Alloy - Metal Combinations The discovery of alloy – combination of metals Mixing of Tin with Copper – Bronze Copper ore invariably contains some Tin – Mixing of different ores having different Tin content produced the first Bronzes. Iron and Steel – Building blocks of human civilization Iron wheels – discovery of iron making. Revolution in warfare and cultivation Invention of Blast furnace – Production of pig iron from ores Sir Henry Bessemer (1813-1898) Bessemer steel making patent 20th Century Many other steel making processes Early 20th Century – The golden era 1890 - 1910 AD Hall process- Electrochemical process for extraction of Aluminium from Alumina (Al2O3) Revolution in Transportation – Discovery of automobiles and Aero plane Process for making Nylon – Introduction of plastics The Electronic Revolution Zone refining – A metallurgical process to produce ultra pure Si Ultra pure Si through zone refining – Si chip, the heart of electronics. Smaller and smaller Si wafers - Miniaturization Superconductors High temperature ceramic MRI Machine, Brain Scan – superconductors Advancement in Medical science Magnetic Levitation: Maglevtrain :– 300 – 500 kmph Why do we need to study Materials Science and Engineering? Processing/Structure/Properties/Performance Correlations • Structure of a material usually relates to the arrangement of its internal components which can be further classified into four categories described in the next section. • A property is a material trait in terms of the kind and magnitude of response to a specific imposed stimulus. Structure •Macroscopic – viewable with the un-aided eye •Microscopic – groups of atoms that are normally agglomerated together •Atomic – organization of atoms or molecules •Sub atomic – electrons and nuclei (protons and neutrons) In addition to structure and properties, two other important components are involved in the science and engineering of materials – namely, processing and performance. With regard to the relationships of these four components, the structure of a material will depend on how it is processed. Furthermore, a materials performance will be a function of its properties. Processing Structure Properties Performance Classification of Materials 1.) Metals Materials in this group are composed of one or more metallic elements and often also nonmetallic elements. Atoms in metals and their alloys are arranged in a very orderly manner, and in comparison to the ceramics and polymers, are relatively dense. 2.) Ceramics Ceramics are compounds between metallic and nonmetallic elements; they are most frequently oxides, nitrides and carbides. For example, common ceramic materials include aluminum oxide, silicone dioxide, silicon carbide, etc. Ceramic materials are more resistant to high temperatures and harsh environments than metals and polymers. 3.) Polymers Polymers include the familiar plastic and rubber materials. Many of them are organic compounds that are chemically based on carbon, hydrogen and other nonmetallic elements. These materials typically have low densities, whereas their mechanical characteristics are generally dissimilar to the metallic and ceramic materials – they are not as stiff nor as strong as these other material types. 4.) Composites A composite is composed of two or more materials, which come from metals, ceramics and polymers. The design goal of a composite is to achieve a combination of properties that is not displayed by any single material, and also to incorporate the best characteristics of each of the component materials. 5.) Advanced Materials Materials that are utilized in high-technology applications are termed as advanced materials. These materials are typically traditional materials whose properties have been enhanced, and also newly developed, high-performance materials. These type of materials is further classified into four kinds, namely, semiconductors, biomaterials, smart materials and nanomaterials. a.) Semiconductors Have electrical properties that are intermediate between the electrical conductors (metals and alloys) and insulators (ceramics and polymers) b.) Biomaterials Biomaterials are employed in components implanted into the human body to replace diseased or damaged body parts. c.) Smart Materials The adjective “smart” implies that these materials are able to sense changes in their environment and then respond to these changes in predetermined manners. d.) Nanomaterials Nanomaterials may be one of the four basic materials, however, unlike those other materials, they are not distinguished on the basis of their chemistry, but rather, size. Summary: • One aspect of materials science is the investigation of relationships that exist between the structures and properties of materials. By structure we mean how some internal component(s) of the materials is (are) arranged. In terms of (and with increasing) dimensionality, structural elements include subatomic, atomic microscopic, and macroscopic. • On the basis of chemistry and atomic structure, materials are classified into three general categories: metals (metallic elements), ceramics (compounds between metallic and nonmetallic elements), and polymers (compounds composed of carbon, hydrogen, and other nonmetallic elements.) In addition, composites are composed of at least two different material types. • Another materials category is the advanced materials that are used in high-tech applications. These include semiconductors (having electrical conductivities intermediate between conductors and insulators), biomaterials (which must be compatible with body tissues), smart materials (those that sense and respond to changes in their environments in predetermined manners), and nanomaterials (those that have structural features on the order of a nanometer, some of which may be designed on the atomic/molecular level) Good, better, best. Never let it rest. Until your good is better and your better is best. - St. Jerome -end-