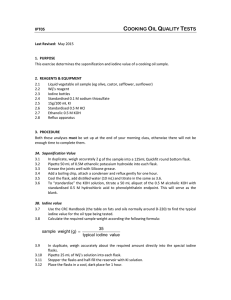

INDUSTRIAL OILS AND DERIVATIVES AOCS Official Method Tg 1-64 Reapproved 2009 Iodine Value, Wijs Method DEFINITION The iodine value is a measure of the unsaturation of industrial oils and derivatives and is expressed in terms of the number of cg of iodine absorbed per g of test sample (% iodine absorbed). SCOPE Applicable to normal industrial oils and derivatives, such as natural or synthetic drying oils and their fatty acids. For a specific class or product, refer to the AOCS method for testing the particular product (see Notes, 1). Replaces Ka 9-51. APPARATUS 1. Glass-stoppered bottles or wide mouth Erlenmeyer flask—500 mL. 2. Glass-stoppered volumetric flask—conforming to National Institute of Standards & Technology (NIST) tolerances and accurately calibrated to contain 1000 mL. 3. Pipets—5, 20, and 25 mL. 4. Filter paper—Whatman no. 41H, or equivalent. REAGENTS (See Notes) 1. Glacial acetic—ACS grade. The permanganate test should be applied to be sure that this specification is met. (a) Permanganate test—dilute 2 mL of the acid with 10 mL of distilled water and add 0.1 mL of 0.2 M KMnO4. The pink color must not be entirely discharged within 2 hr. 2. Potassium iodide—ACS or AR grade. 3. Chlorine—99.8% (see Notes, Caution). Satisfactory commercial grades are available in cylinders, but gas must not be dried by passing through sulfuric acid (sp. gr. 1.84) before introducing into the iodine solution. Note—Prepared Wijs (see Notes, Caution and 2) solution is available commercially and may be used in place of laboratory-prepared solution. 4. Soluble starch—tested for sensitivity. Make a paste with 1 g of starch and a small amount of cold distilled water. Add, while stirring, 200 mL of boiling water. Place 5 mL of this solution in 100 mL of water and add 0.05 mL of 0.1 M iodine solution. The deep blue color produced must be discharged by 0.05 mL of 0.1 M sodium thiosulfate. 5. Potassium dichromate—ACS grade. The potassium dichromate is finely ground and dried to constant weight at about 110°C before using. Note—A standard sample of potassium dichromate with a certificate of analysis may be obtained from the National Institute of Standards Testing in Washington, D.C. This sample, or equivalent, is strongly recommended for the primary standard for this method. Treat as directed in the certificate of analysis accompanying the sample. 6. Sodium thiosulfate (Na2S2O3·5H2O)—ACS grade. 7. Iodine—ACS grade. 8. Carbon tetrachloride—ACS grade (see Notes, Caution, Recommendations and 5). 9. Wijs solution, AR grade (see Notes, Caution). SOLUTIONS 1. Potassium iodine solution—dissolve 150 g in distilled water and make up to 1 L. 2. Starch indicator solution—make a homogeneous paste of 10 g of potato starch in cold distilled water. Add to this 1 L of boiling distilled water, stir rapidly and cool. Salicylic acid (1.25 g/L) may be added to preserve the indicator. If long storage is required, the solution must be kept in a refrigerator at 4–10°C (40–50°F). Fresh indicator must be prepared when the end point of the titration from blue to colorless fails to be sharp. If stored under refrigeration, the starch solution should be stable for about 2–3 wk. 3. Sodium thiosulfate solution, 0.1 M—dissolve 24.9 g of sodium thiosulfate in distilled water and dilute to 1 L. (a) Standardization—weigh 0.16–0.22 g of finely ground and dried potassium dichromate into a 500 mL flask or bottle by difference from a weighing bottle. Dissolve in 25 mL of water, add 5 mL of hydrochloric acid, 20 mL of potassium iodine solution and rotate to mix. Allow to stand for 5 min and then add 100 mL of distilled water. Titrate with sodium thiosulfate solution, shaking continuously until yellow color has almost disappeared. Add 1–2 mL of starch indicator and continue the titration, adding the thiosulfate solution slowly until the blue color has just disappeared. The strength of the sodium thiosulfate solution is expressed in terms of its molarity. Molarity of Na2S2O3 solution = 20.394 × mass of K 2 Cr2 O7 , g volume, mL of sodium thiosulfate solution Page 1 of 4 INDUSTRIAL OILS AND DERIVATIVES Tg 1-64 • Iodine Value, Wijs Method 4. Wijs solution (see Notes, Caution) can be purchased (see Reagents) or prepared in the laboratory. Dissolve 13.0 g of iodine in 1 L glacial acetic acid. Gentle heating may be necessary to promote solution. Cool remove a small quantity (100–200 mL) and set aside in a cool place for future use. Pass dry chlorine gas into the iodine solution until the original titration is not quite double. A characteristic color change takes place in the Wijs solution when the desired amount of chlorine has been added. This may be used to assist in judging the end point. A convenient procedure is to add a small excess of chlorine and immediately bring back to the desired titration by addition of some of the original iodine solution which was taken out at the beginning. The original solution and finished Wijs solution are both titrated with Na2S2O3 solution as directed in Procedure, 6 and 7. The Wijs solution may be prepared from commercial iodine monochloride as follows: (a) Stock Solution—Add 317 ± 0.1 g of iodine monochloride to 1 L of glacial acetic acid and filter through Whatman no. 41H filter paper or equivalent into a clean and dry actinic glass bottle. Filter rapidly to prevent contamination with moisture and store in a cool place. Discard the solution if a precipitate forms on standing. (b) Wijs Solution—Using a graduated cylinder pour 117.0 ± 0.1 mL of the stock solution into a standard 5 lb bottle of glacial acetic acid and mix well by shaking. 5. The I/Cl ratio of the Wijs solution shall be within the limits of 1.10 ± 0.1. The procedure for determining the ratio is as follows: (a) Iodine content— (1) Pour 150 mL of saturated chlorine water into a 500 mL Erlenmeyer flask and add a few glass beads. (2) Pipet 5 mL of the Wijs solution into the flask containing the saturated chlorine water. Shake, and heat to boiling. (3) Boil briskly for 10 min, cool and add 30 mL of 2% sulfuric acid and 15 mL of 15% potassium iodide solution. (4) Mix well, and titrate immediately with 0.1 M sodium thiosulfate solution to a starch end point. (b) Total halogen content— (1) Pour 150 mL of recently boiled distilled water into a clean, dry 500 mL Erlenmeyer flask. (2) Add 15 mL of 15% potassium iodine solution. (3) Pipet 20 mL of Wijs solution into the flask, and mix well. (4) Titrate with 0.1 M sodium thiosulfate solution to a starch end point. CALCULATIONS Halogen Ratio R = 2A 3B − 2A Where— A = volume of titrant, mL, of iodine content as mL sodium thiosulfate B = volume of titrant, mL, of total halogen content as mL sodium thiosulfate PROCEDURE 1. Melt the test sample, if it is not already liquid, and filter through filter paper to remove any solid impurities and the last traces of moisture. The temperature during melting and filtering should not exceed the melting point of the test sample by more than 10°C. The test sample must be absolutely dry. Note-All glassware must be absolutely clean and dry. 2. Weigh the test sample (see Notes, 3) accurately into a 500 mL flask or bottle to which has been added 20 mL of carbon tetrachloride (see Notes, Caution) or other solvent (see Notes, Recommendations and 5). The weight of the test sample must be such that there will be an excess of Wijs solution of 100–150% over the amount absorbed. Table 1 is a guide to the size of test sample to weight. 3. Pipet the 25 mL of Wijs solution into flask containing the test sample, stopper the flask, and swirl to ensure an intimate mixture. 4. Prepare and conduct at least two blank determinations with each group of test samples simultaneously and similar in all respects to the test samples. 5. Store the flasks in a dark place for 30 min at a temperature of 25 ± 5°C. For conjugated oils such as tung, oiticica or dehydrated castor oil, allow the absorption to proceed for 1 hr at 25 ± 1°C. 6. Remove the flasks from storage and add 20 mL of KI solution, followed by 100 mL of distilled water. 7. Titrate with 0.1 M Na2S2O3 solution, adding it gradually and with constant and vigorous shaking (see Notes, 4). Continue the titration until the yellow color has almost disappeared. Add 1–2 mL of starch indicator solution and continue the titration until the blue color has just disappeared. Page 2 of 4 INDUSTRIAL OILS AND DERIVATIVES Tg 1-64 • Iodine Value, Wijs Method CALCULATION Iodine Value = (B − S) × M × 12.69 mass of test portion, g Where— B = volume of titrant, mL of blank S = volume of titrant, mL of test portion M = molarity of Na2S2O3 solution NOTES Caution Carbon tetrachloride is a known carcinogen. It is toxic by ingestion, inhalation and skin absorption. It is a narcotic. It should not be used to extinguish fires. It decomposes to phosgene gas at high temperature. The TLV is 5 ppm in air. A fume hood should be used at all times when using carbon tetrachloride. Chlorine is a poisonous gas. The TLV is 1 ppm in air. It is a strong oxidizing agent and should not be allowed to come in contact with organic materials, hydrogen, powdered metals and reducing agents. A fume hood should be used at all times when using chlorine. Wijs solution causes severe burns and vapors can cause lung and eye damage. Use of a fume hood is recommended. Wijs solution without carbon tetrachloride is available commercially. Potassium dichromate is toxic by ingestion and inhalation. There is sufficient evidence in humans for the carcinogenicity of chromium [+6], in particular lung cancer. It is a strong oxidizing agent and a dangerous fire risk in contact with organic chemicals. RECOMMENDATIONS Cyclohexane has been proposed as a replacement for carbon tetrachloride in the iodine value method—see AOCS Recommended Practice Cd 1-87 (89), AOCS Official Method Cd 1d-92 and JAOCS 65:745 (1988). Isooctane has been reported to be a suitable replacement for chloroform in the peroxide value method, and therefore could be tried as a substitute for carbon tetrachloride in the iodine value method. These recommendations do not represent official approval by the AOCS Uniform Methods Committee. Laboratories that use these solvents may report their findings to the AOCS Technical Director. NUMBERED NOTES 1. When the iodine value is determined on materials having conjugated systems, the result is not a measure of total unsaturation, but rather is an empirical value indicative of the amount of unsaturation present. Reproducible results are obtained which afford a comparison of total unsaturation. When the iodine value is required on the fatty acids of natural and synthetic drying oils, the preparation and separation are performed as directed in AOCS Official Method Cd 6-38. 2. All Wijs solutions are sensitive to temperature, moisture and light. Store in a cool and dark place and never allow to come to a temperature above 25-30°C. 3. In the case of dehydrated castor oils, weigh 0.11–0.13 g. 4. Mechanical stirring is satisfactory for agitating during the addition of thiosulfate. 5. 1,1,1-Trichloroethane (TCE) has been suggested as a replacement for chloroform in this method. Although TCE is a halogenated hydrocarbon, the TLV (350 ppm) is less than those of chloroform, carbon tetrachloride, and methylene chloride. Cyclohexane and cyclohexaneacetic acid may also be considered as alternate solvents. See AOCS Methods Cd 1b-87 and Cd 1d-92. Page 3 of 4 INDUSTRIAL OILS AND DERIVATIVES Tg 1-64 • Iodine Value, Wijs Method Table 1 Test portion mass, g Iodine Value <3 3 5 10 20 40 60 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 Page 4 of 4 Normal oils 100–150% excess of reagent 10 –10 8.4613–10.576 5.0770–6.3460 2.5384–3.1730 0.8461–1.5865 0.6346–0.7935 0.4321–0.5288 0.3175–0.3969 0.2822–0.3528 0.2540–0.3175 0.2309–0.2886 0.2117–0.2646 0.1954–0.2442 0.1814–0.2268 0.1693–0.2116 0.1587–0.1984 0.1494–0.1868 0.1411–0.1764 0.1337–0.1671 0.1270–0.1587 0.1210–0.1547 0.1155–0.1443 Conjugated oils 115–135% excess of reagent 0.3377–0.3691 0.3002–0.3281 0.2702–0.2953 0.2456–0.2684 0.2252–0.2461 0.2078–0.2271 0.1930–0.2109 0.1801–0.1969 0.1689–0.1846 0.1589–0.1737 0.1501–0.1640 0.1422–0.1554 0.1351–0.1476 0.1287–0.1406 0.1228–0.1374