1

Inverter performance prediction

L. Kaci1, A. Hadj Arab2, R. Zirmi1, S. Semaoui2 and S. Boulahchiche2

1

Centre de Développement des Energies Renouvelables, CDER, BP 62 Route de l'Observatoire, Algiers Algeria

2

Université Mouloud Mammeri, Tizi Ouzou, Algeria

Abstract— based on the outdoor PV system of the CDER at the

height of Algiers the inverter efficiency under field conditions has

been analyzed and compared to manufacturer data.

A model is developed that expresses the inverter efficiency as a

function of the inverter AC output power. Model parameters are

calculated using field data. The model is used to predict inverter

efficiencies for different periods of time and compared to the

measured ones.

Index Terms—Inverter electrical conversion efficiency, PV

system

I. INTRODUCTION

T

he cost reduction in photovoltaic technology coupled to

environmental concerns, led to an important increase in

the installed PV systems worldwide, it shows the PV

technology will play an important role in the energy mix. The

additional installed photovoltaic PV capacity worldwide (98

GW) an increase of up to 29 % compared to 2016, bringing

the cumulative installed capacity to 402.5 GW [1].

The estimation of the payback time and the profitability of

grid-connected photovoltaic (PV) systems require information

about performance of PV modules and inverters. For this

reason, the attention is strongly paid on the efficiency.

The performance of a PV system depends on the

performances of its components namely, PV modules and

inverters. Energy losses are present in all solar energy

conversion process. Specifically, losses can be categorized

into pre-module losses, module losses and system losses. A

PV system comprises three main units: the PV generator unit,

the string combiner unit and the power conditioning system.

The PV generator unit is the PV array. The string combiner

unit includes the connections and wiring between strings as

well as the fuses/block diodes, which are employed for string

overcurrent protection. Finally, the main parts of the power

conditioning system are the inverters, AC connections and

wiring. All three units are associated with operational losses

[2]

Increasing the performance of PV systems is one of the

main goals of research [3]; to increase the amount of

electricity produced per Wp installed PV capacity. To achieve

such goal we need to understand power losses that occur in the

installed PV systems. Losses due to the energy conversion by

PV cell need a technology breakthrough in the PV components

to be reduced, other losses are unavoidable such us shading.

Inverters are key components in a grid connected PV

Submission date April 5th 2020

system; they influence system performance to a great extent, a

small improvement in their efficiency will reduce the overall

cost of the system significantly.

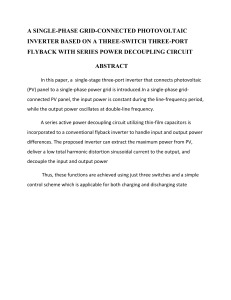

PV inverters consists of variety of components such as

power semiconductors, sensors, resistors, magnetics and

control circuits those components introduce an amount of

power loss dissipated as heat in the inverter. Figure 1 shows

classification of the power losses of the power converter [2].

All of the inverters manufacturers still use the calculation

method of the EURO efficiency in their datasheets [4], which

is a weighted conversion efficiency and originally were taken

for the location of North Germany and still represent a so

called standard on the international level.

The Present work will deal with inverter electrical

efficiency measurement and modeling. A model is developed;

its parameters calculated using field data and applied to data

collected under real operation conditions.

Fig. 1: Classification of the power losses of the power converter.

II. PV SYSTEM DESCRIPTION AND DATA COLLECTION

The PV system is located in the Centre de Développement

des Energies Renouvelables (CDER), Algeria. The main

purpose of the PV system facility is to learn how different

modules perform with a variety of inverters and to learn about

the performance of grid-tied photovoltaic systems.

The PV system is formed by 90 PV modules (Isofoton

106Wp-12 at STC) divided in three sub-generators of 3 kWp

each. The sub-generators are formed by two parallel strings of

15 PV modules in series. Each sub-generator is connected to a

single phase inverter of 3 kW (SMA/ Sunny Boy 3000TL see

table I for the specifications) that injects the generated energy

into a phase of the public low voltage distribution network of

the National Company (SONELGAZ).

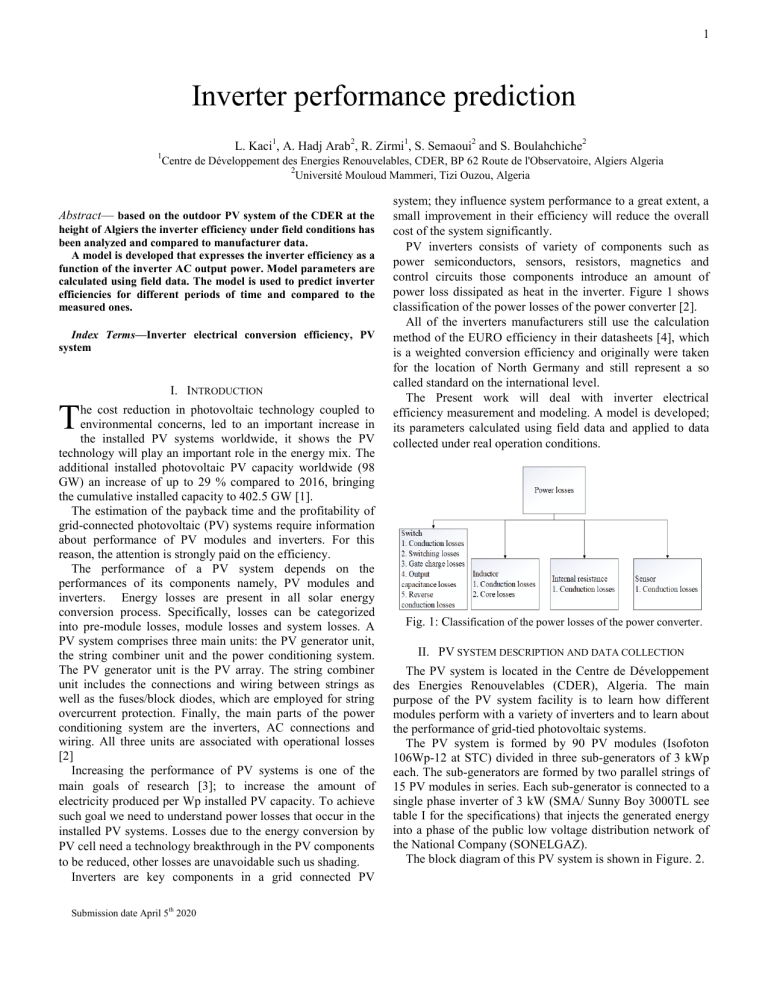

The block diagram of this PV system is shown in Figure. 2.

2

TABLE I

SMA/ SUNNY BOY 3000TL SPECIFICATIONS

DC input

Fig. 2: Schematic diagram of the CDER grid connected PV system.

The CDER PV system is fully instrumented which allow

performance analysis of both PV array and inverters, it is

monitored at five minute intervals, five-minute average

performance data was recorded for the CDER PV system for

up to one year of operation.

III. INVERTER EFFICIENCY MODELS

Inverter efficiency calculation and modeling is very

important for the following reasons:

Optimum yield of expensive PV energy

Criteria for purchase decision

Indicator for innovation capability of the inverter

manufacturer

It can be used in conjunction with a photovoltaic

array performance to calculate expected system

performance.

Inverter manufacturer’s published data generally lists the

conversion efficiencies under optimal conditions; figure 3

shows measured inverter efficiencies versus output power at

three different input voltages VDC of the SMA/ Sunny Boy

5000TL PV inverter (Based on manufacturers data).

Conversion efficiencies under optimal conditions can be

misleading as the optimal efficiencies are not maintained over

the whole range of operation. Inverter performance models

have been proposed to continuously monitor efficiencies that

may indicate need for repair or maintenance.

Maximum DC power at cos φ = 1

Maximum DC voltage*

MPP voltage range at AC nominal power

DC nominal voltage

Minimum DC voltage

Start voltage, adjustable

Maximum input current

Maximum input current per string

Number of MPP trackers

Strings per MPP tracker

AC output

AC nominal power at 230 V, 50 Hz

Maximum AC apparent power

Nominal AC frequency

Nominal AC current at 220 V / 230 V / 240 V

Maximum AC current

Total harmonic distortion of output current at

AC THD voltage < 2 %, AC power > 0.5 AC

nominal power

AC voltage range*

Nominal AC frequency*

Operating range at nominal AC

frequency 50 Hz

Operating range at nominal AC

frequency 60 Hz

cos φ at nominal AC power

3,200 W

550 V

188 V … 440 V

400 V

125 V

150 V

17 A

17 A

1

2

3,000 W

3,000 VA

220 V / 230 V / 240 V

13.6 A / 13 A / 12.5 A

16 A

≤3%

180 V … 280 V

50 Hz / 60 Hz

45 Hz … 55 Hz

55 Hz … 65 Hz

1

Supply phases

1

Connection phases

1

Overvoltage category**

III

* Depends on country configuration

** Voltage surge resistance in accordance with IEC 60664-1

Power losses in the inverter Ploss and conversion efficiency

of the inverter ηinv are calculated from two fundamental

measurements namely the actual power delivered to the

output, Pac, and the input power from the generator Pdc. There

are various mays to express the relationship between these

variables.

𝜂𝑖𝑛𝑣 = 𝑓(𝑃𝑎𝑐 , 𝑉𝑑𝑐 )

𝜂𝑖𝑛𝑣 = 𝑓(𝑃𝑑𝑐 , 𝑉𝑑𝑐 )

𝑃𝑙𝑜𝑠𝑠 = 𝑓(𝑃𝑎𝑐 , 𝑉𝑑𝑐 )

𝑃𝑙𝑜𝑠𝑠 = 𝑓(𝑃𝑑𝑐 , 𝑉𝑑𝑐 )

𝑃𝑎𝑐 = 𝑓(𝑃𝑑𝑐 , 𝑉𝑑𝑐 )

(1)

Where 𝑉𝑑𝑐 in the output voltage from the generator.

Fig. 3. Example of efficiency data available from the CEC.

These curves are for SMA/ Sunny Boy 5000TL

A. Euro model:

Efficiency varies for an inverter depending on the input

power from the generator Pdc; so instead of looking at the

efficiency when the inverter is operating at its rated capacity;

calculating weighted efficiency requires selecting a few DC

input levels relative to the inverter’s rated capacity. European

(EU) efficiency and California Energy Commission (CEC)

inverter efficiency, these types of efficiency are ‘weighted’

efficiencies.

3

European efficiency is widely used all over the world for

grid-connected inverter comparison; it is weighted conversion

efficiency. The European conversion efficiency combines the

weighed inverter efficiency at six points of operation, at

nominal DC voltages.

𝜂𝐸𝑈𝑅𝑂 = 0.03 ∙ 𝜂5% + 0.06 ∙ 𝜂10% + 0.13 ∙ 𝜂20% +

0.10 ∙ 𝜂30% + 0.48 ∙ 𝜂50% + 0.20 ∙ 𝜂100% (2)

Where 𝜂𝑖% is the conversion efficiency at i% of the inverter

output rated power [5].

The European efficiency is mainly used as a reference for

comparison between different inverters; it is not used for

continuous monitoring of inverter efficiency.

B. SANDIA model:

Inverter efficiency, ηinv, derives from the ratio between the

actual power delivered to the output, Pac, and the input power

from the generator Pdc. The difference between Pdc and Pac,

Ploss is converted to heat inside the inverter.

The quadratic function

2

𝑃𝑙𝑜𝑠𝑠 = 𝑎0 + 𝑎1 . 𝑃𝑎𝑐 + 𝑎2 . 𝑃𝑎𝑐

(3)

Fig. 4: Field test results for a 3-kWp SMA/ Sunny Boy 3000TL

inverter recorded during system operation at CDER

C. DRIESSE model:

Sandia model uses true voltages and power values which

will lead to parameters values that span several orders of

magnitude. To overcome this problem Driesse& al proposed

normalization of the measured data.

Power can be normalized to the nominal maximum rating,

𝑃𝑛𝑜𝑟𝑚 (usually output power) [6]; and input voltage can be

normalized to a nominal input voltage, 𝑉𝑛𝑜𝑟𝑚 giving the form:

𝑃𝑙𝑜𝑠𝑠

𝑃𝑛𝑜𝑟𝑚

Provide a good fit for empirical data [6]

Efficiency of the inverter is calculated as follows

𝜂𝑖𝑛𝑣 = 𝑃𝑎𝑐 /(𝑃𝑎𝑐 + 𝑃𝑙𝑜𝑠𝑠 )

(4)

Sandia model expresses 𝑃𝑎𝑐 as a function of 𝑃𝑑𝑐

𝑃𝑎𝑐 = {(

𝑃𝑎𝑐𝑜

𝐴−𝐵

) – 𝐶 ⋅ (𝐴 − 𝐵)} ⋅ (𝑃𝑑𝑐 − 𝐵) + 𝐶 ⋅ (𝑃𝑑𝑐 – 𝐵)2

(5)

Where

𝐴 = 𝑃𝑑𝑐𝑜 ⋅ {1 + 𝐶1 ⋅ (𝑉𝑑𝑐 − 𝑉𝑑𝑐𝑜 )}

𝐵 = 𝑃𝑠𝑜 ⋅ {1 + 𝐶2 ⋅ (𝑉𝑑𝑐 − 𝑉𝑑𝑐𝑜 )}

𝐶 = 𝐶𝑜 ⋅ {1 + 𝐶3 ⋅ (𝑉𝑑𝑐 − 𝑉𝑑𝑐𝑜 )}

We can see from the equation (3) above that it is a quadratic

function just like equation (1). 𝑃𝑑𝑐𝑜 is the rated DC power,

𝑃𝑎𝑐𝑜 the rated AC power and 𝑃𝑠𝑜 the self-consumption are

directly for the inverter specification data sheet [6]. Co is a

parameter defining the curvature (parabolic) of the

relationship between ac-power and dc-power at the reference

operating condition, default value of zero gives a linear [6].

The performance model was very effective in fitting

measured data for inverters Xantrex GT3.8 and PVP3200 with

a standard error in measured versus modeled efficiency of

about 0.1% [7]. And the model was also very effective with

SMA/ Sunny Boy 3000TL [1].

Relations between 𝑃𝑑𝑐 vs 𝑃𝑎𝑐 and 𝑃𝑑𝑐 vs 𝜂𝑖𝑛𝑣 are illustrated

in fig 4 using field data of the CDER PV system with

hundreds of measurements recorded over a 5-days period from

September 1st 2018 to September 5th 2018.

𝑃𝑑𝑐

= 𝑓(𝑃

𝑛𝑜𝑟𝑚

𝑉𝑑𝑐

,𝑉

𝑛𝑜𝑟𝑚

)

(6)

This model is essentially the double quadratic model

expressing this in normalized form, and using voltage

deviation from nominal rather than absolute voltage, gives the

equation:

𝑃𝑙𝑜𝑠𝑠 = (𝑏(0,0) + 𝑏(0,1) (1 − 𝑣𝑑𝑐 ))

+ (𝑏(1,0) + 𝑏(1,1) (1 − 𝑣𝑑𝑐 )) 𝑝𝑑𝑐

2

+ (𝑏(2,0) + 𝑏(2,1) (1 − 𝑣𝑑𝑐 )) 𝑝𝑑𝑐

(7)

This model was successfully tested with the California

Energy Commission (CEC) data for 12 different inverters and

achieved a very good accuracy[6].

IV. PROPOSED MODEL

In field testing the inverter performance data recorded are

completely representative of the actual system operating

conditions.

The two fundamental measurements, to calculate the

inverter performance are 𝑃𝑑𝑐 the input power from generator

and 𝑃𝑎𝑐 the output power from inverter that are available in

field installed PV system.

Most of the existing models departs from the quadratic

function equation (3) to estimate PV inverter efficiency; our

proposed model will use the double exponential as it is clear

from 𝜂𝑖𝑛𝑣 versus 𝑃𝑎𝑐 curve (fig 5) that 𝜂𝑖𝑛𝑣 (𝑃𝑎𝑐 ) is of the

following form.

𝜂𝑖𝑛𝑣 (𝑃𝑎𝑐 ) = 𝛼1 . 𝑒 𝛽1.𝑃𝑎𝑐 + 𝛼2 . 𝑒 𝛽2.𝑃𝑎𝑐

(7)

Where 𝛼1 , 𝛽1 , 𝛼2 and 𝛽2 are constants to be determined.

4

Figure 5 illustrates a field test carried out at the CDER

facility with hundreds of measurements recorded over a 6days period.

The coefficients 𝛼1 ,𝛽1 , 𝛼2 and 𝛽2 must be found by fitting

the function to the measured field data. The fit is done using

the least square method, MATLAB software is used. Results

are shown in table II

TABLE II

PARAMETERS OF THE MODEL

Parameters

Values

𝛼1

𝛽1

𝛼2

𝛽2

0.9885

-1.56E-05

-0.6678

-0.02325

Goodness of fit:

SSE: 0.3249

R-square: 0.9426

Adjusted R-square: 0.9423

RMSE: 0.02428

Where :

Sum of Squares Due to Error (SSE): It measures the total

deviation of the response values from the fit to the response

values. The closer its value to 0 the better is the fit.

R-Square.: This statistic measures how successful the fit is in

explaining the variation of the data, a value closer to 1

indicating a better fit.

Root Mean Squared Error: This statistic is also known as the

fit standard error. RMSE value closer to 0 indicates a better fit

[8].

Fig. 7: Model residual plot

V. MODEL VALIDATION

This model is tested using the CDER facility PV system

using the SMA/ Sunny Boy 3000TL single phase inverter.

Model parameters are shown in table II they are calculated

using 5-days period data from September 1st 2018 to

September 5th 2018. Validation data used are from 5-days

period of November and December.

Results for November are shown Figure 8, residuals are

shown in figure 9 and figure 10 shows a linear regression of

estimated efficiency 𝜂𝑖𝑛𝑣 versus measured efficiency.

Fig. 8: 𝜂𝑖𝑛𝑣 Versus 𝑃𝑎𝑐 curve estimated and measured 5-days

period November

Fig. 6: 𝜂𝑖𝑛𝑣 Versus 𝑃𝑎𝑐 curve

Model residual plot is shown in Figure. 7 the difference

between the measured efficiencies and the predicted

efficiencies using the prediction equation (7). As we can see

the data points for Pac greater than 100 W the residual is

around zero.

Model residual plot shown in Figure. 9 describes the

difference between the measured efficiencies and the predicted

efficiencies using the prediction equation (7) with the

calculated parameters in table II. As we can see the data

points for Pac greater than 100 W the residual is around zero

almost the same as for the September data used for parameters

calculation.

5

Fig. 9: 𝜂𝑖𝑛𝑣 measured residual plot (Nov)

Fig. 13: 𝜂𝑖𝑛𝑣 estimated versus 𝜂𝑖𝑛𝑣 measured linear regression

(December)

VI. CONCLUSION

Fig. 10: 𝜂𝑖𝑛𝑣 estimated versus 𝜂𝑖𝑛𝑣 measured linear regression

November

Results for December are shown Figure 11 residuals are

shown in figure 12 and figure 13 shows a linear regression of

estimated efficiency 𝜂𝑖𝑛𝑣 versus measured efficiency

High-resolution (five minutely) performance data, recorded

for the CDER PV system over a 1- year period, model has

been used to construct simple empirical model of the

performance of the SMA/ Sunny Boy 3000TL Inverter during

normal operation.

This paper describe a new model for inverter electrical

conversion efficiency whose parameters are calculated using

only measured actual power delivered to the output, Pac, and

the input power from the generator Pdc ; measurements that are

available in field.

Once the inverter model 𝜂𝑖𝑛𝑣 = 𝑓(𝑃𝑎𝑐 ) parameters

calculated, they are used to predict efficiency for other periods

of the year namely November 2018 and December2018.

The model very effective with SMA/ Sunny Boy 3000TL and

as future work it will be tested on other types of inverters. .

By incorporating inverter performance model in the process

of PV monitoring system it will allow users to continuously

monitor the inverter efficiency and it’s deviation from the

estimated efficiency. This will help in diagnose causes of

inverter performance degradation, and facilitate expedient

and cost-effective field maintenance as well as need for

repair and maintenance [7].

REFERENCES

Fig. 11: 𝜂𝑖𝑛𝑣 Versus 𝑃𝑎𝑐 curve estimated and measured 5-days

period December

[1]

[2]

[3]

[4]

[5]

Fig. 12: 𝜂𝑖𝑛𝑣 measured residual plot (December)

A. Hadj Arab & al“ Analyse des performances des

onduleurs du système photovoltaïque connecté au réseau du

”. Revue des Energies Renouvelables Vol. 22 N°1 (2019)

123 – 134

Elena Koumpli“Impact of data quality on photovoltaic (PV)

performance assessment” A Doctoral thesis Loughborough

University. November 2017.

S.K. Firth & al “A simple model of PV system performance

and its use in fault detection” Solar Energy 84 (2010) 624–

635.

F.P. Baumgartner, “euro realo inverter efficiency: dcvoltage dependency” 20th European photovoltaic solar

energy conference, 6-10 June 2005; Barcelona, Spain

assimo Valentini “PV Inverter Test Setup for European

efficiency, Static and Dynamic MPPT Efficiency

Evaluation”. Conference Paper · June 2008 DOI:

10.1109/OPTIM.2008.4602445 · Source: IEEE Xplore

6

Anton Driesse, Praveen Jain “beyond the curves: modeling

the electrical efficiency Of photovoltaic inverters” 2008

[7] David L. King & al “Performance Model for GridConnected Photovoltaic Inverters” SANDIA REPORT

SAND2007-5036 Unlimited Release Printed September

2007.

[8] Mathworks user guide “Curve Fitting Toolbox” p 29

[9] Adarsh Nagarajan & al “Photovoltaic Inverter Reliability

Assessment”. Technical Report NREL/TP-5D00-74462

October 2019

[10] BENDIB D, “Experimental setup for testing

commercial pv inverters” Conference Paper · December

2015

[6]