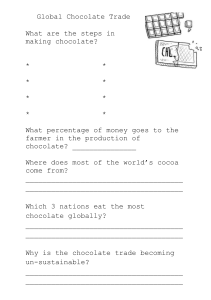

Please use the sharing tools found via the share button at the top or side of articles. Copying articles to share with others is a breach of FT.com T&Cs and Copyright Policy. Email licensing@ft.com to buy additional rights. Subscribers may share up to 10 or 20 articles per month using the gift article service. More information can be found at https://www.ft.com/tour. https://www.ft.com/content/dbd20f9f-b9f7-4bf4-86dd-1a8c84069f01 Fairafric, a German-Ghanaian company, is trying to break the mould by producing exportquality chocolate in large quantities. It has built a $10m factory north of Accra, the capital, that will produce 50m bars a year, rising to 100m. That is still modest by the standards of automated European contract manufacturers, which can churn out 10 times that amount for global brands. Hendrik Reimers, fairafric’s founder, says that by turning beans into bars domestically, five times more value stays in Ghana. The problem, he says, is not that cocoa beans are sold too cheaply. In Europe 200 years ago, most people were smallholder subsistence farmers. “I don’t think Germany would have developed any faster if there were better prices for potatoes,” he says. The remedy is not to raise the price of cocoa but to process it. Ghana starts off at a disadvantage. It has no dairy industry, so milk powder must be imported. Its packaging does not compare for cost or sophistication with the west. Energy is more expensive and less reliable. Ghana is hot, which means you need more power to keep the chocolate from melting. It is further from global markets and so less attuned to consumer tastes and less close to big retailers such as supermarkets. None of this is insurmountable, says Reimers. True, Ghana cannot yet compete on price with robotised western factories. But made-in-Ghana chocolate does well in a premium market. It can also tap a growing segment of western consumers, especially millennials, who respond to stories about supply chains that create decently paid jobs. The discussion goes well beyond chocolate. In Asia, almost no economy of any size clambered out of poverty without manufacturing. As economists including Dani Rodrik and Ha-Joon Chang have argued, Asian economies from Japan and South Korea to Taiwan and China clawed their way on to the development escalator by training their workforce in factories.