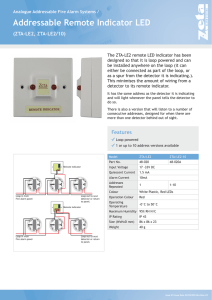

TECHNICAL SPECIFICATION FOR FIRE DETECTION AND ALARM SYSTEM GENERAL: This General Technical Specification covers the technical requirement for Microprocessor Based Analogue Addressable Type Intelligent Fire Detection and Alarm System (FDAS) for Utility building and Vashi Zonal Store Building at BRIT Vashi Complex, Mumbai. SCOPE OF WORK: 1. The FDA system shall cover design, engineering, supply, erection, installation, testing & commissioning of the FDA system. 2. The FDA system shall consist of minimum following equipment: Smoke detectors, Heat detectors, and Multi criteria detectors combination of rate of rise heat detector & photo electric smoke detector, other types of detectors as per the design criteria. 3. Two MAIN FIRE ALARM CONTROL PANEL (FACP) along with accessories to integrate with the firefighting system for automatic actuation. 4. Break glass type microprocessor based addressable manual call points with chain & hammer. 5. Hooters. 6. Transponders/ Interface Modules. 7. Response indicators where required for above false ceiling detectors & normally closed rooms. 8. Power supply equipment. 9. U.P.S system with Battery back - up for 24 hours, in case of power failure, shall be provided. 10. Siren and Accessories. 11. All types of cables (FRLS) and cabling accessories. 12. Erection materials 13. Earthing Materials & Earthing. 14. Minor civil works required for installing FDA System equipment as required. 15. GI pipes /GI conduits /PVC rigid conduits and other accessories wherever required for laying of cables. Trench work, if required, for cabling. 16. All erection accessories, consumables and miscellaneous material not indicated in specification but required for completing the job in all respects. 17. Preparation of Design and detailed engineering drawings and documentation, bill of materials with specification. 18. Testing and Training for operation and maintenance of the system, manuals, asbuilt drawings, Commissioning spares till handing over of the system 19. One year onsite comprehensive warranty. LIST OF ITEMS: Sr. no 1. 2. 3. 4. Item Description Qty a) MAIN FIRE ALARM CONTROL PANEL with Analogue Addressable Microprocessor based Networkable Two loop fire detection panel capable of handling 99 detectors and 99 devices with Modbus compatible with standard accessories. b) MAIN FIRE ALARM CONTROL PANEL with Analogue Addressable Microprocessor based Networkable Single loop fire detection panel capable of handling 99 detectors and 99 devices with Modbus compatible with standard accessories. Analogue Addressable Photoelectric Detector with base for below ceiling. Analogue Addressable Heat Detector with base. 1 no 1 no 110 nos. 25 nos 5. Analogue Addressable Multisensory (Heat + 5 nos Photo) Detector with base for below ceiling Addressable Manual Call Point with back box 13 nos 6. Fault Isolator with Base. 7 nos 7. Response Indicator with base 40 nos 8. Loop powered sounder with base 13 nos 9. 11. Armoured Cable: 2 Core 1.5 sq-mm armoured 3000 Metres FRLS cable (ISI Marked Polycab, Neoflex Masterflex ), UPS for fire panel of capacity 1100 VA with 2 nos standard accessories. Junction Box , Size 4” X 4” 160 nos 12. Beam detector of 50 m with standard accessories. 3 nos 13. Fire Exit Board 8 nos 14. Installation Charges LumSum 10. 1. Single Loop and Two Loop Addressable Main Fire Alarm Control Panel: - The Fire Alarm Control Panel should be completely modular system construction and should allow it to be used in almost any system, from small systems up to networked systems covering a large area. Basic Configuration of Fire Alarm Control Panel shall include. Fully-redundant microprocessor technology. Full redundancy of the panel for backup in the event of an error. All hardware components of the devices as well as bus connections, shall be doubly (redundantly) laid out. The control panel shall provide an analogue Addressable Microprocessor based Networkable Single / Two loop fire detection, panel capable of handling 99 detectors and 99 devices with Modbus compatible. The control module shall provide a indicating circuit where indicated on the plan. An open circuit fault shall be annunciate at the Fire alarm panel. Some of general requirements of the control is as mentioned below: Feature: User interface LCD Display / LED Display / Touch Screen Panel shall monitor the status of all devices on the addressable loop for fire, short circuit fault, open circuit fault, incorrect addressing, unauthorized device removal or exchange. Supply Voltage : 230V 50Hz AC (+10%, -15% voltage tolerance) Max. PSU Rating : 2.5A total, comprising Battery Charger: 0.5 Amp Internal & External Loads : System Load: 1.8A @ 24V nominal, Max Loop Load: 460mA :24V sealed lead acid batteries, 2x 12V 12Ah Standby Batteries Dimensions (mm) Weight Environmental Operating Limits Construction Cable Entry : 400 x 400 x 135 (H x W x D) :10 kg without batteries Temperature : 0°C to +40°C Humidity : 85% non-condensing (maximum : Sheet steel painted, sealed to IP30 : 14 x 20mm knock-outs in top of cabinet 2 x 20mm knock-outs in bottom of cabinet Loop Capacity Zones : 460mA per loop maximum : Up to 20 zone with individual LED indicators Internal Sounder : Intermittent buzzer (fault condition) High-pitched continuous buzzer (fire condition) Sounder Outputs: 2 programmable outputs. Open and short-circuit monitoring. 1A maximum per output. Auxiliary Relays: 1 fault and 1 fire relay voltage free, changeover outputs Contacts rated at 24V AC/DC, 1A, 0.6 PF maximum. External Outputs User Controls Programming Controls : SOUND ALARMS, SILENCE/ RESOUND, MUTE BUZZER, ACCEPT, SYSTEM RESET : Alphanumeric multi-level keypad with 15 keys and 5 control keys: YES, NO, CHANGE, ENTER and SHIFT LED type general panel status indicators : FIRE, FAULT, ACKNOWLEDGED, ISABLEMENT, TEST, SOUNDER FAULT, DELAYED MODE, RELAYS DISABLED, EARTH FAULT, SYSTEM /CPU FAULT, SOUNDERS DISABLED, ALARMS SILENCED, SUPPLY FAULT, POWER. LED type zone Indicators (for 20 zones) Display : FIRE, FAULT/TEST/DISABLED : LCD Display or Touch Screen with back-light. Serial Interface : 2 serial ports with connections for optional RS485 or RS232 plug-in communication cards. Or USB : Maximum 99 panels can be networked using a Master Network and connected Sub-Networks. Networking 2. Analogue Addressable Photoelectric Detector With Base For Below Ceiling:Features: - • Rotary decade address switches • Aesthetic design to harmonise with the modern built environment • Base complements the detector and is easy to install and wire • Genuine and fast response • Advanced protocol and smoothing filter to suppress false alarm • Easy to maintain (washable filter) • Analog addressable communication • Enhanced smoke chamber design to reduce false alarms by dust or contamination • Dual integrated LED for 360° visibility • LPCB approved • Conforms to EN54-7/ EN54-5 and EN54-29 • Environment friendly - meets RoHS legislative requirements Mechanical specification Height : 52 mm installed in B501AP base Diameter : 102 mm installed in B501AP base Weight : 97 g (incl. base) Max Wire Gauge for : 2.5 mm2 Colour : White Material : PC/ABS el Non-Isolated Product Electrical specification Operating Voltage Range : 15-32 V DC Maximum Standby Current: 260 μA @ 24 V DC (no communications) :310 μA @ 24 V DC (LED blink enabled, once every 5s) LED Current : 3.5 mA @ 24 V DC Remote Output Voltage : 22.5 V DC @ 24 V DC Remote Output Current :10.8 mA @ 24 V DC Additional loop Resistance : 20 mohm (max 30 mohm) Environmental Specifications: Temperature Range -30°C ... +70°C Humidity 10 ... 93% relative humidity (non-condensing) APPROVALS: EN54-17: 2005 EN54-7: 2000+A1:2002+A2:2006 Detectors: HM/PSE Optical smoke detector Accessories: Sensor and AV standard base, Deep base for B501AP/IV 781814 MI, Remote indicator for HM Series detectors 3. Analogue Addressable Heat (Thermal) Detector With Base:Features: • Dual thermistors • Rate-of-rise fixed temperature and high fixed temperature models • Common base for optical, ionisation and thermal sensors • Addressable-analogue communication • Stable communication technique with noise immunity • Low stand-by current • Rotary decade 01 to 99 address switches • Remote LED output as standard • Dual LED design provides 360° viewing angle • Visible LED’s blink every time the detector is addressed, and illuminate steady on alarm • Built-in functional test switch activated by external magnet • Optional relay, isolator, or sounder bases Mechanical Specifications Dimensions (Height) : 51 mm installed in B501 Weight : 170 gr. (6 oz) Operating temperature : - 10°C to 60°C Humidity : 10% to 93%, non-condensing Compatible bases : B501, B524IEFT, B524RLY Electrical Specifications Operating voltage : 15 to 32 Vdc Alarm Current (LED on) : 7mA maximum Stand by current : 200 μA maximum Terminals : SEMS screws with clamping plates for up to 2.5 mm2 (13 AWG) wire Environmental Specifications: Temperature Range -30°C ... +70°C Humidity 10 ... 93% relative humidity (non-condensing) APPROVALS: M-RHSE: EN54-5: 2000 Class A1R (and EN54-17: 2005 for -I) HMFHSE: EN54-5: 2000 Class A1S (and EN54-17: 2005 for -I) EN54-5 states that Class A1 has a maximum application temperature of 50°C, Class B has a maximum application temperature of 65°C. Detectors: HM/FHSE Fixed 58° thermal detector HM/RHSE Rate of Rise thermal detector Accessories: Sensor and AV standard base, deep base, remote indicator for HM Series detectors 4. Analogue Addressable Multisensory (Heat + Photo) Detector With Base For Below Ceiling:The Multi Sensor Detector shall be deployed as a smoke detector, heat detector or as a combination detector, as per the site requirement. • Principle of function shall be “Scattered light” and “NTC sensor”. • Smoke detection shall also always involve temperature evaluation. • In the event of a rapid increase in temperature, it should get annunciate without the formation of smoke. • Smoke and temperature sensors would be able to be activated and disabled separately. • Automatic changeover based on time of day /season to season. • The highest degree of safety should be maintained by detecting smoke particles of all sizes. • Detectors should have in-built integrated short circuit isolator which shall ensure, in the event of a wire break or a short circuit, the fault is localised and that the operation the loop circuit continues unimpeded. • The detectors should constantly monitor their surrounding conditions with regard to absolute highest temperature and relative temperature increase and should calculate the optimum smoke and heat sensitivity for the area it is deployed in based on these factors. The sensitivity should always remain within the range set out in standards. • Detectors should be capable of constant self-tests and should have resistant against environmental influences. • Detectors shall have in-built over voltage protection Features: • Optical and thermal sensors • Microprocessor controlled with internal algorithms • Enhanced signal processing for improved stability • High immunity to unwanted alarms 2 auto learn sensitivity settings • 3 fixed sensitivity photo thermal settings • Thermal only detection mode • Twin LEDs for 360º visibility • Built-in test • Third party certified to CEA 4021, EN54-7:2000 and EN54-5:2000 Specifications: Mechanical Specification Dimensions (mm) : 400 x 400 x 135 (H x W x D) Weight : 115g Colour : Pantone warm grey 1C Material : Bay blend FR110 Terminal wire gauge : 2.5mm2 max. Operating temperature: -20ºC to +60ºC Relative humidity : 10% to 93 %( non-condensing) Electrical Specification Voltage : +15 to +32Vdc Standby current: No communication : 250μA @ 24Vdc maximum One communication every 5 seconds, LED blink : 300μA @ 24Vdc maximum Alarm current : 7mA @ 24Vdc maximum Sensitivity modes 1 High (1%/ft.) 2 Medium to high - auto adjusting (1-2%/ft.) 3 Medium (2%/ft.) 4 Low to Medium - auto adjusting (2-3%/ft.) 5 Low (3.5%/ft.) 6 Thermal only - Class A1R (58ºC) Environmental Specifications: Temperature Range -30°C ... +70°C Humidity 10 ... 93% relative humidity (non-condensing) APPROVALS: EN54-5:2000+A1:2002 EN54-17 : 2005 CEA 4021:2003 EN547 : 2000+A1:2002+A2:2006 EN54-29:2015 6,1 to 9,4% variable Obs./m + Class A1R Alarm Level 1 3% Obs./m + Class A1R Alarm Level 2 3% ... 6.1% variable Obs./m + Class A1R Alarm Level 3 6.1% Obs./m + Class A1R Alarm Level 4 6.1 ... 9.4% variable Obs./m + Class A1R Alarm Level 5 9.4% Obs./m + Class A1R Alarm Level 6 Class A1R Detectors: HM/PTSE Optical-thermal smoke detector Accessories: Sensor and AV standard base, deep base, remote indicator for HM Series detectors 5. Addressable Manual Call Point With Back Box: - The addressable Manual Call Point (MCP) should be capable to manually trigger a fire alarm and should be suitable for connecting to OEMs loop technology. The MCPs should contain a short circuit isolator and a red alarm LED. The alarm should be triggered by smashing the glass panel, with the alarm remaining in alarm state until a new glass panel is inserted. Manual call point shall be in compliance to EN54 Standards. Features: • Direct decade addressing (01-99) • Built-in electronics • Fast response • LED shows polling (optional) and activation • Flush or surface mounting • Up to 99 per loop (+99 analogue sensors) • LPCB approved • Simple to test • Designed to the requirements of BS5839, Part 2 • IP67 rated model Specifications: Mechanical Specification Operating temperature : - 10°C to 60°C Humidity : 10% to 93% non-condensing Dimensions (HxWxD) : Surface: 87 x 87 x 52 mm Weight : 125 gr. Electrical Specification Operating voltage : 15 to 32 Vdc Current consumption Stand by current : 200 μA @ 24 Vdc LED current : 7 mA @ 24 Vdc 6. Fault Isolator With Base: - Fault Isolator Module shall be used on panel intelligent loop communication circuits along with other modules and sensors. It detect a wire-to-wire short and electrically isolates that condition from the circuit so that communication is maintained with unaffected devices on the same circuit. Application: The module enables part of an intelligent interface board communication circuit to continue operating when a short occurs on the circuit. If used in a two wire loop configuration, one module isolates a short to the part of the loop between the module and the intelligent interface board, allowing the rest of the loop to continue operating normally, the modules isolate a short or open to the part of the loop between them. In a star configuration a module can be used in each leg so a short on one leg does not affect communication on any other leg. An integral LED blinks to indicate normal status and is on to indicate a short in the loop. Features: DIN rail mounting option • Surface mounting option • Plug in connectors • Tri-colour LED status indication • Address selector switches visible in 2 planes • LED status visible in 2 planes • Approved to GEA GEI 1-082 and CEA GEI 1-084 Mechanical: Dimensions (mm) 93 x 94 x 23 (H x W x D) Weight 62g Operating Environmental Specifications: Temperature -20 ºC to +60 ºC Humidity 0 to 95% maximum non-condensing Electrical Specification Electrical Operating voltage 15 to 30 Vac Standby current 200µA at 24 Vdc maximum Fault detection delay 100 to 400 mS on resistance 0.065Ω at 15 Vdc maximum Terminal Wire 2.5 mm DIN rail mounting clip 7. Response Indicator: - The response indicators should have to be of approved quality. Duel LED should be there and should get actuate at the time fire detected in the detector. FEATURES Compatibility with all Detectors Dual LED Lamp ABS Plastic Indoor use only Wall Mounted & Ceiling Mount TECHNICAL SIZE H61m.m x W72m.m x D18m.m Wire Entrance Back side of the Component Alarm Current 10 mA, LED Lamp 5 mm LED Lamp Glow Light colour red Enclosure Colour White or Off White Voltage 24v Dc Mounting Methods in of the Cabinet 8. Loop Powered Sounder With Base: - Shall be suitable for indoor allocation. All hooters shall be 24 VDC operated. The Max sound level shall be about 100 dB @ 10 feet. Hooter shall be in compliance to EN54 standards The hooters shall be loop powered and shall drew power from the main panel for their operation in alarm condition. Electrical Specification: Supply Voltage: 15 to 32VDC (Non-isolation) 15 to 28VDC (Isolation) Standby Current: 120μA (Non-Isolation) 225μA (Isolation) Max current consumption: 11.4mA (High Volume Tone 21 @24V) Max Sound Output 97dB (A) +/-3dB @1metre (High Volume, Tone 8 @24V) Environmental Specification: Operating Temp: -25o C to 70o C Relative Humidity: Up to 95% non-condensing Ingress Protection: IP44 (with surface mount base) IP65 (Waterproof base) Approvals: Approved to: EN54-3, EN54-17 where applicable and CPD for RoHS, WEEE & REACH information Terminal Size: 1.5 - 2.5mm2 max Number of Tones: 32 Volume Setting: High, Medium, And Low Mounting options: Low Profile, Surface or High IP 9. Armoured Cables: - The cables required for detectors connection shall be multi core, stranded as per IS-1554, IS – 8130 & IS – 5831. The cable shall be Fire Resistant Low Smoke (FRLS), screened type. However if any special cables are required for detector cabling etc., the tenderer shall specify clearly briefing the specification. For detector wiring - Annealed tinned solid copper conductor of 1.5 sq. mm, as required (IS – 1554) PVC insulated & PVC sheathed, Armoured cable. Cables connected to detectors shall be given ‘S’ loop on both sides of the detectors which shall be properly clamped to the ceiling. ‘S’ loop shall also be left where cables connect sounders, panels, dampers, etc., Appropriate glands shall be provided for the armoured cable near terminals of junction box. All the cables and wires shall be tagged for proper identification. Wires shall be identified by ferrules at junction and cables by colour bands at every 3 M distance. Over-headlines for fire alarm system shall not be used when connecting different building. They shall be laid underground according to IS: 1255-1983. The cables and wiring for fire Alarm circuit shall not be clubbed with other cables and wiring which must be laid well away from them. The panel should have additional capacity to operate auxiliary equipment like fire dampers, ventilation and / or pressurizing fans, emergency light, smoke vents etc. if required. Unused cable holes if any should be plugged. The contractor shall dispose of the debris in connection with this job at his own expenses by his own transport and labour and clean out all part of the work and leave everything clean. 10. UPS: Emergency power supply for a supply interruption period of 24 hours. • One point monitoring for all detector zones. • Alarm counter. • Real time clock and Recognition and evaluation of the status of detectors along with this all other parameters that are required for making the addressable type control panel full proof should be maintained. Input Voltage 220 - 240 Vac Frequency 50/60 Hz ±3 Hz (Auto-sensing) Brownout Transfer 155 Vac, Typical Over-voltage Transfer 280 Vac, Typical Output UPS Capacity (total) 1100 VA / 550 W Voltage On Battery 230 Vac rms Frequency on Battery 50/60 Hz ± 1 Hz Transfer Time 4 ms typical Protection AC Input Resettable circuit breaker Battery Type (maintenance free, lead acid) 12 V, with 4 nos 12 AH 11. Junction Box: 4”/4” metal Junction box made of 16SWG sheet steel is to be provided for mounting of detectors in the concrete mother ceiling along with necessary glancing. 12. Beam Detector: The linear BEAM type smoke detector should consists of a combined transceiver unit and an accompanying reflector which is to be fitted without any other accessories. The distance between opposite walls is to be kept between 10 and 80 m from one another. If required, special additional stable ball joint units may be used to ensure that they are precisely fitted. The infrared beam that is emitted by the transmitter and is to be bounced back by the reflector and to be evaluated by the receiver. This is to be done by measuring the absorption of the infrared beam and of the smoke or fire modulation. The detectors should get individually adapted to local conditions in the event of there being difficult visible conditions like strong interference from foreign light sources, reflections or very short monitoring distances etc. The beam detector should be connected to the loop line via. individual monitor/ IO module to enable the detector being addressable and it should operate in separate DC supply of 12 – 24 V 13. Fire Exit Board: Self illuminous “FIRE EXIT” sign boards shall be provided indicating escape routes to escape. TERMS AND CONDITIONS 1. INSTALLATION AND COMMISSIONING: Installation and commissioning of the entire system is in the scope of the Vendor /Supplier. The scope of work is as mentioned above. 2. FREE ISSUE MATERIAL: There will not be any free issue material by BRIT. 3. The complete system along with all its accessories should be from the same supplier so that there will not be any compatibility issues during system integration. Also only one party shall be responsible for the warranty and maintenance of the complete equipment after delivery. 4. Vendor / Supplier shall supply the complete documentation of the fire alarm system that: includes supply of three of sets of the following: - circuit diagrams, wiring diagram, operation and maintenance manual, installation manual, software, catalogues of individual components etc. . 5. WARRANTI: All work performed and all material and equipment furnished under this contract shall be free from defects and shall guarantee least one year of trouble free operation from the date of acceptance by the end user. The full cost of maintenance, labour and materials required to correct any defect during this period shall be a part of the submittal bid. 6. MAINTENANCE CONTRACT: The Vendor/Supplier shall provide complete service for the supplied equipment during the warranty period. However after the warranty is expired the supplier shall be able to undertake maintenance contract (Three years) on demand by the purchaser with additional charges whichever is applicable. 7. COMPLETION OF ORDER: The above mentioned work should be completed within 60 days from the date of release of purchase order. 8. Any minor design modifications/changes required at the time of installation should be incorporated by the supplier to suit our requirement with no extra charges. 9. Vendor/Supplier shall have an experience of installation of at least 10 similar systems in the past 3 years in any industry preferably few in Department of Atomic Energy. 10. Order copies of at least l0 similar systems sold & serviced in India: by the vendor in the last 3 years and currently under Warranty / Annual Maintenance Contract duly certified by end user to be provided. 11. Vendor/ Supplier shall have local agents capable of providing any type of services after the complication of installation and commissioning system. 12. Pre-dispatch inspection and training should be arranged by the supplier for at least three personnel of BRIT at the supplier site. 13. Police Verification Certificate: For working inside BRIT facility, it is mandatory to have a Police Verification Certificate, police in respect of all the contractor's employees, including proprietor. Without PVC workers will not be allowed to work inside the premises. 14. PLACE Of DELIVERY: Vashi zonal stores, BRlT/BARC Vashi complex, sector- 20, Vashi, Navi Murnbai, PRE-DISPATCH INSPECTION: The following activities will be earned out without any additional charges. 1. Checking the specifications of individual components. 2. Physical in inspection, dimensional check and mechanical fittings of individual subassemblies. 3. Checking of functions of the microcontroller based control panel. 4. Checking of smoke detector, heat detector, hooter etc. 5. Testing of the micro controller panel using few of the test loops connected with smoke detector, heat detectors and hooters. 6. Test for identification of fault in any detector m a loop and random checking of smoke detectors, heat detectors and sounder from the panel. 7. Training can be given for operational and maintenance of the equipment. It includes demonstration of systematic operating procedures for the operation of the equipment as wen as handling of the instrument in case of system failure or some human faults and training for the maintenance of the complete equipment. 8. Any instruments required to carry out the test at the time of inspection can be supplied by the supplier. ACCEPTANCE CRITERIA: - The following acceptance tests shall be apart from the standard or routine tests should be normally conducted by the supplier after the installation of the complete system. Few of the test are mentioned below. 1. Testing of each components like smoke detectors, Heat detectors etc., by physical simulation. 2. Functional tests of the microcontroller based fire alarm panel. 3. Zone alarm. Test, fault detection test etc. 4. The Mock trial of the complete Fire Detection and Alarms system, 5. Mains failure performance. 6. UPS consistency test. 7. Open/Short circuit of each detectors, sounder circuit to be tested etc.