Equilibrium Ratios of Water in the Water-Triethylene

Glycol-Natural Gas System

FRANK R. SCAUZILLO

ABSTRACT

INTRODUCTION

During the last several years, the drying of natural

gas with aqueous triethylene-glycol (TEG) solutions

has become very prominent. Most users of TEG as a

drying agent have been satisfied with the performance of

TEG solutions at the conditions used; however, there

always has been some discussion of the drying ability

of TEG solutions at conditions not commonly encountered such as temperatures below 50° or 60 P, but more

particularly temperatures above 100 P, and pressures

above 1,000 psia. Today, when higher wellhead temperatures such as 120 P are more commonly encountered

many are skeptical of TEG's ability to dry sufficiently

well to provide dew points around 32°P, which is generally the maximum tolerable when attempting to dry a

gas to contract specifications of 7 Ib/MMscf.

These views probably have evolved to some extent

from the days when suppliers would not guarantee dewpoint depressions in excess of 65° to 75°P. Also, the

feelings about TEG drying may have arisen from the

lack of information about the equilibrium relation of

water in the drying operations.

Porter and Reid ' have reported equilibrium data for

a 95 per cent TEG solution, while Townsend' reported

0

0

0

Original manuscript received in Society of Petroleum Engineers

office July 13, 1960. Rovised manuscript received March 10, 1961.

Paper presented at 35th Annual Fall Meeting of SPE, Oct. 2-5.

1960, in Denver

lReferences given at end of paper.

JULY,

1961

SPE 1567-G

equilibrium data for 95, 98 and 100 per cent TEG

solutions. Townsend also presented a calculational

method which obtains activity coefficients in the liquid

phase and, subsequently, the equilibrium water content

of a saturated gas over glycol from published' atmospheric dew points. Wise, Puck and Pailey' present~d

activity data for the water-TEG system at atmosphenc

pressure.

In the past, the equilibrium ratios published for water

in a 95 per cent by weight aqueous TEG solution have

been used indiscriminately by many for all concentrations of TEG encountered in gas drying operations.

Since essentially all such gas operations require the use

of more concentrated TEG solutions, a study was undertaken to correlate the existing equilibrium data for

aqueous TEG and gas systems and to provide some

means of calculating the equilibrium ratio of water in

the natural gas-water-TEG system where TEG concentrations were other than 95 per cent. The data presented

herein consider only the equilibrium drying ability of

the TEG solutions and do not consider the effect of

temperature and pressure on the tray efficiency of contactors. In other words, this paper is concerned primarily with the development of the equilibrium relationship between water in the dried natural gas and the

water in the lean TEG entering the top tray of the

absorber.

BASIC EQUILIBRIUM RELATIONS

A relationship which relates the K value of water in

the natural gas-water-TEG system to the vapor pressure

of water at the system temperature, the total pressure

of the system and the activities of the liquid and gas

phases has been evaluated.

It is well known that, for any component of a mixture at equilibrium between a gas phase and a liquid

phase,

(1)

fv = fL and Yv Y fv ° = yr, X fLO

Y

YL fr,O

X

=

(2)

Yv---Y:O ,

and

I

V(p -

y

Yr,

p

)

I' e -~'~'1-

(3)

x

Yvvp

At the vapor pressure of water p', f' is essentially

equal to the vapor pressure, and

,

V(p - P )

yp

Xp'

-~R~1-

yL e

y.v

(4)

697

Downloaded from http://onepetro.org/JPT/article-pdf/13/07/697/2237725/spe-1567-g-pa.pdf by guest on 12 July 2022

Equilibrium data which should be useful in the design

and/or evaluation of glycol dehydration units were prepared from an analysis of various published data and

the correlation of these data by the use of the thermodynamic equilibrium ratio. The equilibrium ratios of

water are used to solve the glycol absorber problem;

such solutions are necessary to define the number of

trays and the glycol circulation rate needed to meet

drying requirements.

Activity coefficients were obtained which relate directly to the equilibrium ratios of water in the waterTEG-natural gas system. These activity coefficients have

been used to calculate the equilibrium dew points for

aqueous TEG concentrations of 60 to 99.9 weight per

cent for the temperature range of 40° to 120°F. They

also provide a means of calculating equilibrium ratios

for water in the water-TEG-natural gas system; this

applies to any desired TEG concentration and to the

temperature range from 40° to 120°F.

SO CONY MOBIL OIL CO., INC.

DALLAS, TEX.

To solve Eq. 4, as it applies to the water-TEG system,

a knowledge of the activity coefficients of water in both

phases is required. This type of information for the

natural gas-water-TEG system is not easy to come by

experimentally. The problem deals with the determination of small amounts of water in the vapor phase, and

any absolute error in the water determination can conceivably result in a large error on a percentage basis.

It seems practical, then, to devise some manner of

calculating the equilibrium for water in the subject

system. The vapor phase in equilibrium with a glycol

solution contains essentially no TEG, and the liquid

phase contains very little methane or natural gas. Therefore, it appears that the activity of water in either phase

can be obtained independently of the other phase.

NON·IDEALITY OF WATER IN THE VAPOR PHASE

YP

xp'

'II,

aL

yLx -

Yu

ACTIVITY OF WATER IN THE LIQUID PHASE

The data used to evaluate the activity of water in

aqueous TEG solutions were taken from the experiments of Townsend' and of Wise, Puck and Failey.'

Townsend experimentally obtained the concentration

of water in the vapor phase of a natural gas in equilibrium with 95 and 9S weight per cent TEG glycol solutions and approximately 100 per cent TEG. The glycol

concentrations were reported accurate to 0.5 weight per

cent. Since 100 per cent TEG normally contains about

0.3 weight per cent water, it was decided to treat the

100 per cent glycol as a 99.5 per cent solution in this

evaluation.

Table 1 presents the experimental data of Townsend

and the equilibrium data calculated therefrom with Eqs.

7 and S. The temperatures investigated were 70°, Soo

and 90°F over the pressure range of approximately 500

to 2,500 psia. The data for all three temperatures were

averaged for each pressure level used in the experiments,

and the results are tabulated in Table 2. These data

reveal that the activity of water in glycol solutions is

essentially independent of the system pressure. There

were insufficient data to evaluate any temperature effect

on activity.

Wise, et aI, investigated the activities of aqueous TEG

solutions at atmospheric pressure and 70°, Soo and

90°F. The highest TEG concentration reported was

96.S per cent. The activities reported then were used to

determine the more useful variable, the activity coefficient. The activity coefficients for water in TEG concentrations greater than 96.S per cent were evaluated with

the aid of the binary Van Laar equations; namely,

A

logy, = -(~-AX'

where C is an empirical constant and equal to ~e

V(p -

p )

--RT-'

This eliminates evaluating the fugacity coefficient as a

separate variable. The value of C then can be evaluated

from existing data on the natural gas-water system, such

as the data of McCarthy, Boyd and Reid:

In the natural gas-water system, the liquid phase

will follow ideal behavior because the mol fraction of

methane in the liquid is very small even at high pressures

and YL ;:.:;: 1.0. The value of x (mol fraction of water)

can be assigned a value of 1.0 for all practical consideratioris. The only information then needed to evaluate

C is the water content of the water-saturated gas, the

total pressure and the vapor pressure of water at the

temperature of interest.

p'

(' = - - - ,

yp

(6)

and

c=

47500 p'

Wp

(7)

where W is the water content of the gas in Ib/MMscf.

(S)

Y

where aL is then the ratio of the concentration of water

in the dry gas to the concentration of water when gas

is saturated at the same pressure and temperature.

(5)

=C

=

),

(9)

BX2

and

B

logy, =

(1 + BX')'

(10)

Ax,

where A = logy, at x, = 0 and B = log '12 at x, =

1.0. Values of A and B were estimated from the activity

coefficients of water and TEG calculated from the experimental data of Wise, et al. The best agreement with

the experimental data was obtained for A = --OA05

and B = -0.356. The average deviation of the experimental data from the calculated data thus obtained was

about 0.3 per cent for water and 4 per cent for TEG.

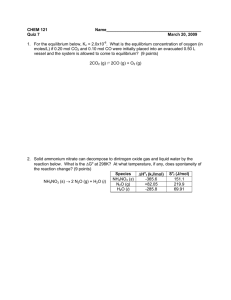

Fig. 1 presents the calculated curve for water. The

plotted points are the activity coefficients calculated

from the experimental data of Wise, et aI, and Townsend. Table 3 summarizes the activity coefficients and

activities of water at SO°F. These data are considered as

representative of the temperature range from 40° to

120°F since the effect of temperature in this range is

negligible.

The effect of temperature on the activity coefficient of

JOURNAL OF PETROLEUM TECHNOI.OGY

Downloaded from http://onepetro.org/JPT/article-pdf/13/07/697/2237725/spe-1567-g-pa.pdf by guest on 12 July 2022

In the vapor phase, TEG is normally present in

amounts up to 1 Ib/MMscf. This is a pretty well-accepted maximum for glycol units operating with a good

mist eliminator. Assuming all of the glycol lost overhead is in a true solution in the gas phase, this amounts

to a concentration of approximately 2.5 X 10- 6 mol

fraction TEG; for all practical considerations, the TEG

can be thought of as nonexistent in this phase. This

then leads to the natural gas-water system for which

there is sufficient information to define the behavior

of water in the vapor phase.

Considering the right side of Eq. 4 as it applies to

the natural gas-water system, all of the terms except

the activity coefficients YL and 'Iv are explicit functions

of the contact temperature and pressure, while the

activity coefficients are primarily functions of concentration. Since the water concentrations usually dealt with

fall in the range of approximately 7 to 120 Ib/MMscf

(the mol fractions being approximately 0.000147 to

0.00252), the systems are essentially at infinite dilution

and the activity coefficient of water in the vapor phase

can be taken as a constant value at any given temperature and pressure normally encountered. Therefore,

Eq. 4 can be rewritten as

If Eq. 6 is substituted into Eq. 5, the resulting equation can be used to determine the activity of the water

in the aqueous phase from experimental data.

TABLE l-VAPOR-liQUID EQUILIBRIA DATA FOR NATURAL GAS-AQUEOUS TRIETHYlENE GLYCOL SYSTEMS

Glycol

Mol

Concentration

Temp.

(Wt.%)

99_5

(0 F)

70

80

90

98

70

80

90

70

80

(psia)

~

2035

1555

1090

515

2515

1540

540

2565

1540

565

2545

2085

1555

1015

505

2515

2015

1535

990

455

2536

2055

1565

1005

575

2535

2040

1600

1015

435

2525

2095

1515

1015

485

p'

(psia)

0_3631

0.5069

0.6982

0.3631

0.5069

0.6982

0.3631

0.5069

W

(lb/MMscf)

14.0

15.5

18.5

23.5

42.0

19.2

25.0

54.0

24.7

34.0

73.0

14.0

15.1

18.5

24.7

42.0

19.2

21.5

25.0

34.0

62.0

24.9

28.0

34.0

47.0

72.0

13.9

15.2

18.5

24.7

48.0

19.3

21.0

26.0

34.0

59.0

Fraction

Water

Wu*

(lb/MMscf)

1.32

0.32

0

0.87

0.73

1.22

0.93

2.10

0.60

1.25

1.05

1.05

1.00

2.75

2.50

2.70

0.87

1.20

0.90

1.73

4.35

2.27

3.33

2.00

2.05

4.17

2.35

3.10

2.17

3.60

6.45

1.85

2.80

3.50

4.12

7.85

C

0.484

0.547

0.599

0.673

0.798

0.499

0.626

0.828

0.522

0.633

0.803

0.484

0.548

0.599

0.688

0.813

0.499

0.557

0.628

0.715

0.855

0.524

0.576

0.622

0.701

0.800

0.490

0.557

0.582

0.688

0.825

0.494

0.548

0.612

0.699

0.842

0.0391

0.0392

0.0393

0.0396

0.0399

0.0391

0.0393

0.0399

0.0391

0.0393

0.0399

0.1405

0.1410

0.1412

0.1420

0.1434

0.1405

0.1410

0.1412

0.1420

0.1434

0.1405

0.1410

0.1412

0.1420

0.1434

0.294

0.295

0.296

0.298

0.300

0.294

0.295

0.296

0.298

0.300

/,L/C

/,1,

~

0964

0

1.39

0.546

3.25

1.515

1.18

1.19

1.48

0.448

1.10

0.857

1.76

1.04

0.551

0.646

0.711

0.407

0.502

0.572

1.24

,1.47

0.669

0.438

0.504

L18

1.24

0.68

0.712

0.544

0.66

0.825

0.744

0.582

0.532

~

al

Tom-

0.528

0

0.935

0.436

1.62

0.949

0.977

0.621

0.936

0.359

0.538

0.469

1.055

0.716

0.448

0.322

0.396

0.256

0.359

0.489

0.650

0.847

0.416

0.307

0.403

0.578

0.691

0.396

0.490

0.449

0.326

0.452

0.455

0.407

0.448

0.0207

0

0.0370

0.0174

0.0635

0.0373

0.0390

0.0243

0.0368

0.0143

0.0750

0.0662

0.149

0.102

0.0643

0.0452

0.0558

0.0361

0.0510

0.0701

0.0913

0.119

0.0587

0.0436

0.0578

0.169

0.204

0.117

0.146

0.135

0.096

0.133

0.134

0.121

0.134

*Data of Townsend (Ref. 2). Above data for 99.5 per cent TEG was reported by Townsend as approximately 100 per cent.

a component in a solution of two completely miscible

liquids is approximated by the following equation.

H-H(l D. In y =--~~R----T;~

1) -

T

(11 )

where H - H is the average differential heat of solution

for the component in question for the temperatures considered. Table 4 is a tabulation of enthalpy data for the

water-TEO binary system compiled from the Union

Carbide Coos heat-capacity data on TEO solutions. The

partial enthalpy of water was obtained by applying the

method of intercepts to the solution heats calculated

from the heat-capacity data.

The differential heat of solution was found to be

positive in the temperature range from 40° to 120°F; as

such, the activity coefficient of water will decrease as

the temperature increases. The change in activity coefficient is about 3 per cent/40°F. Since drying at the

higher temperatures is of primary concern, the data of

Fig. 3 and Table 3 can be applied conservatively at

temperatures around 120°F without fear of any detrimental temperature effects.

data of natural gases after McCarthy, Boyd and Reid,'

and the activity coefficient at 80°F for water in a 98

weight per cent aqueous solution of TEO by solving

Eq. 5 for y/x or K.

The data of Fig. 2 present the K values of water in

the 98 per cent solution over the temperature range

from 40° to 120°F and over the pressure range from

14.7 to 2,500 psia. These data are considered accurate

through this temperature range because the effect of

temperature on the activity of the water phase in the

range is small. A relationship which relates K for any

concentration to the K for 98 per cent TEO is given

and allows the user to correct the plotted values to any

desired concentration with the use of the activity coefficients of water found in Fig. 1 and Table 3.

The values of K were found to decrease linearly as

the pressure increased to about 200 psia. Thereafter,

the incremental changes in the K value became smaller

1.0

C-'l

x

II

APPLICATIONS

EQUILIBRIUM RATIOS FOR WATER IN THE

WATER-TEG-NATURAL GAS SYSTEM

The vapor-liquid eqUilibrium ratios for water in this

basic system have been calculated and are suggested as

the values to be used in all dehydration calculations involving TEO. The K values for the system, 98 weight

per cent TEO-natural gas, are plotted in Fig. 2. These

values have been calculated from the water-content

TABLE 2-ACTIVITY AND ACTIVITY COEFFICIENTS FOR WATER IN THE

NATURAL GAS-AQUEOUS TRIETHYlENE GLYCOL SOLUTIONS

IN TEMPERATURE RANGE FROM 70° TO 90°F'

95 WI % TEG

98 WI % TEG

99.5 WI % TEG

Pressure

(psia)

"IL

aI,

"IL

aJ,

OL

"IL

~ 0.448

0.134

0.447

0.0641

0.591

0.0236

1000

0.448

0.134

0.461

0.0655

0.935

0.0370

1500

0.426

0.126

0.576

0.0813

0.628

0.0247

2000'

0.572

0.169

0.571

0.0805

0.528

0.0207

2500

0,452

0.136

0.502

1.550

0.0705

0.0606

Average

0.469

0.140

0.511

0.0724

0.846

0.0333

*From data of Townsend (Ref. 2).

JULY, 1961

-'

O.9

•

0.8

)0

0.7

~

z

W

0.6

U

LL.

LL.

0.5

W

0

•

u

>>

~

o WISE, ET AL

0.4

• TOWNSEND

~

u

ex

o

0.2

0.4

0.6

0.8

1.0

MOL FRACTION WATER IN TEG SOLUTION

FIG. I-ACTIVITY COEFFICIENTS OF WATER IN TRIETHYLENEGLYCOL SOLUTIONS AT 80°F.

699

Downloaded from http://onepetro.org/JPT/article-pdf/13/07/697/2237725/spe-1567-g-pa.pdf by guest on 12 July 2022

95

Pressure

by McCarthy, et ai: Eq. 12 enables one to evaluate K

from any source of water-content data he might choose.

If the water-content data of McCarthy, et ai, is used,

the K's obtained from Eq. 12 will be consistent with K's

evaluated from Fig. 1.

A sample dehydration calculation which explains the

use of the water equilibrium ratio is presented in the

Appendix. This problem solves for the circulation rate

of lean glycol when given the inlet temperature

and pressure, the lean glycol concentration, tray efficiency and the number of trays in the contactor. The

problem can be amended to solve for anyone of these

variables as the unknown.

6

4

2

"'1"

0.001

8

6

II

"

4

2

1000

PRESSURE, psi a

WATER-VAPOR DEW POINTS

WITH TEG SOLUTIONS

FIG. 2-VAPOR-LIQUID EQUILIBRIUM RATIO FOR WATER IN 98

WEIGHT PER CENT TRIETHYLENE-GLYCOL SOLUTIONS.

K

v

= -=

x

(2.105) (10") (W) (YL)

(12)

The equilibrium ratios presented herein have been

based on the water content of natural gases as presented

TABLE 3-ACTIVITY OF WATER IN AQUEOUS TRIETHYLENE GLYCOL

SOLUTIONS AT 80°F

Mol Fraction

TEG

Water

(Wt%l

"II,

aL

0.02

99.76

0.410

0.0082

0.05

99.37

0.434

0.0217

0.10

98.68

0.475

0.0475

0.15

97.93

0.520

0.0780

0.20

97.08

0.113

0.565

95.1

0.654

0.196

0.30

0.40

92.6

0.295

0.738

0.50

89.3

0.815

0.408

0.60

84.7

0.880

0.528

78.1

0.935

0.656

0.70

67.5

0.776

0.80

0.970

0.90

48.0

0.891

0.990

1.00

1.000

1.000

o

TABLE 4-ENTHALPY DATA FOR AQUEOUS TRI ETHYLENE

GLYCOL SOLUTIONS

40°F

86° F

122°F

Mol Fraction

Water

H,

H1

H.,

H,

H.o

H,

0

0.01

0.02

0.05

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

0.95

0.98

1.00

577.2

573.8

570.5

560.2

541.2

502.3

461

418

374

330

284

238

192

168

154

144

254

253

241

221

204

187

177

169

163

158

154

150

147

145

144

144

4018

3995

3968

3888

3754

3473

3183

2887

2590

2285

1975

1655

1323

1150

1042

972

1550

1514

1462

1368

1282

1192

1147

1098

1067

1042

1022

1002

988

980

975

972

68-'8

6820

6772

6652

6430

5952

5445

4929

4400

3887

3350

2796

2230

1940

1780

1620

2840

2841

2720

2505

2320

2120

2000

1910

18<0

1785

1735

1695

1655

1638

1623

1620

H.~

= enthalpy of solution, Btu/mol solution.

"'H';" =

partial enthalpy water, Btu/mol water.

Enthalpy datum

700

=

32°F.

JOURNAL OF PETROI.EUM TECHNOLOGY

Downloaded from http://onepetro.org/JPT/article-pdf/13/07/697/2237725/spe-1567-g-pa.pdf by guest on 12 July 2022

as the pressure increased, and K neared a limiting value

as the pressure approached 10,000 psia. The latter is

inherent in the way the K values were calculated because equilibrium water contents over glycol solutions

were related directly to the water content of a gas over

pure water, and the water content of a gas over water

tends to approach a limiting value as pressures around

10,000 psia are reached.

The equilibrium ratios for water in the water-TEGnatural gas system also can be evaluated directly from

the water content of the saturated gas at the temperature and pressure of interest and the activity coefficient of the water in the glycol solution. The data of

Townsend reveal that the ratio of the water content of

the gas over a glycol solution to the water content of

the saturated gas is essentially constant for any given

glycol concentration and is equal to the activity of the

water in the glycol solution, or W g = WaL. Then,

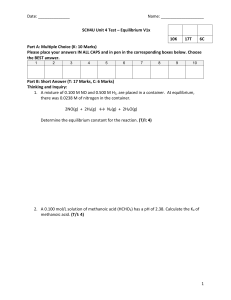

The equilibrium dew points available with glycol concentrations of 60 to 99.9 per cent by weight in the

temperature range 40° to 120°F are presented in Fig. 3.

These have been obtained by calculating the water content of the gas at the dew point as equal to the product

of the activity and the water content of the gas saturated

with water at the contact temperature and pressure. The

dew-point temperature then was taken directly from the

water-content chart of McCarthy, et ai,' by entering

the chart with the water concentration at the dew point

and the contact pressure.

The temperature of contact affects the dew point

such that the dew-point depression, or the difference in

the contact temperature and the dew-point temperature,

at a temperature of 40°F is approximately 75 per cent

of the dew-point depression theoretically possible at

120°F.

Pressure was found to have no effect on the equilibrium dew point. The dew points of Fig. 3 represent

data calculated over the pressure range from 14.7 to

2,500 psia. These dew points for any given contact

temperature were found to agree within 1°F throughout this range of pressures.

Data such as shown in Fig. 3 have limited application

in the design of glycol units. One bit of information obtained from it is the minimum glycol concentration

which can be used to obtain a certain dew point. For

example, if a 32°F dew point at a contact temperature

of 100°F is desired, the lowest lean glycol concentration

which will suffice is approximately 97 per cent TEG.

If it is assumed the desired dew point will be about

20°F above the equilibrium dew point (quite often expressed as an approach to equilibrium of 20°F), the

lean glycol concentration should be one which gives a

dew point of 32 minus 20, or 12°F. This sets the desired lean glycol concentration at approximately 98.5

per cent TEG.

Another application of Fig. 3 is to use the glycol

concentration shown as the average concentration in the

dehydrator. Then the dew point obtained in this manner

will approximate the dew point which is obtained in the

actual operation. Nothing has been said about rates,

and this information cannot be obtained without performing the more detailed analysis illustrated in the

Appendix.

During the last several years, the gas engineer has

become more aware of the fact that dew-point depressions in excess of 100°F are needed and that depressions of this magnitude are possible only if the lean

glycol is stripped to very small water concentrations. At

a contact temperature of 120°F and using a lean glycol

concentration of 99.7 per cent TEG, a dew-point de-

of a dried natural gas, (2) a more critical look at dehydrator performance and (3) a more accurate prediction of rate and tray requirements.

80

L1..

60

0

~

IZ

NOMENCLATURE

40

(/,. = activity of water in liquid phase

0

Q.

20

3:

w

0

~

::::>

0::

CD

...J

99 9

::::>

0 -60

W

-80

20

40

60

80

100

120

CONTACT TEMPERATURE, of

FIG. 3-WATER-VAPOR DEW POINTS OBTAINED BY

DRYING NATURAL GAS WITH TRIETHYLENE-GLYCOL

SOLUTIONS.

pression of 133°P is theoretically possible. However,

the theoretical dew point (based on the concentration

of the incoming lean glycol) is never obtained in field

operations due to the enriching of the glycol with water

on the top tray and the inefficiency of the gas-liquid

contact in the absorber. The approach to equilibrium

dew point is often 20 P or less, and this approach can

always be improved by increasing the circulation rate

or by adding more trays. In the problem in the Appendix, an 18°P approach to equilibrium is obtained. The

dew point of the dried gas is 28°P, and the theoretical

dew point for the stated conditions is lOoP. At the same

circulation rate with an extra tray added, the dew point

of the dried gas will be approximately 22°P to give

a 12°P approach to equilibrium. If the circulation were

approximately doubled, and with five trays, the approach

to equilibrium would be approximately lOOP.

Consider drying a natural gas at 600 psi a and 120 P.

In an average four-tray contactor, a 100 P dew-point

depression could be made by circulating approximately

20 gal of 99.7 per cent TEG/lb of water in the inlet

gas. Increasing the number of trays by two to a sixtray unit at the same conditions, a 120 P dew-point

depression would be possible at only one-third of the

same circulation rate. The point to remember is that

drying to meet some requirements at higher temperatures can be done, although an extra tray or two may

be required as well as more complete regeneration of

the glycol. More complete regeneration of glycol is

being accomplished by the use of stripping gas as part

of the regeneration system.

In years past, the rule of thumb was 3 gal of glycol

circulated/lb of water in the wet gas. This rule probably

does very well at temperatures below 90 0 P and pressures above 600 psia, but it is not a recommended

practice. The absorber-type analysis such as presented

in the Appendix should be used to properly define drying needs.

R = gas constant = 10.71 (psia) (cu ft)

(lb mol) (OR)

0

1.99

T

V

V" " 1

W

W"

X,X,

x"

y

Yo

0

0

0

CONCLUSIONS

The application of the data presented herein should

permit (1) a more accurate estimate of the dew point

JULY,

1961

y"

+

I

Y,

y"

Y" YL

Yv

v

Btu

(lb mol) (OR)

= absolute temperature, OR

= molal volume of water, cu ft/mol

= inlet gas, mol

= water content of water-saturated gas, lb/

MMscf

= water content of gas over glycol solution,

Ib/MMscf

= mol fraction of water in the liquid phase

= mol fraction of water in lean glycol

= mol fraction of water in water-saturated gas

= mol fraction of water in the vapor phase

over glycol solution

= mol fraction of water in wet inlet gas

= mol fraction of water in dry outIet gas

= mol fraction of water in outIet gas in equilibrium with lean glycol

= activity coefficient of water in liquid phase

= activity coefficient of water in vapor phase

= fugacity coefficient of pure water at temperature and pressure of system.

ACKNOWLEDGMENT

The author wishes to thank the Socony Mobil Oil

Co. for permission to publish these data and to thank

E. B. Elfrink, Ovid Baker and Will Swerdloff of the

Socony Mobil Oil Co. for their critical reviews of this

paper.

REFERENCES

1. Porter, J. A. and Reid, L. S.: Trans. AIME (1950) 139,

235.

'

2. Townsend, F. M.: "Equilibrium Water Contents of Natural

10[

Downloaded from http://onepetro.org/JPT/article-pdf/13/07/697/2237725/spe-1567-g-pa.pdf by guest on 12 July 2022

o

A = absorption factor for water

A, = absorption factor for methane

r = fugacity of pure liquid water at its vapor

pressure, psia

r = fugacity of pure component in standard

state taken as temperature and pressure of

systems, psia

II. = fugacity of liquid water at system conditions,

psia

Iv = fugacity of water vapor at system conditions,

psia

H = partial enthalpy, Btu/mol

H = enthalpy of pure component, Btu/mol

K = equilibrium ratio of water

K, = equilibrium ratio of methane

L" = rich glycol rate, mol rich solution/mol inlet

gas

L" = lean glycol rate, mol lean solution/mol inlet

gas

p' = vapor pressure of water at system temperature, psia

p = system pressure, psia

~ IOOr---------~~------._~r_T1~

o

.....

n = NUMBER

THEORETICAL

TRAYS

U

<l

50

Z

o

30

.....

20

LL

a..

o

~

a::

10

<l

TABLE 5-APPROXIMATE EQUILIBRIUM RATIOS FOR METHANE IN

TRIETHYlENE GLYCOL SOLUTIONS'

PSIA

50°F

80°F

120°F

150

152

100

150

126

122

150

126

110

106

200

III

96

99

250

100

87

91

94

300

76

79

400

82

66

70

500

72

58

62

600

66

54

57

60

700

48

51

800

53

44

48

49

900

39

43

44

1000

29

33

34

1500

27

31

32

2000

*Calculated from data given in Ref. 1.

W

>

5

U

W

3

.....

LL

LL

W

<l

=

Yn+1 - y,

2

~~~----~------~~~--------~

0.7

0.8

0.9

1.0

EQUILIBRIUM FRACTION ABSORBED

n+1

Y

n+1

-

Y

-

Y

0

=A

A

n+ 1

n+1

-A

-I

FIG. 4---KREMSER·BROWN ABSORPTION FACTOR FOR ABSORB,ERS.

Gas Dehydrated by Aqur.ous Diethylene and Triethylene

Glycol Solutions at Various Temperatures and Pressures",

PhD dissertation, The U. of Oklahoma (1955).

3. Union Carbide Co.: Gas Treating Chemicals.

4. Wise, H., Puck, T. T. and Failey, C. F.: Jour. Phys. Chem.

(1950) 54, 734.

5. McCarty, E. L., Boyd, W. L. and Reid, L. S.: Trans., AIME

(1950) 189, 241.

equilibrium fraction to be absorbed

0.001515 - 0.000147

0.001515 - 0.0000772

= 0.951.

Past experience has indicated trays in glycol units

to be approximately 25 per cent efficient. Then assume

25 per cent efficiency for each tray and n, the number

of theoretical trays, = 5 (.25) = 1.25 theoretical trays.

Refer to Fig. 4 and find the absorption factor A = 10.6

for 1.25 trays and an absorbed fraction = 0.951.

Then the circulation rate of rich glycol,

L.

=

(A) (Vn+1) (K)

= (10.6) (1.0) (0.000728)

= 0.00772 mol rich glycol/mol inlet gas

A, = absorption factor of methane or natural

gas

APPENDIX

= ~ = 0.00772 = 0.000154,

SAMPLE DEHYDRATION CALCULATIONS

where K, is equilibrium ratio of methane in glycol solutions (Table 5) .

Since the gas phase consists mainly of methane (C,),

the absorption factor will approximate the moles of

natural gas absorbed when using 1 mol of gas as basis,

or

moles C absorbed = 0.000154 mol/mol inlet

gas;

moles water absorbed =0.001515 - 0.000147

= 0.001368 mol/mol inlet

gas.

Then the circulation rate of lean glycol,

Lo = L. - (mol C, absorbed + mol water absorbed)

= 0.00772 - (0.000154 + 0.001368)

= 0.0062 mol lean glycol/mol inlet gas.

Molecular weight

(MW) of lean glycol = mol fraction water (MW

water) + mol fraction TEO

(MW TEO)

= 0.106 (18) + 0.894 (150)

= 136.

Density of lean glycol = 9.3 lb/ gal.

Therefore,

_

(mOl lean gIYCOI)(2637 mol gas)

Lo - 0.0062

.

M

f

mol mlet gas

Msc gas

136 gal TEO)

( 9.3 mol TEO

239 galjMMscf

= 0.166 gal/min / MMscflD

= 3.32 gal/lb water in inlet gas.

Calculate the circulation rate of 98.6 weight per cent

TEO solution required to dry 1 MMscfjD of gas at

800 psi a and 100°F so as to make a dry gas containing

7 IbjMMscf. The contactor has five trays.

COMPUTATION OF K

K from water content of natural gas and the activity

coefficient of water in the 98.6 weight per cent solution

can be calculated by either of the following methods.

Method 1

K =

~ = (2.105) (lO·') (W)

(y[,)

(24)

x

where W = water content of saturated gas = 72 lbj

MMscf.

YL = activity coefficient of water = 0.481 (Fig.

1) and (2.105) 10" is a constant converting water concentration from IbjMMscf

to mol fraction.

K = (2.105) (10") (72) (0.481) = 0.000728.

Method 2

K from Fig. 2 and YL

K",. = (K,,) (1.94) (YL)

= (0.00079) (1.94) (0.481) = 0.000728.

CIRCULATION RATE

Yn+1 = mol fraction water in wet gas

(72) (2.105) 10-' = 0.001515.

y, = mol fraction water in dry gas

(7) (2.105) 10-' = 0.000147.

Yo = mol fraction water in dry gas

= at equilibrium (Yo = Kxo)

702

=

KYn+1

50(1)

***

JOURNAL OF PETROLEUM TECHNOLOGY

Downloaded from http://onepetro.org/JPT/article-pdf/13/07/697/2237725/spe-1567-g-pa.pdf by guest on 12 July 2022

Y

Yn+l - Yo

(0.000728) (0.106) =0.0000772.