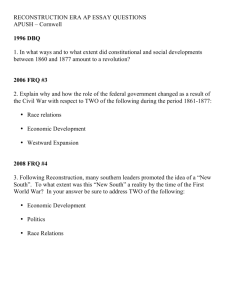

Heat, Air, and Moisture Control in Building Assemblies—Material Properties Table 1 Licensed for single user. © 2021 ASHRAE, Inc. Description 26.11 Building and Insulating Materials: Design Valuesa (Continued) Density, lb/ft3 Conductivityb k, Resistance R, Specific Heat, Btu/lb·°F Referenceo Btu·in/h·ft2 ·°F h·ft2 ·°F/Btu 12 in., 50 lb, 125 lb/ft3 concrete, 2 cores ....................... — — Medium-weight aggregate (combinations of normal and lightweight aggregate) — — 8 in., 26 to 29 lb, 97 to 112 lb/ft3 concrete, 2 or 3 cores with perlite-filled cores............................................ — — with vermiculite-filled cores.................................... — — with molded-EPS-filled (beads) cores ..................... — — with molded EPS inserts in cores ............................ — — Lightweight aggregate (expanded shale, clay, slate or slag, pumice) — — 6 in., 16 to 17 lb, 85 to 87 lb/ft3 concrete, 2 or 3 cores . with perlite-filled cores............................................ — — with vermiculite-filled cores.................................... — — — — 8 in., 19 to 22 lb, 72 to 86 lb/ft3 concrete ...................... with perlite-filled cores............................................ — — with vermiculite-filled cores.................................... — — with molded-EPS-filled (beads) cores ..................... — — with UF foam-filled cores........................................ — — with molded EPS inserts in cores ............................ — — — — 12 in., 32 to 36 lb, 80 to 90 lb/ft3, concrete, 2 or 3 cores with perlite-filled cores............................................ — — with vermiculite-filled cores.................................... — — Stone, lime, or sand.............................................................. 180 72 Quartzitic and sandstone...................................................... 160 43 140 24 120 13 Calcitic, dolomitic, limestone, marble, and granite ............. 180 30 160 22 140 16 120 11 100 8 Gypsum partition tile 3 by 12 by 30 in., solid................................................... — — 4 cells................................................ — — 4 by 12 by 30 in., 3 cells ................................................ — — Limestone............................................................................. 150 3.95 163 6.45 Concretesi Sand and gravel or stone aggregate concretes ..................... 150 10.0 to 20.0 (concretes with >50% quartz or quartzite sand have 140 9.0 to 18.0 conductivities in higher end of range) 130 7.0 to 13.0 Lightweight aggregate or limestone concretes .................... 120 6.4 to 9.1 expanded shale, clay, or slate; expanded slags; cinders; 100 4.7 to 6.2 80 3.3 to 4.1 pumice (with density up to 100 lb/ft3); scoria (sanded 60 2.1 to 2.5 concretes have conductivities in higher end of range) 40 1.3 Gypsum/fiber concrete (87.5% gypsum, 12.5% wood chips) 51 1.66 Cement/lime, mortar, and stucco ......................................... 120 9.7 100 6.7 80 4.5 Perlite, vermiculite, and polystyrene beads ......................... 50 1.8 to 1.9 40 1.4 to 1.5 30 1.1 20 0.8 Foam concretes .................................................................... 120 5.4 100 4.1 80 3.0 70 2.5 Foam concretes and cellular concretes ................................ 60 2.1 40 1.4 20 0.8 Aerated concrete (oven-dried) ............................................. 27 to 50 1.4 Polystyrene concrete (oven-dried) ....................................... 16 to 50 2.54 Polymer concrete ................................................................. 122 11.4 138 7.14 Polymer cement ................................................................... 117 5.39 Slag concrete........................................................................ 60 1.5 80 2.25 100 3 125 8.53 1.23 0.22 Valore (1988) 1.71 to 1.28 3.7 to 2.3 3.3 3.2 2.7 — — — — — Van Geem (1985) Van Geem (1985) Van Geem (1985) Van Geem (1985) Van Geem (1985) 1.93 to 1.65 4.2 3.0 3.2 to 1.90 6.8 to 4.4 5.3 to 3.9 4.8 4.5 3.5 2.6 to 2.3 9.2 to 6.3 5.8 — — — — — — — — — — — — 0.21 — — — — — — — — — — — 0.19 — — — 0.19 — Van Geem (1985) Van Geem (1985) Van Geem (1985) Van Geem (1985) Van Geem (1985) Shu et al. (1979) Shu et al. (1979) Shu et al. (1979) Shu et al. (1979) Van Geem (1985) Van Geem (1985) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) 1.26 1.35 1.67 — — 0.19 — — 0.2 0.2 Rowley and Algren (1937) Rowley and Algren (1937) Rowley and Algren (1937) Kumaran (2002) Kumaran (2002) — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — 0.19 to 0.24 — — 0.2 0.2 — — 0.2 — — — — 0.15 to 0.23 — — — — — — — — — 0.2 0.2 — — — — — — — Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Rowley and Algren (1937) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Valore (1988) Kumaran (1996) Kumaran (1996) Kumaran (1996) Kumaran (1996) Kumaran (1996) Touloukian et al (1970) Touloukian et al. (1970) Touloukian et al. (1970) Touloukian et al. (1970) 26.12 2021 ASHRAE Handbook—Fundamentals Licensed for single user. © 2021 ASHRAE, Inc. Table 1 Building and Insulating Materials: Design Valuesa (Continued) Description Density, lb/ft3 Woods (12% moisture content)l Hardwoods Oak....................................................................................... Birch..................................................................................... Maple ................................................................................... Ash ....................................................................................... Softwoods Southern pine ....................................................................... Southern yellow pine ........................................................... Eastern white pine................................................................ Douglas fir/larch .................................................................. Southern cypress .................................................................. Hem/fir, spruce/pine/fir ....................................................... Spruce .................................................................................. Western red cedar ................................................................ West coast woods, cedars .................................................... Eastern white cedar .............................................................. California redwood .............................................................. Pine (oven-dried) ................................................................. Spruce (oven-dried) ............................................................. — 41 to 47 43 to 45 40 to 44 38 to 42 — 36 to 41 31 25 34 to 36 31 to 32 24 to 31 25 22 22 to 31 23 24 to 28 23 25 Conductivityb k, Resistance R, Specific Heat, Btu/lb·°F Referenceo Btu·in/h·ft2 ·°F h·ft2 ·°F/Btu — 1.12 to 1.25 1.16 to 1.22 1.09 to 1.19 1.06 to 1.14 — 1.00 to 1.12 1.06 to 1.16 0.85 to 0.94 0.95 to 1.01 0.90 to 0.92 0.74 to 0.90 0.74 to 0.85 0.83 to 0.86 0.68 to 0.90 0.82 to 0.89 0.74 to 0.82 0.64 0.69 — — — — — — — — — — — — — — — — — — — 0.39n — — — — 0.39 n — — — — — — — — — — — 0.45 0.45 Wilkes (1979) Cardenas and Bible (1987) Cardenas and Bible (1987) Cardenas and Bible (1987) Cardenas and Bible (1987) Wilkes (1979) Cardenas and Bible (1987) Kumaran (2002) Kumaran (2002) Cardenas and Bible (1987) Cardenas and Bible (1987) Cardenas and Bible (1987) Kumaran (2002) Kumaran (2002) Cardenas and Bible (1987) Kumaran (2002) Cardenas and Bible (1987) Kumaran (1996) Kumaran (1996) Notes for Table 1 aValues are for mean temperature of 75°F. Representative values for dry materials are intended kVinyl as design (not specification) values for materials in normal use. Thermal values of insulating materials may differ from design values depending on in situ properties (e.g., density and moisture content, orientation, etc.) and manufacturing variability. For properties of specific product, use values supplied by manufacturer or unbiased tests. bSymbol also used to represent thermal conductivity. cDoes not include paper backing and facing, if any. Where insulation forms boundary (reflective or otherwise) of airspace, see Tables 2 and 3 for insulating value of airspace with appropriate effective emittance and temperature conditions of space. dConductivity varies with fiber diameter (see Chapter 25). Batt, blanket, and loose-fill mineral fiber insulations are manufactured to achieve specified R-values, the most common of which are listed in the table. Because of differences in manufacturing processes and materials, the product thicknesses, densities, and thermal conductivities vary over considerable ranges for a specified R-value. eValues are for aged products with gas-impermeable facers on the two major surfaces. An aluminum foil facer of 0.001 in. thickness or greater is generally considered impermeable to gases. For change in conductivity with age of expanded polyisocyanurate, see SPI Bulletin U108. fCellular phenolic insulation may no longer be manufactured. gInsulating values of acoustical tile vary, depending on density of board and on type, size, and depth of perforations. hValues for fully grouted block may be approximated using values for concrete with similar unit density. iValues for concrete block and concrete are at moisture contents representative of normal use. jValues for metal or vinyl siding applied over flat surfaces vary widely, depending on ventilation of the airspace beneath the siding; whether airspace is reflective or nonreflective; and on thickness, type, and application of insulating backing-board used. Values are averages for use as design guides, and were obtained from several guarded hot box tests (ASTM Standard C1363) on hollow-backed types and types made using backing of wood fiber, foamed plastic, and glass fiber. Departures of ±50% or more from these values may occur. lSee assembly. As discussed previously, low air permeance is not sufficient to ensure a reliable air barrier assembly: the system must be properly fastened and supported (on both sides) to resist wind loads, and all materials must be durable for the expected service life of the assembly. The air barrier must also be continuous, and should be installed in such a way as to discourage wind washing (i.e., air movement that reduces the thermal resistance of insulation layers in the assembly). 4.5 WATER VAPOR PERMEANCE DATA Table 5 gives typical water vapor permeance and permeability values for common building materials. These values can be used to specific heat = 0.25 Btu/lb·°F Adams (1971), MacLean (1941), and Wilkes (1979). Conductivity values listed are for heat transfer across the grain. Thermal conductivity of wood varies linearly with density, and density ranges listed are those normally found for wood species given. If density of wood species is not known, use mean conductivity value. For extrapolation to other moisture contents, the following empirical equation developed by Wilkes (1979) may be used: –2 –4 1.874 10 + 5.753 10 M k = 0.1791 + --------------------------------------------------------------------------------1 + 0.01M where is density of moist wood in lb/ft3, and M is moisture content in percent. mDimension referenced is taken at the maximum siding profile thickness. The range of R values and associated thicknesses represent values for products tested to ASTM Standard D7793, which requires applying 15 mph airstream perpendicular to surface of siding during testing. nFrom Wilkes (1979), an empirical equation for specific heat of moist wood at 75°F is as follows: 0.299 + 0.01M c p = ---------------------------------------- + c p 1 + 0.01M where cp accounts for heat of sorption and is denoted by c p = M 1.921 10 –3 –5 – 3.168 10 M where M is moisture content in percent by mass. oBlank space in reference column indicates historical values from previous volumes of ASHRAE Handbook. Source of information could not be determined. calculate water vapor flow through building components and assemblies using equations in Chapter 25. Water vapor permeability of most building materials is a function of moisture content, which, in turn, is a function of ambient relative humidity. Permeance values at various relative humidities are presented in Table 6 for several building materials. Figure 4 depicts the increase in permeability with increasing relative humidity for oriented strand board (OSB) and plywood samples (Kumaran 2002). Users of the dew-point method may use constant values found in Table 5. However, if condensation in the assembly is predicted, then a more appropriate value should be used. Transient hygrothermal modeling typically uses vapor permeability values that vary with relative humidity. Vapor permeability of homogeneous materials Heat, Air, and Moisture Control in Building Assemblies—Material Properties 26.13 Table 2 Emissivity of Various Surfaces and Effective Emittances of Facing Air Spacesa Effective Emittance eff of Air Space Licensed for single user. © 2021 ASHRAE, Inc. Surface Aluminum foil, bright Aluminum foil, with condensate just visible (>0.7 g/ft2) Aluminum foil, with condensate clearly visible (>2.9 g/ft2) Aluminum sheet Aluminum-coated paper, polished Brass, nonoxidized Copper, black oxidized Copper, polished Iron and steel, polished Iron and steel, oxidized Lead, oxidized Nickel, nonoxidized Silver, polished Steel, galvanized, bright Tin, nonoxidized Aluminum paint Building materials: wood, paper, masonry, nonmetallic paints Regular glass Average One Surface’s Both Emissivity Emittance ; Surfaces’ Other, 0.9 Emittance 0.05 0.05 0.03 0.30b 0.29 — 0.70b 0.65 — 0.12 0.12 0.06 0.20 0.20 0.11 0.04 0.74 0.04 0.2 0.58 0.27 0.06 0.03 0.25 0.05 0.50 0.038 0.41 0.038 0.16 0.35 0.21 0.056 0.029 0.24 0.047 0.47 0.02 0.59 0.02 0.11 0.41 0.16 0.03 0.015 0.15 0.026 0.35 0.90 0.82 0.82 0.84 0.77 0.72 Fig. 4 Permeability of Wood-Based Sheathing Materials at Various Relative Humidities apply in 4 to 40 m range of electromagnetic spectrum. Also, oxidation, corrosion, and accumulation of dust and dirt can dramatically increase surface emittance. Emittance values of 0.05 should only be used where the highly reflective surface can be maintained over the service life of the assembly. Except as noted, data from VDI (1999). bValues based on data in Bassett and Trethowen (1984). aValues can be calculated from thickness and vapor permeance (as given in Table 6). 4.6 MOISTURE STORAGE DATA Transient analysis of assemblies requires consideration of the materials’ moisture storage capacity. Some materials (hygroscopic) adsorb or reject moisture to achieve equilibrium with adjacent air. Storage capacity of these materials is typically shown by graphs of moisture content versus humidity. The curve showing uptake of moisture (the sorption isotherm) is usually above the curve showing drying (the desorption isotherm) because the material’s uptake and release of moisture are inhibited by surface tension. Table 7 provides data for these curves for several hygroscopic materials, and Kumaran (1996, 2002) and McGowan (2007) provide actual curves, additional data, and conditions under which they were determined. Table 7 expresses moisture content as percentage of dry weight, followed by a subscript value of the relative air humidity at which this moisture content occurs. Note that these values are based on measurement of materials that have reached equilibrium with their surroundings, which in some cases can take many weeks. Most hygrothermal simulation software programs that use these values assume that equilibrium is achieved instantaneously. Maximum values in Table 7 are those that could be realistically measured in laboratory conditions, so not all materials have a listing for maximum moisture content at 100% relative humidity. For those that do, there may be two listings: the moisture content measured when the material’s capillary pores were saturated (shown as 100c), Fig. 5 Sorption/Desorption Isotherms, Cement Board and the value at total saturation (shown as 100t). Note that the moisture content of any material is 0.0 at a theoretical relative humidity of 0%, so this point is not shown in the table. Figure 5 shows an example of a conventional sorption isotherm graph. Curves show sorption (wetting) and desorption (drying) for data in Table 7 and from Kumaran (2002). (Data from Table 7 were selectively used to provide an accurate representation of the sorption isotherm; not all data from the original source are represented.) 4.7 SOILS DATA Apparent soil thermal conductivity is difficult to estimate and may change in the same soil at different times because of changed moisture conditions and freezing temperatures. Figure 6 shows typical apparent soil thermal conductivity as a function of moisture content for different general types of soil. The figure is based on data presented in Salomone and Marlowe (1989) using envelopes of thermal behavior coupled with field moisture content ranges for different soil types. In Figure 6, “well graded” applies to granular soils with good representation of all particle sizes from largest to smallest. “Poorly graded” refers to granular soils with either uniform gradation, in which most particles are about the same size, or skip (or gap) gradation, in which particles of one or more intermediate sizes are not present. 26.14 2021 ASHRAE Handbook—Fundamentals Effective Thermal Resistance of Plane Air Spaces,a,b,c h·ft2 ·°F/Btu Air Space Effective Emittance effd,e Table 3 Position of Air Space Horiz. Licensed for single user. © 2021 ASHRAE, Inc. 45° Slope Vertical 45° Slope Horiz. Direction of Heat Flow Temp. Mean Temp.d, °F Diff.,d °F 0.03 0.5 in. Air Spacec 0.05 0.2 0.5 0.82 0.03 0.75 in. Air Spacec 0.05 0.2 0.5 0.82 Up 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 2.13 1.62 2.13 1.73 2.10 1.69 2.04 2.03 1.57 2.05 1.70 2.04 1.66 2.00 1.51 1.29 1.60 1.45 1.70 1.49 1.75 0.99 0.96 1.11 1.12 1.27 1.23 1.40 0.73 0.75 0.84 0.91 1.00 1.04 1.16 2.34 1.71 2.30 1.83 2.23 1.77 2.16 2.22 1.66 2.21 1.79 2.16 1.74 2.11 1.61 1.35 1.70 1.52 1.78 1.55 1.84 1.04 0.99 1.16 1.16 1.31 1.27 1.46 0.75 0.77 0.87 0.93 1.02 1.07 1.20 Up 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 2.44 2.06 2.55 2.20 2.63 2.08 2.62 2.31 1.98 2.44 2.14 2.54 2.04 2.56 1.65 1.56 1.83 1.76 2.03 1.78 2.17 1.06 1.10 1.22 1.30 1.44 1.42 1.66 0.76 0.83 0.90 1.02 1.10 1.17 1.33 2.96 1.99 2.90 2.13 2.72 2.05 2.53 2.78 1.92 2.75 2.07 2.62 2.01 2.47 1.88 1.52 2.00 1.72 2.08 1.76 2.10 1.15 1.08 1.29 1.28 1.47 1.41 1.62 0.81 0.82 0.94 1.00 1.12 1.16 1.30 Horiz. 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 2.47 2.57 2.66 2.82 2.93 2.90 3.20 2.34 2.46 2.54 2.72 2.82 2.82 3.10 1.67 1.84 1.88 2.14 2.20 2.35 2.54 1.06 1.23 1.24 1.50 1.53 1.76 1.87 0.77 0.90 0.91 1.13 1.15 1.39 1.46 3.50 2.91 3.70 3.14 3.77 2.90 3.72 3.24 2.77 3.46 3.02 3.59 2.83 3.60 2.08 2.01 2.35 2.32 2.64 2.36 2.87 1.22 1.30 1.43 1.58 1.73 1.77 2.04 0.84 0.94 1.01 1.18 1.26 1.39 1.56 Down 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 2.48 2.64 2.67 2.91 2.94 3.16 3.26 2.34 2.52 2.55 2.80 2.83 3.07 3.16 1.67 1.87 1.89 2.19 2.21 2.52 2.58 1.06 1.24 1.25 1.52 1.53 1.86 1.89 0.77 0.91 0.92 1.15 1.15 1.45 1.47 3.53 3.43 3.81 3.75 4.12 3.78 4.35 3.27 3.23 3.57 3.57 3.91 3.65 4.18 2.10 2.24 2.40 2.63 2.81 2.90 3.22 1.22 1.39 1.45 1.72 1.80 2.05 2.21 0.84 0.99 1.02 1.26 1.30 1.57 1.66 Down 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 2.48 2.66 2.67 2.94 2.96 3.25 3.28 2.34 2.54 2.55 2.83 2.85 3.15 3.18 1.67 1.88 1.89 2.20 2.22 2.58 2.60 1.06 1.24 1.25 1.53 1.53 1.89 1.90 0.77 0.91 0.92 1.15 1.16 1.47 1.47 3.55 3.77 3.84 4.18 4.25 4.60 4.71 3.29 3.52 3.59 3.96 4.02 4.41 4.51 2.10 2.38 2.41 2.83 2.87 3.36 3.42 1.22 1.44 1.45 1.81 1.82 2.28 2.30 0.85 1.02 1.02 1.30 1.31 1.69 1.71 1.5 in. Air Spacec Air Space Horiz. 45° Slope Vertical Up Up Horiz. 3.5 in. Air Spacec 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 2.55 1.87 2.50 2.01 2.43 1.94 2.37 2.41 1.81 2.40 1.95 2.35 1.91 2.31 1.71 1.45 1.81 1.63 1.90 1.68 1.99 1.08 1.04 1.21 1.23 1.38 1.36 1.55 0.77 0.80 0.89 0.97 1.06 1.13 1.26 2.84 2.09 2.80 2.25 2.71 2.19 2.65 2.66 2.01 2.66 2.18 2.62 2.14 2.58 1.83 1.58 1.95 1.79 2.07 1.86 2.18 1.13 1.10 1.28 1.32 1.47 1.47 1.67 0.80 0.84 0.93 1.03 1.12 1.20 1.33 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 2.92 2.14 2.88 2.30 2.79 2.22 2.71 2.73 2.06 2.74 2.23 2.69 2.17 2.64 1.86 1.61 1.99 1.82 2.12 1.88 2.23 1.14 1.12 1.29 1.34 1.49 1.49 1.69 0.80 0.84 0.94 1.04 1.13 1.21 1.35 3.18 2.26 3.12 2.42 2.98 2.34 2.87 2.96 2.17 2.95 2.35 2.87 2.29 2.79 1.97 1.67 2.10 1.90 2.23 1.97 2.33 1.18 1.15 1.34 1.38 1.54 1.54 1.75 0.82 0.86 0.96 1.06 1.16 1.25 1.39 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 3.99 2.58 3.79 2.76 3.51 2.64 3.31 3.66 2.46 3.55 2.66 3.35 2.58 3.21 2.25 1.84 2.39 2.10 2.51 2.18 2.62 1.27 1.23 1.45 1.48 1.67 1.66 1.91 0.87 0.90 1.02 1.12 1.23 1.33 1.48 3.69 2.67 3.63 2.88 3.49 2.82 3.40 3.40 2.55 3.40 2.78 3.33 2.75 3.30 2.15 1.89 2.32 2.17 2.50 2.30 2.67 1.24 1.25 1.42 1.51 1.67 1.73 1.94 0.85 0.91 1.01 1.14 1.23 1.37 1.50 Heat, Air, and Moisture Control in Building Assemblies—Material Properties 26.15 Table 3 Effective Thermal Resistance of Plane Air Spaces,a,b,c h·ft2 ·°F/Btu (Continued) Air Space Effective Emittance effd,e Position of Air Space 45° Slope Horiz. Direction of Heat Flow Temp. Mean Temp.d, °F Diff.,d °F 0.03 1.5 in. Air Spacec 0.05 0.2 0.5 0.82 0.03 3.5 in. Air Spacec 0.05 0.2 0.5 0.82 Down 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 5.07 3.58 5.10 3.85 4.92 3.62 4.67 4.55 3.36 4.66 3.66 4.62 3.50 4.47 2.56 2.31 2.85 2.68 3.16 2.80 3.40 1.36 1.42 1.60 1.74 1.94 2.01 2.29 0.91 1.00 1.09 1.27 1.37 1.54 1.70 4.81 3.51 4.74 3.81 4.59 3.77 4.50 4.33 3.30 4.36 3.63 4.32 3.64 4.32 2.49 2.28 2.73 2.66 3.02 2.90 3.31 1.34 1.40 1.57 1.74 1.88 2.05 2.25 0.90 1.00 1.08 1.27 1.34 1.57 1.68 Down 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 6.09 6.27 6.61 7.03 7.31 7.73 8.09 5.35 5.63 5.90 6.43 6.66 7.20 7.52 2.79 3.18 3.27 3.91 4.00 4.77 4.91 1.43 1.70 1.73 2.19 2.22 2.85 2.89 0.94 1.14 1.15 1.49 1.51 1.99 2.01 10.07 9.60 11.15 10.90 11.97 11.64 12.98 8.19 8.17 9.27 9.52 10.32 10.49 11.56 3.41 3.86 4.09 4.87 5.08 6.02 6.36 1.57 1.88 1.93 2.47 2.52 3.25 3.34 1.00 1.22 1.24 1.62 1.64 2.18 2.22 Up 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 3.01 2.22 2.97 2.40 2,90 2.31 2.80 2.82 2.13 2.82 2.33 2.79 2.27 2.73 1.90 1.65 2.04 1.89 2.18 1.95 2.29 1.15 1.14 1.31 1.37 1.52 1.53 1.73 0.81 0.86 0.95 1.06 1.15 1.24 1.37 Up 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 3.26 2.19 3.16 2.35 3.00 2.16 2.78 3.04 2.10 2.99 2.28 2.88 2.12 2.71 2.00 1.64 2.12 1.86 2.24 1.84 2.27 1.19 1.13 1.35 1.35 1.54 1.46 1.72 0.83 0.85 0.97 1.05 1.16 1.20 1.37 Horiz. 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 3.76 2.83 3.72 3.08 3.66 3.03 3.59 3.46 2.69 3.49 2.95 3.49 2.95 3.47 2.17 1.97 2.36 2.28 2.59 2.44 2.78 1.25 1.28 1.44 1.57 1.70 1.81 2.00 0.86 0.93 1.01 1.17 1.25 1.42 1.53 Down 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 4.90 3.86 4.93 4.24 4.93 4.28 4.93 4.41 3.61 4.52 4/-1 4.63 4.12 4.71 2.51 2.42 2.80 2.86 3.16 3.19 3.53 1.35 1.46 1.59 1.82 1.94 2.19 2.35 0.91 1.02 1.09 1.31 1.37 1.65 1.74 Down 90 50 50 0 0 –50 –50 10 30 10 20 10 20 10 11.72 10.61 12.70 12.10 13.80 12.45 14.60 9.24 8.89 10.32 10.42 11.65 11.14 12.83 3.58 4.02 4.28 5.10 5.38 6.22 6.72 1.61 1.92 1.98 2.52 2.59 3.31 3.44 1.01 1.23 1.25 1.64 1.67 2.20 2.26 5.5 in. Air Spacec Licensed for single user. © 2021 ASHRAE, Inc. Air Space Horiz. 45° Slope Vertical 45° Slope Horiz. Chapter 25. Thermal resistance values were determined from R = 1/C, where C = hc + εeff hr , hc is conduction/convection coefficient, εeff hr is radiation coefficient ≈ 0.0068εeff [(tm + 460)/100]3, and tm is mean temperature of air space. Values for hc were determined from data developed by Robinson et al. (1954). Equations (5) to (7) in Yarbrough (1983) show data in this table in analytic form. For extrapolation from this table to air spaces less than 0.5 in. (e.g., insulating window glass), assume hc = 0.159(1 + 0.0016tm)/l, where l is air space thickness in in., and hc is heat transfer through air space only. bValues based on data presented by Robinson et al. (1954). (Also see Chapter 4, Tables 5 and 6, and Chapter 33.) Values apply for ideal conditions (i.e., air spaces of uniform thickness bounded by plane, smooth, parallel surfaces with no air leakage to or from the space). This table should not be used for hollow siding or profiled cladding: see Table 1. For greater accuracy, use overall U-factors determined through guarded hot box (ASTM Standard C1363) testing. Thermal resistance values for multiple air spaces must be based on careful estimates of mean temperature differences for each air space. aSee cA single resistance value cannot account for multiple air spaces; each air space requires a separate resistance calculation that applies only for established boundary conditions. Resistances of horizontal spaces with heat flow downward are substantially independent of temperature difference. d Interpolation is permissible for other values of mean temperature, temperature difference, and effective emittance eff. Interpolation and moderate extrapolation for air spaces greater than 3.5 in. are also permissible. e Effective emittance of air space is given by 1/ = 1/ + 1/ 1, eff eff 1 2 where 1 and 2 are emittances of surfaces of air space (see Table 2). Also, oxidation, corrosion, and accumulation of dust and dirt can dramatically increase surface emittance. Emittance values of 0.05 should only be used where the highly reflective surface can be maintained over the service life of the assembly. 26.16 2021 ASHRAE Handbook—Fundamentals Table 4 Air Permeability of Different Materials Mean Air Permeability, lb/ft·h·in. Hg Material lb/ft3 Licensed for single user. © 2021 ASHRAE, Inc. Cement board, 1/2 in., 71 Fiber cement board, 1/4 in., 86 lb/ft3 Gypsum wall board, 1/2 in., 39 lb/ft3 with one coat primer with one coat primer/two coats latex paint Hardboard siding, 3/8 in., 46 lb/ft3 Oriented strand board (OSB), 41 lb/ft3, 3/8 in. 7/16 in. 1/2 in. Douglas fir plywood, 1/2 in., 29 lb/ft3 5/8 in., 34 lb/ft3 Canadian softwood plywood, 3/4 in., 28 lb/ft3 Wood fiber board, 3/8 in., 20 lb/ft3 Masonry Materials Aerated concrete, 28.7 lb/ft3 Cement mortar, 100 lb/ft3 Clay brick, 4 by 4 by 8 in., 124 lb/ft3 Limestone, 156 lb/ft3 Portland stucco mix, 124 lb/ft3 Eastern white cedar, 3/4 in., 22 lb/ft3 (transverse) 0.24 0.00002 0.03 0.18 0.02 0.037 0.008 0.016 0.008 0.0003 0.008 0.0002 2.0 Table 4 Air Permeability of Different Materials Mean Air Permeability, lb/ft·h·in. Hg Material Source: Kumaran (2002). 0.04 0.01 32 negligible 8.15E-05 negligible Eastern white pine, 3/4 in., 29 lb/ft3 (transverse) Southern yellow pine, 3/4 in., 31.2 lb/ft3 (transverse) 8.2E-06 0.00024 Fig. 6 Trends of Apparent Thermal Conductivity of Moist Soils Spruce, 3/4 in., 25 lb/ft3 (transverse) Western red cedar, 3/4 in., 21.8 lb/ft3 (transverse) Cellulose insulation, dry blown, 2 lb/ft3 Glass fiber batt, 1 lb/ft3 Polystyrene expanded, 1 lb/ft3 sprayed foam, 2.4 lb/ft3 0.4 to 1/2 lb/ft3 Polyisocyanurate insulation, 1.7 lb/ft3 Bituminous paper (#15 felt), 28 mil, 54 lb/ft2 (transverse) 0.00041 < 7E-06 2364 2038 0.09 0.000082 0.034 negligible 20 Although thermal conductivity varies greatly over the complete range of possible moisture contents, this range can be narrowed if it is assumed that the moisture contents of most field soils lie between the wilting point of the soil (i.e., the moisture content of a soil below which a plant cannot alleviate its wilting symptoms) and the field capacity of the soil (i.e., the moisture content of a soil that has been thoroughly wetted and then drained until the drainage rate has become negligibly small). After a prolonged dry spell, moisture is near the wilting point, and after a rainy period, soil has moisture content near its field capacity. Moisture contents at these limits have been studied by many agricultural researchers, and data for different types of soil are given by Kersten (1949) and Salomone and Marlowe (1989). Shaded areas in Figure 6 approximate (1) the full range of moisture contents for different soil types and (2) a range between average values of each limit. Table 8 summarizes design values for thermal conductivities of the basic soil classes. Table 9 gives ranges of thermal conductivity for some basic classes of rock. The value chosen depends on whether heat transfer is calculated for minimum heat loss through the soil, as in a ground heat exchange system, or a maximum value, as in peak winter heat loss calculations for a basement. Hence, high and low values are given for each soil class. When calculating annual energy use, choose values that represent typical mean site conditions. In climates where ground freezing is significant, accurate heat transfer simulations should include the effect of the latent heat of fusion of water. Energy released during this phase change significantly retards the progress of the frost front in moist soils. For further information, see Chapter 17, which includes a method for estimating heat loss through foundations. Asphalt-impregnated paper #10, 5 mil, 5.9 lb/ft2 (transverse) #30, 6 mil, 8.2 lb/ft2 (transverse) #60, 9 mil, 16.1 lb/ft2 (transverse) Spun bonded polyolefin (SBPO) 4 mil, 0.87/ft2 (transverse) with crinkled surface, 3 to 4 mil, 0.92 lb/ft2 (transverse) Wallpaper, vinyl, 5 mil, 5.9 lb/ft2 (transverse) Exterior insulated finish system (EIFS), 0.17 in. acrylic, 71 lb/ft3 9 54 58 4 2 0.041 0 As heat flows through soil, moisture tends to move away from the heat source. This moisture migration provides initial mass transport of heat, but it also dries the soil adjacent to the heat source, thus lowering the apparent thermal conductivity in that zone of soil. Typically, when other factors are held constant, k increases with moisture content and with dry density of a soil, but decreases with increasing organic content of a soil and for uniform gradations and rounded soil grains (because grain-to-grain contacts are reduced). The k of a frozen soil may be higher or lower than that of the same unfrozen soil (because the conductivity of ice is higher than that of water but lower than that of typical soil grains). Differences in k below moisture contents of 7 to 8% are quite small. At approximately 15% moisture content, k may vary up to 30% from unfrozen values. 4.8 SURFACE FILM COEFFICIENTS/ RESISTANCES As explained in Chapter 25, the overall thermal resistance of an assembly comprises its surface-to-surface thermal resistance Rs and Heat, Air, and Moisture Control in Building Assemblies—Material Properties 26.17 Table 5 Typical Water Vapor Permeance and Permeability for Common Building Materialsa Material Weight, lb/100 ft2 Plastic and Metal Foils and Filmsb Aluminum foil 0.001 0.00035 0.002 0.004 0.006 0.008 0.010 0.002 0.004 0.001 0.0032 0.0076 0.01 0.125 Polyethylene Polyvinylchloride, unplasticized Polyvinylchloride, plasticized Polyester Licensed for single user. © 2021 ASHRAE, Inc. Cellulose acetate Liquid-Applied Coating Materials Commercial latex paints (dry film thickness) Vapor retarder paint Primer-sealer Vinyl acetate/acrylic primer Vinyl/acrylic primer Semigloss vinyl/acrylic enamel Exterior acrylic house and trim Paint, 2 coats Asphalt paint on plywood Aluminum varnish on wood Enamels on smooth plaster Primers and sealers on interior insulation board Various primers plus 1 coat flat oil paint on plaster Flat paint on interior insulation board Water emulsion on interior insulation board Paint, 3 coats Exterior paint, white lead and oil on wood siding Exterior paint, white lead/zinc oxide and oil on wood Styrene/butadiene latex coating Polyvinyl acetate latex coating Chlorosulfonated polyethylene mastic Asphalt cutback mastic 1/16 in., dry 3/16 in., dry Hot-melt asphalt Building Paper, Felts, Roofing Papersc Duplex sheet, asphalt laminated, aluminum foil one side Saturated and coated roll roofing Kraft paper and asphalt laminated, reinforced Blanket thermal insulation back-up paper, asphalt coated Asphalt, saturated and coated vapor retarder paper Asphalt, saturated, but not coated, sheathing paper asphalt felt, 15 lb tar felt, 15 lb Single kraft, double Polyamide film, 2 mil Thickness, in. Permeance, perm Dry-Cup Wet-Cup Other Method Permeability, perm-in. 3.2 3.2 3.2 3.2 3.2 3.2 0.0 0.05 0.16 0.08 0.06b 0.04b 0.68b 0.8 to 1.4 0.73 0.23 0.08 4.6 0.32 0.0031 0.0012 0.002 0.0016 0.0024 0.0017 0.45 6.28 7.42 8.62 6.61 5.47 0.4 0.3 to 0.5 0.5 to 1.5 0.9 to 2.15 1.6 to 3.0 4 30 to 85 12.5 25 21.9 43.8 0.3 to 1.0 0.9 11 5.5 1.7 0.06 12.5 21.9 0.14 0.0 0.5 0.1 8.6 65 6.8 6.2 8.6 4.4 14 14 3.2 0.002 0.05 0.3 0.4 0.2 to 0.3 3.3 1.0 4.0 31 1.10 Source: Lotz (1964). aThis table allows comparisons of materials, but when selecting vapor retarder materials, exact values for permeance or permeability should be obtained from manufacturer or from laboratory tests. Values shown indicate variations among mean values for materials that are similar but of different density, orientation, lot, or source. Values should not be used as design or specification data. Values from dry- and wet-cup methods were usually obtained from investigations using ASTM Standards C355 and E96; other values were obtained by two-temperature, special cell, and air velocity methods. 0.176 0.24 1.8 0.6 to 4.2 0.6 20.2 5.6 18.2 42 20.53 bUsually installed as vapor retarders, although sometimes used as exterior finish and elsewhere near the cold side, where special considerations are then required for warmside barrier effectiveness. cLow-permeance sheets used as vapor retarders. High permeance used elsewhere in construction. 26.18 2021 ASHRAE Handbook—Fundamentals Table 6 Water Vapor Permeance at Various Relative Humidities and Capillary Water Absorption Coefficient Licensed for single user. © 2021 ASHRAE, Inc. Material Building Board and Siding Asbestos cement board with oil-base finishes Cement board, 71 lb/ft3 Fiber cement board, 86 lb/ft3 Gypsum board, asphalt impregnated Gypsum wall board, 39 lb/ft3 with one coat primer with one coat primer/two coats latex paint Hardboard siding, 46 lb/ft3 Oriented strand board (OSB), 41 lb/ft3 41 lb/ft3 41 lb/ft3 Particleboard, 48 lb/ft3 Plywood Douglas fir, 29 lb/ft3 Douglas fir, 34 lb/ft3 Canadian softwood, 28 lb/ft3 Exterior-grade, 36 lb/ft3 Thickness, in. Permeance at Various Relative Humidities, perm 10% 50% 70% 90% 13 3.6 17 10 22 32 0.16 0.31 56 38 7.0 7.5 0.86 2.0 1.3 3.8 2.1 65 50 14 8.2 2.4 3.7 2.4 4.9 4.6 78 62 29 9.0 6.7 6.6 3.9 8.6 9.4 0.023 0.28 4-8 0.3-0.5 10 1.3 40 47 26 3.6 6.9 0.31 0.97 0.49 4.0 0.86 0.59 0.70 0.48 0.18 0.06 0.37 0.48 0.56 0.38 1.3 2.2 0.53 3.4 6.0 1.7 9.3 13 11 Exterior-grade, 32 lb/ft3 Wood fiber board, 20 lb/ft3 19 lb/ft3 0.51 0.46 1 18 47 1.2 20 48 1.4 22 50 3.2 24 53 15 27 58 0.012 Masonry Materials Aerated concrete, 29 lb/ft3 Cement mortar, 100 lb/ft3 Clay brick, 124 lb/ft3 Concrete, 138 lb/ft3 Concrete block (cored, limestone aggregate) Lightweight concrete, 83 lb/ft3 Limestone, 156 lb/ft3 Perlite board, 10 lb/ft3 11 lb/ft3 0.80 0.51 0.49 1 8 1 1 1 1 14 22 6.2 0.9 20 27 6.7 1.0 2.4 29 33 7.2 1.7 43 40 7.7 4.5 0.44 0.25 2.1 0.22 7.8 0.18 23 44 13 0.18 56 44 14 2.9 16 4.0 0.15 Plaster, on metal lath on wood lath on plain gypsum lath (with studs) Polystyrene concrete, 16-50 lb/ft3 Portland stucco mix, 124 lb/3 Tile masonry, glazed Woods Cedar Eastern white cedar, 22 lb/ft3 (transverse) Western red cedar, 22 lb/ft3 (transverse) Pine 21 lb/ft3 (longitudinal) Eastern white pine, 29 lb/ft3 (transverse) Southern yellow pine, 31 lb/ft3 (transverse) Sugar pine, 23 lb/ft3 (transverse) Spruce 28 lb/ft3 (longitudinal) 26 lb/ft3 (transverse) 25 lb/ft3 (transverse) Insulation Air (still) Cellular glass Cellulose, dry blown, 1.9 lb/ft3 Corkboard Glass fiber batt, 0.7 lb/ft3 0.12 30% Water Absorption Coefficient, lb/(ft2·h1/2) 0.5 0.31 0.5 0.5 0.43 0.39 0.43 0.48 0.75 0.47 10 0.46 41 12 1.9 6.3 0.01 0.04 0.06 9.6 18 5.8 44 8.4 0.18 19 44 0.75 0.18 44 15 11 20 13 2.0 0.12 0.0088 0.020 0.027 0.020 0.052 0.038 0.045 0.0041 References/Comments Dry cup* Dry cup* Kumaran (2002) Kumaran (2002) Dry cup* Kumaran (2002) Kumaran (2002) Kumaran (2002) Kumaran (2002) Kumaran (2002) Kumaran (2002) Kumaran (2002) Burch et al. (1992) Kumaran (2002) Kumaran (2002) Kumaran (2002) Burch and Desjarlais (1995) Burch et al. (1992) Kumaran (2002) Burch and Desjarlais (1995) Kumaran (2002) Kumaran (2002) Kumaran (2002) Kumaran (1996) * Kumaran (1996) Kumaran (2002) Kumaran (1996) Burch and Desjarlais (1995) * * * Kumaran (1996) Kumaran (2002) * 1 0.55 4 11 1.0 12 1.4 0.75 0.01 0.07 0.44 2.8 19 0.020 Kumaran (2002) 0.71 1 0.10 0.22 20 0.47 27 1.0 51 2.2 82 0.012 0.20 Kumaran (2002) Kumaran (1996) 0.75 0.77 0.51 0.52 0.04 0.11 0.45 41 0.16 0.36 0.54 98 0.62 1.2 0.93 112 2.4 4.2 2.3 120 9.3 15 8.4 121 0.081 0.017 0.12 Kumaran (2002) Kumaran (2002) Burch et al. (1992) Kumaran (1996) 0.45 0.77 0.34 1.1 0.96 2.1 2.8 8.6 8.3 30 26 0.025 Kumaran (1996) Kumaran (2002) 1 1 2.5 1 3.5 30 34 38 2.1-2.6 34 120 0.0 42 34 45 9.5 34 48 34 1.2 * * Kumaran (2002) * Kumaran (2002) Heat, Air, and Moisture Control in Building Assemblies—Material Properties Table 6 Water Vapor Permeance at Various Relative Humidities and Capillary Water Absorption Coefficient (Continued) Material Thickness, in. Permeance at Various Relative Humidities, perm Water Absorption Coefficient, lb/(ft2·h1/2) 10% 30% 50% 70% 90% 0.93 145 145 145 145 145 0.065 0.004 0.01 0.04 0.12 0.35 Mineral fiber insulation, 9 to 11 lb/ft3 Mineral wool (unprotected) Phenolic foam (covering removed) Polyisocyanurate insulation, 1.7 lb/ft3 2.0 lb/ft3 1 1 1 1 0.97 87 87 87 87 2.8 2.0 3.1 2.3 87 116 26 3.5 2.5 4.0 2.8 4.5 3.2 Polyisocyanurate glass-mat facer, 27 lb/ft3 0.032 10 15 22 32 48 Polystyrene expanded, 0.9 lb/ft3 extruded, 1.8 lb/ft3 Polyurethane expanded board stock sprayed foam, 2.4 lb/ft3 0.4 to 0.5 lb/ft3 Structural insulating board, sheathing quality interior, uncoated Unicellular synthetic flexible rubber foam 0.96 2.0 2.4 2.8 3.3 3.9 1 1 0.8 0.8 0.4-1.6 0.8 0.8 0.8 Kumaran (2002) * 1 1 1 0.5 1 1.6 60 1.7 60 1.9 60 20-50 50-90 2.0 60 2.2 60 Kumaran (2002) Kumaran (2002) * * Dry cup* 0.0079 4.1 7.4 14 26 53 0.012 Kumaran (2002) 0.0087 0.013 0.028 0.002 0.0055 0.00390.0043 7.7 26 5.1 22 42 5.1 4.1 76 55 40 55 6.9 11 76 55 81 74 20 35 76 55 0.011 0.014 0.0063 76 55 13 33 5.1 0.93 76 55 0.0038 0.0029 Kumaran (2002) Kumaran (2002) Kumaran (2002) Gatland II (2005) Kumaran (2002) Kumaran (2002) 0.011 0.017-0.028 0.0081 1.5 86-120 11-20 2.4 3.7 250-380 160-500 5.5 8.0 0.0031 Kumaran (1996) Kumaran (1996) Kumaran (2002) ** 1.6 1.6 0.0 1.6 1.6 1.6 0.0065 * Kumaran (2002) Glass-fiber insulation board, 7.6 lb/ft3 facer, 55 lb/ft3 Licensed for single user. © 2021 ASHRAE, Inc. 26.19 Foil, Felt, Paper (transverse) Asphalt-impregnated paper, 10 min rating, 3.5 lb/100 ft2 30 min rating, 4.1 lb/100 ft2 60 min rating, 5.7 lb/100 ft2 Bituminous paper (#15 felt), 10.6 lb/100 ft2 Polyamide film Spun bonded polyolefin (SBPO), 1.3 lb/100 ft2 with crinkled surface, 1.4 lb/100 ft2 Wallpaper paper, 3.1 to 3.4 lb/100 ft2 textile, 6.0 to 6.8 lb/100 ft2 vinyl, 3.5 lb/100 ft2 Other Construction Materials Built-up roofing (hot-mopped) Exterior insulated finish system (EIFS), 71 lb/ ft3 Glass fiber reinforced sheet, acrylic Polyester 0.056 0.048 0.02-0.15 0.12 0.05 References/Comments Burch and Desjarlais (1995) Burch and Desjarlais (1995) Kumaran (1996) * * Kumaran (2002) Burch and Desjarlais (1995) Burch and Desjarlais (1995) Kumaran (2002) Dry cup* Dry cup* *Historical data, no reference available **EIFS vapor permeance was tested with polymer cement base coat and latex acrylic finish coat of 0.17 in. thickness applied to expanded polystyrene of 1.3 in. thickness. the surface film resistances between the assembly’s surfaces and the interior and exterior environment (Ri and Ro). Table 10 gives typical values for the surface film coefficients hi and ho and their reciprocals, the surface resistances Ri and Ro. As shown, the indoor values depend on position of the surface, direction of heat transfer, and the surface’s long-wave emissivity. Outdoors, the values depends on air speed and the surface’s long-wave emissivity. Table 10 reflects standard situations, with an assumed (approximate) interior surface temperature representative of wall or roof assemblies. For situations that deviate substantially from standard conditions, including interior surface temperatures for fenestration systems, use ASHRAE (1998) or values from Chapter 15 to determine the surface film coefficients/resistances. 4.9 CODES AND STANDARDS ASHRAE. 2010. Energy standard for buildings except low-rise residential buildings. ANSI/ASHRAE/IES Standard 90.1-2010. ASTM. 2010. Standard terminology relating to thermal insulation. Standard C168-10. American Society for Testing and Materials, West Conshohocken, PA. ASTM. 2010. Standard test method for steady-state heat flux measurements and thermal transmission properties by means of the guarded-hot-plate apparatus. Standard C177-10. American Society for Testing and Materials, West Conshohocken, PA. ASTM. 2010. Standard test method for steady-state heat transfer properties of pipe insulation. Standard C335/C335M-10e1. American Society for Testing and Materials, West Conshohocken, PA. 26.20 2021 ASHRAE Handbook—Fundamentals Table 7 Sorption/Desorption Isotherms of Building Materials at Various Relative Humidities Sorption, % Moisture Content at % Relative Humidity Licensed for single user. © 2021 ASHRAE, Inc. Material Building Board and Siding Cement board, 1/2 in., 70 lb/ft3 Fiber cement board, 5/16 in., 86 lb/ft3 Gypsum wall board, 1/2 in., 39 lb/ft3 Hardboard siding, 7/16 in., 46 lb/ft3 Oriented strand board (OSB), 3/8 in., 41 lb/ft3 7/16 in., 41 lb/ft3 1/2 in., 41 lb/ft3 Particle board, 3/4 in., 47 lb/ft3 Plywood, 1/2 in. 5/8 in. 3/4 in. Plywood (exterior grade), 1/2 in., 36 lb/ft3 Wood fiber board, 7/16 in., 20 lb/ft3 1.0 in., 18.7 lb/ft3 Masonry Materials Aerated concrete, 29 lb/ft3 37.5 lb/ft3 Cement mortar, 100 lb/ft3 Clay brick, 4 × 4 × 8 in., 124 lb/ft3 Concrete, 138 lb/ft3 Lightweight concrete, 98 lb/ft3 Limestone, 156 lb/ft3 Perlite board Portland stucco mix, 124 lb/ft3 Woods Eastern white cedar, 1 in., 22.5 lb/ft3 Eastern white pine, 1 in., 28.7 lb/ft3 Southern yellow pine, 1 in. 31 lb/ft3 Spruce (transverse), 25 lb/ft3 Western red cedar, 1 in., 21.8 lb/ft3 Insulation Cellulose, dry blown, 1.87 lb/ft3 Glass fiber batt, 0.72 lb/ft3 Glass fiber board, 0.9 in., 7.5 lb/ft3 Glass fiber board facer, 0.06 in., 55 lb/ft3 Mineral fiber, 2.5 lb/ft3 Polystyrene, expanded, 0.92 lb/ft3 extruded, 1.79 lb/ft3 Polyurethane, sprayed foam, 2.43 lb/ft3 0.4 to 1/2 lb/ft3 Polyisocyanurate, 1.65 lb/ft3 Polyisocyanurate glass facer, 0.04 in., 26.8 lb/ft3 143 1.970 3.481 6.193 450.6 5.870.4 16.889.9 34.7100t 0.450.5 0.6570.5 1.890.8 4.294 42.7100t Desorption, % Moisture Content at % Relative Humidity 1.643 3.270 4.681 6.293 1899.27 2899.93 References Kumaran (2002) 6.650.5 12.370.5 19.690.6 31.395.32 32.599.49 33.999.93 Kumaran (2002) 68.9100c 113100t 0.9950.4 1.3271.5 1.6984.8 1.8288.3 Kumaran (2002) 4.750.3 6.969.6 13.191.3 90100t 4.450.3 7.669.2 13.491.3 3891.3 Kumaran (2002) 4.648.9 7.669.1 14.788.6 126100c 6.949.9 9.169.4 16.290.3 17.392.3 39.399.3 60.699.8 Kumaran (2002) 5.448.9 8.269.1 14.788.6 160100t 7.949.9 9.969.4 17.490.3 39.199.3 62.799.8 Kumaran (2002) 4.648.9 7.869.1 14.888.6 124100t 7.949.9 1069.4 17.690.3 2092.3 4299.3 59.5 Kumaran (2002) 1.211.3 6.357.6 9.778.6 11.384.1 15.993.6 21.597.3 1.711.3 8.857.6 1478.6 16.684.1 1993.6 23.397.6 Kumaran (1996) 748.9 6.848.9 6.748.9 1.8311.3 9.269.1 9.669.1 10.169.1 6.958 15.888.6 16.888.6 17.688.6 9.578.7 170100t 140100t 190100t 12.184.5 17.993.8 22.1 4.650.6 7.470.5 15.891.1 304 8.449.9 8.649.9 8.949.9 2.0911.3 10.869.4 11.369.4 11.369.4 9.358 18.290.3 19.890.3 19.390.3 13.778.7 3.950.6 7.471.1 1590.6 1992.3 19.392.3 20.792.3 15.284.5 7099.3 4799.3 6699.3 19.893.8 101 79 9999.8 23.4 23099.71 23099.85 23099.93 0.6311.3 5.758 9.278.7 11.384.5 16.493.8 24.697.4 1.2611.3 7.658 1278.7 14.684.5 20.693.8 28.197.4 1.150.6 1.817.8 0.4249.9 0.0850 588.1 4.690.3 5.389.9 0.191.2 6.388.1 455.2 6.189.9 4.598.9 3497.81 6.675.6 1798.9 699.63 2.171.5 3.275.8 2.370.1 0.1269.1 83100c 172 6.492.4 9.695.9 17.598.4 26100t 9.9100t 1.150.6 2.317.8 3.449.9 050 2.271.5 2.833 4.470.2 091.2 7299.85 15.491.6 2299.63 8.299.71 9299.99 36.598 2599.93 9.199.93 Kumaran (2002) Kumaran (2002) Kumaran (2002) Burch and Desjarlais (1995) Kumaran (2002) Kumaran (2002) Kumaran (1996) Kumaran (2002) Kumaran (2002) 0.8825.2 1.1544.9 1.7465 2.6280 3.3589.8 4.4598.2 0.9420 2.1945.4 2.9865.6 3.8584.8 4.5794.8 2.924.4 3.445.2 465.2 4.685 6.698 3.119.6 4.440 5.259.8 679.6 7.194.7 Kumaran (1996) Kumaran (1996) 050 13033 350 Kumaran (2002) Kumaran (1996) Kumaran (2002) 070 0.188.5 1.8100t 16052 26075 38086 80097 3.770.3 5.889.9 12100t 070.5 0.188.6 0.2195.3 0.598.9 0.699.27 1.399.93 4.250 5.270.3 790.3 117099.8 10.395.29 11.698.9 11.799.93 3.449.8 7.670 12.888.5 228100t 1.750 7.470.5 11.988.7 8598.9 3.249.8 7.670 1288.5 192100t 3.250 970.5 12.488.7 8499.78 3.649.8 8.170 15.288.5 158100t 4.350 1070.5 15.688.7 5799.78 4.149.8 9.270 3.449.8 670 16.788.5 228100t 9.688.5 228100t 4.950 150 11.370.5 17.788.7 14895.96 18799.78 970.5 13.388.7 11399.78 550.2 1272.8 6.150.5 9.671.5 2488.1 11899.63 17699.92 2688 Kumaran (2002) 0.2150.6 0.3471.5 0.7588.1 0.2450.4 0.3571.4 0.6788.2 Kumaran (2002) 0.1611.3 0.75 0.8278.7 0.9684.5 1.393.8 2.0397.4 0.4311.3 0.8632.8 1.1158 1.2684.5 1.7493.8 2.1697.4 Burch and Desjarlais (1995) 0.0911.3 0.5358 0.7678.7 0.8484.5 1.1493.8 1.5497.4 0.1811.3 0.5658 0.8778.7 1.0984.5 1.4593.8 1.8197.4 Burch and Desjarlais (1995) 0.520.1 0.5545.4 0.5965 0.785.2 0.7694.5 0.897.5 0.520.1 0.5844.9 0.6364.9 0.8184.5 1.194.7 1.697.8 Kumaran (1996) 0.450.4 0.368.3 0.288.3 0.450.1 0.567.9 0.587.9 Kumaran (2002) 0.650.4 0.568.3 0.488.3 0.550.1 0.567.9 0.487.9 Kumaran (2002) 1.350.4 1.768.3 288.4 1.150.1 1.567.9 1.887.9 Kumaran (2002) 0.550.4 170.2 1.690.3 1.350.4 1.768.3 2.188.3 1.3611.3 4.558 6.878.7 984.5 150.5 2.170.9 791.3 1.150.1 1.567.9 1.987.9 0.8911.3 5.858 8.378.7 10.9 Kumaran (2002) Kumaran (2002) Burch and Desjarlais (1995) 12.593.8 17.997.4 14.493.8 18.497.4 Licensed for single user. © 2021 ASHRAE, Inc. Heat, Air, and Moisture Control in Building Assemblies—Material Properties ASTM. 2010. Standard test method for steady-state thermal transmission properties by means of the heat flow meter apparatus. Standard C518-10. American Society for Testing and Materials, West Conshohocken, PA. ASTM. 2015. Standard practice for selection of water vapor retarders for thermal insulation. Standard C755-10 (R2015). American Society for Testing and Materials, West Conshohocken, PA. ASTM. 2005. Standard classification of potential health and safety concerns associated with thermal insulation materials and accessories. Standard C930-05. American Society for Testing and Materials, West Conshohocken, PA. ASTM. 2013. Standard practice for calculating thermal transmission properties under steady-state conditions. Standard C1045-07 (R2013). American Society for Testing and Materials, West Conshohocken, PA. ASTM. 2011. Standard test method for thermal performance of building materials and envelope assemblies by means of a hot box apparatus. Standard C1363-11. American Society for Testing and Materials, West Conshohocken, PA. ASTM. 2016. Standard specification for insulated vinyl siding. Standard D7793-16. American Society for Testing and Materials, West Conshohocken, PA. ASTM. 2010. Standard test methods for water vapor transmission of materials. Standard E96/E96M-10. American Society for Testing and Materials, West Conshohocken, PA. ASTM. 2009. Standard practices for air leakage site detection in building envelopes and air barrier systems. Standard E1186-03 (2009). American Society for Testing and Materials, West Conshohocken, PA. ASTM. 2011. Standard specification for air barrier (AB) material or system for low-rise framed building walls. Standard E1677-11. American Society for Testing and Materials, West Conshohocken, PA. ASTM. 2011. Standard test method for determining air leakage of air barrier assemblies. Standard E2357-11. American Society for Testing and Materials, West Conshohocken, PA. CAN/ULC. 2003. Standard for determination of log-term thermal resistance of closed-cell thermal insulating foams. CAN/ULC Standard S7702003. Standards Council of Canada, Ottawa, ON, and Underwriters Laboratories Canada, Toronto, ON. VDI. 1999. Environmental meteorology—Interactions between atmosphere and surfaces—Calculation of short-wave and long-wave radiation. Standard 3789 Part 2. Verein Deutscher Ingenieure (Association of German Engineers), Dusseldorf. REFERENCES ASHRAE members can access ASHRAE Journal articles and ASHRAE research project final reports at technologyportal.ashrae .org. Articles and reports are also available for purchase by nonmembers in the online ASHRAE Bookstore at www.ashrae.org/bookstore. Adams, L. 1971. Supporting cryogenic equipment with wood. Chemical Engineering (May):156-158. ASHRAE. 1998. Standard method for determining and expressing the heat transfer and total optical properties of fenestration products. SPC 142. ASTM. 1985a. Guarded hot plate and heat flow meter methodology. Special Technical Publication STP 879. American Society for Testing and Materials, West Conshohocken, PA. ASTM. 1985b. Building applications of heat flux transducers. Special Technical Publication STP 885. American Society for Testing and Materials, West Conshohocken, PA. ASTM. 1988. Thermal insulation: Material and systems. Special Technical Publication STP 922. American Society for Testing and Materials, West Conshohocken, PA. ASTM. 1990. Insulation materials: Testing and applications. Special Technical Publication STP 1030. American Society for Testing and Materials, West Conshohocken, PA. ASTM. 1991. Insulation materials: Testing and applications, 2nd vol. Special Technical Publication STP 1116. American Society for Testing and Materials, West Conshohocken, PA. ASTM. Annual. Annual book of ASTM standards, vol. 04.06, Thermal insulation; building and environmental acoustics. American Society for Testing and Materials, West Conshohocken, PA. Bassett, M.R., and H.A. Trethowen. 1984. Effect of condensation on emittance of reflective insulation. Journal of Thermal Insulation 8(October):127. Binder, A., D. Zirkelbach, and H.M. Künzel. 2010. Test method to quantify the wicking properties of insulation materials designed to prevent interstitial condensation. Proceedings of Buildings XI Conference, ASHRAE. Bomberg, M.T., and M.K. Kumaran. 1986. A test method to determine air flow resistance of exterior membranes and sheathings. Journal of Thermal Insulation 9:224-235. Brandreth, D.A., ed. 1986. Advances in foam aging—A topic in energy conservation series. Caissa Editions, Yorklyn, DE. Table 10 Table 8 Normal Range 4.2 to 17.4 6 to 17.4 6 to 11.4 6 to 17.4 Lowb 5.4 11.4 7.8 6.6 Highc 15.6 15.6 10.8 15.6 a Reasonable values for use when no site- or soil-specific data are available. conservative values for minimum heat loss through soil (e.g., use in soil heat exchanger or earth-contact cooling calculations). Values are from Salomone and Marlowe (1989). c Moderately conservative values for maximum heat loss through soil (e.g., use in peak winter heat loss calculations). Values are from Salomone and Marlowe (1989). b Moderately Table 9 Surface Film Coefficients/Resistances Typical Apparent Thermal Conductivity Values for Soils, Btu· in/h·ft2 ·°F Surface Emittance, Recommended Values for Designa Sands Silts Clays Loams 26.21 Typical Apparent Thermal Conductivity Values for Rocks, Btu· in/h·ft2 · °F Normal Range Pumice, tuff, obsidian Basalt Shale Granite Limestone, dolomite, marble Quartzose sandstone 3.6 to 15.6 3.6 to 18.0 6 to 27.6 12 to 30 8.4 to 30 9.6 to 54 Position of Surface Direction of Heat Flow Indoor Horizontal Sloping at 45° Vertical Sloping at 45° Horizontal Upward Upward Horizontal Downward Downward Reflective = 0.20 = 0.05 hi Ri hi Ri hi Ri 1.63 1.60 1.46 1.32 1.08 0.61 0.62 0.68 0.76 0.92 0.91 0.88 0.74 0.60 0.37 1.10 1.14 1.35 1.67 2.70 0.76 0.73 0.59 0.45 0.22 1.32 1.37 1.70 2.22 4.55 ho Ro Any 6.00 0.17 — — — — Any 4.00 0.25 — — — — Outdoor (any position) 15 mph wind (for winter) 7.5 mph wind (for summer) Nonreflective = 0.90 Notes: 1. Surface conductance hi and ho measured in Btu/h·ft2 ·°F; resistance Ri and Ro in h·ft2 ·°F/Btu. 2. No surface has both an air space resistance value and a surface resistance value. 3. Conductances are for surfaces of the stated emittance facing virtual blackbody surroundings at same temperature as ambient air. Values based on surface/air temperature difference of 10°F and surface temperatures of 70°F. 4. See Chapter 4 for more detailed information. 5. Condensate can have significant effect on surface emittance (see Table 2). Also, oxidation, corrosion, and accumulation of dust and dirt can dramatically increase surface emittance. Emittance values of 0.05 should only be used where highly reflective surface can be maintained over the service life of the assembly.