ENVIRONMENTAL SCIENCE

AND ENGINEERING

CE102

Water Quality Characteristics

Physical Characteristics

Colour, Turbidity, Taste, Odour, Temperature

Chemical Characteristics

pH, TDS, Total (Alkalinity, Hardness),

Calcium,

Magnesium, Fluoride, Chlorides, Sulphates, Nitrates, Total

Nitrogen, Chloramines, Residual Chlorine, Iron, Ag, Cu, Zn

Biological Characteristics

Pathogens

Color

Color in drinking-water may be due to the presence of organic matter such as

Humic Substances, metals such as Iron and Manganese, or highly colored

industrial wastes

Term ‘color’ is used to mean True Color – Due to Dissolved Solids

Term ‘Apparent Color’ includes not only the color due to substances in

solution but also that due to Suspended Matter or Colloid Solids

Measured by comparing the color of water sample with other standard glass tubes

containing solutions of different standard Platinum Cobalt (Pt-Co) color intensities

Normally expressed as Hazen Units (Dissolve 1.246 g potassium chloroplatinate

(equivalent to 500 mg metallic platinum ) and 1.00 g crystalline cobaltous chloride

(equivalent to 250 mg metallic cobalt) in distilled water containing 100 ml of

concentrated hydrochloric acid. Dilute to 1000 ml with distilled water. This standard

solution is equivalent to 500 Hazen Units(HU) or True Color Unit (TCU)

Humic Substances can be defined as “a general category of naturally

occurring, biogenic, heterogeneous organic substances that can

generally be characterized as being yellow to black in color, of high

molecular weight (MW) and refractory” (Aiken et al., 1985b)

Indian

Standards

IS 10500:1983

IS 10500:1991

IS 10500:2012

IS 14543:2004

Desirable Limit

(HU/TCU)

-5

5

2

Permissible Limit in

Absence of Alternate

Sources (HU/TCU)

-25

15

--

Taste & Odour

The Dissolved Organic materials or the inorganic Salts or dissolved gases may impart taste

and odor

Gasses: H2S,CH4, CO2, O2 + Organic Matter

Minerals: NaCl, Iron Compounds, Carbonates & Sulphates

Taste expressed by Flavor Threshold Number (TKN)

Odour expressed by Threshold Odour Number (TON)

The character and intensity of taste and odour discloses the nature of pollution or the

presence of microorganisms

TON =

𝐴+𝐵

𝐴

=

𝑽𝒐𝒍.𝒐𝒇 𝑹𝒂𝒘 𝑾𝒂𝒕𝒆𝒓 𝑺𝒂𝒎𝒑𝒍𝒆 + 𝑽𝒐𝒍.𝒐𝒇 𝑫𝒊𝒔𝒕𝒊𝒍𝒍𝒆𝒅 𝒘𝒂𝒕𝒆𝒓 𝒖𝒔𝒆𝒅 𝒇𝒐𝒓 𝑫𝒊𝒍𝒖𝒕𝒊𝒐𝒏

𝑽𝒐𝒍𝒖𝒎𝒆 𝒐𝒇 𝑹𝒂𝒘 𝑾𝒂𝒕𝒆𝒓 𝑺𝒂𝒎𝒑𝒍𝒆

Permissible Limit is 1:3

Nephelometric Turbidity unit

Indian

Standards

Desirable Limit

(NTU)

Permissible Limit in Absence

of Alternate Sources (NTU)

IS 10500:1983

Agreeable

Agreeable

IS 10500:1991

Agreeable

Agreeable

IS 10500:2012

Agreeable

Agreeable

IS 14543:2004

Agreeable

Agreeable

Turbidity

Reduction of transparency due to the presence of particulate matter such as clay or silt,

finely divided organic matter, plankton or other microscopic organisms - First Attempt

was made in the year 1900 to determine turbidity

Originally turbidity was measured by Jackson candle turbidity meter

A water sample is poured into the tube until the visual image of the candle flame,

as viewed from the top of the tube

When the intensity of the scattered light equals that of the transmitted light, the

image disappears; the depth of the sample in the tube is read against the ppmsilica scale, and turbidity was measured in Jackson Turbidity Units (JTU)

The calibration was done based on suspensions of silica - consistency in

standard formulation was difficult to achieve

Nowadays turbidity is measured by applying Nephelometry - technique

to measure level of light scattered by the particles at right angles to

the incident light beam

Scattered light level is proportional to the particle concentration in

the sample

Higher the intensity of scattered light, higher the turbidity

Formazin polymer is generally used as turbidity standard because it is

more reproducible than other types of standards used previously

Unit of expression is Nephelometric Turbidity Unit (NTU)

Typical series of Formazin

turbidity standards shown in

NTU/FTU

Turbidity - Measurements

Turbidity – Limits & its Importance

Turbidity < 40 Units - No Issues

Turbidity > 40 Units - Dilute the Sample and calculate

using the following equation:

𝐴 ∗ (𝐵 + 𝐶)

𝐶

A : Turbidity units found in diluted sample,

B : Volume in ml of dilution water used, and

C : Volume of sample in ml taken for dilution

𝑇𝑢𝑟𝑏𝑖𝑑𝑖𝑡𝑦 𝑈𝑛𝑖𝑡𝑠 =

Indian

Standards

Desirable Limit

(NTU)

Permissible Limit in

Absence of Alternate

Sources (NTU)

IS 10500:1983

10

25

IS 10500:1991

5

10

IS 10500:2012

1

5

IS 14543:2004

2

--

Why it is Important ?

Turbidity is important because it

affects both the acceptability of

water to consumers, and the

selection and efficiency of treatment

processes, particularly the efficiency

of disinfection with chlorine since it

exerts a chlorine demand and

protects microorganisms and may also

stimulate the growth of bacteria

Solids (Dissolved, Suspended)

Total Dissolved Solids: A well-mixed water sample (100 mL) is filtered through a

standard glass fiber filter (2.0 µm pore size), and the filtrate is evaporated to dryness in a

weighed dish and dried to constant weight at 180°C for 1 hour

TDS↑ Hardness ↑

3

𝑚𝑔 𝑜𝑓 𝑇𝑜𝑡𝑎𝑙 𝐷𝑖𝑠𝑠𝑜𝑙𝑣𝑒𝑑 𝑆𝑜𝑙𝑖𝑑𝑠/𝐿 =

𝑊𝑒𝑖𝑔ℎ𝑡 𝑜𝑓𝑑𝑟𝑖𝑒𝑑 𝑟𝑒𝑑𝑖𝑠𝑢𝑒 + 𝑑𝑖𝑠ℎ − 𝑊𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑑𝑖𝑠ℎ

𝑉𝑜𝑙𝑢𝑚𝑒 𝑜𝑓 𝑆𝑎𝑚𝑝𝑙𝑒

∗ 10

Total Suspended Solids: A well-mixed water sample (100 mL) is filtered through a

weighed standard glass-fiber filter (2.0 µm pore size) and the residue retained on

the filter is dried to a constant weight at 103 - 105°C for 1 hour

If the suspended material clogs the filter and prolongs filtration, it may be

necessary to increase the diameter of the filter or decrease the sample volume

𝑚𝑔 𝑇𝑜𝑡𝑎𝑙 𝑆𝑢𝑠𝑝𝑒𝑛𝑑𝑒𝑑 𝑆𝑜𝑙𝑖𝑑𝑠/𝐿 =

𝑊𝑒𝑖𝑔ℎ𝑡 𝑜𝑓𝑓𝑖𝑙𝑡𝑒𝑟 + 𝑑𝑟𝑖𝑒𝑑 𝑟𝑒𝑑𝑖𝑠𝑢𝑒 − 𝑊𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑓𝑖𝑙𝑡𝑒𝑟

{𝑉𝑜𝑙𝑢𝑚𝑒 𝑜𝑓 𝑆𝑎𝑚𝑝𝑙𝑒}

∗ 103

Solids – Temperature

Drying at 103°C ensures the removal of all free water, provided that the drying

period is long enough, and minimizes the loss of water of crystallization

Water of Crystallization - Water that occurs inside crystals, this water is not

bonded to the crystal but embedded during the crystallization of the mineral

Ex - CaSO4·2H2O Gypsum contains two water molecules in their crystals

Residues dried at 103 - 105°C may retain not only water of crystallization but also

some mechanically blocked water

Residues dried at 180 ± 2°C will lose almost all

mechanically occluded water (water molecules

trapped in mineral matrix). Some water of

crystallization may remain, especially if sulfates

are present

550°C is about the lowest temperature at

which organic matter, particularly carbon residues

resulting from pyrolysis of carbohydrates and

other organic matter, can be oxidized at

reasonable speed, while Inorganic salts are stable

Solids (Fixed, Volatile)

“Fixed Solids” is the term applied to the residue of Total, Suspended, or Dissolved

Solids after heating to dryness for a specified time at a specified temperature

(550°C for 1 hour). The weight loss on ignition is called “Volatile Solids”

Total Fixed Solids - approximation of the Mineral Matter Present (Inorganic)

Total Volatile Solids - approximation of the Organic Material Present

This test is accomplished by a combustion procedure in which organic matter is

converted to gaseous CO2 and H2O, and thus volatilized, while the temperature is

controlled to prevent decomposition and volatilization of inorganic substances as much

as is consistent with complete oxidation of the organic matter

• 𝑚𝑔 𝑉𝑜𝑙𝑎𝑡𝑖𝑙𝑒 𝑆𝑜𝑙𝑖𝑑𝑠/𝐿 =

• 𝑚𝑔 𝐹𝑖𝑥𝑒𝑑 𝑆𝑜𝑙𝑖𝑑𝑠/𝐿 =

𝑊𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑟𝑒𝑑𝑖𝑠𝑢𝑒+𝑑𝑖𝑠ℎ 𝑏𝑒𝑓𝑜𝑟𝑒 𝑖𝑔𝑛𝑖𝑡𝑖𝑜𝑛 − 𝑊𝑒𝑖𝑔ℎ𝑡 𝑜𝑓𝑟𝑒𝑑𝑖𝑠𝑢𝑒+𝑑𝑖𝑠ℎ/𝑓𝑖𝑙𝑡𝑒𝑟 𝑎𝑓𝑡𝑒𝑟 𝑖𝑔𝑛𝑖𝑡𝑖𝑜𝑛 ∗103

𝑉𝑜𝑙𝑢𝑚𝑒 𝑜𝑓 𝑆𝑎𝑚𝑝𝑙𝑒

𝑊𝑒𝑖𝑔ℎ𝑡 𝑜𝑓𝑟𝑒𝑑𝑖𝑠𝑢𝑒+𝑑𝑖𝑠ℎ/𝑓𝑖𝑙𝑡𝑒𝑟 𝑎𝑓𝑡𝑒𝑟 𝑖𝑔𝑛𝑖𝑡𝑖𝑜𝑛 − 𝑊𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑑𝑖𝑠ℎ/𝑓𝑖𝑙𝑡𝑒𝑟 ∗103

𝑉𝑜𝑙𝑢𝑚𝑒 𝑜𝑓 𝑆𝑎𝑚𝑝𝑙𝑒

Solids Standards

Indian

Standards

IS 10500:1983

Desirable Limit

(mg/L)

1000

Permissible Limit in Absence

of Alternate Sources

--

IS 10500:1991

IS 10500:2012

IS 14543:2004

500

500

500

2000

2000

--

Environmental Significance

Laxative or reverse effects on people whose bodies are not used to the higher

levels

Imparts taste to water

Water stain glassware

Experiment - Solids

Experiment - Solids

Dissolved Solids

Suspended Solids

Settleable Solids

Settleable Solids is applied to solids in

suspension that will settle, under gentle

(period of inactivity or dormancy)

conditions, because of the influence of

gravity

Fill an Imhoff cone to the 1-L mark with a well-mixed sample. Settle for 45

min, gently agitate sample near the sides of the cone with a rod or by spinning,

settle 15 min longer, and record volume of settleable solids in the cone as

milliliters per liter (mL/L)

Reported as volume (mL/L) basis

Solids Analysis Application in Env. Engg.

Application

TS

VS

TDS

Drinking Water

x

Natural Waters

x

Municipal Wastewater

Industrial Wastewater

x

x

Sludge

x

x

x

TSS

VSS

x

x

x

x

x

Example Problem

Given the following data:

• Weight of a dish = 48.6212 g

• 100 mL of sample is placed in a dish and

evaporated

• Weight of the dish and dry solids = 48.6432 g

• The dish is then placed in a 550°C furnace, then

cooled. Weight = 48.6300 g

• Find the total, fixed, and volatile solids

(expressed as mg/L)

pH -

Universally to express the intensity of the acid or

alkaline condition of a solution

Expressed on a scale ranging from 0 to 14

Logrithm of Reciprocal of Hydrogen ion activity (moles/L)

Recommended pH range for treated drinking waters is 6.5 to 8.5

It is a factor that must be considered in chemical coagulation,

disinfection, water softening, and corrosion control

In wastewater treatment employing biological processes, pH must

be controlled within a range favorable to the particular organisms

involved

Indian

Standards

Desirable Limit

Permissible Limit in Absence of

Alternate Sources

IS 10500:1983

6.5 to 8.5

--

IS 10500:1991

6.5 to 8.5

--

IS 10500:2012

6.5 to 8.5

--

IS 14543:2004

6.5 to 8.5

--

pH should preferably be determined at the time of sample collection

pH value obtained in the lab may not be the same as that of water at the time of

collection of samples due to loss-or absorption of gases, reactions with sediments,

hydrolysis and oxidation or reduction taking place within the sample bottle

Pure water dissociates to yield a concentration of Hydrogen Ions equal to about

10-7mol/L

+

−

𝑯𝟐𝑶 ↔ 𝑯 + 𝑶𝑯

−

H2O dissociates to− produce one 𝑶𝑯 ion for each H+ ion, it is obvious that about

10-7mol/L of 𝑶𝑯 ion is produced simultaneously

By substitution into the equilibrium equation, we obtain,

+

−

𝑯 {𝑶𝑯 }

=𝑲

{𝑯𝟐𝑶}

+

−

𝑲𝑾 = 𝑯 𝑶𝑯 = {10-7}{10-7} = {10-14}

Kw = is known as Ionization Constant for water and changes with change in

Temperature

The pH of water is a measure of the acid–base equilibrium and, in most

natural waters, is controlled by the carbon dioxide–bicarbonate–carbonate

equilibrium system

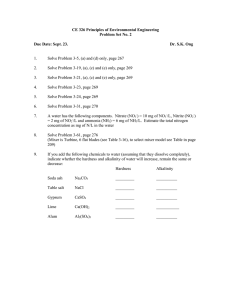

An increased carbon dioxide concentration will therefore lower pH, whereas a

decrease will cause it to rise

The pH of the water entering the distribution system must be controlled to

minimize the corrosion of water mains and pipes in household water systems

Failure to do so can result in the contamination of drinking-water and in

adverse effects on its taste, odour, and appearance

For effective disinfection with chlorine, the pH should preferably be less than 8

The pH of water determines the solubility (amount that can be dissolved in the

water) and biological availability (amount that can be utilized by aquatic life) of

chemical constituents such as nutrients (phosphorus, nitrogen, and carbon) and

heavy metals (lead, copper, cadmium, etc.)

+

𝑝𝐻 = −𝑙𝑜𝑔 𝐻 𝑜𝑟

1

𝑝𝐻 = log{ +}

𝐻

pH is usually represented from 0 to 14, with pH 7 at 25ᵒC

representing absolute neutrality

Example: In a water treatment plant, the pH values of upcoming and outgoing

water are 7.2 and 8.4 respectively. Assuming a linear variation of pH with time,

determine the average pH value of water

Iron & Manganese

These are present in insoluble forms in significant amounts in nearly all soils

Fe exists in soils and minerals mainly as insoluble Ferric Oxides (Fe2O3) and Iron

Sulfide (FeS) (pyrite)

It occurs in some areas also as Ferrous Carbonate (siderite), which is very slightly soluble

Further, groundwaters usually contain significant amounts of CO2, appreciable amounts

of Ferrous Carbonate may dissolved by the reaction shown in the equation,

FeCO3(s) + CO2 + H2O → Fe2++ 2HCO3Under reducing (anaerobic) conditions, however, the ferric iron (Fe3+) is reduced to

ferrous iron (Fe2+)

Fe imparts a taste to water which is detectable at very low concentrations

Mn exists in the soil principally as Manganese Dioxide (MnO2), which is very

insoluble in water containing CO2

Under reducing (anaerobic) conditions, Manganese in the dioxide form is reduced from an

oxidation state of III to II

Humans suffer no harmful effects from drinking waters containing Fe & Mn

Iron & Manganese

Groundwaters that contain appreciable amounts of Fe or Mn or both are always empty of

dissolved oxygen and are high in CO2 content. The Fe and Mn are present as Fe (II) and Mn

(II). The high CO2 content indicates that bacterial oxidation of organic matter has been extensive,

and the absence of dissolved oxygen shows that anaerobic conditions were developed

It has been shown, on the basis of thermodynamic considerations, that Mn(IV) and Fe(III) are

the only stable oxidation states for Fe & Mn in oxygen-containing waters. Thus, these forms can

be reduced to the soluble Mn (II) and Fe (II) only under highly anaerobic reducing conditions.

Both Fe & Mn interfere with laundering operations, impart objectionable stains to plumbing

fixtures, and cause difficulties in distribution systems by supporting growths of iron bacteria

Iron bacteria are small living organisms which

naturally occur in soil, shallow groundwater, and surface

waters. These nuisance bacteria combine Fe (or Mn)

and oxygen to form deposits of "rust," bacterial cells,

and a slimy material that sticks the bacteria to well

pipes, pumps, and plumbing fixtures. The bacteria are

not known to cause disease, but can cause

undesirable stains, tastes and odors

Iron & Manganese

Indian

Standards

IS 10500:1983

IS 10500:1991

IS 10500:2012

IS 14543:2004

Desirable Limit (Fe)

(mg/L)

0.3

0.3

0.3

0.1

Permissible Limit in

Absence of Alternate

Sources

1

No relaxation

No relaxation

--

Indian Standards Desirable Limit (Mn)

(mg/L)

Permissible Limit in

Absence of Alternate

Sources

IS 10500:1983

IS 10500:1991

IS 10500:2012

0.1

0.1

0.1

0.5

0.3

0.3

IS 14543:2004

0.1

--

Source of Fluoride: Occurs in Igneous and Sedimentary Rocks

Fluoride occurs as

Sellaite [MgF2],

Fluorite Or Fluorspar [CaF2],

Cryolite [Na3AlF6],

Fluorapatite [3Ca3(PO4)2 Ca(F,Cl2)],

Apatite [CaF2.3Ca3(PO4)],

Topaz [Al2SiO4(F,OH)2],

Fluormica (phlogopite) [KMg3(Si3Al)O10(F,OH)2],

Biotite [K(Mg,Fe)3AlSi3O10(F,OH)2],

Epidote [Ca2Al2(Fe3+;Al)(SiO4)(Si2O7)O(OH)],

Amphibole such as tremolite [Ca2Mg5Si8O22(OH)2],

Hornblende [Ca2(Mg,Fe,Al)5(Al,Si)8O22(OH)2],

Mica, Clays, Villuanite and Phosphorite

Fluoride minerals such as Fluorite and Cryolite are not readily soluble in water under

normal pressure and temperature

Under alkaline conditions and range of specific conductivity between 750 and

1750 µS/cm, dissolution rate of fluorite minerals increase (Saxena and Ahmed, 2001)

The weathering of Granitic rocks results in increased fluoride content in

groundwater

Longer residence time in aquifers with fractured fluoride rich rocks enhance

fluoride levels in the groundwater

Nalgonda, India contain fluoride rich minerals such as Fluorite (0 to 3.3%),

Biotite (0.1 to 1.7%) and Hornblende (0.1 to 1.1%) (Ramamohana Rao et al., 1993)

Fluoride

The discovery of high consumption of Fluoride (two-edge sword) being harmful for

humans and animals was made in India in 1937 (Nalgonda-Telangana)

When present in concentration of < (0.8-1.0 mg/L) – Cause Dental Caries (Tooth Decay)

due to formation of excessive cavities in the teeth of young children during calcination of their

permanent teeth

Fluoride makes the tooth more resistant to acid attack from bacteria

When fluoride compounds are in your mouth, they can actually make teeth stronger and

prevent cavities

• Higher Fluoride Concentration of (1.5-2.0 mg/L) – Discoloration of teeth (Dental Fluorosis)

• Dental Fluorosis: Tooth Enamel (which is stronger than bone) is the outer covering of teeth

which is principally made up of Hydroxyapatite (96%) (Ca10(PO4)6(OH)2) and is made from

calcium and phosphate

• Fluoride displaces the hydroxide ions from hydroxyapatite to form Fluorapatite (Ca10(PO4)6F2)

• On prolonged continuation of this process the teeth become hard and brittle

• Dental fluorosis : Tooth becoming colored from yellow to brown to black

• At still higher concentration, (> 3.0 mg/L) Skeletal Fluorosis which affects the bone and

ligaments

• Fluorosis is a crippling disease resulted from deposition of fluorides in the hard and soft

tissues of body

Dental Fluorosis

Fluoride - Limits

Indian Standards

IS 10500:1983

IS 10500:1991

IS 10500:2012

IS 14543:2004

Desirable Limit (F)

(mg/L)

0.6 – 1.2

1.0

1.0

1.0

Permissible Limit in

Absence of Alternate

Sources

Desirable

1.5

1.5

1.5

Alkalinity

Alkalinity of a water is a measure of its capacity to Neutralize Acids or its ability to

maintain a relatively constant pH

Alkalinity in natural water is due to:

1. Salts of Weak Acids

Carbonate, bicarbonate

Borate, Silicate, Phosphate

A few organic acids resistant to

biological oxidation (humic subs)

In polluted or anaerobic waters

(Acetic, Propionic acid, H2S)

2. Weak or Strong Bases

Ammonia

Hydroxides

Alkalinity

The major portion of the alkalinity in natural waters is caused by three major classes

of materials which may be ranked in order of their association with high pH values

as follows

1. Hydroxide

2. Carbonate

3. Bicarbonate

Alkalinity is an important parameter in

evaluating the Optimum Coagulant Dosage

Carbon dioxide (CO2) dissolves in water to

form carbonic acid (H2CO3), which

dissociates and is in equilibrium with

bicarbonate (HCO3-) and carbonate (CO3-)

ions

CO2 (Gas) ↔ CO2 (Dissolved)

CO2 (Dissolved)+ H2O ↔ H2CO3 ↔ H+ + HCO3- ↔ 2H+ + CO32-

Alkalinity

Measured volumetrically by titration with N/50 H2SO4 (N/EW = N/50), and is

reported in terms of equivalent CaCO3

It is most convenient to have the standard titrating agent of such strength that 1

mL is equivalent to 1 mg of the material being measured

Samples whose initial pH is > 8.3, the titration is made in two steps:

In the first step the titration is conducted until the pH is lowered to 8.3, the point

at which phenolphthalein indicator turns from pink to colorless (Phenolphthalein

Alkalinity)

OH- + H+ → H2O

CO32- + H+ → HCO3The second phase of the titration is conducted until the pH is lowered to about 4.5,

corresponding to the methyl orange end point (Orange to Pink) (Total Alkalinity)

HCO3- + H+ → H2CO3

When the pH of a sample is < 8.3, a single titration is made to a pH of 4.5

Alkalinity

@ pH 10 - All OH- are neutralized

@ pH 8.3 – All CO32- converted to HCO3 Titration till pH 8.3- Phenolphthalein Alkalinity

Titration till pH 4.5- Total Alkalinity (till H2CO3)

Total Alkalinity is the amount of acid required

to lower the pH of the solution to 4.5

Alkalinity - Calculations

There are three methods commonly used to make calculations:

1. From Alkalinity Measurements Alone

Based on empirical relationships for the calculation of the various forms of alkalinity

from Phenolphthalein and Total Alkalinities

This is used by technicians and others who do not have a knowledge of the

fundamental chemistry involved

This method are only approximate for samples with pH > 9

2. From Alkalinity + pH Measurements

This procedure gives sufficiently accurate estimates for most practical purposes, and

also makes use of Phenolphthalein & Total Alkalinity Measurements

In addition, an accurate initial pH measurement is required for the direct calculation

of OH- alkalinity

3. From Equilibrium Equations

Various equilibrium equations for H2CO3 are used to compute the concentrations of

the various alkalinity forms

This method gives reasonably accurate results for constituents, even when present in the

fractional mg/L range, provided that an accurate pH measurement is made

1. From Alkalinity Measurements Alone

From the Measurements of Phenolphthalein and Total Alkalinities - calculation of

other three types of alkalinity, Hydroxide, Carbonate, and Bicarbonate, are made

Assumption: That both hydroxide and bicarbonate alkalinity cannot exist

together in the same sample

This permits only five possible situations to be present, which are as follows:

1. Hydroxide Only

2. Carbonate Only

3. Hydroxide + Carbonate

4. Carbonate + Bicarbonate

5. Bicarbonate Only

1. From Alkalinity Measurements Alone

When…

OH-

CO32-

HCO3-

T=P

P

0

0

T= 2P

2P

0

2(T-P)

0

T>2P

0

T-2(T-P) =

(2P-T)

0

2P

T-2P

P=0

0

0

T

T<2P

2. From Alkalinity + pH Measurements

Measurements are made for pH, Phenolphthalein, and Total Alkalinity

This will allow calculation of Hydroxide, Carbonate, and Bicarbonate Alkalinity

𝑲𝒘

1. Hydroxide Alkalinity (from pH Measurement)

−

𝑶𝑯 =

+

[𝑯 ]

Since a hydroxide concentration of 1 mol/L is equivalent to 50,000 mg/L of alkalinity as CaCO3

𝑯𝒚𝒅𝒓𝒐𝒙𝒊𝒅𝒆 𝑨𝒍𝒌𝒂𝒍𝒊𝒏𝒊𝒕𝒚 = 𝟓𝟎, 𝟎𝟎𝟎 ∗ 𝟏𝟎(𝒑𝑯 −𝒑𝑲𝒘)

At 25ᵒC, pKw = 14.00. However, it varies from 14.94 at 0ᵒC to 13.53 40ᵒC

2. Carbonate Alkalinity

Carbonate Alkalinity = 2 (Phenolphthalein Alkalinity – Hydroxide Alkalinity)

3. Bicarbonate Alkalinity

Bicarbonate Alkalinity = Total Alkalinity - (Carbonate Alkalinity + Hydroxide Alkalinity)

3. From Equilibrium Equations

Total Alkalinity is a measure of the equivalent concentration of all cations

associated with the Alkalinity-Producing Anions, Except Hydrogen Ion

[H+] +

𝑨𝒍𝒌𝒂𝒍𝒊𝒏𝒊𝒕𝒚

𝟓𝟎,𝟎𝟎𝟎

= [HCO3- ]+ 2[CO32-] + [OH-]

The equilibrium equations that must be considered are those for water 𝑶𝑯

+

and for the second ionization of carbonic acid is 𝑲𝑨𝟐 =

𝑯 [𝑪𝑶𝟑𝟐

−

[𝑯𝑪𝑶𝟑 ]

−]

−

=

𝑲𝒘

+

[𝑯 ]

Alkalinity – CO2 – pH

pH Changes due to Aeration of water

Aeration: To remove CO2, NH3, and VOCs

CO2 removal from water, tends to decrease [H+] and pH

increases

Alkalinity of Boiler Waters

CO2 is insoluble in boiling water and so is removed with the steam

This causes an increase in pH and a shift in alkalinity forms from

HCO3- to CO32- and from CO32- to OH-, as indicated below

HCO3- ↔ CO32- + H2O+ CO2

CO32- + H2O ↔ 2OH-+ CO2

If Ca2+ levels are high, precipitation of CaCO3(s) may occur.

pH – CO2 - Alkalinity

Respiration & Photosynthesis affect addition or removal of CO2

Addition of CO2 reduces the pH of a system

Removal of CO2 increases the pH of a system

Alkalinity – CO2 – pH

pH Changes in the presence of Algal Bloom

Algae use CO2 for their photosynthetic activity

Diurnal variations in pH due to algal photosynthesis and respiration

are common in surface waters

Many shallow surface waters support extensive algal blooms and

they found to grow rapidly when the pH values are as high as 10

Algae can continue to extract CO2 from water until an inhibitory

pH is reached, which is usually in the range of pH 10 to 11

As pH increases, alkalinity forms change

Total Alkalinity remains constant unless CaCO3 precipitation

occurs

HCO3- ↔ CO32- + H2O+ CO2

Ca 2+ + CO32- ↔ CaCO3 (s)

This precipitation usually happens before pH levels have exceeded 10

The CaCO3 precipitated as a result of removal of CO2 through algal action produces the Marl Deposits

in lakes

Marl Deposits are the Precursors of Limestone

Alkalinity Data - Application

Chemical Coagulation

– Chemicals used for coagulation of water and wastewater react with water to form insoluble

Hydroxide precipitates. The H+ ions released react with the alkalinity of the water. Thus,

the alkalinity acts to buffer the water in a pH range where the coagulant can be effective

Water Softening

– Alkalinity - major point to be considered in calculating lime and soda ash

requirements in softening of water

Corrosion Control

– Used to calculate the Langelier saturation index (degree of saturation of Calcium Carbonate

in water)

Indian

Desirable Limit Permissible Limit in

Buffer Capacity

Standards

(mg/L)

Absence of Alternate

Used for evaluating the buffering

capacity of wastewaters and sludges

IS 10500:1983

Also used to assess natural waters

IS 10500:1991

ability to resist the effects of acid rain

IS 10500:2012

IS 14543:2004

Sources

--

--

200

600

200

600

200

--

Hardness

Soft Water - Forms lather easily with soap

Hard water - Needs more soap to form lather

Because of dissolved chemicals in the hard water react with soap to form a scum

Types of Hardness

1. Temporary Hardness (Easily removed by boiling)

Due to the presence of HCO3- of Ca2+ & Mg2+

2. Permanent Hardness (Cannot be removed by boiling)

Due to the presence of Cl- & SO42- of Ca2+ & Mg2+

Hardness - Causes

Hardness is caused by Multivalent Metallic Cations

In general, hard waters originate in areas where the

topsoil is thick and limestone formations are

present

Soft waters originate in areas where the topsoil is thin and

Limestone formations are sparse or absent

Health Significance

Calcium needed for healthy bones and teeth

Magnesium needed for effective metabolism

Hardness – Determination

Complete Cation Analysis – Accurate

Atomic Absorption Spectroscopy (AAS)

Inductively Coupled Plasma (ICP)

Ion Chromatography (IC)

𝑚𝑔

50

2+ (mg/L) *

+

𝐻𝑎𝑟𝑑𝑛𝑒𝑠𝑠

(

𝑜𝑓

𝐶𝑎𝐶𝑂

)

=

MC

Ion Specific Electrodes (ISE)

3

𝐿

𝐸𝑊 𝑜𝑓 𝑀𝐶2

Cation Conc. (mg/L) Anion

20

ClNa+

15

SO42Ca2+

10

NO3Mg2+

2

Alkalinity

Sr2+

Conc. (mg/L)

40

16

1

50

Cation

Ca2+

Mg2+

Sr2+

Conc. (mg/L)

15

10

2

EW

20

12.2

43.8

Hardness (mg/L as CaCO3)

=(15*50) /(20) = 37.5

?

?

Hardness – Determination

EDTA – Titrimetric Method

Initially, water sample is buffered to pH 10.1 using

ammonia buffer solution

Erichrome Black T (EBT) (indicator dye - Blue

Color), is then added to the solution containing Ca2+

& Mg2+ ions. Color of solution turns to wine red

MC2+ + EBT → [M.EBT]Complex

Ethylenediaminetetraacetic Acid (EDTA), the titrant

(0.02 N), complexes with Ca2+ & Mg2+ ions, and the

indicator will turn blue which is the end point of

the titration

MC2+ + EDTA → [M.EDTA]Complex

𝐻𝑎𝑟𝑑𝑛𝑒𝑠𝑠 (

𝑚𝑔

𝑜𝑓

𝐿

𝐶𝑎𝐶𝑂3) =

𝑉𝑜𝑙𝑢𝑚𝑒 𝑜𝑓 𝐸𝐷𝑇𝐴 ∗𝑁∗ 50∗1000

𝑉𝑜𝑙𝑢𝑒𝑚 𝑜𝑓 𝑆𝑎𝑚𝑝𝑙𝑒 𝑇𝑎𝑘𝑒𝑛 (𝑚𝐿)

Hardness – Types

w.r.t the metallic ion

(1) Calcium Hardness

(2) Magnesium Hardness

w.r.t the anions associated with the metallic ions

(1) Carbonate Hardness (2) Noncarbonate Hardness

Calcium Hardness

Calcium usually found in highest conc. in natural water

Calcium in water results from deposits of lime stone, gypsum

Calcium is one of the principal cations in water hardness

These cations form insoluble salts with soap and decrease

the cleaning effectiveness of soap

They also form hard water deposits in hot water heaters

𝐶𝑎𝑙𝑐𝑖𝑢𝑚 𝐻𝑎𝑟𝑑𝑛𝑒𝑠𝑠 (

𝑚𝑔

𝑜𝑓

𝐿

𝐶𝑎𝑙𝑐𝑖𝑢𝑚 𝑖𝑜𝑛 𝐶𝑜𝑛𝑐. =

𝐶𝑎𝐶𝑂3) =

𝐶𝑎 𝐻𝑎𝑟𝑑𝑛𝑒𝑠𝑠

𝑉𝑜𝑙𝑢𝑚𝑒 𝑜𝑓 𝐸𝐷𝑇𝐴 ∗𝑁∗ 50∗1000

𝑉𝑜𝑙𝑢𝑒𝑚 𝑜𝑓 𝑆𝑎𝑚𝑝𝑙𝑒 𝑇𝑎𝑘𝑒𝑛 (𝑚𝐿)

𝑚𝑔

𝐶𝑎𝐶𝑂3

𝐿

∗𝑀𝑜𝑙𝑒𝑐𝑢𝑙𝑎𝑟 𝑤𝑒𝑖𝑔ℎ𝑡.𝑜𝑓 𝐶𝑎𝑙𝑐𝑖𝑢𝑚

𝑀𝑜𝑙𝑒𝑐𝑢𝑙𝑎𝑟 𝑊𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝐶𝑎𝑙𝑐𝑖𝑢𝑚 𝐶𝑎𝑟𝑏𝑜𝑛𝑎𝑡𝑒

Total Hardness – Calcium Hardness = Magnesium Hardness

Temporary or Carbonate Hardness: Metallic Cations is associated with Bicarbonate

and Carbonate ions which tend to precipitate at elevated temperatures such as occur in boilers or

during the softening process with lime

Ca(HCO3)2 → CaCO3 ↓ + CO2 ↑+ H2O

Mg(HCO3)2 → Mg (OH) 2 ↓ + 2CO2 ↑

Permanent or Non-Carbonate Hardness: Contains

Chlorides or Sulphates of

calcium or magnesium or of both and can’t be removed by boiling

CaCl2 → Ca2+ + 2ClMgSO4 → Mg2++ SO42When Alkalinity < Total Hardness:

Carbonate Hardness = Alkalinity

When Alkalinity ≥ Total Hardness:

Carbonate Hardness = Total Hardness

Non-Carbonate Hardness = Total Hardness - Carbonate Hardness

Pseudo-Hardness: Sea, brackish, and other waters that contain appreciable amounts

of Na+. Sodium is not a hardness-causing cation, and so this action which it exhibits

when present in high concentration is termed Pseudo-hardness

Hardness

Reactions for the Precipitation of CaCO3

Reactions for the Dissolution of CaCO3

Hardness - Limits

Indian

Standards

Desirable Limit

(mg/L)

Permissible Limit in

Absence of Alternate

Sources

IS 10500:1983

300

--

IS 10500:1991

300

600

IS 10500:2012

200

600

IS 14543:2004

Not Available

Not Available

Hardness – Problem

A Sample of Water having pH 7.2, has the following Conc. of ions

Ions

Ca2+

Mg2+

Na+

K+

HCO3SO42-

Conc. (mg/L)

40

10

11.8

7

110

67.2

Cl-

11

Calculate TH, CH, NCH, Alkalinity

Hardness – Solution

Ions

Ca2+

Mg2+

Na+

K+

HCO3SO42Cl-

Molecular

Conc. (mg/L)

Weight

(mg/mmol)

40

40.1

10

24.3

11.8

23.0

7

39.1

110

61.0

67.2

96.1

11

35.5

Sum of Cations

175.6

Z

2

2

1

1

1

2

1

Equivalent

Conc. (mg/L

Conc. (eq/L)

Weight

as CaCO3)

(Col.2/Col.5)

(mg/meq.)

(Col.6*50)

20.05

1.998

99.8

12.15

0.823

41.2

23.0

0.51

25.7

39.1

0.179

8.95

61.0

1.8

90.2

48.05

1.4

69.9

35.5

0.031

15.5

=

Sum of Anions

=

175.6 mg/L as CaCO3

99.8

141

166.7

175.65

90.2

160.1

175.6

Hardness – Solution

Total Hardness

Total Hardness

=

Sum of (Ca2+ & Mg2+)

=

99.8 + 41.2

=

141 mg/L as CaCO3

Carbonate Hardness : Portion of Hardness associated with CO32- or HCO3Total Hardness

=

141 mg/L as CaCO3

Carbonate Hardness

=

90.2 mg/L as CaCO3

Non-Carbonate Hardness

=

141 - 90.2 mg/L as CaCO3

=

50.9 mg/L as CaCO3

•

•

•

•

•

•

•

•

Chlorides

Chloride one of the major inorganic anions in saltwater and freshwater

It originates from the dissociation of salts, such as NaCl or CaCl2 in water (taste producing salts)

Chloride occurs in all natural waters in varying concentration

Low [Cl-]

Upland & Mountain Supplies

High [Cl-]

River & Groundwaters

Very High [Cl-]

Sea & Ocean Waters

As mineral content ↑ chloride content ↑

Human urine, contain Cl- - consumed with food and water - averages about 6 g of Cl- per person per

day

Indian Standards Desirable Limit Permissible Limit in Absence

(mg/L)

of Alternate Sources

IS 10500:1983

250

--

IS 10500:1991

250

1000

IS 10500:2012

250

1000

IS 14543:2004

200

--

Chlorides - Determination

• (1) Argentometric Method (Mohr Method)

(2) Potentiometric Method

• (3)Mercuric Nitrate Method

(4) Ferricyanide Method

(5) Ion Chromatography

Argentometric Method (Mohr Method)

• AgNO3 (0.0141 N) as titrant (1 ml of AgNO3 = 0.5

mg Cl- ion)

• Cl- precipitated as white AgCl (Ag+ + Cl- ↔ AgCl(s))

• Indicator: Potassium Chromate

• As conc. of Cl- ions approaches extinction, Ag+ ion

conc. increases to a level at which the solubility

product of Silver Chromate is exceeded and it begins

to form a Reddish Brown precipitate (2Ag+ + CrO42↔ Ag2CrO4(s))

• Endpoint: Color change to Reddish-Brown

• An excess of Ag+ is needed to produce a visible

amount of Ag2CrO4(s), - Blank must be determined

& subtracted from all titration

Chlorides – Analysis - Precautions

1.

2.

3.

A uniform sample size must be used, preferably 100 mL, so that ionic concentrations needed to

indicate the end point will he constant.

The pH must he in the range of 7 to 8 because Ag+ is precipitated as AgOH(s) at high pH levels and

the CrO42- is converted to Cr2O72- at low pH levels

A definite amount of indicator must be used to provide a certain concentration of CrO42-;

otherwise Ag2CrO4 may form too soon or not soon enough

𝐶𝑙

−

(

𝑚𝑔

)

𝐿

=

𝑚𝐿 𝑜𝑓 𝐴𝑔𝑁𝑂3 −𝐵𝑙𝑎𝑛𝑘 ∗ 0.0141 𝑁 ∗35.45 ∗1000

𝑉𝑜𝑙𝑢𝑒𝑚 𝑜𝑓 𝑆𝑎𝑚𝑝𝑙𝑒 𝑇𝑎𝑘𝑒𝑛 (𝑚𝐿)

Chlorides - Significance

• Too much of Cl- in soil, can accumulate in leaf

tissue, resulting in leaves with a scorched or

burned appearance.

• Trees with scorched leaves have brown or dead

tissue on the tips, margins, or between the veins

of the leaf.

• Evapotranspiration tends to increase Cl- and

salinity at the root zone of irrigated plants,

making it difficult for crops to take up water due

to osmotic pressure differences between the water

outside the plants and within the plant cell

• Interferes in COD Analysis

Water Treatment

Treatment – Surface Water

Treatment – Surface Water

Treatment – Ground Water

Aeration

Air in Water

Water in Air

Aerator

Aeration brings water and air in close contact in order to remove dissolved gases

(such as carbon dioxide) and oxidizes dissolved metals such as iron, hydrogen

sulfide, and volatile organic chemicals (VOCs)

Aeration is often the first major process at the treatment plant

Size Range of Particles of Concern in Water Treatment

Sedimentation

Separation of Unstable & Destabilized SS by force of gravity

Applications in Water Treatment:

1) Settling of coagulated and flocculated waters prior to filtration

2) Settling of coagulated and flocculated water in a softening plant

3) Settling of treated waters in Fe and Mn removal plant

Applications in Wastewater Treatment:

1) Grit removal

2) Suspended solids removal in primary clarifier

3) Biological floc removal in activated sludge

Settling or Sedimentation

Settling - A unit operation in which solids are drawn toward a source of

attraction. The particular type of settling that will be discussed in this section

is gravitational settling. It should be noted that settling is different from

sedimentation

Sedimentation - The condition whereby the solids are already at the bottom

and in the process of sedimenting. Settling is not yet sedimenting, but the

particles are falling down the water column in response to gravity. Of course,

as soon as the solids reach the bottom, they begin sedimenting. In the

physical treatment of water and wastewater, settling is normally carried out in

settling or sedimentation basins

Settling Depends on..

1. Characteristics of the Particles

I.

Discrete particles : Particles whose size, shape and specific gravity do not

change with time (Ex: Inert particles such as Sand Grains)

II. Flocculating particles : Particles whose size, shape and specific gravity change

with time. (Example – Clay)

2. Concentration of Particles in Suspension

I.

Dilute Suspensions : Suspensions in which the conc. of particles is not

sufficient to cause significant displacement of water as they settle or in which the

particles will not be close enough for velocity field interference to occur

II. Concentrated Suspensions : Suspensions in which the conc. of particles is too

great to meet the conditions mentioned for dilute suspensions

Sedimentation Tank Basins

Rectangular

Circular

Hopper - Bottom

SedimentationTank Design - Circular Basins

Settling Basins

Advantages

1.

2.

3.

4.

5.

Simplest technology

Energy input - Less

Relatively inexpensive to install and operate

No specialized operational skills

Easily incorporated into new or existing facilities

Disadvantages

1.

2.

3.

4.

Low hydraulic loading rates

Poor removal of small suspended solids

Large floor space requirements

Re-suspension of solids and leeching

Coagulation Overview

Colloidal Particles

• Difficult to settle

• Pass through small pores of conventional filters

How to remove colloidal particles?

• By Aggregation (making them bigger sizes)

Why aggregation is difficult?

• Small size of particles

• Physical and Electrical forces

How to Aggregate?

• Use of Chemical Agents

Coagulation & Flocculation

Colloidal particles size ranging 10-6 mm (1 nm) - 10-3mm (1 µm)

Colloidal impurities in surface water cause water to appear turbid or may impart color

It is difficult to separate colloids from water because

– Colloids do not settle by gravity

– They are so small particles that pass through the pores of most common filtration

media

Measurement of Colloid Concentration

Surface area might be an excellent measure of colloid concentration but it’s a

difficult measurement and standard suspended solids measurement won’t work

because the colloids will pass through most filters

The best method of quantifying colloid concentration is Nephelometry or the

measurement of light scattered by the colloids

Since colloid size is on the order of the wavelength of visible light they will

scatter incident visible light

Intensity of incident light is measured at right angles to the light source

The percent of “deflected” light is proportional to the colloid concentration

A standard colloid concentration is used to calibrate the system

The colloid concentration is often expressed as TU (turbidity units)

Coagulation & Flocculation

Coagulation involves the addition of a chemical coagulants for the purpose of conditioning the

suspended, colloidal, and dissolved matter for subsequent processing by flocculation or to

create conditions that will allow for the subsequent removal of particulate and dissolved matter.

Flocculation is the aggregation of destabilized particles (particles from which the

electrical surface charge has been reduced) and precipitation products formed by the addition of

coagulants into larger particles known as flocculant particles or, more commonly, ‘‘floc.’

Coagulation

The chemistry is extremely complex.

Because metal coagulants Hydrolyze

to form Acid Products that affect

pH that in turn affects the solubility

of the coagulant

Selection of the type and dose of

coagulant depends on,

The characteristics of the coagulant

Concentration and type of

particulates,

Concentration and characteristics of

Natural Organic Matter (NOM),

Water temperature, and water quality

Coagulation-Stoichiometry

Each mole of trivalent ion will produce 1 mole of the metal hydroxide and 3

moles of hydrogen ions

Al3+ + 3H2O ↔ Al (OH)3, am↓ + 3H+

Fe3+ + 3H2O ↔ Fe (OH)3,am↓ + 3H+

The ‘‘am’’ subscript refers to amorphous solids (hours old), which have a much

higher solubility product than crystalline precipitates

Chlorinated Copperas: Ferric Chloride + Ferric Sulfate

Alum Eff. pH : 6.5-8.5

Ferric Chloride Eff. pH :

3.5 - 6.5 & > 8.5

Ferric Sulfate Eff. pH :

4.0 -7.0 & > 9.0

Coagulation-Stoichiometry

When alum is added to water and aluminum hydroxide precipitates, the

overall reaction is,

Al2(SO4)3·14H2O → 2Al(OH)3↓ + 6H+ + 3SO42- + 8H2O

Ferric chloride:

FeCl3 + 3H2O → Fe(OH)3↓ + 3H+ + 3Cl Ferric sulfate:

Fe2(SO4)3 · 9H2O → 2Fe(OH)3↓ + 6H+ + 3SO42- + 3H2O

After Al(OH)3 or Fe(OH)3 precipitates, the species remaining in water are the same

as if H2SO4 or HCl had been added to the water

Thus, adding alum or ferric is like adding a strong acid

When alum reacts with bicarbonate alkalinity,

Al2(SO4)3·14H2O + 3Ca(HCO3)2 → 2Al(OH)3↓ + 3CaSO4 +14 H2O+ 6CO2 ↑

Alkalinity-Coagulation Relationships

Addition of Metallic salts release Hydrogen ions:

Al2(SO4)3·14H2O → 2Al(OH)3↓ + 6H+ + 3SO42- + 8H2O

Hydrogen ions neutralize alkalinity

1 mg/L alum neutralize 0.5 mg/L alkalinity

Low alkalinity must be buffered to maintain coagulation

Lime Ca(OH)2 or soda ash (Na2CO3)

Coagulation-Stoichiometry

Ferrous Sulfate (Copperas):

Fe2(SO4)3·7H2O + 3Ca(OH)2 → Fe(OH)2 {Ferrous Hydroxide}+ CaSO4 + 7H2O

Fe2(SO4)3·7H2O + 3Ca(HCO3)2 → Fe(HCO3)2 + CaCO4 + H2O

Fe(HCO3)2 + 2Ca(OH)2 → Fe(OH)2 + 2CaCO3 + 2H2O

4Fe(OH)2 + O2 + 2 H2O → 4Fe(OH)3↓

Chlroniated Copperas:

6 (Fe2(SO4)3·7H2O) + 3Cl2 → 2Fe2(SO4)3 + 2FeCl3 + 42H2O

2Fe2(SO4)3 + 3Ca(OH)2 → 2 Fe(OH)3 ↓ + 3CaSO4

2FeCl3 + 3Ca(OH)2 → 2 Fe(OH)3 ↓ + 3CaCl2

Alum vs Iron Salts

Iron Salts produce heavy floc & remove more suspended matter than Alum

Iron Salts being good oxidising agents, can remove H2S and its corresponding

taste and odour from water

Iron Salts can be used over a wider range of pH

Iron Salts cause staining and promote growth of iron and bacteria in

distribution system

Iron salts imparts corrosiveness to water than Alum

Handling of Iron Salts needs more skill and control as they are corrosive and

deliquescent

No skilled labour for Alum

Softening

Softening Process of removing hardness from water

Carbonate Hardness is defined as the concentration of Ca2+ and Mg2+

and other polyvalent cations in water that are associated with the anions

that comprise alkalinity (e.g., HCO3−, CO32−)

Noncarbonate Hardness is defined as the concentration of Ca2+ and

Mg2+ and other polyvalent cations in water that are associated with no

alkalinity anions (e.g., SO42−, Cl−)

The presence of hardness causes scale in pipes and hot-water heaters, high

soap consumption, and the deterioration of fabrics

Removing hardness, termed Softening, may be accomplished either by

chemical precipitation as insoluble compounds, ion exchange, or

membrane processes

Softening by Chemical Precipitation

Precipitation softening relies on the relative insolubilities of CaCO3 and

MgOH

The choice of precipitating chemicals (lime and caustic soda) depends

upon the raw-water quality and economics

Lime–soda ash softening has been a traditional process for the removal

of hardness, consisting of both carbonate and noncarbonate hardness,

from water supplies

Lime is used to remove chemicals that cause CH

Soda ash is used to remove chemicals that cause NCH

Softening by Chemical Precipitation

Commercial Lime is in the forms of

quicklime (CaO) and hydrated lime

(Ca(OH)2 )

Quicklime is granular and usually greater

than 90 percent CaO with magnesium

oxide (MgO) the primary impurity

Quicklime is less expensive than

hydrated lime, it must be hydrated or

slaked to Ca(OH)2 before it is used for

Lime Softening can effectively remove

softening

heavy metals (e.g., Pb, Cr, Hg, As), Fe

Powdered, hydrated lime contains about

and Mn, turbidity, and some organic

70 percent Ca(OH)2

compounds including a substantial

Soda ash is a grayish-white powder and

amount of NOM and kill algae, bacteria,

is nearly 98 % Na2CO3

and viruses

Lime Soda Softening

Lime :

Soda :

Ca(OH)2 or CaO → Ca2+ + OH-

Reactions:

Na2CO3 → Na+ + CO3=

Ca2+ + CO3= ↔ CaCO3 (s)

Mg2+ + 2OH- ↔ Mg(OH)2 (s)

Lime Softening: Carbonate Hardness

CO2 + Ca(OH)2 → CaCO3(s) + H2O

Ca2+ + 2HCO3− + Ca(OH)2 → 2CaCO3(s) + 2H2O

Detailed Equations:

H2CO3 + Ca(OH)2 ↔ CaCO3(s) + 2 H2O

Ca(OH)2 ↔ Ca2+ + 2OHH2CO3 + OH- ↔ HCO3- + H2O

HCO3- + OH-↔CO3= + H2O

Ca2+ + CO3= ↔ CaCO3(s)

Lime Softening: Carbonate Hardness

Mg2++ 2HCO 3−+ 2Ca(OH)2→ 2CaCO3(s) + Mg(OH)2(s) + 2H2O

Detailed Equations:

Ca(OH)2 ↔ Ca2+ + 2OH2HCO3- + 2OH- ↔ 2CO3= + 2H2O

Mg2+ + 2OH- ↔ Mg (OH)2(s)

2Ca2+ + 2CO3= ↔ 2CaCO3(s)

Filtration

Filtration

Removing particles from water

Removal of particles (solids) from a suspension (two-phase system

containing particles and liquid) by passage of the suspension

through a porous medium

The most common granular filtration technology in water treatment is

Rapid Filtration

The term is used to distinguish it from Slow Sand Filtration, an older

filtration technology with a filtration rate 50 to 100 times lower than

rapid filtration

Principal Features of Rapid Filtration

The most important features are

1. A filter bed of granular material that has been processed to a more

uniform size than typically found in nature

2. The use of a coagulant to precondition the water

3. Mechanical and hydraulic systems to efficiently remove collected

solids from the bed

Mechanism

Mechanism

Mechanical straining

Biological Action

Electrolytic action

Uniformity of Filter Media

Media uniformity allows the filters to operate at a higher hydraulic

loading rate with lower head loss but results in a filter bed with void

spaces significantly larger than the particles being filtered

As a result, straining is not the dominant removal mechanism

Instead, particles are removed when they adhere to the filter

grains or previously deposited particles

Particles are removed throughout the entire depth of the filter bed by a

process called depth filtration, which gives the filter a high capacity for

solids retention without clogging rapidly

Coagulation Pre-treatment

If particles are not properly destabilized, the natural negative surface

charge on the particles and filter media grains cause repulsive

electrostatic forces that prevent contact between particles and media

Properly designed and operated rapid filters can fail quickly if the

coagulant feed breaks down or the raw water quality changes and the

coagulant dose is not adjusted accordingly

Dual Media Filter

Stages in Rapid Filtration

Filtration stage, during which particles accumulate,

During the filtration stage, water flows downward through the filter

bed and particles collect within the bed

Backwash stage, during which the accumulated material is

flushed from the system

During the backwash stage, water flows in the direction opposite to

remove the particles that have collected in the filter bed

Conventional Filtration

Classification of Filters

According to type of Granular Medium used

1. Single Media (Sand or Anthracite)

2. Dual Media (Anthracite and Sand)

3. Multi Media (Anthracite, Sand, Garnet)

According to Flow

1. Gravity Filter - Open to Atmosphere

2. Pressure Filter - Closed

According to Rate of Filtration

1. Rapid Sand

2. Slow Sand

Materials Used in Filter Media

The common materials are sand, anthracite coal, garnet, and ilmenite

Anthracite is harder and contains less volatile material than other types of coal

Garnet (group of minerals containing a variety of elements, often

appearing reddish or pinkish) and ilmenite (is an oxide of Fe and Ti) are

heavier than sand and are used as the bottom layer in tri media filters

In addition to these four minerals, Granular Activated Carbon is sometimes

used as a filter material when adsorption and filtration are combined in a

single unit process

Filter- Examples

Backwash

Water Quality Management

Water quality is affected by natural factors:

– Historical uses in the watershed

– Geometry of the watershed area

– Climate of the region

Good water quality protects drinking water as well as wildlife

Point Sources of Pollutants

Point sources include domestic sewage and industrial wastes

Point sources - collected by a network of pipes or channels and

conveyed to a single point of discharge in receiving water

Municipal sewage - domestic sewage and industrial wastes that are

discharged into sanitary sewers - hopefully treated

Point source pollution can be controlled by waste minimization and

proper wastewater treatment

Nonpoint Sources

Urban and agricultural runoff

that

are

characterized

by

overland discharge

This type of pollution occurs

during rainstorms and spring

snowmelt

Pollution can be reduced by

changing land use practices

Combined Sewer Flow

Nonpoint pollution from urban storm water collects in combined

sewers

Combined sewers- carry both storm water and municipal sewage - older

cities

Combined Sewer Overflow

Eliminating this involves:

– Construction of separate storm and sanitary sewers

– Creation of storm water retention basins (Rainwater Harvesting)

– Expanded treatment facilities to treat the storm water

Combined sewers are not prohibited by the U.S. because removal would

disrupt streets, utilities, and commercial activities

Oxygen- Demanding MATERIAL

Dissolved Oxygen (DO) - fish and other higher forms of aquatic life

that must have oxygen to live

Oxygen - Demanding Material - anything that can be oxidized in the

receiving water resulting in the consumption of dissolved molecular

oxygen - BOD, COD

Almost all naturally occurring organic matter contributes to the

depletion of DO

Nutrients

Nitrogen and phosphorus are considered pollutants when too much

present in high conc.

High levels of nutrients cause disturbances in the food web

Organisms grow rapidly at the expense of others

Major sources of nutrients (N, P):

–

–

–

–

Phosphorus-based detergent

Fertilizer and agricultural runoff

Food-processing wastes

Animal and human waste

Pathogenic Organisms

Include bacteria, viruses, and protozoa from diseased persons or

animals

Water is made unsafe for drinking, swimming, and fishing

Antibiotic-resistant bacteria are the most dangerous

Bacteria are found in both urban and rural environments with no

observable pattern

Pathogenic Organisms

Serious Outbreaks of these cause great suffering

Escherichia(E.) Coli - indicator of fecal coliform bacteria

Salmonella (typhoid fever)

Shigella (dysentery)

Cryptosporidium - protozoa

Giardia- protozoa

Suspended Solids

Suspended solids - organic and inorganic particles that are carried by

wastewater into a receiving water

A slower flow causes particles to settle and form sediment

Colloidal particles - do not settle, cause an increase in the turbidity of

surface water

Organic suspended solids - exert oxygen demand

Inorganic suspended solids - result from soil erosion

Suspended Solids

Suspended solids - organic and inorganic particles that are carried by

wastewater into a receiving water

A slower flow causes particles to settle and form sediment

Colloidal particles - do not settle, cause an increase in the turbidity of

surface water

Organic suspended solids - exert oxygen demand

Inorganic suspended solids - result from soil erosion

Suspended Solids

With an increase in the amount of sediment comes

– Increase of turbidity

– Decrease of light penetration

– Increase in amount of bacteria

– Increase in solids settled on the bottom which causes animal habitats

to be destroyed

Salts

Total dissolved solids - TDS

Water collects salt as it passes over soil during irrigation practice

Too much salt can cause crop damage and soil poisoning

Heat Impacts

An increase in the Temp of water

can cause:

– Increase in DO which leads to

a deterioration in water quality

– Large fish kills

– Blocked migration of fish

– Altered genetic makeup in fish

Water Pollution Problems in Streams - Self purification

Dilution and decay of degradable, oxygen-demanding wastes and

heat in a stream

Dissolved Oxygen Depletion

(From: Environmental Science: A Global Concern, 3rd ed. By W.P Cunningham and B.W. Saigo, WC Brown Publishers, 1995

Transport characteristics that affect concentration

Velocity

Dilution (mixing)

Dispersion

Degradation (mass loss)

Adsorption (to soils)

Sedimentation (to bottom)

Aquatic Life (attached)

v

Effect of Oxygen-demanding wastes on rivers

Depletes the dissolved oxygen in water

Threatens aquatic life that require DO

Concentration of DO in a river is determined by the rates of

photosynthesis of aquatic plants and the rate of oxygen consumed by

organisms

Biochemical oxygen demand

Biochemical oxygen demand (BOD) - oxidation of an organic

compound is carried out by microorganisms using the organic matter as

a food source

Bioassay - to measure by biological means

BOD is measured by finding the change in dissolved oxygen

concentration before and after bacteria is added to consume organic

matter

BOD

Ultimate BOD - maximum

amount of oxygen consumption

possible when waste has been

completely degraded

Numerical value of the rate

constant k of BOD depends on:

– Nature of waste and T

– Ability of organisms in the

system to use the waste

Temperature

Oxygen consumption speeds up as the

temperature increases and slows down

as the temperature decreases

Oxygen consumption is caused by the

metabolism of microorganisms

BOD rate constants depend on:

– Temperature of receiving water

throughout the year

– Comparing data from various

locations at different T values

Dissolved Oxygen DO

If the discharge of oxygendemanding wastes is within the

self-purification capacity, the DO

is high

If the amount of waste increases,

it can result in detrimental changes

in plant and animal life

Aquatic life cannot survive

without DO

Objective of

water quality

management is to assess the

capability of a stream to absorb

waste

Oxygen-Sag Curves

Do Sag Curve

DO concentration dips as oxygen-demanding materials are oxidized and

then rises as oxygen is replenished from atmosphere and photosynthesis

Major sources of oxygen:

– Reaeration from the atmosphere

– Photosynthesis of aquatic plants

Factors of oxygen depletion:

–

–

–

–

BOD of waste discharge

DO in waste discharge is less than that in the river

Nonpoint source pollution

Respiration of organisms and aquatic plants

Oxygen-Sag Curves

What is an oxygen sag curve?

– Is the dip in dissolved oxygen observed when BOD waste water is

discharged continuously into a river

– The extent of the sag is determined by BOD level in the

wastewater stream, by the rate of discharge, and by other factors

such as temperature and river characteristics (flow rate, turbulence,

etc)

– An oxygen sag curve is also observed due to a one-time discharge of

BOD waste into a lake

– In that case, the DO drop is with time instead of distance downriver

– Continuous discharge of BOD waste into a lake results in a decrease

in steady-state DO level (not a “sag” followed by a recovery)

Dynamics of Oxygen Depletion & Dissolution

Figure on left shows a model framework to

calculate:

DO as a function of distance downstream from

a point source discharge; or

DO as a function of time after a single “spike”

discharge of BOD wastewater

DO falls when decomposition rate > dissolution

rate and DO rises when decomposition rate <

dissolution rate

Rate of decomposition (deoxygenation)

Linearly proportional to BOD level

BOD falls exponentially with time

Rate of oxygen dissolution (reaeration)

Linearly proportional to the oxygen deficit:

DOsat - DOactual

Wastewater Treatment

RWE

Raw water

Community

WWE

Wastewater engineering

Quickly drain off the wastewater away from the community

To make wastewater fit for dispose or environmental friendly

RWE

Raw water

Community

Disposal

Treatment of

Wastewater

Conveyance

Collection

Wastewater is a term that is used to describe waste material that includes

industrial liquid waste and sewage waste that is collected in towns and

urban areas and treated at urban wastewater treatment plants

Wastewater treatment: A process to convert wastewater - which is water no

longer needed or suitable for its most recent use - into an effluent that can be

either returned to the water cycle with minimal environmental issues or

reused

Wastewater

Contaminants

Suspended solids

Biodegradable

organics (e.g., BOD,

COD)

Pathogenic bacteria

(e.g., E-coli)

Nutrients (N & P)

Wastewater Sources

Residences

human and animal excreta and

waters used for washing, bathing, and

cooking

―

Commercial institution

Dairy and industrial establishment

― slaughterhouse waste, dairy waste,

tannery wastewater, etc.

Where does the

water from the

washer go?

When you flush the

toilet where does

the contents go?

By gravity flow, the waste is on its way to your local

wastewater treatment plant!

Why to treat wastewater?

Causes a demand for dissolved oxygen (lower DO levels of streams)

Adds nutrients (nitrate and phosphate) to cause excessive growth

Increases suspended solids or sediments in streams (turbidity increase)

Objectives of WWT

Reduce organic content i.e., BOD

Removal/reduction of nutrients i.e., N,P

Removal/inactivation of

pathogenic microbes

Levels of Treatment

Primary

removal by physical separation of grit and

large objects (material to landfill for

disposal)

Sedimentation and screening of large

debris

Secondary

Biological and chemical treatment

aerobic microbiological process (sludge)

organic matter + O2

CO2 + NH3 + H2O

Primary treatment

Typical materials that are removed during primary treatment

include

fats, oils, and greases

sand, gravels and rocks

larger settle-able solids including human waste

floating materials

Methods used in primary treatment

Bar screens

Grinding

Grit Chamber

Sedimentation Tank - primary Settling tank

Chlorination of effluent

Biological treatment

activated sludge

trickling filter

oxidation ponds

Secondary treatment

Activated sludge process

Primary wastewater mixed with bacteria-rich (activated) sludge and air or

oxygen is pumped into the mixture

Both aerobic and anaerobic bacteria may exist

Promotes bacterial growth and

decomposition of organic matter

BOD removal is approximately

85%

Microbial removal by activated

sludge

80-99% removal of bacteria

90-99% removal of viruses

Trickling filters

Trickling filters are beds made of coke

(carbonized coal),

limestone chips or

specially fabricated plastic media

Optimize their thickness by insect or worm

grazing

The primary wastewater is sprayed over

the filter and microbes decompose

organic material aerobically

Low pathogen removal

Bacteria, 20-90%

Viruses, 50-90%

Giardia cysts, 70-90%

Stabilization or oxidation ponds

Oxidation ponds are a few meters deep, and up to a hectare in size

They are low cost with retention times of 1 to 4 weeks. Odor and mosquitoes can be a problem

Pathogen removal:

Stabilization ponds are the preferred wastewater treatment

Bacteria, 90-99%

process in developing countries due to low cost, low

maintenance

- Virus, 90-99%

This is balanced by larger land requirement

Protozoa, 67-99%

Mechanisms include the long detention time, high pH (10- 10.5) generated by photosynthesis,

predation, sunlight, temperature

Sludge Treatment Processes

Thickening (water removal)

Digestion (pathogen inactivation and odor control)

Conditioning (improved dewatering with

alum and high temp, 175-230° C)

Dewatering (pathogen inactivation and odor control)

Incineration (volume and weight reduction)

Final disposal

Wastewater Treatment

Alternatives

Septic Tanks

Constructed Wetlands

Composting

Wastewater treatment

5R Concept

Introduction

At the center of social and economic development, WATER is vital for energy

generation, agriculture, industry, environmental management and cultural development

World Bank points out that

~4.5billion people lack sanitation services and

~2.1 billion people lack clean drinking water

World Economic Forum’s Global Risks Report, 2017 states that water scarcity is

becoming the largest global risk, due in part to climate change, which will lead to more

intense droughts, floods, glacial melting, and unpredictable precipitation

Other Driving Factors for water scarcity:

Improving living standards

changing consumption patterns

Irrigated agriculture expansion

Uneven Water Distribution

Uneven distribution of water resources

highlights the problems of worldwide

water scarcity

Worldwide predictions indicated severe

water scarcity prevails

in locations with either high population

density (e.g., in North Africa, Australia,

Arabian peninsula, London, San Francisco

Bay, and Hainan island)

in

areas of

intensely irrigated

agriculture (Great Plains in the United

States)

or both (India, eastern China, and the

Nile delta)

Distribution of water availability

(bottle size representing annual water

stock m3/person).

Managing urban water

Used

water from household

activities is called gray water, and

it is not heavily polluted

Contrasting is black water, which

comes from toilet flushing

Black water is a relatively small

fraction of the flow (parts of toilet

flushing, only 30% of total

household utilization) but contains

most of the BOD, nitrogen,

phosphorus, and bacteria of health

concern

Blue line indicates that storm water can be collected to be part of the supply, and

gray water and black water also can be treated and returned as a supply - thus,

“wasted waters” become new source

“wasted waters” become new sources

Projects of “wasted waters” reuse have been applied and were not

successful, such as one initiated in Hamburg (German)

Public Utilities Board in Singapore processed water reclamation and

reuse in1966 but, failed because of costly and unreliable technology

Public acceptance of recycled

water also withdrawn “wasted

waters”

reuse

project

promotion, such as failure cases

of Toilet to Tap campaign in

California (USA) and Drinking

Sewage

campaign

in

Toowoomba (Australia)

5R Generation

It approaches to manage urban water

It harvests storm water, gray water and black water in

several forms

It offers promise for moving solutions for

urban water scarcity in practice

Recover (storm water)

Reduce (toilet flushing water)

Recycle (gray water)

Resource (black water) and

Reuse (advanced-treated wastewater)

5R generation integrates newer technologies,

available for practice only in recent years, to

gradually replace traditional wastewater treatment

systems to enhance water utilization

Recover

Reduce

Resource

Recycle

Reuse

Framework of 5R generation

Recycle

B

Applicable

in common-use

settings, such as community

and shopping centers, hotels,

and office buildings

Recover (storm water)

It focuses on urban storm water and includes

technologies for collection, treatment, and storage

Storm water often requires less treatment than

municipal waste-waters, and its collection offers an

added benefit of reducing pollution and erosion

issues in receiving water bodies

After storm water is collected from a drain, creek,

roof, or pond, it can be treated to achieve quality

requirements for different purposes

Storage is a major challenge for Recover, due to

space constraints

Traditionally, storm water is temporarily held

behind dams or in tanks to balance supply and

Mobile treatment and storage

demand, but alternatives are being sought

for storm water

Wetlands are also being applied for storm water storage

Recover in 5R generation was built to collect storm water from roofs, and mobile treatment

and storage of the storm water can be used when rainfall is heavy

Reduce (toilet flushing water)

Reduce in 5R generation mainly uses high

efficiency, water-saving toilets to minimize

the flushing volume, which contributes for

approximate 30%of the black water flow

Reducing the water for flushing is a direct

method to address scarcity in urban areas

A vacuum toilet uses only 0.5–2 L water

(adjustable) per flush, compared to ~10

L/flush for a typical conventional toilet

Vacuum flushing already is widely applied

for toilets in airplanes and high-speed

trains, and it is beginning to be used in homes

and hotels

Vacuum Toilet

Recycle (gray water)

Recycle in 5R generation mainly involves processing and recycling gray water in a

household or community system

Gray water is generated from kitchen and bathroom sinks, showers and bathtubs, and

laundry discharges, and it excludes toilet discharge which could be applied for toilet

flushing and irrigation after reuse

According to lifestyle, living standard, population structure (age, gender), customs,

water infrastructure, and the degree of water scarcity, gray water varies typically from

90 to 120 L/person/day, indicating a huge volume recyclable gray water as potential

water source

Based on civil wastewater calculation, 50%–70% of total domestic wastewater, which

could be classified into gray water, only contains 30% of the organic matter and 9%–

20% of the nutrients

Resource (black water)

Resource in 5R generation mainly involves capturing resources from black water in a

household or community water system.

Household wastewater normally consists around 30% black water, making black water

a non-trivial water source if it is not discharged immediately to the sewer

Black water was ignored in the water-recycle system, as it typically was discharged

directly into a sewer for transport to a municipal wastewater treatment plant

Biochemical oxygen demand (BOD) and nutrients(phosphorus and nitrogen) usually

are the most valuable resources in black water

Recently, recovery of black water has become a hot topic, and anaerobic digestion is

the most effective method for treatment and recovery of black water

Reuse (advanced-treated wastewater)

Even when Recover, Reduce, Recycle, and Resource are well implemented in a

community, some wastewater is going to a conventional wastewater-treatment plant

That water also can be reused for a range of purposes, if the effluent quality is

sufficient for the purpose

Thus, 5R generation includes Reuse to overcome water-quality deficiencies

At municipal wastewater treatment plants, advanced treatment, which aims to remove

suspended, colloidal, and dissolved constituents remaining after biological treatment,

is applied to improve effluent quality

Bed filtration, surface filtration, micro- and ultra-filtration, reverse osmosis, electro

dialysis, adsorption, air stripping, ion exchange, advanced oxidation, distillation,

chemical precipitation, chemical oxidation, and disinfection are the typically advanced

technologies used to improve effluent quality