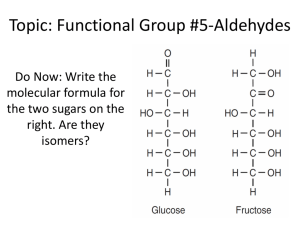

CL 452 – Design Project Spring 2019 Group 22 Production of Acetaldehyde Report - Evaluation stage I Members: Dhrumil Shah : 150020009 Harsh Prasad : 150110013 Prajakta Gajbhiye : 150020102 Cheeranesh Ganeshamoorthy: 150020109 Jayprakash Ghritlahre: 150020039 Department of Chemical Engineering Indian Institute of Technology Bombay 1 Table of Contents 1. Introduction 4-8 1.1. About acetaldehyde 4 1.2. Properties 4-5 1.3 Hazards and handling practices 5-6 1.4 Uses 6 1.5 Market survey 6-8 1.6 Production pathway 8 2. Production process 9-13 2.1. Reactions 9 2.2. Process flow diagram 10 2.3. Catalyst regeneration process 10 2.4. Selection of reactor 11-13 2.5. Separation processes 13 3. Mass balances 14-16 3.1 Overall balance 14 3.2 Balance around reactor 14 3.3 Balance around scrubber 14-15 3.4 Balance around distillation column 15-16 4. References 17 2 List of tables Content Page no. Table 1.a - Physical properties : Table 2.a -Membrane reactor vs Bubble Column Reactor 4 13 List of figures Content Page no. Figure 1.a - 2 D structure of acetaldehyde 4 Figure 1.b - Geography wise split of acetaldehyde consumption as of 2016 7 Figure 1.c - Price trends of acetaldehyde 8 Figure 2.a - Reaction mechanism for production through Wacker-Hoechst process. ..... 9 Figure 2.b - Process Flow Diagram 10 Figure 2.c - Schematic diagram for Membrane Reactor 11 Figure 2.d - Conc. vs. residence time results of silicone rubber membrane reactor 11 Figure 2.e - Conc. vs residence time results of polypropylene membrane reactor 12 Figure 2.f - Schematic diagram for Bubble column Reactor 14 Figure 3.a - Mass balance around reactor 14 Figure 3.b - Mass balance around scrubber 15 Figure 3.c - Mass balance around extractive distillation column 16 Figure 3.d - Mass balance around distillation column 16 3 Chapter 1 INTRODUCTION 1.1 About acetaldehyde Acetaldehyde is one of the most used organic chemicals in the world. It’s colourless, miscible with water and is flammable in nature. The chemical formula of acetaldehyde is C2H4O. It is a common substance naturally found in coffee, ripe fruits, breads , vegetables, gasoline , cigarette smoke and diesel exhaust. It is widely used in the manufacturing a downstream chemicals. Acetaldehyde has been flagged as a ‘Group 1 carcinogen’ by ‘The International Agency for Research on Cancer’. Acetaldehyde is also produced by the partial oxidation of ethanol in the liver and is a contributing cause of hangover after alcohol consumption. One can be exposed to acetaldehyde through both air(smoke) and water(groundwater). Fig. 1a : 2D structure of acetaldehyde 1.2 Properties 1.2.1 Physical Properties Table 1a - Physical properties Property Values Colour Colourless Odour Pungent choking odour Solubility Miscible with organic solvents and water Molar mass 44.05 g /mol Density 0.784 g/cm3 (at 20 oC) Melting pt. -127.37 oC Boiling pt. 20.2 oC 4 1.2.2 Chemical properties Acetaldehyde is a highly reactive compound. It is flammable ,toxic and corrosive in nature and is a very dangerous fire hazards when exposed to heat or flames.It is a strong reducing agent which undergoes number of condensation, addition and polymerization reactions. ● Decomposition - Acetaldehyde decomposes into a methane and carbon monoxide at temperature greater than a 400 degree celsius through a radical basis process ● Oxidation - Acetaldehyde is rapidly oxidized with air(oxygen) and form a acetic acid, acetic anhydride, and peracetic acid . The main products from above are depends on a reaction conditions. For example acetic acid is produced commercially by the liq. Phase oxidation of acetaldehyde at a 65°C with with cobalt or manganese acetate as catalyst ● Reduction- Acetaldehyde is rapidly reduced to a ethanol . Before 1940’s when petrochemical didn’t came into picture this method is used for production of ethanol ● Polymerization- When acetaldehyde is reacted with acids such as sulphuric, mineral, hydrochloric acid it polymerize into a Paraldehyde,2,4,6- trimethyl – 1,3,5 – trioxane, a cyclic trimer of acetaldehyde.Paraldehyde may also be formed by continuously feeding of acetaldehyde at room temperature over an acidic medium ● Reaction with nitrogen compound - Acetaldehyde rapidly react with ammonia to form a acetaldehyde ammonia. Pyridine and many pyridine derivatives are formed from a paraldehyde and aqueous ammonia in the presence of a catalyst at elevated temperature (450 to 550 0F) 1.3 Hazards and handlings ● Potential health effects - Hazardous in case of direct eye contact (irritant), of ingestion, of inhalation (lung irritant). Slightly hazardous in case of skin contact (irritant, permeator) Levels reported for acute exposure25-200 ppm concentration in air --→ eye irritation , upper respiratory infection Concentration greater than 300 ppm --→ Asthma and cancer ● Potential Chronic Health Effects - Acetaldehyde is reported as group 1 carcinogenic compound in nature . In risk assessment is found that cancer risk is one in a millions 5 Precautions- At plants for workers safety 1. Exposure must be avoided and adequate ventilation and suction at critical points must be available 2. Must be kept away from alkalis , strong acids and oxidizing agents 1.4 Uses Acetaldehyde is mainly used for production of downstream chemicals viz acetic acid, acetic anhydride, ethyl acetate( used as a solvent in glue), chloral ( used as a sedative) and 1,3-butadiene (used in rubbers) besides a variety a dyes and drugs. Globally, the top revenue generating uses of acetaldehyde are: A. Pyridine Acetaldehyde with ammonia leads to the formation of pyridine. Pyridine is used as precursors for many agrochemical and pharmaceutical products, widely used as solvent and reagent in reactions B. Pentaerythritol Formed by the condensation of acetaldehyde with formaldehyde. Pentaerythritol is used in various products such as alkyd resins, rosin esters, synthetic lubricants, antioxidants, and explosives. C. Acetic acid Produced by oxidation of acetaldehyde, it is used as a reagent to produce various compounds such as vinyl acetate monomers and esters. In the form of vinegar, it finds application in foods and beverages 1.4.1 Specifications for industrial use 1. Practically colourless 2. Conc. : more than 99% by wt. 3. Acid(as acetic acid): less than 0.1% by wt. 4. Water : less than 0.02% by wt. 1.5 Market survey 1.5.1 Overview Globally, the major source of acetaldehyde production is ethylene. However, a small portion of it is produced from ethanol and acetylene as well. In the past decade, the growth in the acetaldehyde market has slowed down primarily due to a declining demand from acetic acid producing plants which no longer use acetaldehyde as a raw material since a more efficient process has been discovered. However, rising demand from paper and pulp; pharmaceuticals; food and beverages and waste water treatment industries have arrested the decline in 6 demand and have ensured enough demand growth to set up a new plant viabally. 1.5.2 Growth trends The acetaldehyde demand is expected to grow at a CAGR of 6.3% for the next 5 years and reach $2Bn in value by 2024. Manufacturing facilities have been able to keep up with the rising demand and the global production capacity of acetaldehyde is expected to reach 1.4Mn T.P.A. by 2022. 1.5.3 Geographical distribution Asia is currently the major producer and consumer of acetaldehyde with India and China together accounting for more than 50% of the global production as well as consumption. While the western economies have phased out production of acetic acid using acetaldehyde, India and China continue to do so. As a result their share in the global market has jumped over the past couple of decades. Fig. 1b - Geography wise split of acetaldehyde consumption as of 2016 Source : Chemical Economics Handbook (Ref. item 13) 1.5.4 Major players and price trends The price of acetaldehyde has declined over the past few years. The prices shown in the graph below have been calculated using the import/export data of the total quantity shipped and the overall worth of trade. 7 Fig 1c - Price trends of acetaldehyde Source: UN Comtrade website(Ref. Item 14) Celanese Corp., LCY Chemicals, EuroChem are among the many major players of acetaldehyde globally. Most of the plants manufacture multiple chemicals and not just acetaldehyde. This gives them an opportunity to exploit economies of scale and its associated synergies. Acetaldehyde is consumed in-house for producing downstream chemicals in most of the chemical plants producing it in bulk.In India, a few players like Trichy Distilleries and Kumaka Industries manufacture acetaldehyde with annual capacities of around 5000 TPA. 1.6 Production pathway There are 3 major methods in production of acetaldehyde● Production from ethylene (oxidation of ethylene) (Chosen pathway) ● Production from ethanol(oxidation of ethanol/ethyl alcohol) ● Production from acetylene Lower cost, better conversion and comparatively lesser environmental damage lead us to choose production from ethylene using the Wacker-Hoechst process as the desired pathway. The required raw materials are ethylene which can be obtained from a petrochemical plant and pure oxygen to get high selectivity and better conversion. Aqueous palladium chloride solution is used as catalyst for this process.This process is called Wacker-Hoech. 8 Chapter 2 Process Flow Diagram 2.1 Reactions 2.1.1 Reaction mechanism: Fig 2a: Reaction mechanism for production through Wacker-Hoechst process In the Wacker-Hoechst process, ethylene is oxidized in a bubble column reactor with the catalyst being CuCl2, CuCl and PdCl2. The operating temperature is around 400 K and pressure is 3 bar. The gaseous stream consists of steam, acetaldehyde, ethylene and small amounts of oxygen, carbon dioxide, acetic acid, crotonaldehyde and chlorinated compounds (such as methyl chloride, ethyl chloride and chloro acetaldehyde). The stream is later separated into following streams: light streams (ethyl chloride, methyl chloride etc), acetaldehyde, crotonaldehyde and waste water stream (consisting of acetic acid, chloroacetaldehyde and water). 2.1.2 Main Reaction: C2H4 + ½ O2 → CH3CHO ΔH= -240 KJ/mol 2.1.3 Side Reactions : CH3CHO + ½ O2 → CH3COOH C2H4 + HCl → C2H5Cl 2CH3CHO → CH3CH=CHCHO + H2O 9 2.2 Process Flow Diagram Fig. 2b - Process Flow Diagram 2.3 Catalyst regeneration process 2.3.1 Brief explanation Catalyst particles are carried up by the gaseous mixture. Then, they are separated using separating vessel(flash).Further, the stream is split into two one directly fed back to the reactor and the other sent through a catalyst regeneration process 2.3.2 Reactions involved Pd + 2CuCl2 → PdCl 2+ 2CuCl 2CuCl + ½ O2 + 2HCl → 2CuCl2 + H2O Here,we are using HCl and oxygen to convert Pd back to PdCl2 which is then fed back to the reactor. 2.3.3 Physical conditions Typical flash temperatures are around 50 to 100 deg C. The liquid needs to be dried of water and HCl is later added to the spent catalyst to regenerate it. Devices which work under reduced pressure, e.g. rotary evaporators are considered. Catalyst solids are preferred to be dehydrated. Source : Ref. item 1 and 2 10 2.4 Selection of reactor 2.4.1 Membrane Reactor Fig 2c: Schematic diagram for Membrane Reactor The design is similar to shell and tube heat exchanger. The catalyst solution containing PdCl2, CuCl and CuCl2 fills the shell side and the reactants fill the tube side while the tubes are made of membrane.The following steps occur in the reactor: 1) Permeation of reactants from tube to shell 2) Diffusion of reactants and products in the liquid phase (shell) 3) Chemical reaction in the liquid phase 4) Permeation of gas products back to the gas phase There are two single-bundle membrane reactors, one with non porous silicone rubber (SR) and the other with porous polypropylene (PP). Tygon tubing is used as outer shell. Fig 2d: Conversion vs. residence time results of the silicone rubber membrane reactor. 11 Fig 2e: Conversion vs residence time results of the polypropylene membrane reactor Source for fig. 2d and 2e : Ref. item 15 2.4.2 Bubble Column Reactor The bubble column reactor contains catalyst solution through which the reactor gas is bubbled. A gas dispersion tube could be used to ensure an even distribution of bubbles. Reaction occurs at 130 deg C and pressure of 400 kPa. The reactors are passed co-currently in a reaction tower which is bubble column reactor. Fig 2f: Schematic diagram for Bubble column Reactor 12 Table 2a : Membrane reactor vs Bubble Column Reactor Parameters Membrane Reactor Bubble Column reactor Mass Transfer area 3000-5000 m2/m3 50-1000 m2/m3 Low flow rates Higher conversion Lower conversion High flow rates Lower conversion Higher conversion Need for catalyst and product separation No Yes With high rate of production of acetaldehyde, we will have high flow rates and hence, we will go with Bubble Column Reactor. Source : Ref. item 15 2.5 Separation processes In the Scrubber, unreacted ethene and oxygen is separated and recycled back to reactor. The remaining products undergo extractive distillation to separate light products like Chloromethane,Chloroethane and Carbon dioxide from heavy impurities like acetaldehyde and other impurities which is followed by distillation where acetaldehyde, Crotonaldehyde and acetic acid+water is separated out to give our final product. Source : Ref. item 1 13 Chapter 3 Mass Balance 3.1 Quantities of major reactants and products The targeted plant capacity is 5000 T.P.A. and assuming 8000 annual operating hours, the hourly production rate required is 625kg. To achieve this, nearly 1200 kg of ethylene and 320 kg of oxygen is needed. Oxygen used is of 99.5% purity with the remainder gases being argon and other inerts. Some extra amount of oxygen is added as compared to that calculated stoichiometrically to account for the side reactions and the impurities present in the oxygen being fed in. 3.2 Mass balance around reactor+regenerator system Ethylene and oxygen are the main reactants and HCl is added to help in the catalyst regeneration. The presence of chlorine in the catalyst also leads to the formation of alkyl chlorides. To make up for this,chlorine is supplied through HCl. The main reaction has a single pass conversion of 35% and ethylene has a selectivity of 94% towards the main reaction. The catalyst regeneration process is included in this step itself. Make up water needs to be added since the reaction is exothermic. Using patent (Ref. item 5) water required is calculated. 15 tons of water is required as make-up for every 13 tons of acetaldehyde produced. Fig. 3a - Mass balance around the reactor 3.3 Balance around scrubber The effluents from the reactor are sent through a knock out drum wherein the entrained liquid water is removed. The gases left after that are sent through a cooler to a scrubber 14 wherein water is added to separate the water soluble components. Amount of water added in scrubber = 77.5/13 * 625 = 3726 kg/hr The following figures were used with reference to a patent( Ref. item 5) wherein a thumb rule for scrubbing was explained as 77.5 tons of scrubbing liquid for every 13 tons of acetaldehyde produced. Ethylene(unreacted), oxygen(unreacted), carbon dioxide and crotonaldehyde are the gaseous products which are later separated into the recycle and purge streams . Fig. 3b- Mass balance around the scrubber 3.4 Balance around distillation columns Similar to the thumb rule followed for the scrubbing process, 1.5 tons of water is added for every 13 tons of acetaldehyde produced in the extractive distillation column. Acetic acid, acetaldehyde,crotonaldehyde and water form the crude aldehyde end which are further separated using distillation. Final distillate composition : 99.88% acetaldehyde : 0.1% acetic acid : 0.02% water 15 Fig. 3c Mass balance around extractive distillation column Fig 3d- Mass balance around the distillation column. 16 References 1. Ullman’s Encyclopaedia of Industrial Chemistry, Vol. 1; Pg. no. 192-207 article by Marc Eckert & Gerald Fleischmann 2. Shioyama, T. K., & Straw, J. J., U.S. Patent 4,419,525, 1983 3. California Office of Environmental Health Hazard Assessment’s website 4. https://pubs.acs.org/doi/pdf/10.1021/ja01232a023. Article contributed by J. Carrel Morris, Harvard University. Reviewed on 20/1/19 5. Steppich, W., & Sartorius, R., U.S. Patent 4,237,073, 1980 6. Van Leeuwen, P. W. N. M. (2004). Homogeneous Catalysis, Page no. 53-90. 7. https://www.wacker.com/cms/media/documents/wacker_group/sustainability_1/g ps_product_summaries.pdf Safety summary of acetaldehyde on wacker.com (Date of publishing : 19/03/12) 8. Annual report 2018 ( http://www.airproducts.com/ Date reviewed: 20/01/2019) 9. Jira R et al; Chloroacetaldehydes. Ullmann's Encyclopedia of Industrial Chemistry 7th ed. (1999-2013). New York, NY: John Wiley & Sons. Online Posting Date: July 15, 2007 10. https://www.researchandmarkets.com/research/lc8hz5/acetaldehyde Market research report by researchandmarkets.com reviewed on 11/1/19 11. https://www.techsciresearch.com/report/global-acetaldehyde-market/2266.html Market research report by techsciresearch.com reviewed on 11/1/19 12. https://www.scribd.com/doc/122192768/acetaldehyde-doc Article by Er Bali Pandhare reviewed on 20/1/19 13. https://ihsmarkit.com/products/acetaldehyde-chemical-economics-handbook.html Chemical Economics handbook published on ihsmarkit.com 14. https://comtrade.un.org (UN Comtrade) 15. Chen, S., & Kao, Y. DIRECT OXIDATION OF ETHYLENE TO ACETALDEHYDE IN A HOLLOW FIBER MEMBRANE REACTOR (2010). https://doi.org/10.1080/00986449008940545 17