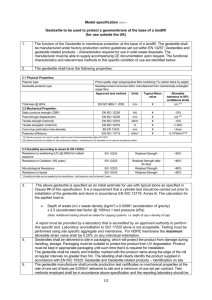

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/329861218 Evaluation of the Long-Term Performance of Woven Geotextile Used between Base Course and Subgrade of a Paved Road Article in Transportation Research Record Journal of the Transportation Research Board · April 2019 DOI: 10.1177/0361198119827567 CITATIONS READS 8 462 5 authors, including: Saad Ullah Burak F Tanyu Tetra Tech Inc. George Mason University 15 PUBLICATIONS 69 CITATIONS 62 PUBLICATIONS 1,686 CITATIONS SEE PROFILE SEE PROFILE Erol Guler Edward J. Hoppe George Mason University Government of Virginia 90 PUBLICATIONS 693 CITATIONS 30 PUBLICATIONS 331 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: Seismic Performance of Geosynthetic-Encased Stone Columns View project Microbial Induced Calcite Precipitation View project All content following this page was uploaded by Saad Ullah on 10 July 2019. The user has requested enhancement of the downloaded file. SEE PROFILE Research Article Evaluation of the Long-Term Performance of Woven Geotextile Used between Base Course and Subgrade of a Paved Road Transportation Research Record 1–12 Ó National Academy of Sciences: Transportation Research Board 2019 Article reuse guidelines: sagepub.com/journals-permissions DOI: 10.1177/0361198119827567 journals.sagepub.com/home/trr Saad Ullah1, Burak F. Tanyu1, Erol F. Guler1, Edward J. Hoppe2, and Emre Akmaz1 Abstract The purpose of this research was to investigate the properties of the exhumed geotextile from a low-volume road on the Virginia Department of Transportation network. The exhumed geotextiles have been in service for 23 years, which provided an opportunity to evaluate the longevity of the materials as well as to make assessments of how it relates to the changes in material properties. During this investigation, subgrade and base course materials were also obtained from the same site and an experimental program was developed to evaluate the effectiveness of the exhumed geotextiles for separation, stabilization, and filtration for the base course thicknesses of 4, 6, and 8 in. The results from this study combined with the results from the previous studies conducted at the same site showed that when the geotextile is placed between the subgrade and base course, the thinner the pavement section, the more evident the effectiveness of the geotextile improvements. One important finding of this research was that the placement of a geotextile reduced the particle breakage caused by abrasion under the applied transient loads. This was observed as a stabilization effect of the geotextile inclusion. As a general conclusion, for low-volume roads with relatively thin pavement sections, properly selected geotextiles provide benefits for separating the subgrade and base course (minimizing pumping), filtering infiltrated or ground water, and stabilizing the road profile. These benefits become more apparent when the thickness of the base course is less than 8 in. In the literature it is often shown that roadway with a geosynthetic undergoes less rutting; however, these works often do not provide strong evidence to describe in what mode the geosynthetic was effective in improving the performance (e.g., stabilization, separation, filtration, etc.). In this research, there was an opportunity to exhume woven geotextile placed above the subgrade and below the base course that has been in service for 23 years. The site was initially constructed as part of research funded by the Center for Innovative Technology (1). This opportunity allowed the study described in this manuscript to focus on evaluating the long-term performance of the exhumed geotextile and its effectiveness in providing efficient filtration, stabilization, and separation. The findings obtained from these evaluations are then used to make recommendations for the best pavement profile scenario for the use of geotextiles in construction of low-volume roads. AASHTO M-288 (2) defines the function of geotextiles in roadway applications as subsurface drainage (i.e., filtration), separation, stabilization, and enhancement (which combines all three functions). Several field studies have previously been conducted with woven geotextile placed in between subgrade and base course in pavement profiles (3–6). Some of these studies involved exhuming geotextiles after they had been in service for up to 12 years and others were primarily based on monitoring performance. The overall results showed that the functionality of the geotextiles depends on their properties as well as the conditions of the site where they are used. Over time, the permittivity and tensile strength of the geotextiles reduce, sometimes pumping of subgrade through the geotextile is observed, and often results show a stabilization effect based on modulus values. The general consensus of the findings from these studies is that the thinner the base course, the more effective the geotextile in providing its intended functions. However, 1 Volgenau School of Engineering, George Mason University, Fairfax, VA Virginia Transportation Research Council (VTRC), Charlottesville, VA 2 Corresponding Author: Address correspondence to Burak F. Tanyu: btanyu@gmu.edu 2 Transportation Research Record 00(0) Figure 1. Layout of the field test site. these studies do not indicate whether or not there is an upper threshold for thickness of the base course for the geotextile to provide effective support as it relates to separation, filtration, and stabilization, and especially as it relates to roads where the traffic is considered low volume. The study described in this manuscript makes an attempt to provide such guidance. Characterization of the Field Test Site from Previous Studies The site where the geotextiles were exhumed in this study was constructed in 1994 as part of a research study led by Virginia Polytechnic Institute and State University (7). The test site is located in Bedford County, Virginia and is classified as a low-volume road. The average daily traffic was predicted during the initial phase of the construction as approximately 500 (700 in summer) vehicles, with approximately 8% trucks (8). The traffic measurements conducted between 2001 and 2016 indicate that the average daily traffic was 1,300 vehicles per day for Route 616 and 1,500 for Route 757 (9). The pavement section is composed of nine individual sections (;50 ft each). The base courses of the first three sections were constructed with a 4-in., another three with a 6-in., and the remaining three with an 8-in. thick base course. For each base course thickness, one control, one section with geotextile, and another with geogrid was constructed. In all sections, the geosynthetics were placed between the subgrade and the base course. The layout of the test site is shown in Figure 1. For the purposes of this study, only the Sections 1, 4, and 7 (control) and 2, 5, and 8 (all of which were constructed with same geotextile) have been evaluated. Samples for this study were exhumed only from the sections located within the southbound lane. The properties of the subgrade have been described in literature (8) as primarily a reddish-brown residual soil, which was classified as high-plasticity clay with a soaked California bearing ratio (CBR) of 2% to 3%. Parts of the test site also included a yellowish-brown residual soil Figure 2. Grain size distribution of the base course. that was classified as low-plasticity silt; however, during this study all of the exhumed geotextiles only had the remnants of the reddish-brown residual soil. According to AASHTO M288 (2), the properties of the subgrade at this site would call for the installation of a woven geotextile for stabilization application. The grain size distribution of the base course aggregate was characterized in the literature (10) as 51% of the particles passing a #4 sieve, 9% passing a #40 sieve, and 5% passing a #200 sieve (Figure 2). The properties of the woven geotextile are summarized in Table 1. Characterization of Exhumed Subgrade and Base Course Samples Even though the subgrade and base course was previously characterized by Bhutta (10), during the efforts to exhume the geotextiles in this study, samples of subgrade and base course were also obtained and used for characterization. Properties of the subgrade and base course samples obtained from the field are depicted in Table 2. The results show that the subgrade is primarily characterized as low plasticity silt (ML) even at the sections that were previously characterized as high-plasticity clay. However, when the Atterberg limits of this material are evaluated closely, the results show that the properties lie around the borders of the A and B lines defined in Casagrande’s plasticity chart. Therefore, even though in this study the subgrade is defined as ML, it is not believed that overall there is a discrepancy between the previous literature and this study. The base course material gradation matches within the boundaries of what is specified by the Virginia Department of Transportation (DOT) as 21A aggregate (13). The grain size distribution obtained from multiple Ullah et al 3 Table 1. Properties of the Geotextile Property Test standard Value Grab tensile strength Grab elongation Mullen burst strength Puncture Trapezoidal tear strength UV resistance ASTM D4632 ASTM D4632 ASTM D3786 ASTM D4833 ASTM D4533 ASTM D4355 Apparent opening size Permittivity Water flow rate ASTM D4751 ASTM D4491 ASTM D4491 Tensile strength Machine direction Ultimate elongation Machine direction Tensile strength Cross machine direction Ultimate elongation Cross machine direction ASTM D4595 200 lbfa 15%a 406 psia 90a–95b lbf 75 lbfa 70% of tensile strengtha 40 US sieve sizeb 0.05 sec–1 b 42 US gallon/min/m2 b 20 kips/ftc ASTM D4595 14.8%c ASTM D4595 18 kips/ftc ASTM D4595 9.9%c a Source of information: Bhutta 1998 (10). Source of information: Manufacturer’s Data (11). c Source of information: Al-Qadi and Appea 2003 (12). b samples (15 tests) of the base course gave results that are quite similar to each other. Therefore the average values have been given in Table 2. When the grain size distribution of the base course provided in the literature (10) is compared with the average grain size distribution results presented in Table 2, it is observed that the amount passing the #4 sieve remained almost the same. However, the percentages passing the #40 and #200 sieves appeared to be slightly increased over time in 23 years, by about 6% (from 9% to 15% for the #40 sieve) and 5% (from 5% to 10% for the #200 sieve), respectively. In addition, a comparison was made from the grain size distribution of the bottom 2 in. of the 4-in. base course taken from the field with and without geotextile. In that comparison (in which the age of the samples is the same), the results showed that for the #40 sieve, the percentages of particles passing are 13% and 16% with and without geotextiles, respectively. For the #200 sieve, the percentages of the passing particles are 9% and 11% with and without geotextiles, respectively. Furthermore to understand the characteristics of the fines content of the base course, Atterberg limit tests were conducted and it was determined that this content is of non-plastic nature as indicated in Table 2. Summary of Previous Results Obtained by Others The falling weight deflectometer (FWD) tests conducted directly on the pavement at the site between 1994 and 1997 have been described in the literature (10). The results showed that the geotextile sections had larger stiffness values compared with the control sections, although the effects of the geotextile were more pronounced in Section 2 where the base course thickness was 4 in. In 1999, base course samples from the control and from sections with geosynthetics were exhumed from the field (8). Their findings show that the fines percentage (as defined by the #200 sieve) of the base course material had increased over the first 3 years after construction from 5% to 17% for the control section and to 12% for the geotextile stabilized section (Section 1 versus Section 2). The dynamic pressure response right at the subgrade– base course interface has been measured by past researchers, in 1999 (1). When the pressures corresponding to the vehicle speed of 50 km/h were evaluated, the results showed that in the 4-in. base course with geotextile section, the measured pressures were 5% to 7% less than the pressures measured from the control sections. This indicates that the installed geotextile provides lateral constraint to the base course, causing the stress of the tire to be distributed over a larger area and reducing the maximum pressure transmitted to the subgrade. In 2001, 8 years after the construction of the road, rut measurements were performed by researchers (12). These values show that for a base course thickness of 4 in., the rutting was significantly less in the section with geotextile (0.75 in. on average) compared with the control section (1.8 in. on average). For the 6-in. and 8-in. base course thicknesses, the geotextile sections did not differ significantly from the control sections. The information from the past studies of the same site provides evidence that when the geotextile is placed between the subgrade and the base course, on lowvolume roads, the thinner the base course, the more effective geotextile becomes in stabilization. However, the past studies do not provide evidence or discussion of the contribution of the specific functions of the geotextile that results in these improvements. Moreover, none of the previous results depict performance behavior after the geotextiles have been in service for 23 years. Methodology Used in This Study to Evaluate Exhumed Samples All geotextiles used in this study were exhumed in the fall of 2017 with the assistance of the Virginia DOT. As part of this effort, the Virginia DOT has exposed an area within the base course approximately 5 ft by 7 ft by removing the hot-mix asphalt (HMA) layer. After carefully sampling and removing the base course, the perimeter of the geotextile was cut, and geotextiles were 4 Transportation Research Record 00(0) Table 2. Properties of Subgrade and Base Course as Determined in This Study Classification Average values Base Course (21A Aggregate) Specific gravity (ASTM C127) Apparent specific gravity 2.8 Water absorption (%) 0.5 Average grain size distribution (GSD) (ASTM D5444) Passing 3/4’’ (\19 mm) 95% Passing 3/8’’ (\9.5 mm) 75% Passing #4 sieve (\4.75 mm) 54% Passing #40 sieve (\0.43 mm) 15% Passing #200 sieve (\0.075 mm) (per ASTM D1140) 10% GSD from the bottom 2-in. of the 4-in. base course in the field Section 1 Section 2 (without geotextile) (with geotextile) Passing #40 sieve (\0.43 mm) 16% 13% Passing #200 sieve (\0.075 mm) 11% 9% Atterberg limits (ASTM D4318) Liquid limit (%) 14.0 Plastic limit (%) Non-plastic USCS classification Well graded sand with silt (SW-SM) (ASTM D2487 2017) California bearing ratio (CBR) (ASTM D4429) Unsoaked CBR (%) 75 Soaked CBR (%) 55 Field density measurements (ASTM D2937) Field moisture content (%) 4.0 Field density (pcf) 130 Subgrade Hydrometer test (ASTM D7928) Passing #10 sieve (\2.00 mm) 100 Passing #200 sieve (\0.075 mm) 77 Clay size fraction (\0.002 mm) 45 Atterberg limits (ASTM D4318) Liquid limit (%) 49.0 Plastic limit (%) 29.0 Plasticity index (%) 20.0 USCS Classification (ASTM D2487) Low-plasticity silt (ML) California bearing ratio (CBR) (ASTM D4429) Unsoaked CBR (%) 4 Soaked CBR (%) 2 Field density measurements (ASTM D2937) Field moisture content (%) 29.0 Field density (pcf) 122 Note: USCS = Unified Soil Classification System; pcf = pounds per cubic foot. gently removed. Samples of the subgrade were also collected from the same locations. The experimental methodology of this research was designed to evaluate the effectiveness of the exhumed geotextiles to function in separation, filtration, stabilization, and potential enhancement. It is understood that it is not always necessary for the same geotextile to satisfy all of these functions; however, specific tests were developed in this study to understand how the exhumed geotextile functioned after being in service for 23 years. Therefore, the research methodology has been divided into three phases. In the first phase, the properties of all of the collected materials were characterized. In the second phase, the aspect of movement of subgrade particles (pumping) into the base course and the effectiveness of the geotextile in providing stabilization were evaluated. In the third phase, the properties of the exhumed geotextiles in terms of water being able to permeate were investigated. Tensile Strength and Permittivity Tests Tensile strength of the exhumed geotextiles has been tested following the ASTM D4595 testing protocols. Ullah et al Specimens for the tests were obtained from the geotextiles exhumed from the sections with 4-in., 6-in., and 8-in. thick base courses. All tests were conducted to determine the ultimate strength along both the machine direction and the cross machine direction. Permittivity tests were conducted with geotextile specimens with a diameter of 6 in. Repeated Load Triaxial Tests The repeated load triaxial (RLT) tests conducted in this study involved essentially the same type of set-up as is typically seen in permanent deformation tests (14). The samples were 6 in. in diameter and 12 in. in height. Uniquely to this study (as there are no such ASTM standards), all of the samples for these evaluations were created by placing first 6 in. of subgrade and then 6 in. of base course on top. This set-up was similar to the set-up used by another piece of research (15); however, in that research the diameter of the sample was 4 in. The reason the sample height in this test set-up was chosen as 6 in. for each layer as opposed to a 4-in., 6-in., and 8-in. base course was to create a more uniform stress distribution within the sample. Non-uniform samples result in stress concentrations differing at the sides of the samples compared with the stresses observed in the middle of the samples (16, 17). Keeping all sample sizes uniform allowed the results to be compared with each other. In the tests in which geotextiles were used, they were placed in between the subgrade and base course. All samples and layers within each sample were compacted to 100% relative compaction at optimum moisture content as obtained from the literature (10) and field test results. Exhumed geotextiles from the field from each section (sections 2, 5, and 8) were cleaned and then used in the RLT tests that were conducted with the geotextile. Therefore the geotextiles used in these tests have already been aged in the field for about 23 years. To simulate the differences in base course thicknesses in the field, the samples in the RLT were loaded to simulate the stresses that would be present at the boundary of subgrade–base course for base course thicknesses of 4, 6, and 8 in. The magnitude of applied stresses was determined from multilayer and finite element models recommended in the literature based on the 100-psi tire pressure over the area of 6-in. radius applied on the surface of the pavement (14). The thickness of the asphalt layer at this site was designed as 3 in (10). The approach followed in this study by applying different stresses to simulate different base course profiles was possible because in a cylindrical sample the stresses applied at the top of the sample uniformly distribute within the sample. The load was applied using haversine impulse for 10,000 5 cycles as recommended by prior literature for permanent deformation tests (14, 15, 18, 19). All the RLT tests were repeated at least twice. The results presented in this manuscript are the average of two test runs. At the end of each test, three different results were obtained: (i) accumulated permanent deformation with time, (ii) estimated elastic modulus based on the elastic deformations recorded at the end of the tests, and (iii) changes in grain size distribution within the base course after the end of the tests. The grain size distribution was performed on the base course material obtained only within the 1 in. of the subgrade/base course interface in the RLT tests. To eliminate the potential errors caused by blending the subgrade with base course during sample preparation because of compaction, the samples obtained from the base course material for the grain size distribution were only taken from the middle of the cylindrical sample (approximately 0.5 in. away from the edges). In addition, at the end of each test, the geotextiles exhumed from the sample were evaluated under the microscope and traces of the reddish subgrade clay determined to confirm the changes noted in the grain size distributions of the base course. Results were used to evaluate the respective contributions of separation and stabilization functions of the geotextiles. Furthermore, the results from changes in grain size distribution within the base course were used to evaluate the effectiveness of the filtration function (i.e., minimizing the migration of the fines from subgrade into the base course). Hydraulic Conductivity Tests The hydraulic conductivity tests conducted in this study had the same type of set-up as is typically seen in the gradient ratio tests per ASTM D5101. The samples were 6 in. in diameter and 4 in. in height. All samples were prepared at 95% relative dry density obtained from prior studies conducted on the same project (10). The experiments were performed with hydraulic gradient of 1 (the gradient was gradually increased from 0.25 to 0.5 to 0.75 to 1), which covers the worst-case scenario in pavement applications (20). The results of the tests were evaluated in accordance with the interpretations described in literature (21). The particular intent of conducting these hydraulic conductivity tests in this study was to understand and evaluate the filtration performance of the exhumed geotextiles, which were exposed to subgrade and base course for 23 years. Although permittivity tests were also conducted in this study, during such permittivity tests, the geotextiles are placed directly under the flow of water. This can often result in washing out the particles of the 6 Transportation Research Record 00(0) Table 3. Changes in Tensile Properties of the Exhumed Geotextiles over Time After 23 years in servicea Pavement section Direction sult. (kip/ft) eult. (%) 4-in. base Machine X-Mach. Machine X-Mach. Machine X-Mach. 1.34 1.20 1.31 1.11 1.30 1.00 9.5 14.4 7.8 12.8 9.6 10.8 6-in. base 8-in. base Manufacturer’s datab After 5 years in servicec sult. (kip/ft) eult. (%) sult. (kip/ft) eult. (%) Machine 1.85 14.8 1.23 23.6 X-Machine 1.71 9.9 1.71 12.5 Direction Note: sult. = Ultimate wide-width tensile strength; eult = Ultimate elongation; X-Mach. = Cross machine. a Values obtained as part of this study. b Values obtained from the manufacturer’s website; manufacturer data for original samples were minimum average roll values (MARV) (11). c Values published in literature (8) (the measured strains at failure are excessive considering the values presented by the manufacturer and measured after 23 years). specimens and not necessarily depicting the actual permeability/permittivity. To prevent/minimize such effect, the hydraulic conductivity tests were conducted by placing 4-in. base course aggregate over the top of the exhumed geotextiles. In addition, one test was conducted with a cleaned geotextile. The aggregate used for these tests was obtained from the site and had a hydraulic conductivity of approximately 4 3 10–2 cm/s. Considering that the manufacturer’s reported permittivity value is 0.05 s–1 and the measured thicknesses of the cleaned samples are approximately 16 mil, the estimated permeability of the virgin geotextile is expected to be in the order of 2 3 10–2 cm/s (and the permeability of the exhumed geotextiles is expected to be significantly less than this value). Therefore, it is assumed that placement of the base course aggregate not only simulates the actual field condition but also does not hinder the permeability of the geotextile that was already in contact with the subgrade. Properties of the Exhumed Geotextiles from the Site after 23 Years of Service Life All of the exhumed geotextiles after 23 years appeared to be in great shape with no signs of physical degradation. Tensile strength and permittivity of the exhumed geotextiles have been evaluated to quantitatively determine the changes in the geotextile properties after being in service for 23 years. Table 3 presents the results of the wide-width tensile tests conducted as part of this study and also compares these results with the manufacturer’s reported values and results obtained previously by others on the same geotextile from the same road sections after they had been in service for 5 years. The results compiled from previous studies show that by the end of the 5 years of service, the geotextile retained its tensile strength in the cross machine direction and that approximately 30% reduction was observed in the machine direction. After 23 years of service, the changes in machine direction appear to have remained the same as compared with 5 years, but additional changes occurred in the cross machine direction. The geotextiles exhumed from below the 4-in., 6-in., and 8-in. thick base courses retained 68%, 64%, and 60% of their tensile strengths, respectively. The strains at ultimate tensile strength values show that there was not a significant reduction compared with the strains reported by the manufacturer. Therefore, it is concluded that no significant polymer aging took place in 23 years. All these results indicate that the geotextiles retained their original mechanical properties. Table 4 summarizes the permittivity values of the geotextiles as reported by the manufacturer and after they were exhumed at the end of 23 years of service. The socalled ‘‘uncleaned’’ results in Table 4 depict the permittivity values of the exhumed geotextiles and the ‘‘cleaned’’ values show the results after the exhumed geotextiles were washed and tested. The difference between the permittivity values of the original material and cleaned geotextiles shows reduction in permittivity of about 60% in the section with 4-in. base course and 72% in sections with 6-in. and 8-in. base course. The occurrence of these reductions is interpreted as the geotextiles being compressed under the surcharge pressure for a long time so that the pores of the geotextile have slightly reduced. This explanation is also supported by the reduction being less for the section with the thinnest base course (Section 2), for which the static overburden pressure was the smallest. Although there was no filter cake type of appearances, the surface of all of the exhumed geotextiles had some of the reddish color subgrade on the base Ullah et al 7 Table 4. Summary of Hydraulic Properties of the Exhumed Geotextiles are interpreted as the effect of the penetrated subgrade into the pores of the geotextile. Permittivity test results Permittivity after 23 years in service (s–1) Pavement section Permittivity of geotextiles before installation (s–1)a 4-in. base 0.05 6-in. base 8-in. base Permeability test results Sample Base course (BC) BC + geotextile from 4-in. base BC + geotextile from 6-in. base BC + geotextile from 8-in. base BC + cleaned geotextile Uncleaned Cleaned 0.010 0.011 0.011 0.020 0.014 0.014 System permeability (cm/s) 4.211 3 0–2 8.641 3 0–3 1.011 3 0–2 2.111 3 0–2 3.711 3 0–2 a Values obtained from manufacturer’s website (11). course side of the geotextile. Therefore, the difference between the uncleaned and cleaned permittivity values Results of Repeated Load Triaxial Tests Accumulated Permanent Deflections with Time: Evaluation of Stabilization Function Figure 3 shows the accumulated permanent deformations from the tests conducted in this study with the exhumed material after 23 years. For each section, two sets of tests were conducted: one with the base course– subgrade combination and the other with a geotextile between the subgrade and base course. Based on the applied stress conditions which simulate each base course thicknesses in the field, the results indicate that the amount of accumulated permanent deformation is very sensitive to the magnitude of the applied stress and therefore the pavement section thickness. The following summarizes the observations from these test results. For a base course thickness of 4 in., the deformations increase very quickly and reach a value of Figure 3. RLT test on (a) base–subgrade sample and (b) subgrade sample alone, and (c) the schematic showing the RLT test set-up. 8 Transportation Research Record 00(0) 0.57 in. regardless of whether separated by a geotextile or not. For a base course thickness of 6 in., the accumulated deformation for the tests conducted without geotextile was 0.08 in. and with geotextile was 0.071 in. (approximately 85% improvement compared with the 4-in. thick base course). Although at the end, the difference between the tests with geotextile and without the geotextile was relatively small and therefore negligible, the presence of the geotextile delayed the deformation build-up significantly. That is, whereas the sample without the geotextile reached maximum deformation in only hundreds of cycles, the sample with geotextile reached a similar amount of deformation in 10,000 cycles. For the base course thicknesses of 8 in., the permanent deformation at the end of 10,000 cycles was 0.04 in. without geotextile and 0.035 in. with geotextile). However, it can be concluded that the accumulated deformations were minimal. The purpose of the RLT tests was not to determine a value to be used in design but to compare the behaviors with each other to understand the differences in trends to potentially evaluate the effects of stabilization provided by the geotextile to the subgrade/base course system. The tests representing the 6-in. thick base course clearly show the effect of the geotextile, but this observation is not as clear for the tests conducted with the applied stresses simulating 4-in. and 8-in. thick base course. Prior researchers also made an attempt to investigate multilayer systems in a similar set-up with and without the geotextiles (16). Their experiments indicated that the specimen containing the separator experienced significantly higher deformations across the interface and in the aggregate. The previous study explained this behavior as the separator preventing the aggregate from interlocking with the fine-grained soil and probably providing a lowfriction surface for lateral particle movement (16). The associated changes in the boundary condition for the aggregate have been related to the relative increase in deformation. The results shown in Figure 3 contradict these conclusions because, in this study, the deformations observed with and without geotextile have very similar magnitudes. To understand this behavior, RLT tests were also conducted with 100% subgrade with applied loads corresponding to the stresses caused by 4-in., 6-in., and 8in. base courses (Figure 3b). The results show that for the test simulating the 4-in. base course, the subgrade was very close to failure and deformations continued to increase even after 10,000 cycles. Therefore, placement of the base course and geotextile improved the permanent deformation behavior. However, the separation of the contributions of the base course alone versus the base Table 5. Summary of Elastic Modulus Calculated from the Dynamic Triaxial Tests Simulated pavement profiles 4-in. base course over subgrade 4-in. base course over subgrade with geotextile 6-in. base course over subgrade 6-in. base course over subgrade with geotextile 8-in. base course over subgrade 8-in. base course over subgrade with geotextile Calculated elastic modulus (psi) Percentage improvement 20,113 21,524 7% 11,019 13,996 27% 10,572 11,620 10% course with geotextile was not very evident in the 4-in. base course RLT tests. This is because it is believed that in a triaxial set-up, the geotextile is not fully engaged (as is expected to happen in the field) to influence the permanent deformations. Overall, it is believed that even with these limitations, these test results showed that after being in service for 23 years, geotextiles were still effective in proving stabilization as seen in the 6-in. base course test. Estimated Elastic Modulus: Evaluation of Stabilization Function Table 5 shows the summary of the estimated elastic modulus values from each of the RLT tests. These values are obtained from the elastic strains obtained during the above described tests, so they are referred to as elastic modulus (not to be confused with the resilient modulus values that are determined from the AASHTO TP46-94 testing protocol). The results shown in Table 5 were calculated following the same approach described in the literature (22), whereby the modulus is estimated from the ratio of the applied deviator stress and corresponding resilient strain. The intent of the presented information in Table 5 is not to provide design values but to show (relative to each other) that in all cases the exhumed geotextiles were effective in showing an increase in elastic modulus within the same profiles tested with and without the geotextile. The magnitude of the values is higher with the tests simulating thinner pavement profiles because in those tests the applied loads and the corresponding bulk stresses are also higher. The highest percentage improvement in the elastic modulus was observed for the 6-in. base course (27%). This is also reflected in the deformation delay produced by the geotextile in the representative sample of the 6-in. base course section. In addition to the laboratory estimations, in the field, several light weight deflectometer (LWD) tests were Ullah et al 9 performed directly over the base course in Sections 1 and 2 to compare the effect of the geotextile in the 4-in. base course section. The average calculated elastic moduli from these tests were 7,690 and 9,430 psi for the sections without and with geotextiles, respectively. These numbers cannot be compared with the values in Table 5 but when they are compared with each other, considering that the subgrade is the same, sections with geotextile show 23% higher elastic modulus. This observation contributes to the discussion that even though the results from the laboratory do not clearly show the contribution of the geotextile in 4-in. thick base course, the results from the field provide clarification. Changes in Grain Size Distribution within the Base Course: Evaluation of Separation Function After 10,000 cycles of repeated loading at the RLT tests, samples of the base course were collected from the 1 in. above the geotextile. Location of the geotextile in the RLT tests is shown in Figure 3c. The collected samples were evaluated for the changes in grain size distributions based on the differences at #40 and #200 sieve sizes (Figure 4). The replicate tests conducted in this study for each case resulted in very similar gradations, confirming the strong repeatability of the conducted tests. The changes in grain size distribution from the tests simulating each of the base course thicknesses were evaluated. The test results indicate that, for the comparison of the #40 sieve, the percentages passing with and without geotextiles were 12% and 20% (for 4-in. base course) and 12% and 19% (for 6-in. base course), respectively. Similarly, for the #200 sieve, the percentages passing with and without geotextiles were 10% and 15% (for 4in. base course) and 9% and 12% (for 6-in. base course), respectively. No changes in gradation were observed from the tests simulating the 8-in. base course. These changes in percentage of fines content as described by the #200 sieve can be interpreted as the pumping of the subgrade into the base course, as was also evident from the observations made on the geotextiles exhumed after these tests for which the remnants of the reddish particles (subgrade) within the base course were observed. The results show that some pumping occurs within the thinner base course profiles and the woven geotextile is effective in reducing (but not completely eliminating) this effect. As the thickness of the base course profiles increases, the stresses at the subgrade–base course reduce and the effectiveness of the geotextile as a separator diminishes. This interpretation of pumping is also supported by the differences observed in the grain size distribution curves presented in the literature (10) (reflecting the original gradation) and obtained in this study after 23 years of installation, Figure 4. Evaluation of the changes in grain size distribution of the base course aggregate from the RLT tests simulating: (a) 4-in., (b) 6-in., and (c) 8-in. thick base courses. whereby the fines content increased by about 5% over time. Additionally, plastic limit of the base course was evaluated from the RLT test conducted to simulate the 4-in. base course profile both with and without geotextiles. The results showed that the base course material in 10 the RLT test without the geotextile had a plastic limit of 17 and with the geotextile had eight. When compared with the properties of base course material before the test (as depicted in Table 2), the change in the plastic limit is interpreted to be because of the pumping of the subgrade. Moreover, that the plastic limit measured was significantly lower than the plastic limit of the subgrade indicates that the amount of clay pumped from the subgrade was minimal. On the other hand, the changes in percentages passing the #40 sieve indicate another story because the changes could not have been caused by pumping from the subgrade as the maximum particle size of the subgrade in this study was 2 mm (100% passing #10 sieve) (Table 2). This is interpreted as the changes being partially caused by pumping and partially caused by the breakage of the base course particles (which is more evident in the tests simulating 4-in. base course). Previous literature supports the hypothesis of disintegration of base course aggregate particles under the action of abrasive forces (23). Considering that all of the materials used in these evaluations were exhumed from the site after being in service for 23 years, these findings lead to a discussion that some of the base course crushed stone may abrade under the repeated traffic loading. This assumption of particle abrasion is also supported by the differences observed in the grain size distribution curves from the bottom 2 in. of the 4-in. base course samples obtained from the field. The effect of potential particle abrasion was observed to be reduced in the section with the geotextile. Transportation Research Record 00(0) compared against the hydraulic conductivity of the original geotextile values reported by the manufacturer (Table 4), the results show that over time the hydraulic ability of the geotextile in all sections has decreased (perhaps an order of magnitude). However, considering that 10-2 (or even 10-3) cm/s is within the range of a typical natural sand (24), the filtration properties of the exhumed geotextiles are still considered reasonable and acceptable. Conclusion The properties of the exhumed geotextiles showed that after 23 years, there were differences in tensile strength and permittivity, but all geotextiles were physically intact. When all of the observations obtained from this field site including the ones from the previous studies as well as the results obtained from this particular investigation are combined, the following conclusions are drawn related to the effectiveness of the exhumed geotextiles to function as a separator, and in filtration, stabilization, and potential enhancement in low-volume roads: Results of Hydraulic Conductivity Tests These tests were conducted to evaluate the filtration effect of the geotextiles after they had been in service for 23 years. The results of these tests are shown in Table 4. The results of the tests were evaluated, based on the system permeability as defined in the literature (21), as the overall permeability within the test set-up. The system permeability is dictated by the lowest permeability of the material within the system. Because the permeability of the exhumed base course was slightly higher than any of the geotextiles, the system permeability values presented in Table 4 are primarily controlled by the permeability of the geotextiles. Based on this interpretation, the results show that in all sections the values are very close to each other (in the order of 10–2 cm/s). When these results are compared against the permeability values backcalculated from the permittivity of the ‘‘uncleaned’’ geotextiles (Table 4), it can be seen that they are within the same order of magnitude. If the hydraulic conductivity of the cleaned geotextile (as back-calculated from the permittivity test values) is Stabilization: All previous studies on this site indicate an improvement in elastic modulus and rutting in sections with geotextiles and they show that the evidence of improvements is more pronounced in the sections with thinner base course. These previous observations are also supported from the results that were obtained from the geotextiles even after they had been in service for 23 years. The discussions provided from the RLT test results show that the improved performance of the sections with geotextiles could be seen more easily based on modulus comparisons as opposed to the accumulated permanent deformations. The grain size distribution of the base course obtained in the field and the grain size distribution obtained from the RLT test indicate that particle breakage may have occurred in the base course. In both laboratory and field, the amount of increase in percentages passing the #40 sieve caused by breakage was reduced by the geotextile. Therefore it can be concluded that the geotextile was helpful in reducing the particle breakage and thereby providing a stabilization function for the base course. This mechanism helps in keeping the elastic nature of the base course under repeated traffic load for a longer duration. Separation: Literature (8) indicates that the fines percentage of the base course in both the sections with and without the geotextile has increased over time. Ullah et al However, this past study did not clearly differentiate the cause of this increase as it relates to distinguishing between the pumping of the subgrade and potential breakage of the base course aggregate particles. The results presented in this study showed that the exhumed geotextiles did not prevent pumping but have reduced the effect drastically in the sections with the thinner base course. Filtration: The selected geotextiles for this study still had the ability to provide filtration even though over time the ability of the geotextiles had decreased compared with the original geotextile before it was placed in the ground. The decrease in the hydraulic ability of the exhumed geotextiles after being in service for 23 years was considered acceptable in terms of the ability of the system to convey water. Enhancement: The laboratory evaluations in this study showed the effectiveness of the selected woven geotextile to provide stabilization, separation, and filtration. However, there were not enough data from the field (positive or negative) to also confirm the effectiveness for enhancement (which refers to the combined performances of stabilization, separation, and filtration). The above listed conclusions are based on the specific woven geotextile exhumed from the Virginia DOT’s test site. However, the geotextile used in this study is of a common type that is found in road applications. Practical Implications Based on all of the measurements and observations provided in this paper, and considering the general experience accumulated over the years, it is recommended that a geotextile for stabilization purposes as described by Clause 8.4 of M-288 (2) should be used between the subgrade and base when all the following circumstances are met: The subgrade of the road is considered soft as defined by AASHTO M-288 (2) (i.e., CBR of subgrade \3). The subgrade in this case study had a soaked CBR of 2; therefore the use of geotextile was appropriate for stabilization. The base course used for construction meets the typical gradations defined by DOTs (in coarser aggregates separation between the subgrade and aggregate may become more important and in finer aggregates stabilization may become more important). 11 The thickness of the base course is ł 6 in. This recommendation is made because the evaluation at this particular site did not show any evidence that thicker sections (.6 in.) benefited from the geotextile as seen in thinner sections. Previous literature also states that geotextile separators placed underneath relatively thick pavement sections may not provide significant benefit (25). The asphalt layer at this site was 3-in. thick. The combined thickness of the asphalt layer and base course (i.e., the pavement section) has to be evaluated together for a realistic decision of what to expect from the roadways with geotextiles. The selected geotextile meets the property requirements set forth in AASHTO M-288 (2). In addition, if further improvements are desired (such as minimizing the potential of the base course aggregates to break down), consideration may be given to placing the geosynthetic reinforcement not only at the interface between the subgrade and base course but also within the profile of the base course itself (this particular evaluation has not been conducted in this study but the observations from the study imply this benefit). Based on the above list, in low-volume roads, for base course thicknesses of 8 in. or more and with a slightly stronger subgrade (i.e., CBR . 2) a special evaluation must be done and it is possible that no geotextile may need to be placed between the subgrade and base course. However, it may still be good practice to place a geotextile primarily for separation purposes because in most applications the subgrade properties do not always end up being uniform throughout the project as was also the case at this site, where there was a small section with fill material as a subgrade. The recommendations suggested in this study are based on the materials, results, and observations of the combined field and laboratory data generated from this specific site with the materials tested in this study. Additional evaluations may need to be performed from other sites to strengthen or revise these recommendations—for example, comparison of the performance of woven versus nonwoven geotextiles placed in between the subgrade and base course. Acknowledgments The research presented in this paper was funded by the Virginia Department of Transportation and Geosynthetics Institute (GSI). Author Contributions The authors confirm contribution to the paper as follows: field work: all authors, laboratory experimentation design: 12 B.F. Tanyu and E. Guler, laboratory testing: S. Ullah and E. Akmaz, analysis and interpretation of results: B.F. Tanyu, E. Guler, S. Ullah, and E. Hoppe: manuscript preparation: B.F. Tanyu, E. Guler, S. Ullah. All authors reviewed the results and approved the final version of the manuscript. Transportation Research Record 00(0) 14. References 1. Al-Qadi, I., and S. Bhutta. In Situ Measurements of Secondary Road Flexible Pavement Response to Vehicular Loading. Transportation Research Record: Journal of the Transportation Research Board, 1999. 1652: 206–216. 2. AASHTO M-288-17. Standard Specification for Geosynthetic Specification for Highway Applications. AASHTO, Washington, D.C., 2017, pp. 27. 3. Metcalfe, R. C., R. D. Holtz, and T. M. Allen. Field Investigation to Evaluate the Long Term Separation and Drainage Performance of Geotextile Separators. Proc., Geosynthetics ’95 Conference, Nashville, 1995, pp. 951–962. 4. Black, P. J., and R. D. Holtz. Performance of Geotextile Separators Five Years after Installation. Journal of Geotechnical and Geoenvironmental Engineering, Vol. 125, No. 5, 1999, pp. 404–412. 5. Kim, W. H., T. Edil, C. Benson, and B. Tanyu. Structural Contribution of Geosynthetic-Reinforced Working Platforms in Flexible Pavement. Transportation Research Record: Journal of the Transportation Research Board, 2005. 1936: 43–50. 6. Saghebfar, M., M. Hossain, and B. A. Lacina. Performance of Geotextile-Reinforced Bases for Paved Roads. Transportation Research Record: Journal of the Transportation Research Board, 2016. 2580: 27–33. 7. Al-Qadi, I. L., T. L. Brandon, R. J. Valentine, B. A. Lacina, and T. E. Smith. Laboratory Evaluation of Geosynthetic Reinforced Pavement Sections, Transportation Research Record: Journal of the Transportation Research Board, 1994. 1439: 25–31. 8. Loulizi, A., I. L. Al-Qadi, S. A. Bhutta, and G. W. Flintsch. Evaluation of Geosynthetics Used as Separators, Transportation Research Record: Journal of the Transportation Research Board, 1999. 1687: 104–111. 9. Traffic Data. Primary and Interstate Publications. Virginia Department of Transportation. http://www.virginiadot .org/info/ct-TrafficCounts.asp. Accessed April 10, 2018. 10. Bhutta, S. A. Mechanistic-Empirical Pavement Design Procedure for Geosynthetically Stabilized Flexible Pavements. Ph.D. dissertation. Virginia Polytechnic Institute and State University, 1998. 11. US Fabrics: Construction Geosynthetics. Amoco Propex 2002, Data for Comparison. US Fabrics Incorporation, Ohio. www.usfabricsinc.com/products/amoco-propex-2002. Accessed May 5, 2018. 12. Al-Qadi, I. L., and A. K. Appea. Eight-Year Field Performance of Secondary Road Incorporating Geosynthetics at Subgrade–Base Interface. Transportation Research Record: Journal of the Transportation Research Board, 2003. 1849: 212–220. 13. Road and Bridge Standards. Virginia Department of Transportation, 2016. http://www.virginiadot.org/business/locd View publication stats 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. es/2016_road_and_bridge_standards.asp, Accessed March 30, 2017. Ullah, S., B. F. Tanyu, and E. H. Hoppe. Optimizing the Gradation of Fine Processed Reclaimed Asphalt Pavement and Aggregate Blends for Unbound Base Courses. Transportation Research Record: Journal of the Transportation Research Board, 2018: 0361198118758683. https://doi.org/ 10.1177/0361198118758683. Ullah, S., and B. F. Tanyu. Methodology to Develop Design Guidelines to Construct Unbound Base Course with Reclaimed Asphalt Pavement. Construction and Building Materials, 2019. https://doi.org/10.1016/j.conbuildmat.2019.06.196 Henry, K. S., D. M. Cole, and G. D. Durell. Mixing in an Aggregate/Fine-Grained Soil System Subjected to Cyclic Loading with a Geotextile Separator. In Sound Geotechnical Research to Practice: Honoring Robert D. Holtz II. ASCE Geotechnical Special Publication No: 230, 2013, pp. 307–318. Omar, T. Specimen Size Effect on Shear Behavior of Loose Sand in Triaxial Testing. Master thesis. The University of Western Ontario, 2013. Tutumluer, E., and T. Pan. Aggregate Morphology Affecting Strength and Permanent Deformation Behavior of Unbound Aggregate Materials. Journal of Materials in Civil Engineering, Vol. 20, No. 9, 2008, pp. 617–627. Cook, C. S., B. F. Tanyu, and A. B. Yavuz. Effect of Particle Shape on Durability and Performance of Unbound Aggregate Base. Journal of Materials in Civil Engineering, Vol. 29, No. 2, 2016, p. 04016221.. Luettich, S. M., J. P. Giroud, and R. C. Bachus. Special Issue on Geosynthetics in Filtration, Drainage and Erosion Control Geotextile Filter Design Guide. Geotextiles and Geomembranes, Vol. 11, No. 4, 1992, pp. 355–370. Abbaspour, A., B. F. Tanyu, A. H. Aydilek, and A. Y. Dayioglu. Methodology to Evaluate Hydraulic Compatibility of Geotextile and RCA in Underdrain Systems. Geosynthetics International, Vol. 25, No. 1, 2018, pp. 67–84. Puppala, A., S. Chomtid, and V. Bhadriraju. Using Repeated-Load Triaxial Tests to Evaluate Plastic Strain Potentials in Subgrade Soils. Transportation Research Record: Journal of the Transportation Research Board, 2005. 1913: 86–98. Tanyu, B. F., A. B. Yavuz, and S. Ullah. A Parametric Study to Improve Suitability of Micro-Deval Test to Assess Unbound Base Course Aggregates. Construction and Building Materials, 2017. Vol. 147, pp. 328–338. Fetter, C. W. Applied Hydrogeology, 4th ed. Waveland Press, Long Groove, IL, 2018. Collins, B. M., and R. D. Holtz. Long-Term Performance of Geotextile Separators, Bucoda Test Site—Phase III. Technical Report, Report No. WA-RD 595.1. Washington State Transportation Center, Olympia, 2005. The Standing Committee on Aggregates (AFP70) peer-reviewed this paper (19-03677). The conclusions and recommendations are those of the authors and may not reflect the opinions and policies of the Virginia DOT and GSI.