A presentation on Geo-Textiles : Perspective from the construction

advertisement

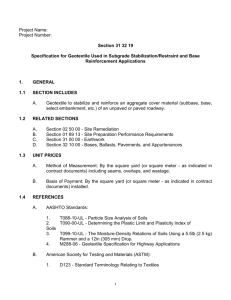

FEDERATION OF INDIAN CHAMBERS OF COMMERCE AND INDUSTRY A Presentation On Geo Textiles : Perspective from the Construction Sector By D C DE CONSULTING ENGINEERING SERVICES (INDIA) PRIVATE LIMITED 19 November 2010 Reinforcement Geo Drains Geo Separations Geotextile Applications in Roads MSE ASTM D4439 defined a geotextile as follows Geotextile : A permeable geosynthetic comprised solely of textiles. Geotextiles are used with foundation, soil, rock, earth, or any other geotechnical engineering-related material as an integral part of a human-made product structure, or system. Due to the very wide range of applications and the tremendous variety of available textiles having widely different properties, the selection of a particular design method or design philosophy is a critical decision that must be made before the actual mechanics of the design process are initiated. Geotextile Functions and Mechanisms An overview of geotextiles, alluded to many applications falling into categories: Separation Reinforcement Filtration Drainage Containment When properly identified, lead to the design-byfunction method. Geotextile choices as available 1. Lightweight Wovens 2. Heavyweight Wovens 3. High Flow Wovens 4. High Strength Wovens 5. Thermally Bonded Non-wovens 6. Needle punched Nonwovens Geotextile Functions and Mechanisms Separation Designed Thickness Bituminious Courses Aggregate Bases Geotextile Layer Subgrade Geotextile Functions and Mechanisms Filtration and Drainage Bituminious Courses Aggregate Bases Geotextile Layer Aggregate Drainage Layer Subgrade Geotextile Functions and Mechanisms Reinforcement This is the synergistic improvement in the total system strength created by the introduction of a geotextile into a soil and developed primarily through the following three mechanisms: One, lateral restraint through interfacial friction between geotextile and soil/aggregate. Two, forcing the potential bearing surface failure plane to develop at alternate higher shear strength surface. And three, membrane type of support of the wheel loads. Geotextile Functions and Mechanisms Pavement Crack with Paving Fabric Sealing Function New Overlay Reflective Crack without Paving Fabric Old Pavement Base Course Major Applications of Geotextiles Separation of Dissimilar Materials Between subgrade and stone base in paved roads and airfields Between landfills and stone base courses Between geomembranes and soil drainage layers Between foundation and embankment soils for surcharge loads Between foundation and embankment soils for roadway fills Between foundation and encapsulated soil layers Between foundation soils and rigid retaining walls Between slopes and downstream stability berms Beneath precast blocks and panels for aesthetic paving e.g. hardscaping Major Applications of Geotextiles Separation of Dissimilar materials Between drainage layers in poorly graded filter blankets Between old and new asphalt layers Reinforcement of Weak Soils and Other Materials To reinforce embankments To aid in construction of steep slopes As basal reinforcement over soft soils To bridge over cracked or jointed rock To create more stable side slopes due to high frictional resistance Major Applications of Geotextiles Filtration (Cross-Plane Flow) Beneath stone base for paved roads and airfields Around crushed stone surrounding under drains Around perforated under drain pipe As a flexible form for restoring scoured bridge pier bearing capacity Between backfill soil and weep holes in retaining walls Between backfill soil and gabions As a filter beneath precast blocks Major Applications of Geotextiles Drainage (In-Plane Flow) As a drain behind a retaining wall As a drain at the base of retaining wall As a replacement for sand or wick drains Band Drains / Prefabricated Vertical Drains (PVD) These are geocomposites formed of a hollow cored, geotextile wrapped drainage element (geonet) inserted vertically into soft ground to speed up the consolidation process. Prefabricated Vertical Drain Installation of PVD Band Drains / Prefabricated Vertical Drains (PVD) Kandla Port – Ground improvement Band drains has been adopted to increase the bearing capacity of the site. The following parameters have been adopted: Scheme SBC Spacing of Preload Duration before Band Drain Height (Days) treatment with Triangular (m) (T/m2) Grid (m) SBC after treatment (T/m2) Scheme-1 2.00 1.25 4.00 80 10.21 Scheme-2 2.00 1.50 4.00 120 10.11 Band Drains / Prefabricated Vertical Drains (PVD) at Kolkata Emerging Issues R&D Needs of the Indian Geotechnical Industry The Need to Encourage the Domestic Synthetic Manufacturing Industry Need for Establishing a Geosynthetic Institute in India Standardization in the Field of Geosynthetics Geosynthetics Test Standards and Specifications

![SECTION 32 01 17 [02976] GEOTEXTILE INTERLAYER FOR BITUMINOUS PAVEMENT OVERLAYS](http://s2.studylib.net/store/data/017559241_1-1d8d816ef97d904072518535dbaef6e2-300x300.png)