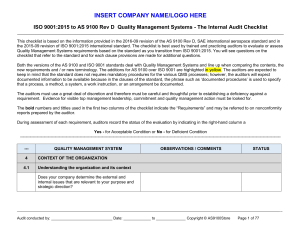

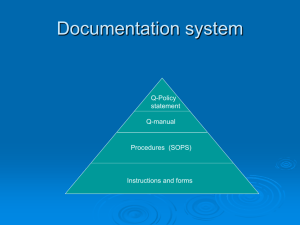

Quality Management Awareness Prepared by: Joseph Mullappally Dated: 10 July 2021 Agenda 2 Why Marafiq Embrace Quality? Marafiq Quality Objectives Define Quality and its evolution Marafiq Quality Manual Define Quality Management Marafiq QMS Key Processes Components of QMS Project Execution Plan Quality Improvement Tools Project Quality Plan QMS Standards Inspection & Test Plan QMS Principles Quality Audits QMS Approaches Audit Nonconformance ISO 9001: 2015 Model Product NCRs and CARs ISO 9001: 2015 Std. Clauses Action Tracking QMS Document Hierarchy Quality Culture Access to QMS Documents QMS Certification Marafiq Quality Policy Tips for Auditees WHY MARAFIQ EMBRACE QUALITY? Any organization focused on quality promotes a culture that results in the behaviour, attitudes, activities and Processes that deliver value through fulfilling the needs and expectations of customers and other relevant interested parties. 3 Quality affects everyone… Good Quality Poor Quality • • • • • • Loss of reputation Loss of business Liability Poor Productivity Low reliability / operability Higher costs Costs decrease because of less rework, fewer mistakes, delays, better use of time & materials Efficiency & productivity Improves Capture market with better quality and price Business growth 4 QUALITY DEFINITION Quality - degree to which a set of inherent characteristics of an object fulfils requirements Characteristic: distinguishing feature There are various classes of characteristic, such as the following: • physical (e.g. mechanical, electrical, chemical or biological characteristics); sensory (e.g. related to smell, touch, taste, sight, hearing); • behavioral (e.g. courtesy, honesty, veracity); • temporal (e.g. punctuality, reliability, availability, continuity); • ergonomic (e.g. physiological characteristic, or related to human safety); • functional (e.g. maximum speed of an aircraft). Object: entity / item / anything perceivable or conceivable. EXAMPLE - Product, service, process, person, organization, system, resource. Requirement: need or expectation that is stated, generally implied or obligatory. 5 QUALITY DEFINITION Note 1 : “Generally implied” means that it is custom or common practice for the organization and interested parties that the need or expectation under consideration is implied. Note 2 : A specified requirement is one that is stated, for example in documented information. Note 3 : A qualifier can be used to denote a specific type of requirement, e.g. product requirement, quality management requirement, customer requirement, quality requirement. Note 4 : Requirements can be generated by different interested parties or by the organization itself. Note 5 : It can be necessary for achieving high customer satisfaction to fulfil an expectation of a customer even if it is neither stated nor generally implied or obligatory. 6 The Evolution of Quality Concepts Strategic Perspective ISO 9001:2015 Series Risks & Opportunities Balanced Scorecard Understanding Six Sigma Customers SPC Policy & Procedure Business Excellence European Quality Awards US Baldridge Awards Cost / Benefit Analysis ISO 9001:2008 Series EFQM Excellence model ISO 9001 Series BS 5750 Quality Assurance Quality Circles Specification Quality Control Product Focus 7 Process Focus Customer Focus Cultural / Stakeholder Focus Focal Emphasis Business Partnering Quality Management System Management System Set of interrelated or interacting elements of an organization to establish policies and objectives, and processes to achieve those objectives. Quality management System Part of a management system with regard to quality. Marafiq Quality Management System (QMS) consists of: - Quality Policy - Quality Objectives - Quality Manual describing overview of our QMS that is in compliance with ISO 9001: 2015 requirements. - Process Charts of all key processes and related procedures / forms 8 Components of QMS Quality Planning Quality Planning Quality Assurance 9 Quality Quality Control Improvement Part of quality management focused on setting quality objectives and specifying necessary operational processes, and related resources to achieve the quality objectives. Example: • Indentifying risks and opportunities, risk rating, risk classification and preparation of risk management plan. • Establishing quality objectives, measures and targets. • Establishing Quality Plans. Quality Assurance Part of quality management focused on providing confidence that quality requirements will be fulfilled. Quality Assurance deals with prevention of quality problems. Quality Assurance makes the consumers trust the quality of the companies goods & services. 10 Quality Control Part of quality management focused on fulfilling quality requirements. – ISO 9000:2015 The operational techniques and activities that are used to fulfil requirements for quality. It is: Conducting production as per the quality standards. Finding out quality deviations (differences) if any, and use this to improve the quality of production. Inspection: Comparison between specified and actual requirements 11 Quality Improvement Part of quality management focused on increasing the ability to fulfill quality requirements - ISO 9000:2015 12 13 14 Quality Improvement Tools Process Improvement Methodology: Select a process Document Study/document Evaluate Seek ways to Improve it Implement the Improved process Design an Improved process 15 Quality Improvement Tools Benchmarking: • • • • • 16 Identify a critical process that needs improving Identify an organization that excels in this process Contact that organization Analyze the data Improve the critical process QMS Standards ISO 9000:2015 ISO 9001:2015 Quality management systems - Requirements ISO 9004:2018 Managing for the sustained success of an organization - A quality management approach ISO 19011:2018 ISO 10005:2018 17 Fundamentals & Vocabulary Auditing Standard Quality management systems Guidelines for quality plans Quality Management Principles 18 Quality Management Principles 1. CUSTOMER FOCUS 19 Organization depends on their customers & therefore should understand current & future customer needs, should meet customer requirements & strive to exceed customer expectations. Customer focus means producing and supplying the products and services that are liked and wanted by the customer and which provide customer satisfaction. Quality Management Principles 2. LEADERSHIP 20 Leaders establish unity of purpose and direction of the organization. They should create & maintain the internal environment in which people can become fully involved in achieving the organization’s objectives. Unity of purpose is a state in which everyone knows why organization exists. Quality Management Principles 3. INVOLVEMENT OF PEOPLE People at all levels are the essence of an organization and their full involvement enables their abilities to be used for the organization’s benefit. To get involvement of the people three things are essential: - desire to get involved, an interesting work system and - capacity to perform the job. 21 - Quality Management Principles 4. PROCESS APPROACH Process : Set of interrelated or interacting activities which transforms inputs into outputs. 22 A desired result is achieved more efficiently when activities and related resources are managed as a process This principle clearly explains that processes achieve results Processes combine activities, physical, financial and human resources The application of system of processes within an organization, together with identification and interactions of these processes and their management, can be referred to as “Process Approach”. Identifying, understanding and managing inter- related processes as a system contributes to the organization’s effectiveness and efficiency in achieving its objectives. Quality Management Principles 5. IMPROVEMENT Successful organizations have an ongoing focus on improvement. It help to maintain current levels of performance, to react to changes in its internal and external conditions and to create new opportunities. 23 Quality Management Principles 6. EVIDENCE-BASED DECISION MAKING Effective decisions are based on the analysis of data and information. All decisions should be based on facts. By the analysis of relevant data, correct information can be generated. Decisions arrived at on fact based information, reduce risk of failure. 24 Quality Management Principles 7. RELATIONSHIP MANAGEMENT 25 An organization and its suppliers are interdependent. For sustained success, organizations manage their relationships with relevant interested parties, such as providers. Continuous feedback on customer needs and requirements to the supplier ensures continuous supply of quality products. Quality Management Approaches QUALITY MANAGEMENT – THE PROCESS APPROACH 26 Quality Management Approaches QUALITY MANAGEMENT – THE RISK-BASED APPROACH A risk-based approach can answer all unexpected changes that matters proactively rather than purely reactive, preventing or reducing undesired effects and promoting continual improvement. Generalized / Compliance Based QMS 27 Specific / Risk Based QMS Quality Management Approaches Risk: • • Risk management: coordinated activities to direct and control with regard to risk. Effect of uncertainty on objectives. probability of suffering loss or harm to objectives. 1. Risk Management Planning - Methodology -Roles & responsibilities 5.Risk monitoring & control - Implement strategy - Evaluate & document results - Update the plans -identify new risks - Communicate with stakeholders 4. Risk response plan -Take -Transfer - Terminate - Treat 28 -2. Risk Identification -Identify Risk Events 3.Risk analysis -analysis risk -Estimate Likelihood -Identify Impact - Qualify & Quantify Risk - Rank and a shortlist events Quality Management Approaches The Marafiq risk management framework is given below. Establish Marafiq Risk Management System & Apply Risk Mgt Risk Mgt Policy Procedure + + Risk Type Opportunity Risk Proposals Risk Project Risk Operations Risk Risk Register Risk Register Corporate Risk Risk Review Workshop Context: Risks associated with business strategy and activities. Participants: All corporate functions & business lines. Agenda: Identify, analyse and evaluate risks. Create and complete Risk Register Risk Treatment: Risk action plan with due dates. Engagement: communicate, consult. Corporate Risk Register Quarterly Risk Review Review and monitor Risk Register. Update action status. Change: add new risks, increase or decrease existing risks in risk register. Marafiq risk management is detailed in procedure ref. GE-PRC-06. Contact our Risk Facilitator / Coordinator Ahmed Bualy for any assistance. 29 Quality Management Approaches QUALITY MANAGEMENT – CONTINUAL IMPROVEMENT APPROACH 30 ISO 9001 Process Model ISO 9001: 2015 Process Model 31 Clause - 7 ISO 9001 Standard Clauses 32 Marafiq QMS Document Hierarchy 1. 2. 3. 4. Level 1 (Top)– Policy documents (POL) Level 2 (High)- Strategy documents • Manual (MAN) / Plan (PLN) Level 3 (Mid)– Process documents • Process Charts (PCT) Level 4 – Detailed procedures and forms • Procedures (PRC) • Specifications (SPC) • Form (FRM) / Template (TMP) • Work Instructions (WI) Policies Manual / Plan Processes Procedures / Specifications / Templates / Forms Mandatory documents as per ISO 9001 Standard requirements. • Scope of QMS (included in Quality Manual), • Quality Policy, • Quality Objectives (included in Quality Manual, monitored through annual KPI) Organizations to decide requirements of other documents based on: Risks / Complexity / impact of variation in meeting Customer needs, Competency of the person performing the processes concerned, 33 Customer requirements for documentation. Access to Marafiq QMS Documents All QMS documents are accessible (read only) in EDMS. Location: General/Company Management Documents. 2 Ways of access: • through Master List of Corporate Management Documents as all documents are linked with corresponding Document number, • Through Overall process chart and drill down till you get the document. Forms are hyperlinked to the respective process chart or the procedure. All QMS documents, Except Forms/Templates, are converted to pdf. You have to directly access from EDMS WHICH is Controlled. Once document is downloaded to your personal folder or print a copy, it will become Uncontrolled. It is your responsibility to ensure that YOU USE always the Controlled copy. 34 Marafiq Quality Policy Directive of the top management with respect to quality. Who we are, what we do Our policy to implement risk based, ISO 9001 2015 compliant QMS to meet Customer expectations consistently Management Commitments: - Understanding needs & expectations; - Establish and implement processes and control measures to deliver, - Maintain quality through verification, audit, monitoring & communicating. - Maintain quality culture & motivation of our staff by training and engagements - Seek Continual improvement - Periodically review QMS performance 35 All company personnel responsible to comply with this policy Quality Objectives Customer Satisfaction Management System Effectiveness On Time Delivery Quality Objectives Meeting Specifications Staff Performance On Budget Considering the above themes, specific KPIs are decided each year and monitored for their achievement coordinated by Corporate Supports. 36 Marafiq Quality Manual Quality Manual is a brief overview of the quality management system and how Marafiq meets ISO 9001 Standard requirements. Our Quality Manual: • Provides company context for internal, customer, and certification body auditors new to the organization • Demonstrates the organization’s plan to conform to the latest ISO 9001 standard • Sets expectations for both management and employees • Provides steps on implementing QMS • Identifies QMS Processes and their interactions. • Guide clear and concise communication and interfaces between departments in executing jobs. See Marafiq Quality Manual ref. QA-MAN-01 for details. 37 Marafiq QMS Processes We have determined the processes needed for our QMS and their application. For each process, we will: • Determine the inputs and outputs required • Determine the sequence and interaction with other connected processes • Determine and apply the criteria and methods needed for effective operation and control • Determine the resources needed and their availability • Assign the responsibilities and authorities • Address the risks and opportunities • Evaluate these processes and implemented any changes • Improve the processes. The Overall business process and some key processes identified for Marafiq is given in the next slide. 38 Overall Business Process Management Business Processes Business Context – Customer & Stakeholder needs, Issues and Risks & Opportunities Core Business Processes Customer Delight Customer Needs Support Business Processes 39 Admin. HR + + PR / ICV IT IM + Legal HSE Quality + + Finance Maintain Asset + Contracting Procurement + + Pursuit Process Strategize to Win Market Understanding and Positioning Sales & Marketing Proposals 40 Asset Creation Process Create Asset Solicit Opportunity Operate Asset Move to Operate Note: 41 Processes performed by Marafiq Processes performed by EPC Contractor EPC Contractor Management Process 42 Asset Operation Process DPC Power & Desalination plant operation has its on Business Manual detailing applicable process and procedures. For details, contact the Plant Manager Chatsuwan Kittichai. 43 Drinking Water Business Overall Process Performance Evaluation, Monitoring, Analysis and Improvement 44 Procurement Process 45 Marafiq Quality Management Process Context of Business Business needs Stakeholder needs Legal needs Internal/external issues Risks and opportunities GE-PRC-01 GE-PRC-02 CMS Audits GE-PRC-03 NCR Capture QMS Requirements Start Establish QMS Documentation and implement on Business Processes Establish Audit Programme. Plan and conduct quality reviews and meeting Carry out Internal Audits Ensure Product / service reviews / verifications / inspections Changes to QMS due to changes in context, risks, new requirements Decision/action on resources, tools, QMS improvement actions Log in Action Log and monitor completion of actions CAR Action Log 46 Review Result? GE-PRC-05 GE-PRC-04 Mgt Review CAR Perform management Review Mgt Review Report Monitor achievement of quality objectives / KPIs NCR, NCR Log Inspection Report Audit Report ISO 9001: 2015 Nonconformance control and corrective actions Analyze trends, perform root cause analysis and take corrective actions CAR, CAR Action Log KPI Report Audits KPIs Client Complaints Reviews / Checks Inspections Feedback Project Quality Management Process Start Review overall Project Risk Conduct Risk Workshop. List and review Risks Quarterly Capture Engineering Quality needs Capture Procurement Quality needs Capture Construction Quality needs Project size? Incorporate Quality Small Planning in Project Execution Plan Large Project Quality Management Process Prepare and issue stand-alone Project Quality Plan Prepare Budget and Resourcing for quality plan implementation Execute Quality control, assurance and monitoring as per Quality Plan Review and Track Progress and trends Communicate performance to Leadership and staff as relevant Conduct QMS Management Review & Follow up Provide feedback for improvement and participate in Lessons Learned. End 47 Water Quality Management Process Water Quality Assurance Process Water Quality Plan Quality requirements of Public Authority for Water Start Prepare and get approval for Water Quality Plan considering various risks from water source, reservoirs and transmission/distribution. Prepare and get approval for specific inspection, monitoring and test plans and procedures. Stop 48 Organize resources like test equipment, test medium and other materials as applicable and implement Quality Plan Implement corrective actions as per corrective action procedure GE-PRC-04. O&M Contractor implement action, e. g. adjust chemical dosage, operating parameters Re-test / inspect / monitor to ensure the water quality has improved. Evaluate inspection / test results and maintain reports. Review and accept Test report from external test laboratories. Quality function & Water Quality operator analyze trends in inspection / test findings bi-annually to identify systemic corrective actions. OK? No Yes Investigate and identify root cause along with Technical. Recommend action for rectification. Quality function audit water quality assurance process to ensure compliance Project Execution Plan Project Execution Plan (PEP) provides a guidance on the framework for execution of projects based upon established standards, processes and work practices. Project Quality Plan A PEP will contain, or make dereference to Project Quality Plan. The Project Quality Plan (PQP) is a documented description of the project management system. It draws together the key documents, which: – describe the quality objectives of the project, – identify the critical QA/QC activities and, – define the controls required to ensure that the project quality objectives are met. 49 Inspection and Test Plan (ITP) • ITP assures that the product will be built in accordance with project specifications, code & standard requirements. • ITP describes the minimum requirements of the quality control activities, Inspection & Test items during fabrication / construction phase, reference documents, required acceptance criteria, certifying or verifying documents, and inspection parties involve. • ITP should be based on the contract specifications, approved drawings and design data sheets. • All review, witness and hold points are mentioned stage wise in ITP. • ITP should be approved by client before start of the work. 50 Quality Audits A quality audit is a systematic, independent and documented process for obtaining audit evidence and evaluating it objectively to determine the extent to which agreed criteria are fulfilled. 100 100 Requirements Results • Quality Manual • Plans • Specifications • Procedures • Standards etc 0 0 The “GAP” measures the lack of effectiveness of the process. The narrower the gap, the more effective. 51 Quality Audits Quality Audit is performed as per procedure GE-PRC-02. Establish Objectives Review and Improve Determine risk and opportunties Monitor Establish Programme Implement Type of Audits • First Party / Internal • Second Party / External • Third Party • Extrinsic Audit 52 Nonconformance 53 Product NCR & CAR 54 Register/Log/Tracker Sl. No. 55 SOR/NCR No. Finding Type / Classification SubProcess Title of finding / brief description of finding Proposed Action Target Date Closing Date Follow up remarks Quality Culture Quality Starts with you. • Expertise and motivation depend on the individual. • Creative thinking skills can be taught. • Continually improve your technical and soft skills to be more efficient. 56 People Build Quality Build relationships to accomplish task Commitment to task and team members Trust & mutual accountability Organize Be flexible Learn Group with different goals Ideal Team The organization that learns to use the diversity of its people to improve its competitive position is ahead of the game. In a quality driven organization, everyone in the organization is empowered! 57 STORY OF THE STONE CUTTER My friend, can you tell me what you are doing? 58 QMS Certification The ISO certificate helps to improve our business credibility and authority as well as the overall efficiency of the business. • Improved customer satisfaction and loyalty • Happier and more competent employees • Better quality products and services • Increased efficiency, fewer mistakes, and less wasted time • Reduced overall risks 59 Tips For the Auditee Prepare for the Audit • Quality policy and objectives: Review the quality policy, objectives & quality manual. • Documentation: Make certain that you know where to get updated copies of documentation pertaining to your roles and function. Answer to Interview Questions • Honesty: Be confident and answer the question directly with honestly. • Answer to the point: Answer to the point. Do not side track or provide extra information to demonstrate your knowledge. • Ask queries: If you do not understand the question, just ask. • Able to say “I don’t know”: If the question is related to your area and you are unsure how to respond, just say “I don’t know.” • Do not volunteer to answer questions that are not in your area: Direct to the concerned person for questions not related to you. • No Argument with Auditor: Be graceful to accept any areas of improvement or NCR. You can clarify, but not justify or argue. • No blame Game: Audit is on Marafiq processes, not on individuals. So do not panic and pass the bucket to others when gaps are identified. • Seek Help: When in need, seek help from your peers or supervisor. 60 THANK YOU joseph@Marafiq.om 61 Always ask when . in doubt