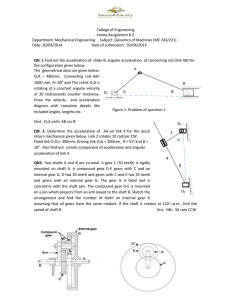

Mechanical And Industrial Engineering Department Vehicle Transmission Drives (Gear Box) 1. Introduction The gearbox is a mechanical device used to increase the output torque or to change the speed (RPM) of a motor. The shaft of the motor is connected to one end of the gearbox and through the internal configuration of gears of a gearbox, provides a given output torque and speed determined by the gear ratio High torque is required to start the vehicle from rest, accelerating, hill climbing, pulling a load and facing other resistances. But the IC engine operates over a limited effective speed range which produces a comparatively low torque. In such a situation, the engine is responsible for the stall and the vehicle rests if the speed falls below the limit. The torque developed by the engine is increasing within limits with the increase of engine speed and reaches a maximum value at some predominant speed. If the engine directly connects to the driving axle, the engine speed may reduce. Due to the variable nature of the vehicle resistance resulting in load and gradient changes, it requires that the engine power should be available over a wide range of road speeds. Hence, for this reason, the engine speed maintain by using a reduction gear resulting in the road wheels rotating at a proper speed suited to the operating conditions of the vehicle. Therefore, a single torque multiplication in the rear axle must be interposed and a variable multiplication factor in the gearbox is provided for this purpose. 2. Objectives To design gear box which uses simple mechanism to reduce/increase speed, increase torque and change the direction of rotation easily. Machine Design Project II Page 1 Mechanical And Industrial Engineering Department 3. Types of gear box There are two main types of Gearbox in an Automobile: 3.1.Manual transmission and 3.2. Automatic transmission But for this discussion, we only focussed on the manual transmission. 3.1. Manual transmission In a manual transmission type of gear system, the driver gets total control and chooses all gear manually operating both a movable gear selector and a driver-operated clutch. This type of transmission is also known as a stick shaft or a standard transmission. This manual transmission allows the driver to either drop a gear to make the faster process or choose an increased gear to conserve fuel. Following are the types of gearbox used in modern vehicles:3.1.1. Sliding mesh type gearbox 3.1.2. Constant-mesh type gearbox 3.1.3. Synchromesh gearbox 3.1.4. Epicyclic gearbox 3.1.1. Sliding Mesh Gear Box It is the simplest type of gearbox. The arrangement of gears is in a neutral position. The gear housing and bearing are not shown. The clutch gear is fixed to the clutch shaft. It remains always connected to the drive gear of the counter-shaft. Three other gears like first speed, second speed, and reverse speed gear are also rigidly fixed to the countershaft or also known as lay shaft. Two gears mounted on the splined main shaft can be slid by the shifter yoke when the shift lever is operated. The gears are connected to the corresponding gears of the countershaft. A reverse idler gear is fixed on another shaft and remains connected to the reverse gear of the countershaft The main parts of the sliding mesh gearbox are:3.1.1.1.Shafts Main Shaft-It is the shaft used as an output shaft in a sliding-mesh over which the sets of gears with internally splined grooves are arranged in an organised fashion. Machine Design Project II Page 2 Mechanical And Industrial Engineering Department Clutch Shaft-It is the shaft that is used to carry engine output to the transmission box with the help of engaging and disengaging clutch which is mounting at the engine end, gear or a pair of gear is mounted over this shaft which is used to transmit rotational motion to the lay shaft. Lay Shaft-It is the shaft having gears mounted over its outer surface and is in continuous rotation with the clutch shaft as one gear of this shaft is always in contact with a gear on the clutch shaft, it is used as an intermediate shaft that provides the meshing of the gears of the main shaft in order to transmit appropriate output to the final drive. 3.1.1.2.Gears Two types of gear were usually used in sliding mesh gearbox. Spur gear- This is the type of gears having straight-cut teethes over its surface, straight teethes proving maximum meshing area. Helical gear- This is the type of gear in which the teethes are cut in an angular fashion, unlike spur gears this type of gears are smooth and less noisy 3.1.1.3.Gear lever It is the selecting mechanism operated by the driver in order to select the appropriate gear ratio, this liver is connected to the main shaft along with the selector forks. 3.1.2. Constant Mesh Gearbox In this type of gearbox, all the gears of the main shaft are in constant mesh with the corresponding gears of the countershaft (lay shaft). In this case sliding two dog clutches are provided on the main shaft. The one sliding dog clutch is placed in between the clutch gear and the second gear, and the other is placed in between the first gear and reverse gear. All gears are free on the splined main shaft. Dog clutch slides on the main shaft to rotate with it. All the gears on the countershaft are fixed with it. When the left-hand dog clutch is made to slide to the left through the gearshift lever, it meshes with the clutch gear and the top speed gear is achieved. When the left-hand log clutch meshes with the second gear, the second speed gear is obtained. Likewise, by sliding the right-hand dog clutch to the left and right, the first gear and reverse gear are obtained. Machine Design Project II Page 3 Mechanical And Industrial Engineering Department In this type of the gearbox, all the gears are in constant mesh, they are safe from being damaged and unpleasant grinding sound does not occur while engaging and disengaging them. The main components of constant mesh gear box 3.1.2.1.Shafts – There are 3 shafts. Main Shaft (output shaft):- It is the splined shaft over which the dog clutches along with gears are mounted. Gears on this shaft are free to rotate. Lay Shaft or Counter Shaft: -It is an intermediate shaft between the Main Shaft and Clutch Shaft. The gears of counter shaft are in constant mesh with gears of main shaft. Also the gears of counter are shaft are not free to rotate as they are directly connected to the Counter Shaft. Clutch Shaft:-The clutch shaft carries the engine output to the gearbox but act as input for the gearbox. 3.1.2.2.Dog Clutch- The dog clutch couples the lay shaft and main shaft by interference and not by friction. 3.1.2.3. Gears- Gears of constant mesh gearbox come in pairs. All gears of lay shaft or counter shaft are always paired with gears of main shaft or output shaft. Two type of gears are used in constant mesh gearbox: Helical Gears- These gears have angular cut teeth over cylindrical cross-section metal body. Bevel Gears- These gears have angular cut teeth over conical cross-section metal body. 3.1.2.4. Gear Lever-it is the lever used for shifting or siding the dog clutches over the main shaft and is operated by the diver. 3.1.3. Synchromesh Gearbox Modern cars use helical gears and synchromesh devices in the gearboxes, that synchronize the rotation of gears that are about to mesh. This eliminates clashing of the gears and makes gear shifting easier. This type of gearbox is similar to the constant mesh gearbox. The synchromesh gearbox is provided with a synchromesh device by which the two gears to be engaged are first taken into frictional contact which adjusts their speed after which they are engaged easily. Machine Design Project II Page 4 Mechanical And Industrial Engineering Department In most vehicles, the synchromesh devices are not fitted to all the gears. They are fitted only on the top gears. Reverse gear, and in some cases the first gear, do not have synchromesh devices. Because they are intended to be engaged when the vehicle is stationary. When the gear lever is moved the synchromesh cone meets with a similar cone on the pinion. Due to friction the rotating pinion is, made to rotate at the same speed as the synchromesh unit. To give a positive drive further movement of the gear lever enables the coupling to override several springs loaded balls and the coupling engages with the dogs on the ride of the pinion. Since both pinion and synchromesh units are moving at the same speed, this engagement is necessary before engaging the dog teeth so that the cones have a chance to bring the synchronizer and pinion to the same speed Synchromesh Gearbox consists of the following key components 3.1.3.1. Engine Shaft 3.1.3.2.Lay Shaft 3.1.3.3. Output Shaft 3.1.3.4. Gears on Lay shaft 3.1.3.5. Gears on Output shaft 3.1.3.6.Cone 3.1.3.7.Synchronizer Hub 3.1.3.8.Synchronizer Ring 3.1.4. Epicyclic Gearbox In an ordinary gearing, the axes of the various gears are fixed, the motion of the gears being simply rotations about their own axes. In epicyclic gearing, at least one gear not only rotates, about its own axis but also rotates bodily about some other axis. These types of gearbox are the most widely used automatic transmission system. In an automatic transmission system, there is only an accelerator and brake will be provided. So there will not be any clutch pedal or gear lever available on the vehicle Epicyclic Gearbox Parts The three basic components of the epicyclic gear are:3.1.4.1 Sun gear:- it is the central gear Machine Design Project II Page 5 Mechanical And Industrial Engineering Department 3.1.4.2 Planet carrier:- Holds one or more peripheral planet gears, of the same size, meshed with the sun gear 3.1.4.3 Annulus or Ring Gear:- An outer ring with inward-facing teeth that mesh with the planet gear or gears In many epicyclic gearing systems, among the three basic components, one component is held stationary; one component is input, provide power to the system and last component is output, receive the power from the system. The ratio of input rotation to output rotation is dependent upon the number of teeth in each gear, and upon which component is held stationary. 4. Working mechanism The working of a manual transmission system contains a set of gears along with a pair of shafts which is the input and output shafts. The gear on the first shaft engages with those on the other shaft. The ratio between the selected gear on the input shaft and the engages on the output shaft determines the overall gear ratio for that gear. Gears are engaged in manual transmission system by moving the shift lever. The engagement is done by the linkages that control the movement of the gears along the input shaft. Cars with four gears or speed have two linkages and cars with five or six speeds have uses three linkages. These linkages changes by moving the shift lever left and right. Clutch plays an important role in the working of the manual transmission as disconnect the engine from the input shaft of the transmission when pressed. It frees the gears on the input shaft causing it to easily move as the engine is sending torque through the input shaft. This caused the engagement. The clutch is said to be disconnected when the clutch lever is not press. Once the clutch disconnects the power from the engine to the transmission, the driver easily selects the gear and release the clutch. Releasing the clutch allowed engine power to be reengaged to the input shaft which makes the car to move at the selected gear ratio. A gearbox contains gears of different sizes. The first gear is the biggest in a gearbox and provides maximum torque output while producing minimum speed. All the gears between 1st and last gear vary Machine Design Project II Page 6 Mechanical And Industrial Engineering Department in size, in a decreasing ratio. Thus, it provides a varying combination of pulling ability and speed. The gearbox, basically, improves the vehicle’s driveability in all conditions. Generally, there are two sets of gears in a conventional gearbox – the input & the output. The input gears are fixed on the countershaft, making them single units. It drives the individual gears on the main shaft, which rotates freely on the bearings. Thus, the gearbox passes the drive to the wheels depending upon the gear which engages on the main shaft. Furthermore, when you push the shiftersleeve towards the desired gear, that gear locks onto the main shaft and rotates it. Thus, the main shaft rotates at the engaged gear’s speed and provides the output according to the engaged gear’s ratio. THE RECOMMENDATION: It is better the working mechanism be sequential like the input power from the engine drives the initial gear(gear mounted on the motion is transferred to the lay shaft clutches shaft )and this by the gear mounted on it. due to this gear the lay shaft rotates ,the rotation of lay shaft is transferred to the main shaft .the output motion is depending on the gears that mesh with the gear in the lay shaft using synchronizer or slider. 5. Main components of gear box 5.1. Clutch shaft/driving shaft/input shaft A clutch shaft is a shaft that takes power from the engine to supply another shaft. The clutch shaft or driving shaft is connected through the clutch and when the clutch is engaged, the driving shaft also rotates. Only one gear is fixed on the clutch shaft and this engine rotates with the same speed as the crankshaft. In addition, the driving shaft and main shaft are in the same line. 5.2. Countershaft/lay shaft The counter shaft is a shaft that connects directly to the clutch shaft. It has gear which connects it to the clutch shaft as well as the main shaft. It can be run at engine speed or below engine speed according to gear ratio. 5.3. Main shaft /output shaft The main shaft or output shaft that rotates at different speeds and also provides the necessary torque to the vehicle. The output shaft is a splined shaft, so that the gear or synchronizer can be moved to engage or disengage. 5.4. Bearings The bearings are required to support the rotating part and reduce friction. The gear box has both a counter and main shaft which is supported by the bearing. 5.5. Gears Machine Design Project II Page 7 Mechanical And Industrial Engineering Department Gears are used to transmitting the power from one shaft to another shaft. The amount of torque transmitted through the gears depends on the number of teeth and the size of the gears. Higher the gear ratio, higher the torque / acceleration and lower the speed. All gears except those on the main shaft are fixed to their respective shafts; they can slide in any of the directions along the shaft. 5.6. Gear selector fork Gear selectors are simple devices that use a lever that selects gears to engage in disengages mechanisms. The motion of the lever slides the engaging part on the shaft. It depends on the type of gearbox whether the lever slides the gear or synchronizer that is already forged along the main shaft. 6. Advantages and disadvantages of each type of gear box 6.1. A) Advantages of Sliding Mesh Gearbox Since only one gear is in mess in the sliding mesh gearbox so less fluctuating loads on shafts causing less vibration and noise Unlike the contact mesh gearbox in which all gears are in constant mesh. Its efficiency is more than a constant gearbox as only one gear is in mess, unlike the contact mesh gearbox in which all gears are in constant mesh. Its manufacturing is easy as compared to a constant mesh gearbox. The mechanism of this gearbox is simple compared to Constant Mesh Gearbox and Synchromesh Gearbox. 6.1. B) Disadvantages of Sliding Mesh Gearbox Only spur gears can be used as gears are not in a constant-mesh gearbox in which helical or herringbone gears can be used. More effort is required to engage the gear as the gear has to be slide in sliding mesh gearbox, unlike constant mesh gearbox where only dog clutch has to be a slide for engagement of different gears. Less life of gear as more wear and tear of gear is caused in sliding mesh gearbox due to friction. It takes more time and money to replace the gears if the gearbox fails The Mechanical Efficiency was very low in the case of Sliding Mesh Gearbox. The driver requires considerable skill for changing the gears because the gears of main shaft and lay shaft are away from each other. Machine Design Project II Page 8 Mechanical And Industrial Engineering Department 6.2. A) Advantages of Constant Mesh Gearbox There is no need for straight spur gears because the gears were always in mesh in the case of constant mesh gearbox. Instead, helical gears will be used which are quiet running Helical gears are used in this system to avoid vibrations during the engagement. During engagement and disengagement, the wear of dog teeth is reduced because all the teeth of dog clutches are involved in the meshing when compared to the sliding gears where only 2 or 3 teeth were under the mesh. The noise level was very low and Mechanical Efficiency was very high compared to Sliding Mesh Gearbox. Since the gears are engaged by dog clutches, if any damage occurs while engaging the gears, the dog unit members get damaged and not the gear wheels 6.2. B) Disadvantages of Constant Mesh Gearbox To avoid little vibrations taking place during the engagement of dog clutch with the gears on the main shaft, it is advised to use synchronizers which can reduce the effect of the vibrations. Double declutching was the biggest disadvantage of Constant Mesh Gearbox It is less efficient than the others due to higher mesh teeth. Skill is required for it. The double clutch mesh is required. This is required to have the spinning movements of the shaft 6.3. A) Advantages of synchromesh gearbox It provides smooth & quite shifting of gears due to use of Synchronizer Ring and Sliding sleeve. No need of skill to operate. It has more power transmission capacity as compared to constant mesh gearbox. No Double Declutching is required. The biggest disadvantage of Constant Mesh Gearbox has been solved by the Synchromesh Gearbox i.e. Double-Declutching. The noise problem during the engagement of Gears has been minimized in the Synchromesh Gearbox. Machine Design Project II Page 9 Mechanical And Industrial Engineering Department Due to the presence of Synchronizers, the quick shifting of gears is possible. During transmission, there is no loss of Torque due to the presence of synchronizers. Smooth and Noise free shifting of gears which is most suitable for cars. No loss of torque transmission from the engine to the driving wheels during gear shifts. Double clutching is not required. Less vibration 6.3. B) Disadvantages of synchromesh gearbox It is Bulky gearbox. It is Expensive. It requires more space Improper gear changing will lead to the failure of gears. It is expensive compared to the other gearbox due to the usage of Synchronizers. Where cost is the consideration, synchronizers can only be used to higher gears whereas dog clutches are used for lower gears and Reverse gears. When teeth make contact with the gear, the teeth will fail to engage as they are spinning at different speeds which cause a loud grinding sound as they clatter together. Improper handling of gear may easily prone to damage. Cannot handle higher loads 6.4. A) Advantages of Epicyclical Gearbox High reduction ratios Compact and lightweight with high torque transmission High radial loads on the output shaft It is quieter in operation Uniform distribution of load over all gears having greater tooth contact. All gears are constantly in mesh, so a change of one gear to another is possible without any loss. It Exist with higher gear ratio It increase the driver comfort It is also used in bicycle for controlling power during pedalling 6.4. B) Disadvantages of Epicyclical gear systems Design complexity Machine Design Project II Page 10 Mechanical And Industrial Engineering Department Assembly of gears is limited to specific teeth per gear ratios Efficiency calculations are difficult Driver and driven equipment must be in line to avoid additional gearing The cost of manufacturing is high. Constant lubrication is required High bearing loads Continuously lubrications is required 7. Design procedure for Gear Box One has to follow a procedure to complete a task and the design of an important part of an automobile. Follow these procedures to have an idea about how to design a complete Gear Box with each component's individual design. 7.1. Determine the maximum and minimum speeds of the output shaft. This will determine the complete speed ratio. Calculate the number of steps or speed reduction stages for this range. This depends on the application as well as space optimization. Higher reduction stages require more space because of more number of gears and shafts requirements. 7.2. Select the type of speed reducer or gearbox based on the power transmission requirements, gear ratio, positions of the axis, space available for speed reducer. Also, make sure that for low gear ratio requires single-speed reduction. Select worm gears for silent operation and bevel gears for intersecting axis. 7.3. Determine the proggression ratio which is ratio maximum speed and minimum speed of output shaft of Gear Box. The nearest progression ratio should be a standard one and is taken either from R 20 or R 40 series. 7.4. Draw the structural diagram and kinematic arrangement indicating various arrangement possibilities during speed reduction or increment. 7.5. Select materials for gears so that gear should sustain the operating conditions and operating load. Normally cast iron is chosen for housing and cast steel or other alloy can be selected as per the load requirements. 7.6. Note down the maximum power output in Horse Power (H.P) or transmission power and revolution per minute of short i.e. rpm of each shaft. 7.7. Determine the centre distance between the driven and driver shaft based on the surface compressive stress. Machine Design Project II Page 11 Mechanical And Industrial Engineering Department 7.8. Determine the module of gear by beam strength as well as fix the number of teeth required. 7.9. Calculate the diameter of the shafts by torque requirements and bending moment considerations. 7.10. Calculate the key size, shape or type of transmission keys for each gear. 7.11. Select appropriate fit and tolerance for mating parts like shaft and gear. 7.12. Select bearings types based on the loading and operating conditions. Also, make sure to include consideration of maximum speed and expected life of gears and gearboxes. Normally ball bearings and roller bearings are used for the small size of gearbox because they have lower thrust requirement due to low-speed reduction. 7.13. Make the shaft stepped or provide collar to prevent axial displacement of bearing and gear. 7.14. Provide suitable clearance between gears and walls of the housing of a gearbox and based on these considerations design the casing/housing of the gearbox. 7.15. Complete the design of the casing. One should provide fins if necessary to have increased heat transfer by convection and conduction. Put inspection hole/manhole as well as a drain hole to drain lubricating oil. Also, provide an oil level indicator to have the proper amount of oil during operation, if not put, this will lead to failure of gear and shaft due to overheating or due to frictional failure. Provide transportation hooks for transporting the gearbox from one place to another or during installation and maintenance. Also, design gear changing lever accordingly. 7.16. Draw neat and clean working drawings in suitable software like AutoCAD, Pro-Engineer etc., indicating required details during manufacturing or assembly. 7.17. One can also perform finite element analysis of the complete Gear Box after it completely designed 8. Conclusion Generally, 9. References ………………………………………………………………………….. ……………………………………………………………………………… Machine Design Project II Page 12