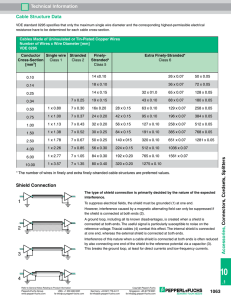

SHORT CIRCUIT PERFORMANCE OF METALLIC SHIELDS AND SHEATHS ON INSULATED CABLE ICEA PUBLICATION P-45-482-2013 Revised February 27, 2013 2013 by INSULATED CABLE ENGINEERS ASSOCIATION, Inc. --``````,,,,,```,``,``,,``,,-`-`,,`,,`,`,,`--- ICEA P-45-482-2013 Approved as an American National Standard ANSI Approval Date: February 27, 2013 Insulated Cable Engineers Assoc., Publication No. P-45-482-Revised 2013 Published by Insulated Cable Engineers Association P.O. Box 1568 Carrollton, Georgia 30112 www.icea.net © Copyright 2013 by the Insulated Cable Engineers Association, Incorporated. --``````,,,,,```,``,``,,``,,-`-`,,`,,`,`,,`--- Short Circuit Performance of Metallic Shields and Sheaths on Insulated Cable ICEA P-45-482-2013 NOTICE AND DISCLAIMER The information in this publication was considered technically sound by the consensus of persons engaged in the development and approval of the document at the time it was developed. Consensus does not necessarily mean that there is unanimous agreement among every person participating in the development of this document. The Insulated Cable Engineers Association, Inc. (ICEA) standards and guideline publications, of which the document contained herein is one, are developed through a voluntary consensus standards development process. This process brings together persons who have an interest in the topic covered by this publication. While ICEA administers the process and establishes rules to promote fairness in the development of consensus, it does not independently test, evaluate, or verify the accuracy or completeness of any information or the soundness of any judgements contained in its standards and guideline publications. ICEA disclaims liability for personal injury, property, or other damages of any nature whatsoever, whether special, indirect, consequential, or compensatory, directly or indirectly resulting from the publication, use of, application, or reliance on this document. ICEA disclaims and makes no guaranty or warranty, expressed or implied, as to the accuracy or completeness of any information published herein, and disclaims and makes no warranty that the information in this document will fulfill any of your particular purposes or needs. ICEA does not undertake to guarantee the performance of any individual manufacturer or seller’s products or services by virtue of this standard or guide. In publishing and making this document available, ICEA is not undertaking to render professional or other services for or on behalf of any person or entity, nor is ICEA undertaking to perform any duty owed by any person or entity to someone else. Anyone using this document should rely on his or her own independent judgment or, as appropriate, seek the advice of a competent professional in determining the exercise of reasonable care in any given circumstances. Information and other standards on the topic covered by this publication may be available from other sources, which the user may wish to consult for additional views or information not covered by this publication. ICEA has no power, nor does it undertake to police or enforce compliance with the contents of this document. ICEA does not certify, test, or inspect products, designs, or installations for safety or health purposes. Any certification or other statement of compliance with any health or safety-related information in this document shall not be attributable to ICEA and is solely the responsibility of the certifier or maker of the statement. ICEA P-45-482-2013 Page i CONTENTS Page Foreword .....................................................................................................................................ii Section 1 Section 2 GENERAL .................................................................................................................................. 1 1.1 SCOPE ......................................................................................................................... 1 1.2 REFERENCES ............................................................................................................. 1 FORMULAE AND CALCULATIONS.......................................................................................... 3 Section 3 Tabulated Parameters ............................................................................................................... 5 LIST OF TABLES Table 1 Table 2 Table 3 Table 4 Table 5 Table 6 Formulas for Determining Metallic Shield/Sheath Cross-sectional Area……………………4 Parameters for Use in Equations (1), (2) or (3)...................................................................5 Values of T1, Approximate Shield or Sheath Operating Temperature, ºC at Various Conductor Temperatures....................................................................................................5 Values for T2, Maximum Allowable Shield or Sheath Transient Temperature, ºC..............6 M Values for T2 Temperature of 200 ºC………………………………………………………..6 M Values for T2 Temperature of 350 ºC………………………………………………………..7 © Copyright 2013 by the Insulated Cable Engineers Association, Incorporated. ICEA P-45-482-2013 Page ii Foreword This publication discusses factors for consideration in approximating the operability of insulated and/or covered wire and cable under the influence of uninterrupted short circuit currents encountered as a result of cable or other equipment faults. The duration of such a fault is considered to be up to approximately 2 seconds. Calculation for single short circuits of longer durations will yield increasingly conservative results. The following items must be considered in order to estimate the short circuit performance of a specific circuit: 1. The magnitude and duration of the fault current including any fault current division due to available conducting paths. 2. The capability of joints, terminations and other accessories in the affected circuit to withstand the thermal and mechanical stresses created by the fault. 3. The interaction between the faulting circuit and surrounding equipment, such as supports, ties and clamps. 4. The capability of the affected cable circuit, as installed, to withstand the electromagnetic forces created during the fault. 5. The maximum temperature that cable components can withstand without incurring damage due to heating caused by fault current flow. 6. Damage to adjacent equipment due to arcing at the site of the fault. 7. For limitations imposed on the short-circuit current in the cable phase conductor see ICEA Publication P-32-382, Short Circuit Characteristics of Insulated Cable. --``````,,,,,```,``,``,,``,,-`-`,,`,,`,`,,`--- An important simplifying assumption in the formula is the adiabatic nature of the heat generated, i.e., the duration of the fault is so short that all the heat developed by the fault current during this time is assumed to be completely contained within the sheath or shield. The amount of heat dissipated from the sheath or shield during continuous, single fault occurrences of relatively short duration is small. A significant amount of heat may be dissipated because of the relatively long cooling periods involved for faults interrupted and reestablished with automatic reclosing of circuit protective devices. A non-adiabatic calculation may be more suitable for these situations and for single, uninterrupted short circuits in excess of 2 seconds requiring close accuracy. Non-adiabatic calculation methods are described in several published works listed in Section 1.2 “References”. The formula (1) described in this publication is based on the thermal capacity of the metallic sheath/shield material and the transient temperature limit of the adjacent cable component materials. The quantity of heat contained in the metallic sheath/shield is that created by the fault current and is also a function of the temperature rise in the metallic sheath/shield. The magnitude of the temperature rise is the difference between the upper temperature of the cable material in contact with the sheath/shield and the operating temperature of the sheath/shield immediately prior to the initiation of the fault. The operating temperature of the sheath or shield depends on the temperature of the conductor and the insulation thickness which is determined by the cable voltage rating. See Section 3, Table 3 for suggested estimated values. ICEA P-45-482-2013 Page iii The maximum transient temperature limits of the cable component materials are those which cause no significant change in the materials. These limits were extrapolated from laboratory test data. Suggestions for improvements in this publication are welcome, and should be sent to ICEA at the address below. Insulated Cable Engineers Association, Inc. P.O. Box 1568 Carrollton, GA 30112 --``````,,,,,```,``,``,,``,,-`-`,,`,,`,`,,`--- © Copyright 2013 by the Insulated Cable Engineers Association, Incorporated. ICEA P-45-482-2013 Page iv <This page intentionally left blank> ICEA P-45-482-2013 Page 1 Section 1 GENERAL 1.1 SCOPE Wires, applied ether helically, as braid or serving; or longitudinally with corrugations. Helically applied flat tape, not overlapped. Helically applied, overlapped, flat tape. Corrugated tape, longitudinally applied. Tubular sheath. The types of cable materials in contact with the sheath or shield are: crosslinked (thermoset), thermoplastic, impregnated paper, and varnished cloth. The materials which determine the maximum allowable short circuit temperatures are: paper, varnished cloth and several thermoplastic and thermosetting materials presently appearing in ICEA standards. Temperature limits, considered safe, were established for the various coverings and insulation materials. The equations may be used to determine: 1.2 The maximum short circuit current permitted for a specific sheath/shield and short circuit duration. The sheath/shield size necessary to carry a specific short circuit current for a given duration. The maximum duration a specific sheath/shield can carry a specific short circuit current. REFERENCES The following references were reviewed in preparing this document. The Transient Temperature Rise of Round Wire Shields of Extruded Dielectric Cables Under Short Circuit Conditions, M. A. Martin Jr., A.W. Reczek Jr., IEEE-ICC Open Forum at 57 Meeting Nov. 17-19, 1975. Optimization of Design of Metallic Shield-Concentric Conductors of Extruded Dielectric Cables Under Fault Conditions, EPRI EL-3014, Project 1286-2, final Report 4/83. Optimization of Metallic Shields for Extruded Dielectric Cables Under Fault Conditions, IEEE Paper 86 T&D 339-B. © Copyright 2013 by the Insulated Cable Engineers Association, Incorporated. --``````,,,,,```,``,``,,``,,-`-`,,`,,`,`,,`--- Equations and parameters have been established for short circuit calculations for sheaths or shields made of aluminum, bronze, copper, lead, steel, zinc and cupro-nickel alloys. The types of sheaths or shields included are: ICEA P-45-482-2013 Page 2 Normal and Short Circuit Operating Characteristics of Metallic Shielded Solid Dielectric Power Cable. M.A. Martin Jr., D. A. Silver, R. G. Lukac, R. Suarez, IEEE Paper 973 495-9. Fault Test on Embedded Copper Wire and Copper Tape Shielded Single Conductor Cables. C. Landinger, L. D. Cronin, IEEE Paper C73-124-5. Buried Power and Telephone Distribution Systems-Analysis of Primary Cable Fault Tests and Evaluations of Experience With Random Separation, EEI Pub. 68-62. The Short Circuit Rating of Thin Metal Tape Cable Shields, AIEE Trans, Vol. 87, pp. 740-758, March 1968. Fault Current Rating of Metallic Cable Screens, T. M. White, S. E. Philbrick, JICABLE 1087, Paper B6.2. Are Cable Shields Being Damaged During Grounds Faults?, P. S. Hamer, B. M. Wood. IEEE Transactions on Industry Applications, Paper PID-86-6. Design of Metallic Shields for Extruded Dielectric Cables, 1984 IEEE IAS Pulp and Paper Conference, D. A. Silver, M. D. Buckweitz, Paper PPI-84-14. Calculations of Thermally Permissible Short Currents Taking Into Account Non-Adiabatic Heating Effects, IEC Publication 60949-9-1988. Standard Handbook for Electrical Engineers, Tenth Edition, Page 4-87, paragraph 211. --``````,,,,,```,``,``,,``,,-`-`,,`,,`,`,,`--- ICEA P-45-482-2013 Page 3 Section 2 FORMULAE AND CALCULATIONS Short circuit current, short-circuit time or effective cross-sectional area of shield or sheath can be calculated from the basic equation where the materials surrounding the shield/sheath are not damaged: T λ T2 λ (1) 247.0x10 6 SGSH 0 Log10 P A 0 T1 λ Where: I0 = Short-circuit current, amperes. A = Effective cross-sectional area of the shield or sheath, circular mils. t = Time for short circuit, seconds. SG = Specific gravity of shield or sheath material. SH = Specific heat of shield or sheath material. T0 = Arbitrary temperature (usually considered 20ºC). P0 = Specific resistivity of shield or sheath material at temperature T 0, microhm-cm. λ = Inferred temperature of zero resistance for the shield/sheath material, ºC below zero. T2 = Maximum allowable shield or sheath transient temperature, ºC. T1 = Operating shield or sheath temperature, ºC. I02 t Letting: T λ K 247.0 x10-6 SGSH 0 P0 (2) Then the Equation (1) becomes: T λ K Log10 2 A T1 λ I02 t (3) 2 Working Equations may be derived from equation (3) giving: I A t T λ K Log10 2 T1 λ (4) Letting: T λ M K Log10 2 T1 λ (5) The Equation becomes: MA I t (6) Or: MA t I Or: A I t 2 (7) (8) M Refer to Section 3 for tabulation values of the various parameters. © Copyright 2013 by the Insulated Cable Engineers Association, Incorporated. --``````,,,,,```,``,``,,``,,-`-`,,`,,`,`,,`--- 2 ICEA P-45-482-2013 Page 4 For Equations (6) and (7) effective cross-sectional area, A, may be calculated from the formulas in Table 1. If A is determined from (8), these formulas may be used to determine characteristics of the shield or sheath. Table 1 Formulas for Determining Metallic Shield/Sheath Cross-sectional Area FORMULA FOR CALCULATING A (SEE NOTES 1 & 2) 1. Wires applied either helically, as a braid or serving; or longitudinally with corrugations. 2. Helically applied tape, not overlapped. 3. Helically applied flat tape, overlapped. See NOTE 3. 4. Corrugated tape, longitudinally applied. 5. Tubular sheath. NOTE 1: Meaning of Symbols: A B b dis dm ds w n L nd2s 1.27 nwb 100 4bdm 2100 L 1.27 π dis 50 B b 4 bdm = Effective cross-sectional area of shield or sheath, cmil. = Tape overlap, mils (usually 375). = Thickness of tape, mils. = Diameter over extruded insulation screen, mils. = Mean diameter of shield or sheath, mils. = Diameter of wires, mils. = Width of tape, mils. = Number of serving or braid wires, or tapes. = Overlap of tape, percent. NOTE 2: The effective area of composite shields is the sum of the effective areas of the components. For example, the effective area of a composite shield consisting of a helically applied tape and a wire serving would be the sum of the area calculated from Formula 2 (or 3) and Formula 1. NOTE 3: The effective area of thin, helically applied overlapped tapes depends, also, upon the degree of electrical contact resistance of the overlaps. Formula 3 may be used to calculate the effective cross-sectional area of the shield for new cable. An increase in contact resistance may occur after cable installation, during service exposed to moisture and heat. Under these conditions the contact resistance may approach infinity, where Formula 2 could apply. © Copyright 2013 by the Insulated Cable Engineers Association, Incorporated. --``````,,,,,```,``,``,,``,,-`-`,,`,,`,`,,`--- TYPE OF SHIELD OR SHEATH ICEA P-45-482-2013 Page 5 Section 3 TABULATED PARAMETERS Table 2 Parameters for Use in Equations (1), (2) or (3) Suggested Values for Properties of K Material§ Metals at T0 = 20 ºC Calculated from Equation (2) SG SH Po λ Aluminum* 2.70 0.22 2.83 228 0.013 Bronze** 8.80 0.094 3.95 564 0.030 Copper† 8.93 0.092 1.72 234 0.030 Lead†† 11.3 0.031 20.6 236 0.0011 Steel‡ 7.85 0.11 12.0 180 0.0036 Zinc‡‡ 7.14 0.093 5.91 268 0.0080 Cupro-Nickel Alloy 8.94 0.09 1800 90Cu-10Ni (C70600) 19.1 0.019 80Cu-20Ni (C71000) 26.6 0.014 70Cu-30Ni (C71500) 37.5 0.010 * ** † †† ‡ ‡‡ § Three quarter hard, 1350 aluminum. Commercial Bronze, 90% copper, 10% zinc. annealed 100% conductivity copper. Pure lead (99.99%). Mild or low carbon steel. Commercial rolled zinc, 0.08% lead. These values are believed accurate for the materials shown. Variations may occur due to small changes in composition. Table 3 Values of T1, Approximate Shield or Sheath Operating Temperature, ºC at Various Conductor Temperatures --``````,,,,,```,``,``,,``,,-`-`,,`,,`,`,,`--- Rated Voltage (kV) 5-15 25 35-46 69-345 105 ºC 100 95 95 90 Shield or Sheath Temperature, ºC, at Conductor Temperatures 100 ºC 95 ºC 90 ºC 85 ºC 80 ºC 75 ºC 70 ºC 95 90 85 80 75 70 65 90 90 85 80 75 70 65 90 85 80 75 70 65 60 85 80 75 70 65 60 55 65 ºC 60 60 55 50 NOTE: The maximum conductor temperature should not exceed the normal temperature rating of the insulation used. For more accurate shield/sheath temperatures, contact the cable manufacturer. © Copyright 2013 by the Insulated Cable Engineers Association, Incorporated. ICEA P-45-482-2013 Page 6 Table 4 Values for T2, Maximum Allowable Shield or Sheath Transient Temperature, ºC Cable Material in Contact with Shield or Sheath T2 Crosslinked (thermoset) 350* Thermoplastic 200 Impregnated Paper 200 Varnished Cloth 200 NOTE: The temperature of the shield or sheath shall be limited by the material in contact with it. For example, a cable having a crosslinked semi-conducting shield under the metallic shield and a crosslinked jacket over the metallic shield would have a maximum allowable shield temperature of 350 ºC. With a thermoplastic jacket it would be 200 ºC. *For lead sheaths this temperature is limited to 200 ºC. Table 5 M Values for T2 Temperature of 200 ºC --``````,,,,,```,``,``,,``,,-`-`,,`,,`,`,,`--- Shield/Sheath Material Aluminum Commercial Bronze Copper Lead Steel Zinc 90Cu-10Ni (C70600) 80Cu-20Ni (C71000) 70Cu-30Ni (C71500) 100 0.039 Values for M for the Limiting Conditions Where T2 = 200 ºC Shield/Sheath Operating Temperature (T1), ºC 95 90 85 80 75 70 65 60 55 0.040 0.041 0.042 0.043 0.044 0.045 0.046 0.047 0.048 50 0.049 0.043 0.058 0.011 0.022 0.029 0.044 0.060 0.011 0.022 0.030 0.045 0.062 0.012 0.023 0.030 0.046 0.047 0.048 0.063 0.065 0.066 0.012 0.012 0.012 0.024 0.024 0.025 0.031 0.032 0.033 Cupro-Nickel 0.049 0.068 0.013 0.026 0.034 0.050 0.070 0.013 0.026 0.034 0.051 0.071 0.014 0.027 0.035 0.052 0.073 0.014 0.027 0.036 0.053 0.074 0.014 0.028 0.037 0.021 0.021 0.022 0.022 0.023 0.023 0.023 0.024 0.024 0.025 0.025 0.017 0.018 0.018 0.019 0.019 0.020 0.020 0.020 0.021 0.021 0.021 0.015 0.015 0.016 0.016 0.016 0.017 0.017 0.017 0.018 0.018 0.018 © Copyright 2013 by the Insulated Cable Engineers Association, Incorporated. ICEA P-45-482-2013 Page 7 100 0.056 Table 6 M Values for T2 Temperature of 350 ºC Values for M for the Limiting Conditions Where T2 = 350 ºC Shield/Sheath Operating Temperature (T1), ºC 95 90 85 80 75 70 65 60 55 0.057 0.058 0.059 0.060 0.060 0.061 0.062 0.063 0.063 50 0.064 0.065 0.085 0.031 0.042 0.066 0.086 0.032 0.043 0.066 0.088 0.032 0.044 0.067 0.068 0.068 0.089 0.090 0.091 0.033 0.033 0.034 0.044 0.045 0.045 Cupro-Nickel 0.069 0.092 0.034 0.046 0.070 0.093 0.035 0.046 0.070 0.094 0.035 0.047 0.071 0.096 0.036 0.047 0.072 0.097 0.036 0.048 0.032 0.032 0.033 0.033 0.033 0.034 0.034 0.034 0.034 0.035 0.035 0.027 0.027 0.028 0.028 0.028 0.028 0.029 0.029 0.029 0.030 0.030 0.023 0.023 0.024 0.024 0.024 0.024 0.025 0.025 0.025 0.025 0.026 Shield/Sheath Material Aluminum Commercial Bronze Copper Steel Zinc 90Cu-10Ni (C70600) 80Cu-20Ni (C71000) 70Cu-30Ni (C71500) © Copyright 2013 by the Insulated Cable Engineers Association, Incorporated.