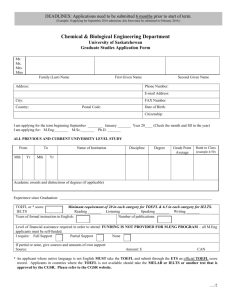

11 Fenton- and ozone-based AOP processes for industrial effluent treatment Q.Q. Cai, L. Jothinathan, S.H. Deng, S.L. Ong, H.Y. Ng, J.Y. Hu Department of Civil & Environmental Engineering, Faculty of Engineering, National University of Singapore, Singapore, Singapore 1 Introduction One of the major threats to water quality is chemical pollution to receiving water bodies, primarily caused by the discharge of inadequately treated industrial effluent. Owing to the adverse effect of industrial effluent containing high levels of hazardous pollutants, the discharge of industrial effluents is regulated by stringent and specific guidelines. The treatment of such industrial effluent is especially challenging due to the inhibitory properties of recalcitrant organic pollutants, the need to meet stringent discharge standards, and the typical variable composition of industrial effluents. Extensive research efforts have been invested, and are still being actively pursued, to explore effective and affordable treatment technologies for the remediation of hazardous pollutants. A widely recognized efficient treatment alternative of industrial effluent containing recalcitrant compounds is the use of advanced technologies based on chemical oxidation, such as the advanced oxidation processes (AOPs). Generally, AOPs are water treatment processes operating at near ambient temperature and pressure conditions (Glaze et al., 1987). AOPs typically involve the generation of hydroxyl radicals (•OH), which are capable of oxidizing most organic compounds without restriction to specific classes or groups of compounds. The classification of conventional AOPs is based on the source used for •OH generation. The Fenton reaction was discovered by H.J.H. Fenton in 1894, when he reported the activation of hydrogen peroxide (H2O2) by Advanced Oxidation Processes for Effluent Treatment Plants. https://doi.org/10.1016/B978-0-12-821011-6.00011-6 # 2021 Elsevier Inc. All rights reserved. 199 200 Chapter 11 Fenton- and ozone-based AOP processes ferrous ion (Fe2+) for tartaric acid oxidation (Fenton, 1894). The core reaction involved in Fenton-based AOPs is the interaction between peroxides (usually H2O2) and iron ions for •OH generation. In recent decades, Fenton-based AOPs have been widely used in cost-effective wastewater treatment processes for removing recalcitrant organic pollutants (Neyens and Baeyens, 2003; Bautista et al., 2008). Technologies for enhanced Fenton reaction and reduced sludge production were also explored and implemented in Fenton-based AOPs, including heterogeneous Fenton, thermal-enhanced Fenton, photo-Fenton, electro-Fenton, and sono-Fenton processes. Ozone-based AOPs are cost-effective industrial effluent treatment technologies that are suitable for full-scale applications. With a redox potential of 2.07 V, ozone is effective in splitting organic bonds and dissociating aromatic rings in recalcitrant organic compounds (Zouboulis et al., 2007). Once ozone molecules are dissolved in water, their decomposition through a series of chain reactions would occur for the generation of various radical species such as •OH. The effectiveness of ozonation is affected by both the reaction kinetics and the ozone mass transfer; low gasliquid ozone mass transfer is the key step that limits the overall reaction rate (Danckwerts, 1970). The techniques adopted to enhance ozonation efficiency mainly include heterogeneous catalytic ozonation, microbubble ozonation, and a combination of the two improvement methods. In this chapter, the fundamentals of conventional Fenton/ ozonation and improved Fenton/ozonation processes, such as fluidized bed reactor Fenton, photo-Fenton, and electro-Fenton processes as well as heterogeneous catalytic ozonation, microbubble ozonation, and microbubble-catalytic ozonation, are described. A historical review on recent developments of Fenton- and ozone-based AOPs for industrial effluent treatment is conducted. Case studies demonstrating industrial applications of Fenton- and ozone-based AOPs are also discussed. 2 Fenton-based AOP processes A range of Fenton-based AOP processes are discussed here, including their main reaction mechanisms, important operating factors, and process performances for industrial effluent treatments. The Fenton process, the base for many other modified Fenton processes, is first introduced, followed by the fluidized bed reactor Fenton, photo-Fenton, and electro-Fenton processes. Chapter 11 Fenton- and ozone-based AOP processes 2.1 Fenton process Fundamental to the Fenton process is the Fenton reaction, which generates hydroxyl radicals at atmospheric pressure and room temperature. H2O2 and ferrous ions are called Fenton reagents. The classic Fenton reaction occurs when these two reagents are brought into contact in aqueous solution at acidic pH. Eqs. (1)–(9) represent the key reaction steps that occur during the Fenton oxidation process with their reported reaction rates (Sychev and Isak, 1995). The ferrous ion initiates and catalyzes H2O2 decomposition, and results in the generation of highly reactive •OH (Eq. 1). Meanwhile, the generated ferric ion could be reduced by excess H2O2 to ferrous ion (Eq. 2), enabling an effective cyclic mechanism for ferrous regeneration. In the reaction described in Eq. (2), another radical species, the hydroperoxyl radical (HO2 ), is also produced; it is less effective than •OH for organic oxidation due to its lower redox potential. Reaction (2) is usually referred to as a Fenton-like reaction, and it is much slower than the Fenton reaction. Thus the produced Ferric ions in Reaction (1) would be progressively accumulated, leading to ferric sludge production in the Fenton system. H2 O2 + Fe2 + ! Fe3 + + HO + OH , k3:1 ¼ 40 80 M1 s1 (1) H2 O2 + Fe3 + ! Fe2 + + HO2 + H + , k3:2 ¼ 9:1 107 M1 s1 (2) Eqs. (3)–(5) depict other rate-limiting steps for ferrous ion regeneration and hydroxyl radical production. Excess ferrous ions could scavenge the produced radical species (Eqs. 3, 4), and HO2 could react with ferric ions for additional ferrous ion regeneration (Eq. 5). It shall be noted that in the above reactions, the ferrous ion acts as a catalyst and H2O2 is continuously consumed for • OH production. Fe2 + + HO ! Fe3 + + OH , k3:3 ¼ 2:5 5 108 M1 s1 1 1 6 Fe2 + + HO2 ! Fe3 + + HO s 2 , k3:4 ¼ 0:72 1:5 10 M (3) (4) Fe3 + + HO2 ! Fe2 + + O2 + H + , k3:5 ¼ 0:33 2:1 106 M1 s1 (5) Eqs. (6)–(8) summarize other radical scavenging reactions that could occur during the Fenton process. HO + H2 O2 ! HO2 + H2 O, k3:6 ¼ 1:7 4:5 107 M1 s1 HO + HO2 ! H2 O + O2 , k3:7 ¼ 1:4 1010 M1 s1 HO + HO ! H2 O2 , k3:8 ¼ 5 8 10 M 9 1 1 s (6) (7) (8) 201 202 Chapter 11 Fenton- and ozone-based AOP processes The whole Fenton process involves a complex reaction mechanism. Hydroxyl radicals are generated in the chain initiation reaction (Eq. 1) while they could be scavenged by ferrous ions (Eq. 3), hydrogen peroxide (Eq. 6), hydroperoxyl radical (Eq. 7), and even themselves. Hydrogen peroxide could be the initiator for radical production, but also could be the inhibitor for the subsequent oxidation process. Ferrous ions could accelerate hydrogen peroxide consumption, but also scavenge the produced radicals. In the presence of organic molecules (RH), the produced hydroxyl radicals will attack them through proton abstraction and produce highly reactive organic radicals (R•) (Walling and Kato, 1971), which could be further oxidized (Eq. 9). RH + HO ! H2 O + R , k3:9 ¼ 108 M1 s1 (9) Based on an exhaustive review of existing studies on the application of Fenton processes for industrial effluent treatment, the main factors affecting process efficiency include pH, temperature, Fenton reagent dosage, and the Fe2+/H2O2 ratio. A classic Fenton system is highly dependent on reaction pH for achieving effective organic oxidation. The optimum pH used in Fenton oxidation for industrial effluent treatment is mostly reported to be 3 (Balcik-Canbolat et al., 2016; Yang et al., 2019; Zeng et al., 2015; Zhang et al., 2019; Cui et al., 2015; Xiao et al., 2017; Yongrui et al., 2015; Methatham et al., 2016). Either lower or higher pH values could adversely affect Fenton process performance. At lower pH values, H2O2 would react with a larger amount of H+ ions to form stable oxonium ions, H3O+2 (Chen et al., 2009), and free ferrous ions would form iron complex species [Fe(H2O)6]2+ (Xu et al., 2009). Due to the lower activity of the Fenton reagent, •OH production is inhibited. The reaction between Fe3+ and H2O2 would also be inhibited under lower pH value conditions. In addition, the steady-state concentration of •OH could be reduced due to the scavenging effect from H+ ions. At higher pH, free iron ion concentration could be dramatically reduced with ferric oxohydroxide formation and ferric hydroxide precipitation, which could inhibit both •OH production and Fe2+ regeneration (Shemer et al., 2006). H2O2 self-decomposition to H2O2 and O2 would be accelerated at a pH level higher than 5 (Szpyrkowicz et al., 2001). Moreover, the redox potential of •OH is reported to be lower at a higher pH (E0 ¼ 2.8–1.95 V at pH 0–14) (Kim et al., 1998). Therefore, adequate pH control along the Fenton reaction is crucial to maintain satisfactory system performance. The Fenton reaction can be initiated in a wide range of ambient temperatures, but is more efficient at temperatures above 20°C. A temperature increase would certainly favor the rate of Fenton Chapter 11 Fenton- and ozone-based AOP processes reaction while temperatures above 50°C would also promote hydrogen peroxide’s thermal decomposition to water and oxygen (Muthukumari et al., 2009). Several studies have reported the optimum temperature for Fenton processes carried out at atmospheric pressure. The optimum temperature in the Fenton process for partially hydrolyzed polyacrylamide wastewater treatment was reported to be 30°C by Yongrui et al. (2015). Bampalioutas et al. (2019) reported the optimum temperature for treating olive mill wastewater as 35°C. According to Xiao et al. (2017), the optimum operating temperature for treating textile wastewater was as high as 40°C. Although these lab-scale studies demonstrated a more effective Fenton reaction at high temperature, ambient temperatures were usually adopted in full-scale operation because this was practically and economically applicable. The Fenton process performance is generally correlated with the amount of •OH generated, and •OH production is directly affected by the dosage of Fenton reagents. Therefore, the optimal dosage of H2O2 and Fe2+ required for the Fenton oxidation of a given wastewater must be established empirically, based on specific lab-scale or pilot-scale studies. The optimal dosage is dependent on wastewater characteristics, the nature and concentration of the target pollutants, treatment conditions, and objectives. Usually, as a rule, H2O2 dosage plays a crucial role in determining the overall efficiency of the Fenton process. The process oxidation efficiencies were generally observed to be increased with higher H2O2 dosage (Kang and Hwang, 2000; Lin et al., 1999). However, it shall be noted that unconsumed H2O2 during the Fenton process may contribute to COD in the treated effluent (Lin and Lo, 1997). An excess amount of H2O2 also scavenges the generated • OH (Eq. 6), thereby inhibiting the entire process performance. The H2O2 dosage shall be optimized so that the total supplied amount is consumed effectively during the Fenton process, and this optimal dosage can only be obtained through testing with specific target wastewater. A higher concentration of Fe2+ usually induces a higher oxidation efficiency of the Fenton process while the efficiency enhancement was observed to be marginal above an excessive concentration of Fe2+ (Kang and Hwang, 2000; Rivas et al., 2001). This is due to the reaction between Fe2+ and • OH (Eq. 3) that reduces the available active radicals for organic oxidation. The optimal Fe2+ dosage could be determined based on the optimal H2O2 dosage; they are related via the optimal molar ratio of Fenton reagents [H2O2]/[Fe2+] for each specific wastewater treatment. The optimal molar ratio between H2O2 and Fe2+ is one of the determinants of the Fenton reaction efficiency as well as one of 203 204 Chapter 11 Fenton- and ozone-based AOP processes the main control parameters of this process. In spite of many research studies and industrial applications of the Fenton process, there is no agreement on a universal value of optimal [H2O2]/ [Fe2+]. Nevertheless, some optimum values of [H2O2]/[Fe2+] were reported from 1.42 to 20.00 for industrial effluent treatment with the Fenton process (Fenton, 1894; Yang et al., 2019; Xiao et al., 2017; Chen et al., 2009; Szpyrkowicz et al., 2001; Bampalioutas et al., 2019; Lin et al., 1999; Lin and Lo, 1997). In the scenario where Fe2+ is overdosed and the molar ratio between H2O2 and Fe2+ is far less than 1, H2O2 is quickly and fully consumed for •OH production (Yoon et al., 2001). The excess amount of Fe2+ reacts with •OH (Eq. 3), which could lead to the termination of the chain reactions. Reactions for Fe2+ regeneration (Eqs. 2, 5) might be inhibited, and under this Fenton reaction condition, Fe2+ is used as a major reactant instead of a catalyst. In addition, the organic compounds would have to compete with the residual Fe2+ for •OH, and the Fenton oxidation efficiency could be limited. Therefore, overdosing of Fe2+ is undesirable as it has an inhibitory nature on the oxidation process. When [H2O2]/[Fe2+] is higher than 1, Fe2+ is rapidly depleted to decompose H2O2 for •OH generation (Yoon et al., 2001). Instead of slowly reacting with Fe3+, the residual H2O2 would react with •OH to produce HO2 (Eq. 6). The generated HO2 could participate in ferrous ion regeneration by reducing Fe3+ to Fe2+ (Eq. 5). In general, higher [H2O2]/[Fe2+] results in increased oxidation efficiency. However, an excess amount of H2O2 has to be considered with care due to its radical scavenging ability, which could limit the organic oxidation efficiency. Compared to other AOPs, the classic Fenton process has simpler equipment/facility design requirements, greater operational simplicity, and process scalability. It has been applied for various types of industrial effluent treatment and contaminant abatement. Table 1 depicts recent research works on industrial effluent treatment with the classic Fenton process. The typical scheme of the Fenton process consists of acidification, oxidation, neutralization, flocculation, and settling. From an operational point of view, the classic Fenton process has three main drawbacks: pH control in the acidification stage, Fenton reagent consumption in the oxidation stage, and sludge production in the neutralization and flocculation stages. A continuous supply of acid and Fenton reagents may excessively increase the operating costs in case of treating wastewater with a high organic loading or flowrate. The reddish-brown ferric precipitate must be separated from the liquid mixture, properly processed, and disposed as solid waste. In real practice, sludge generation is the fundamental reason for improving the Fenton process design, which is generally aiming for two objectives: (1) Reducing ferric sludge Table 1 Recent research works on industrial effluent treatment with the classic Fenton process. Operating condition Wastewaters/ compounds Benzene dye intermediates wastewaters Medium density fiberboard wastewater/ formaldehyde Olive mill wastewater Pharmaceutical wastewater Hydrolyzed polyacrylamide wastewater Hydrolyzed polyacrylamide wastewater Sulfide mineral processing wastewater Textile dye wastewater TFT-LCD wastewater Triethyl phosphate wastewater Initial level (mg/L) H2O2 (mM) Fe2+ (mM) pH Process performance References COD0: 4000 1000 360 4.13 85% COD removal in 60 min, enhanced BOD5/COD ratio from 0.08 to 0.49 Guo et al. (2018) COD0: 395 CH2O0: 59 23.26 9.29 3 58% COD and 77% CH2O removal in 70 min BalcikCanbolat et al. (2016) Total phenols: 9740 COD0: 4061 Berberine0: 709 147 18 4 89% Total phenol removal in 120 min [H2O2]/ [COD]: 1.25 750 [H2O2]/ [Fe2+]: 10 37.5 3 36% COD removal and 91% berberine removal in pilot system with HRT of 2.5 h Bampalioutas et al. (2019) Cui et al. (2015) 3 90% COD removal, enhanced BOD5/COD ratio from 0.078 to 0.463 Zhang et al. (2019) COD0: 1500–1700 5.30 1.44 3 72% COD removal Yongrui et al. (2015) COD0: 130 8.82 1.76 2–4 77% COD removal Zeng et al. (2015) COD0: 522 11.77 7.14 3 Xiao et al. (2017) COD0: 3800–4500 Organic phosphorus0: 58 291 4 3 95% COD removal with 60 min Fenton oxidation and subsequent flocculation with 60–100 mg/L PAC and 10 mg/L CPAM 70% COD removal in 120 min 20 14 3 COD0: 10,381 Organic phosphorus was reduced to 5 mg/L with 120 min Fenton oxidation Methatham et al. (2016) Yang et al. (2019) 206 Chapter 11 Fenton- and ozone-based AOP processes production; and (2) enhancing ferrous ion regeneration. Several improvements to the classic Fenton process for industrial effluent treatment are discussed in the following sections. 2.2 Fluidized bed reactor Fenton (FBR-Fenton) process To address the problem of sludge production in the classic Fenton process, researchers have explored the possibility of conducting the Fenton reaction in a fluidized bed reactor, which could synergistically combine the effectiveness of homogeneous Fenton and the sludge reduction of heterogeneous Fenton. This modified process is called fluidized bed reactor Fenton (FBR-Fenton). A fluidized bed reactor is a contacting device that uses the principle of fluidization for its operation, so that the packed material could be expanded by the upward or downward movement of the fluid. Most fluidized materials used in FBR-Fenton systems are inert solids. They are defined as carriers that provide available sites for the crystallization and precipitation of iron hydroxides, and hence reduce sludge production in the Fenton reaction. The FBR-Fenton process involves five main reaction mechanisms that contribute to its efficient oxidation performance and reduced sludge generation (Fig. 1). The first mechanism relates to the homogenous Fenton reaction for •OH generation and radical chain reactions for ferrous ion regeneration (Eqs. 1–5). Organic pollutants are subsequently oxidized to form less-toxic intermediates. The third mechanism is deposition of ferric hydroxide on the carrier surface via heterogeneous nucleation (Boonrattanakij et al., 2011). The ferric hydroxide-coated carrier may possess some extent of catalytic activity and initiate a Fig. 1 Scheme of main reaction mechanisms involved in the FBR-Fenton process. Chapter 11 Fenton- and ozone-based AOP processes 207 Fig. 2 Schematic diagram of an FBR-Fenton system. heterogeneous Fenton reaction for extra •OH generation. Meanwhile, the presented organic oxidation intermediates, particularly volatile fatty acids, could form soluble complexes with ferric ion, and hence interfere with ferric ion solubility and crystallization (Boonrattanakij et al., 2011). A schematic FBR-Fenton system is shown in Fig. 2; it consists of a cylindrical reactor packed with carriers and their support material. Glass beads and porous ceramsite are usually used to support the carriers as well as provide even distributions of the incoming flow. After wastewater is acidified with sulfuric acid, Fenton reagents are dosed into the influent line and pumped together with wastewater into the FBR-Fenton reactor from the bottom. Internal circulation of the reaction mixture is subsequently initiated to fluidize the carriers with the desired bedexpansion rate. The treated wastewater is collected from the effluent outlet at the top, and has gone through the neutralization, flocculation, and settling processes. As the main mechanism involved in FBR-Fenton for organic oxidation is the classic Fenton process, the operating factors affecting the FBR-Fenton process efficiency are the same as those discussed in the classic Fenton process, including pH, temperature, Fenton reagent dosage, and the Fe2+/H2O2 ratio. An extra parameter that shall be considered in the FBR-Fenton process is the carrier’s material. After the Fenton reaction is initiated, ferric ions would be formed over a very short period of time. Without the presence of carriers, ferric hydroxide would agglomerate via homogeneous nucleation and form ferric sludge. When the Fenton reaction mixture is seeded with foreign particles (carriers), 208 Chapter 11 Fenton- and ozone-based AOP processes ferric hydroxide nuclei can be deposited on these carriers via heterogeneous nucleation. Effective iron crystallization requires the notable dominancy of the heterogeneous nucleation process, which is also one of the key mechanisms for reduced sludge formation. The surface properties and size distribution of the carrier’s material play important roles in iron crystallization kinetics. In this context, different carriers have been adopted in the FBR-Fenton process for industrial effluent treatment, including SiO2, sand, Al2O3, Fe2O3, granular activated carbon, ceramsite, and brick particles (Boonrattanakij et al., 2011, 2018; Briones et al., 2012; Matira et al., 2015; Chen et al., 2015a; Lyu et al., 2016; Liu et al., 2014; Bello et al., 2019; Su et al., 2011, 2013; Anotai et al., 2012). SiO2 is the most popular carrier used in the FBR-Fenton process due to its proved capability to promote iron crystallization. Chen et al. compared the performance of SiO2, Al2O3, and Fe2O3 and reported that SiO2 was the most suitable carrier for the highest organic removal and total iron removal. According to Lyu et al., granular activated carbon (GAC) exhibited a relatively higher iron removal capability than ceramsite. Liu et al. reported sand to be the best carrier for silicon wastewater treatment compared to GAC and brick particles. Sand material was able to achieve better reactor bed expansion, fluidized state, and pollutant removal rate. Boonrattanakij et al. studied iron crystallization onto construction sand and SiO2 the FBR-Fenton process. It was found that iron crystallization onto the construction sand was faster than crystallization onto SiO2, although the final iron removal efficiencies were comparable. Besides the carrier material, the pH also affects the iron crystallization kinetics. Under the most commonly used pH condition in the Fenton process, pH 3, the homogenous nucleation of ferric hydroxide occurs slowly, and hence heterogeneous nucleation could induce effective iron crystallization. As a result, most ferric precipitates are deposited on the carrier’s surface and the remaining iron species for sludge formation are reduced. Diz and Novak (1998) studied iron crystallization on quartz sand in a fluidized bed reactor; it was found that the optimum pH for iron crystallization was between 3 and 4. This pH range matches well with the recommended pH range for conducting classic Fenton oxidation, which makes it possible to combine the classic Fenton process for organic oxidation and the iron crystallization process for sludge reduction. In recent years, the FBR-Fenton process has been adopted for pharmaceutical removal, thin-film transistor liquid crystal displays (TFT-LCD) wastewater, textile wastewater, and silicon wastewater treatment. Table 2 summarizes these research works with detailed information on operating conditions and process performance. Table 2 Recent research works on industrial effluent treatment with the FBR-Fenton process. Operating condition Wastewaters/ compounds Initial level (mg/L) H2O2 (mM) Fe2+ (mM) pH Carrier Acetaminophen (ACT) ACT0: 758.15 19.87 0.06 3.22 SiO2 Dimethyl sulfoxide (DMSO) Flax wastewater DMSO0: 390.65 32.5 5 3 TOC0: 350 17.65 5.35 3 Multidye wastewater Acid yellow (AY): 80 mg/L Disperse red (DR): 50 mg/L Reactive brilliant blue (RBB): 80 mg/L COD0: 800 TOC0: 133 [H2O2]/ [COD]: 1 [H2O2]/ [Fe2+]: 10 3 68.97 g/L SiO2 74.07 g/L SiO2 GAC and ceramsite [H2O2]/ [COD]: 2.6 46 [H2O2]/ [Fe2+]: 13.6 5 3.5 [H2O2]/ [COD]: 7.94 60 [H2O2]/ [Fe2+]: 8.36 5 Silicone wastewater Screw manufacturing wastewater Textile wastewater COD0: 400 TFT-LCD wastewater Monoethanolamine (MEA): 305.4 COD0: 314–404 Process performance 97.8% ACT removal, 62.92% in 120 min, total iron removal compared to 9.06% total iron removal in classic Fenton 95.22% DMSO and 34.38% TOC removal in 120 min 89% TOC removal at 50% bed expansion rate in 100 min 100% AY, 80% DR, 85% RBB, and 93% COD removal in 10 min References Guo et al. (2018) Matira et al. (2015) Chen et al. (2015a) Lyu et al. (2016) 95% COD and 85% TOC removal with HRT of 60 min, total iron removal rate was 26% 80% COD removal in 40 min with 50% bed expansion rate Liu et al. (2014) 3.4 Quartz sand with 35% filling rate SiO2 3 SiO2 Su et al. (2011) 3 SiO2 86.7% COD removal and 97% color decay in 10 min, with 50% bed expansion rate 98.9% MEA, 64.7% COD, 62% TOC, and 43.5% total iron removals in 2 h Boonrattanakij et al. (2018) Anotai et al. (2012) 210 Chapter 11 Fenton- and ozone-based AOP processes 2.3 Photo-Fenton process The photo-Fenton process is another modification of the classic Fenton process that has been brought to the actual practice of industrial effluent treatment. By combining Fenton reagents and UV-vis irradiation, the photoreduction of Fe3+ described in Eq. (10) could facilitate Fe2+ regeneration and simultaneously promote •OH generation through the Fenton reaction. Extra •OH could also be generated through the direct photolysis of H2O2 (Eq. 11). As a result, photo-Fenton achieves a higher oxidation rate and efficiency than the classic Fenton process (Ortegabana et al., 2012). In addition, there are remarkable reductions Lie of total iron usage and ferric sludge formation in the photoFenton process (Hermosilla et al., 2009). FeðOHÞ2 + + hv ! Fe2 + + HO (10) H2 O2 + hv ! 2HO (11) The photo-Fenton process could be conducted in both homogeneous and heterogeneous systems, and the main difference between the two systems is the form of iron source. In the homogenous system, the used iron species exist in the same phase with reactants, and the most common and convenient iron source used for homogeneous photo-Fenton is FeSO47H2O. Due to good mass transfer, the homogeneous Fenton system usually achieves a higher reaction rate and oxidation efficiency. However, strict pH control during the oxidation process and the formation of a large quantity of ferric sludge after the treatment process are the main drawbacks. Hence, the heterogeneous photo-Fenton process was adopted for overcoming these limitations. In the heterogeneous system, iron sources are immobilized within/on the catalyst structure, and they could induce catalytic degradation of the target pollutants without the generation of ferric sludge. Various natural iron minerals and iron oxides were applied for organic pollutant removal in a wider pH range (Rusevova et al., 2012; Gonzalez-Olmos et al., 2012; An et al., 2013). Besides iron (Fe), other transition metals could also catalyze the oxidation process with UV-vis irradiation, such as copper (Cu) and manganese (Mn) (Yip et al., 2005; Lai et al., 2019). The reaction systems using Cu and Mn as catalysts follow a similar network as that of Fe. Photo-Fenton with heterogeneous catalysts is also referred to as a photo-Fenton-like reaction, and recent research studies have mostly focused on specific recalcitrant organic removal with heterogeneous photo-Fenton treatment, such as synthetic dyes, Chapter 11 Fenton- and ozone-based AOP processes phenol, antibiotics, and 1,4-dioxane (Avetta et al., 2015; Lima et al., 2017; Liu et al., 2017; Barndõk et al., 2016; Gao et al., 2015; Lai et al., 2019). It was also found that the heterogeneous photo-Fenton process could be carried out under neutral or unaltered pH conditions. Nevertheless, compared to the homogeneous reaction, the heterogeneous photo-Fenton reaction has a slower oxidation rate due to limited catalyst surface and mass transfer rate. It may not be practically efficient for treating high-strength industrial effluents on a large scale. Industrial effluent treatment with the homogeneous photo-Fenton process will be mainly discussed in the later sections. In the context of the homogenous photo-Fenton process, the key factors affecting the process efficiency include pH, temperature, Fenton reagent dosage, Fe2+/H2O2 ratio, light source, and chelating agents. As the first four factors have been discussed in the classic Fenton process, the effects of light source and chelating agents will be mainly reviewed here. It should be noted that under the optimum Fenton reaction pH conditions, the predominant ion species Fe(OH)2+ has an absorption band between 200 and 410 nm. The maximum quantum yield of Fe3+ photoreduction is obtained at an irradiation wavelength around 313 nm (Faust and Hoign e, 1990). Light irradiation at a shorter wavelength would promote H2O2 photolysis, which is not the actual photo-Fenton reaction. Both UV and visible light irradiation could be adopted for conducting the photo-Fenton process. Generally, the photo-Fenton process with UV irradiation achieves a higher oxidation rate and efficiency than the visible light-assisted Fenton process. Kitsiou et al. (2014) investigated sulfamethazine (SMT) mineralization in UVA- and visible lightassisted photo-Fenton systems. UVA irradiation at a light flux of 0.94 104 Einstein/L min was provided by a 9 W lamp with a peak emission wavelength at 366 nm, and visible light irradiation at a light flux of 0.88 104 Einstein/L min was provided by a 9 W lamp with a peak emission wavelength at 440 nm. The UVA-assisted photo-Fenton process achieved better mineralized efficiency after a 180 min oxidation reaction, with 87% TOC removal compared to 70% TOC removal in the visible light-assisted photo-Fenton system. A pilot-scale study was subsequently conducted with natural solar irradiation at a total light intensity of 2 mW/cm2. The SMT concentration was reduced from 20 to 6 mg/L in 120 min, suggesting that process scale-up was feasible. Martı́nez-Costa et al. (2018) reported the degradation of sulfamethoxazole (SMX) and trimethoprim (TMP) in photo-Fenton processes using UV and solar irradiation. UV irradiation was provided by a 700 W low-pressure mercury lamp (λ ¼ 254 nm) at a light flux of 3.75 107 Einstein/ 211 212 Chapter 11 Fenton- and ozone-based AOP processes s, and solar irradiation was provided by a solar simulator equipped with a 1500 W xenon lamp (λ ¼ 290–800 nm) at an output intensity of 450 W/m2. With a reaction time of 50 min, the solar light-assisted photo-Fenton process removed 97% and 52% of SMX and TMP, respectively. The UV-assisted photo-Fenton process achieved higher antibiotic removal efficiencies, with 100% and 79% removal of SMX and TMP, respectively. In spite of the higher oxidation efficiency in the UV-Fenton systems, the acquisition and operation of the UV system involve high capital and operating costs. Moreover, the excessive effluent turbidity and coloration would significantly hinder the photo-Fenton process efficiency. Therefore, UV-Fenton systems are usually adopted for the low flow rate tertiary treatment of effluents subjected to stringent discharge standards. To avoid high investment and maintenance costs, visible light from natural solar irradiation is suggested as the alternative replacing UV irradiation, and the solar-Fenton process is of great interest in the field of industrial effluent treatment. To avoid the strict pH control required in the conventional photo-Fenton process, chelating agents are introduced into the system for forming stable complexes with ferric ions and preventing ferric precipitation at neutral pH. The ferric complexes could significantly absorb UV-vis light and also undergo photolytic decomposition, which is broadly described in Eq. (12) (Clarizia et al., 2017). Fe 3+ photo-reduction and Fe2+ generation could be initiated through ligand-to-metal charge transfer (LMCT). Fe3 + L + hv ! Fe3 + L ∗ ! Fe2 + + L (12) Clarizia et al. (2017) reported that the most commonly used chelating agents in the photo-Fenton process were oxalate, citrate, ethylenediamine-N,N0 -disuccinic acid (EDDS), ethylenediaminetetraacetic acid (EDTA), and nitrilotriacetic acid (NTA). When EDTA was adopted, the formed ferric complexes allowed for a pH value shifting to 12 with no ferric precipitation. The adoption of oxalate, citrate, EDDS, and NTA could make soluble Fe3+ available at near-neutral pH values. Each ferric-ligand complex exhibits different light absorption properties at varying pH and irradiation wavelength, which thereby affects the LMCT reaction rate. Weller et al. (2013) reported that the ferric-bisoxalate complex had a higher quantum yield (1.23) at 313 nm, and the ferric-trisoxalate complex had a higher quantum yield (1.00) at 436 nm. Kocot et al. (2006) found that the ferric-EDTA complex obtained the highest quantum yield (0.05) at 313 nm and pH of 4. The quantum yields of the ferric-NTA complex were estimated Chapter 11 Fenton- and ozone-based AOP processes at two pH conditions (4 and 6) and irradiation wavelengths (325 and 313 nm) by Abida et al. (2006). The highest quantum yield of 0.46 was obtained at 313 nm and pH of 4. The ferric-citrate complex could achieve good quantum yield values (0.21–28) at a longer irradiation wavelength of 436 nm (Faust and Zepp, 1993). To develop a cost-effective photo-Fenton process at near-neutral pH, the chelating agents should be carefully selected with a minimal increase in chemical cost and initial organic loading. The chelator dosage, operating condition, biodegradability, and ecotoxicity of the species formed should all be evaluated. Table 3 summarizes recent research works investigating the feasibility of the photo-Fenton process for industrial effluent treatment. 2.4 Electro-Fenton process The electro-Fenton (EF) process is another Fenton-based AOP that has been successfully applied for recalcitrant organic removal (Panizza and Cerisola, 2005; Nidheesh and Gandhimathi, 2012; Barhoumi et al., 2015). In the EF process, organic matters could be destroyed by both the action of Fenton reagents in the bulk and anodic oxidation at the anode surface (Brillas et al., 2009; Oturan and Aaron, 2014), where four reaction mechanisms could be involved (Fig. 3): (1) in situ electrical generation of H2O2 via oxygen reduction on the cathode (Guandao et al., 2015); (2) •OH generation via the Fenton reaction between the in situ generated H2O2 and Fe2+ ( Jiang et al., 2018; Zhou et al., 2012); (3) promotion of •OH generation on the anode surface when special materials are utilized as the anode (e.g., boron-doped diamond, BDD) (Panizza and Cerisola, 2005; Barhoumi et al., 2017); and (4) direct reduction of Fe3+ on the cathode for Fe2+ regeneration (El-Ghenymy et al., 2014; Qiu et al., 2015; Trellu et al., 2018). Based on the method of Fenton reagent addition and formation, the EF process could be classified into four categories (Kurt et al., 2007; Isarain-Chávez et al., 2011; Rahim Pouran et al., 2015) (Fig. 4): (1) Fe2+ is externally added and H2O2 is generated using an oxygen sparging cathode; (2) H2O2 is externally added and Fe2+ is generated using a sacrificial anode; (3) H2O2 and Fe2+ are in situ generated using a sacrificial anode and an oxygen sparging cathode, respectively; and (4) H2O2 and Fe2+ are externally added for •OH production, and Fe2+ is regenerated through Fe3+ reduction on the cathode. Among the four categories, the type 4 EF process is the most promising for industrialscale wastewater treatment, as using sacrificial anodes to provide Fe2+ is not economical for long-term practical applications and 213 Table 3 Recent research works on industrial effluent treatment with the photo-Fenton process. Wastewaters/ compounds Initial level (mg/L) Operating condition H2O2 (mM) 2+ Fe (mM) pH Light source Process performance References TOC0: 501 117.65 6.70 2.9 55 W UVC lamp, 200–280 nm 53% TOC removal in 2 h Expósito et al. (2016) COD0: 10,019 COD0: 800 468.74 3.8 Natural solar light, 2424 kJ/m2 77% COD removal in 30 min 29.41 [Fe3+] ¼ 9.11 1.79 3 74% COD removal in 120 min COD0: 35,369 160.56 5.11 3 Antibiotic wastewater Oxacillin0: 81.49 10 0.09 6 150 W mercury lamp, 200–580 nm (a) 80 mW UVA LED, 370 nm, 23 W/m2; (b) 1.4 W UVA LED, 365 nm, 70 W/m2; (c) 1.4 W UVA LED, 365 nm, 85 W/m2 30 W UVA lamp, 365 nm, 1.5 mW/cm2 Guzmán et al. (2016) Marcinowski et al. (2014) Rodrı́guezChueca et al. (2016) Coagulated textile wastewater Pharmaceutical laboratory effluent COD0: 450 TOC0: 151 19.60 1 3 6 W black-light lamp, 365 nm, 0.5 mW/cm2 75% COD removal and 62% TOC removal in 90 min Antipyrine: 389 TOC0: 1914 73.53 0.36 2.7 Solar CPC reactor, 30 W/m2 100% Antipyrine removal and 21% TOC removal in 120 min Beverage industrial wastewater Citrus wastewater Cosmetic wastewater Crystallized-fruit wastewater (a) 45% COD removal in 360 min; (b) 64% COD removal in 360 min; (c) 74% COD removal in 360 min 100% Oxacillin removal in 50 min GiraldoAguirre et al. (2018) GilPavas et al. (2017) Foteinis et al. (2018) Chapter 11 Fenton- and ozone-based AOP processes e– + – OH – Fe 2+ Fe 2+ H 2O 2 Fe 3+ Fe 3+ H + + OH e– H 2O Anode 215 OH RH Products e– H 2O 2 2e– O2 + H+ Cathode Fig. 4 Conceptual classification of electro-Fenton processes. the cathodic production of H2O2 from oxygen is significantly limited by low oxygen solubility in water. The type 4 EF process is also called the Fered-Fenton process, in which organic oxidation is carried out mainly through the homogeneous Fenton reaction, and electric current is applied to the aqueous mixture for provoking the cathodic reduction of Fe3+. The electrolytic regeneration of Fe2+ allows for considerable reduction in sludge production, overcoming the main drawbacks of the classic Fenton process. To enhance the EF process performance, a number of process modifications were developed by incorporating other technologies into the electrochemical process. The photo-electro-Fenton (PEF) process is a combination between the electrochemical process and the photochemical process. With additional light irradiation, Fe2+ regeneration could be facilitated through the photoreduction of Fe3+ (Eq. 10), and •OH generation through the Fenton reaction Fig. 3 Reaction mechanisms of the electro-Fenton process. 216 Chapter 11 Fenton- and ozone-based AOP processes could be simultaneously promoted. Extra hydroxyl radicals would also be produced through peroxide photolysis (Eq. 11). The sonoelectro-Fenton (SEF) process is another type of modified EF process by incorporating the sonochemical process into the EF process. Under the ultrasound wave, more hydroxyl radicals could be generated by water pyrolysis, and hence the degradation of organic pollutants is improved. In addition, the ultrasound wave could benefit the regeneration of Fe2+ from the iron intermediate complexes (Babuponnusami and Muthukumar, 2012). In terms of physical properties, ultrasound wave could effectively clean the electrodes’surface by dispersing the passivated layers, and provide efficient mass transfer in the SEF reaction system (Chen and Huang, 2014). Heterogeneous catalytic electro-Fenton is another technique used to enhance Fenton oxidation efficiency. In most cases, the catalytic effect involves promoting H2O2 decomposition for hydroxyl radical generation, and facilitating oxidative degradation of organic contaminants. Furthermore, the heterogeneous catalytic process could widen the pH range for EF process operation and reduce sludge production. The most adopted heterogeneous catalyst in the EF process could be classified into two categories: (1) natural minerals, and (2) synthetic catalysts. The group of natural minerals mainly includes hematite (α-Fe2O3), wustite (FeO), magnetite (Fe3O4), and goetite (α-FeOOH) (Sánchez-Sánchez et al., 2007; Expósito et al., 2007), and the synthetic catalyst group mainly consists of nanoscale iron minerals (e.g., nano-Fe3O4; Hou et al., 2015) and metal-doped iron catalysts (e.g., Fe-C (Zhang et al., 2015), Pd-Fe3O4 (Luo et al., 2014), and FexCuyOz (GarridoRamı́rez et al., 2016; Ganiyu et al., 2018)). Fig. 5A depicts the dominant catalytic activities in a heterogeneous catalytic EF system. Fig 5B illustrates the promotion of hydroxyl radical generation in the presence of transition metals. Besides process modification, numerous efforts have also been made to enhance the EF process efficiency by optimizing various operating parameters, including pH, dissolved oxygen level, current density, temperature, and the electrode and catalyst types. Recent works on recalcitrant organic compound degradation with different electro-Fenton processes are summarized in Table 4. Table 5 depicts recent research works on industrial effluent treatment with electro-Fenton processes. It was found that the Fered-Fenton and heterogeneous EF processes were more widely applied in real industrial effluent treatment. Real industrial effluents are complex mixtures loaded with high concentrations of pollutants, and they usually have water matrixes with diverse Chapter 11 Fenton- and ozone-based AOP processes - + pH adjustment H+ H pH adjustment + e– a-FeOOH Fe3O4 Fe2+ H+ e O2 Fe OH– – Pd/Fe3O4 FexCuyOz H - + H+ a-Fe2O3 + + H2O2 OH Mn+ M(n+1)+ e– H2O2 2+ Mn+ [H] + H2O Fe2+ 2+ H+ – OH OH Fe Fe-C H+ FeO OH Fe3+ Fe2+ H2O2 e H2O OH R Anode OH [Byproducts] R (A) OH 217 e– Fe3+ Fe2+ Fe3+ e– e– e– OH– H2O2 O2 + OH e– O2 CO2 + H2O Cathode Anode (B) Cathode Fig. 5 Mechanisms of heterogeneous catalytic EF process (A) in the presence of iron catalysts; (B) in the presence of transition metals. pH values and significant radical scavenging effects. FeredFenton could obtain the effectiveness of homogeneous Fenton oxidation yet with less sludge production; it also requires simple process design and operation procedures. The heterogeneous EF process could be carried out under a wider pH operating range as well as with chemical consumption. Hence, these two EF processes were frequently adopted for industrial effluent treatment. 3 Ozonation process Ozonation is one of the most well-known and matured advanced oxidation processes (AOPs). It has been widely applied for the treatment of recalcitrant/toxic organics in industrial effluent (Oturan and Aaron, 2014; Jothinathan and Hu, 2018; Chen et al., 2015b). Ozone molecules are effective oxidants with a high oxidation potential (E° ¼ +2.07 eV). They react with various organic and inorganic compounds either by a direct reaction of molecular ozone or through an indirect radical-type reaction Table 4 Recent research works on recalcitrant organic degradation with different electro-Fenton processes. Target organic compounds Phenol/activated carbon fiber regeneration Florfenicol Sulfomethaxazole Indigo carmine dye Dinitrotoluene (DNT)/2,4,6trinitrotoluene (TNT) Process/ reactor setup Operating conditions Process performance References Lab-scale EF process, open cylindrical, and undivided electrochemical cell Lab-scale EF process Activated carbon (AC) fiber as cathode and BDD as anode, room temperature; pH: 3.0, current: 300 mA 91% of phenol removal, morphological and chemical characteristics of AC were not affected Trellu et al. (2018) A graphene-modified EF catalytic membrane (EFCM) as cathode, Pt foil as counter electrode, T: 25°C, pH: 5.9 0.07 Operating potential: 0.6 V Jiang et al. (2018) Lab-scale PEF process, 3 L undivided twoelectrode quartz cell Lab-scale PEF, thermostatic cylindrical glass cell Lab-scale SEF, 450 mL batch reactor UV lamp, 254/365 nm, RuO2/Ti mesh as anode and ACF felt as cathode, room temperature, pH: 3.0; Fe2+: 1 mM, current: 0.36 A 90% Florfenicol removal, EFCM could not only act as cathode but also as membrane barrier to concentrate and enhance the mass transfer of florfenicol, increasing its oxidation chances 80% TOC removal, PEF could efficiently reduce carboxylic acid production for quicker photodegradation by UV light 6 W fluorescent bulb, 360 nm, BDD as anode and carbon-PTFE as cathode, 35°C, pH: 3.0, Fe2+: 1 mM Ultrasonic frequency: 120 kHz, platinum plates were used as both anode and cathode, T: 30°C, pH: 1, O2 flow rate: 150 mL/min, Fe2+: 150 mg/L, electrode potentials: 6 V Complete mineralization of indigo carmine dye, Fe3+-oxalate complexes were destructed under the action of ultraviolet light 100% DNT and TNT removal in 7 h Wang et al. (2011) Flox et al. (2006) Chen and Huang (2014) Table 4 Recent research works on recalcitrant organic degradation with different electro-Fenton processes—cont’d Target organic compounds Process/ reactor setup Phenol Lab-scale SEF, 5 L ultrasonic reactor (type: DUMAN-120) Catechol Lab-scale heterogeneous EF, one-compartment electrochemical cell Lab-scale heterogeneous EF, 0.3 L undivided cell 2,4Dichlorophenol Phenol Phenol Lab-scale heterogeneous EF, 200 mL undivided reactor Lab-scale heterogeneous EF, singlecompartment electrochemical glass cell Operating conditions Process performance References Ultrasonic frequency: 34 kHz, stainless steel used as both anode and cathode, electrode distance: 5 cm, room temperature; pH: 3.0, Fe2+: 4 mg/L H2O2: 500 mg/L Current density: 12 mA/cm2 Pt sheet as anode and f active carbon fiber as cathode, T: 25°C; pH: 3; nanoFe3O4: 1 g/L Current density: 10 mA/cm2 Phenol removal rate constants of 0.0683 min1 under the optimal condition Babuponnusami and Muthukumar (2012) 100% Catechol removal in 2 h, verified stability and reuse of the catalyst Hou et al. (2015) Ti/IrO2-RuO2 as anode and PTFE as cathode, room temperature, pH: 6.7 Fe-C loading: 6 g/L, current: 100 mA 95% 2,4-Dichlorophenol removal in 2 h, catalytic activity of Fe-C was well maintained with much lower iron leaching after PTFE coating 98% Phenol removal in 60 min with an initial concentration of 20 mg/L Zhang et al. (2015) Pt as both anode and cathode, T: 25°C, Pd-Fe3O4 loading: 1 g/L, pH: 3, current: 50 mA Modified glassy carbon as working electrode, platinum wire as counter electrode, Bimetallic (FexCuy) allophane nanoclays as catalyst T: 25°C, pH: 3, oxygen reduction potential: 0.6 V 100% Phenol and 80% COD removals in 2 h, 100% phenol removal at pH 5.5 in 4 h Luo et al. (2014) Garrido-Ramı́rez et al. (2016) Table 5 Recent research works on industrial effluent treatment with electro-Fenton processes. Wastewaters/process Initial level (mg/L) Operating condition H2O2 (mM) Fe2+ (mM) pH Process performance References 75 7.5 3 Ti sheet as cathode and RuO2/Ti as anode, current density of 5.1 mA/cm2, 49.7% TOC removal in 2 h, BOD5/COD ratio was increased from 0.11 to 0.31 Fan et al. (2015) Electronic wastewater/ Fered-Fenton COD0: 580 TOC0: 198 COD0: 190 14.56 0.2 3 Pharmaceutical wastewater/ Fered-Fenton COD0: 565 [H2O2]/ [Fe2+]: 3.6 2.89 GarciaRodriguez et al. (2018) Davarnejad and Sabzehei (2019) Textile effluents/iron-loaded sepiolite heterogeneous EF COD0: 800 H2O2/ wastewater volume ratio: 0.32 mL/L In situ generated Graphene-based gas diffusion cathode and BDD anode, current density of 29 mA/cm2, air flow of 0.2 L/min, 80% TOC removal in 3 h Ferrous plate electrodes, current density of 58.47 mA/cm2, 97.21% COD removal in 59.68 min 20 g/L catalyst 2 Iglesias et al. (2013) Winery wastewater/Feloaded activated carbon heterogeneous EF COD0: 52.8 In situ generated 0.72 3.1 Coal gasification wastewater/Fe-loaded sludge derived activated carbon heterogeneous EF COD0: 173.3 TOC0: 57.6 Total phenol: 48.3 In situ generated 5 g/L catalyst 6.8 Boron-doped diamond as anode and graphite sheet as cathode, air flow rate of 1 L/min, cell voltage of 5 V, 86.7% COD removal in 90 min Boron-doped diamond as anode and thick nickel foam as cathode, air flow rate of 1 L/min, cell voltage of 15 V, 100% of decolorization, and 82% of COD removal Ti as anode and activated carbon fiber as cathode, air flow rate of 4.0 L/min, cell voltage of 3 V, 78.1% COD, 93.5% phenol, and 65.5% TOC removal in 2 h Reverse osmosis concentrate/Fered-Fenton Iglesias et al. (2015) Hou et al. (2016) Chapter 11 Fenton- and ozone-based AOP processes Fig. 6 Reaction pathway of ozone and hydroxyl radicals (•OH). involving the hydroxyl radicals induced by the ozone decomposition in water (Fig. 6) (Yong and Lin, 2012; Zimmermann et al., 2011). In the direct reaction, ozone molecules could destroy aromatic structured organic compounds through reactions such as cycloaddition, electrophilic addition, and nucleophilic addition (Beltrán, 2004). Direct ozonation is a highly selective oxidation process, that is, it is relatively unreactive toward many inorganic species and some classes of organic compounds (e.g., carboxylic acids) (Buxton et al., 1988; Gottschalk et al., 2010). Additionally, the selective reactions between ozone molecules and unsaturated bonds or amino groups in organics would lead to the formation of aldehydes and carboxylic acid, which results in incomplete mineralization (Rosenfeldt et al., 2006). Indirect ozonation usually occurs through radical chain reactions with the formation of • OH (E° ¼ + 2.80 eV), which is capable of oxidizing saturated aliphatic or aromatic compounds to form stable oxidized end products (Gottschalk et al., 2010). The conventional ozonation process has some drawbacks such as high-energy consumption due to poor utilization of gaseous ozone, process selectivity, incomplete oxidation due to unfavorable reaction kinetics, and incomplete mineralization of recalcitrant organics (Xiong et al., 2018; Xia and Hu, 2018). Hence, it becomes more imperative to develop modified ozonation process that could enhance the ozone mass transfer and promote •OH generation. Techniques for efficient ozone transfer are especially desired for the cost-effective treatment of wastewater containing high concentrations of organic pollutants. Techniques such as catalytic ozonation processes, microbubble ozonation, and catalytic-microbubble ozonation have emerged as efficient treatment methods to enhance ozonation efficiency by improving ozone mass transfer and •OH generation. 221 Chapter 11 Fenton- and ozone-based AOP processes 3.1 Catalytic ozonation process Catalytic ozonation processes have emerged to overcome the drawbacks of the conventional ozonation process. The addition of either a homogeneous or heterogeneous catalyst into the ozonation process could promote •OH generation, thereby enhancing the removal efficiency of organic compounds ( Jung and Choi, 2006; Park et al., 2004; Wang and Bai, 2017). Heterogeneous catalysts are generally preferred when compared to homogeneous catalysts because of the sustained reactions of ozone through the active sites of the catalyst. Additionally, heterogeneous catalysts are easy to recover and reuse, even after several treatment cycles (Wang et al., 2019a; Legube and Karpel Vel, 1999). In most cases, the catalytic effect mainly involves enhancing the ozone molecular decomposition for hydroxyl radical generation and promoting the oxidative degradation of organic contaminants. The catalytic effect only occurs when at least one of the three conditions is fulfilled: (1) ozone is adsorbed on the catalyst surface; (2) Organic molecules are adsorbed on the catalyst surface; or (3) both ozone and organic molecules are adsorbed on the catalyst surface (Fig. 7). An efficient catalyst requires high physical adsorption capacity and excellent catalytic activity, and the catalytic activity highly depends on the catalyst’s chemical-physical properties such as pore volume, pore size, surface area, and mechanical n actio ct re Dire Organics Oxidation byproducts O3 t irec Ind tion c rea 222 Reactive species HO2∑, O2-∑, and O3-∑ ∑OH Organics Oxidation byproducts and CO2 Organics Adsorption Fig. 7 Schematic representation of catalytic ozonation mechanism. Chapter 11 Fenton- and ozone-based AOP processes strength (Legube and Karpel Vel, 1999; Nawrocki and KasprzykHordern, 2010). The most widely used catalysts in heterogeneous catalytic ozonation are supported or unsupported metal oxides and carbon-based heterogeneous catalysts (Nawrocki and KasprzykHordern, 2010). Several studies have been performed using catalysts such as activated carbon, metal oxides, and minerals to prove their effectiveness in initiating O3 decomposition to form •OH, simultaneously improving organic oxidation (Beltrán et al., 2005; Zhang et al., 2008; Kasprzyk-Hordern et al., 2006; Rosal et al., 2009). A literature review has provided evidence that carbon-based heterogeneous catalysts such as activated carbons (ACs) and carbon nanotubes (CNTs) considerably improve the removal rate of organic pollutants due to their physical stability and mesoporous structure (Nawrocki and Kasprzyk-Hordern, 2010; Alvárez’ et al., 2009). Many studies have reported that ACs and CNTs could participate in ozone radical reactions and initiate O3 decomposition for • OH generation (Liu et al., 2009; Beltrán et al., 2009). It has been demonstrated that the main factor responsible for ozone decomposition in the presence of ACs is the combination of basic surface groups and metal centers. Leili et al. (2013) demonstrated the degradation of furfural using AC as a catalyst. It was found that 80.2% of furfural removal was mainly achieved by •OH oxidation via catalytic ozonation. A study from Faria et al. (2008) reported that the AC-initiated catalytic ozonation could achieve significant sulfonated aromatic compound degradation due to the combined effects of direct ozonation, adsorption, and free radical oxidation. In another study (Alvárez’ et al., 2009), the authors demonstrated that using granular activated carbon (GAC) as the catalyst induced the effective removal of gallic acid in a secondary effluent. They observed that GAC could adsorb gallic acid very efficiently, but exhibited limited capacity for COD removal in the secondary effluent due to the substantial fraction of organic matter not adsorbed onto the GAC surface. Similar to ACs, carbon nanotubes promote •OH formation during ozonation to levels exceeding ozone and almost equivalent to O3/H2O2 (Oulton et al., 2015). The alternation of a carbon catalyst surface using HNO3 has exhibited vastly greater rates of ozone consumption and •OH formation (Cho et al., 2011; Sui et al., 2012; Upadhyayula et al., 2009). Tizaoui et al. (2015) demonstrated the degradation of methyl orange using carbon nanotubes as the catalyst. It was found that the addition of CNTs significantly improved the decolorization of methyl orange as compared to the ozone process alone. Liu et al. (2011) studied the degradation 223 224 Chapter 11 Fenton- and ozone-based AOP processes of oxalic acid using multiwalled carbon nanotubes (MWCNTs), where they found that a higher MWCNT dosage resulted in better removal of oxalic acid. Recently, researchers have shown interest in graphene-based carbon material for water treatment as an alternative to CNTs and ACs due to its functional group, high surface area, and distinct mechanical and electrical properties (Yang et al., 2014). Graphene oxide (GO) is an oxidized form of graphene with carboxyl, hydroxyl, carbonyl, and epoxy functional groups in its carbon lattice (Perreault et al., 2015). Jothinathan and Hu (2018) proposed that GO without any surface modification could act as an efficient •OH scavenger and inhibit the reaction between • OH and organics, and surface-modified GO was adopted in this study for effective ibuprofen degradation. Recently, metal-doped catalysts with carbon substrates have become popular due to their better catalyst activity and stability (Jothinathan and Hu, 2018; Le et al., 2015; Shahamat et al., 2014). Huang et al. (2017a) reported that manganese oxide-doped sewage sludge-derived activated carbon (MnOx/SAC) exhibited the highest catalytic activity at acidic pH for the degradation of oxalic acid. Wang et al. (2019b) adopted Fe-supported regenerated granular activated carbon (Fe/rGAC) as the catalyst in textile wastewater treatment. It was found that Fe/rGAC improved the performance of the catalytic ozonation process by 14%–25% when compared to using rGAC as the catalyst. In addition, they demonstrated that • OH generation was significantly improved by Fe/rGAC, contributing to a biodegradability enhancement of 0.24–0.55 times when € et al. (2015) compared to the conventional ozonation process. Lu studied the degradation of 2,4-dichlorophenoxyacetic acid by using bimetal coated activated carbon (Fe-Ni/AC) in the catalytic ozonation process. The target pollutant’s degradation rate constant was 1.9 times higher than that in the conventional ozonation process. Zhuang et al. (2018) reported that manganese oxidesupported activated carbon was highly effective for treating paper-making wastewater. They observed the significant inhibition of radical scavengers in the catalytic ozonation process, which is attributed to the catalyst-promoting ozone decomposition for generating more •OH. Table 6 depicts recent research works on carbon-based heterogeneous catalytic ozonation for industrial effluent treatment. Similar to carbon-based materials, minerals (Al2O3, TiO2, ceramics, etc.) and natural solid minerals (zeolites, soils, sandbased material, and goethite) have been widely used in heterogeneous catalytic ozonation (Wang et al., 2019a). Yuan et al. (2016) reported the effective degradation of p-chloronitrobenzene (p-CNB) during the iron-doped pumice (Fe/Pumice) initiated Table 6 Recent research works on industrial effluent treatment with the carbon-based heterogeneous catalytic ozonation process. Wastewater/ organics Catalyst Operating condition Process performance References Secondary effluent Activated carbon TOC removal: 50% Alvárez’ et al. (2009) Phenol in industrial wastewater Fe-Mn/granular activated carbon Phenol removal: 100% TOC removal: 60.1% Xiong et al. (2019) Reverse osmosis concentrate Activated carbon TOC removal: 58% Fang and Han (2018) Bio-treated textile wastewater Regenerated activated carbon (rGAC) and Fe-rGAC Catalyst dosage: 2 g O3 concentration: 40 mg/L [TOC]0: 171 12 mg/L pH: 6.12 BOD5: 150 100 mg/L Catalyst dosage: 1.0 g/L O3 concentration: 22 mg/L [TOC]0: 149 mg/L [Phenol]0: 200 mg/L BOD5/COD: 0.011 [TOC]0: 67.4 mg/L Catalyst dosage: 2.0 g/L Ozone dosage: 120 mg/L pH: 6–7 COD: 50.5 mg/L pH: 7.8 DOC: 17.8 mg/L UV254: 0.64 Color: 30 (unit) Ozone dosage: 18 mg/L Wang et al. (2019b) Paper-making wastewater MnOx/activated carbon COD removal: Fe- rGAC: 28% rGAC: 21% Color removal: Fe- rGAC: 81.7% rGAC: 56.7% UV254 removal: Fe- rGAC: 59.4% rGAC: 45.3% COD removal: 77.5% BOD5/COD: 0.46 Color: 58.5 COD: 210 20 mg/L Color: 110 10 BOD5/COD: 0.16 Catalyst dosage: 1.0 g/L Ozone dosage: 10 mg/L Zhuang et al. (2018) Continued Table 6 Recent research works on industrial effluent treatment with the carbon-based heterogeneous catalytic ozonation process—cont’d Wastewater/ organics Catalyst Operating condition Process performance References Oxalic acid Fe2O3/activated carbon Oxalic acid removal efficiency: 89% Li et al. (2018) Phenolic wastewater Nano Fe3O4/ activated carbon BOD5/COD: 0.52 Phenol removal: 98.5% COD removal: 69.8% Farzadkia et al. (2014) p-Hydroxyl benzoic acid (PHBA) Reduced graphene oxide (rGO) PHBA removal efficiency: 95% Remarks: carbonyl groups in rGO acted as the active sites to generate reactive oxygen species for catalytic reaction Wang et al. (2016) Oxalic acid Multiwalled carbon nanotubes (MWCNTs) Multiwalled carbon nanotubes (MWCNTs) Catalyst: 0.71 g/L [Oxalic acid]0: 10 g/L Contact time: 60 min Ozone dosage: 0.8 mg/min Catalyst: 2 g/L pH: 8.0 [Phenol]0: 500 mg/L BOD5/COD: 0.3 Ozone dosage: 33 mg/L min Catalyst: 0.2 g/L [PHBA]0: 5 mg/L Contact time: 60 min Ozone dosage: 20 mg/L Initial pH: 3.5 Catalyst: 0.14 mg/L Initial pH: 3.0 [DMP]0: 90 mg/L Catalyst: 20 mg/L Initial ozone dosage: 10 mg/L [pCBA]0: 2 mM Tert-butanol: 320 mM pH: 7 Catalyst: 10 mg/L [MO]0: 20 mg/L Contact time: 2 min Ozone dosage: 2 mg/L Initial pH: 3.0 Catalyst: 0.5 g/L [BPA]0: 50 mg/L Contact time: 40 min Ozone dosage: 3.0 mg/L Removal efficiency: 90%–100% (based on ballmilled MWCNT duration) Soares et al. (2015) Modified MWCNT oxidized with 70% HNO3 performed better pCBA removal efficiency: 80% Oulton et al. (2015) MO removal efficiency: 60% Tizaoui et al. (2015) BPA removal efficiency: 90% Huang et al. (2017b) paraChlorobenzoic acid (pCBA) Methyl orange (MO) Carbon nanotubes Bisphenol A (BPA) MWCNTs/Fe3O4 Chapter 11 Fenton- and ozone-based AOP processes catalytic ozonation process. Liu et al. (2016) reported that Mn-Fe/ Al2O3 exhibited the strongest catalytic activity for bisphenol degradation with good stability and reusability. Roshani et al. (2014) investigated the degradation of benzotriazole by using Cu/Al2O3, Mn/Al2O3, and Mn-Cu/Al2O3 as catalysts. At alkaline pH condition, Mn-Cu/Al2O3 exhibited the highest catalytic activity. Table 7 presents recent studies on the catalytic ozonation processes that adopt metal-doped minerals for industrial effluent treatment. 3.2 Microbubble ozonation process In the ozonation process, the dissolution rate of ozone gas into the liquid phase mainly depends on the gas-liquid interfacial area. In order to enhance the ozone mass transfer rate, it becomes necessary to increase the gas-liquid interfacial area by decreasing the ozone bubble size. Microbubble ozonation technology has drawn great attention as it could provide small bubble size with diameters between 10 and 50 μm. Compared to a macrobubble, the microbubble obtains a huge interfacial area, a long stagnation time, a low bubble rising speed, and a high interior pressure (Xiong et al., 2018; Takahashi et al., 2007). The most distinct characteristic of microbubbles is that they could shrink and collapse in the liquid phase due to high interior pressure while macrobubbles could only burst after rising to the surface of the liquid phase. The size reduction of the microbubbles during the shrinking stage is due to the dissolution of gas present inside the microbubbles; this gas will eventually disappear after the microbubbles collapse (Fig. 8). Takahashi et al. (2007) demonstrated that microbubbles could enhance gas hydrate formation due to their ability to alter the nucleation condition and gas solubility. The correlation between the microbubble size and the interior gas pressure could be presented by the Young-Laplace equation: P ¼ PI + 2σ r (13) where P and PI are the gas and liquid pressure, respectively, σ is the liquid surface tension, and r is the radius of the microbubble. According to Eq. (13), the interior pressure of the microbubbles is inversely proportional to the bubble radius, thus a reduction of bubble size would lead to a sharp increment in the interior pressure. According to Henry’s law, the amount of dissolved gas around the shrinking microbubbles would increase with higher microbubble interior pressure. When the interior pressure’s 227 Table 7 Recent research works on industrial effluent treatment with the metal oxide-based heterogeneous catalytic ozonation process. Wastewater/organics Catalyst Diclofenac Iron silicateloaded pumice Acid Red B Cu-Mn/Al2O3 Coal chemical wastewater-biotreated effluent Cu-Mn-Ce/Al2O3 Petroleum refinery wastewater Mn-Fe-Cu/Al2O3 Nitrobenzene benzoic acid (recalcitrant organic in chemical wastewater) Vanadium oxides/ zeolites Synthetic petroleum effluent g-Al2O3 Operating condition Catalyst: 0.8 g/L Initial O3 concentration: 5.52 mg/L [Diclofenac]0: 29.6 mg/L Catalyst: 4.0 g/L [Acid Red B]0: 250 mg/L Contact time: 20 min Ozone dosage: 4.26 mg/min Initial pH: 8.5 Catalyst: 20 mg/L Initial pH: 7.0 [COD]0: 180 mg/L Ozone dosage: 80 mg/L Catalyst: 20 g Initial pH: 8.2 [COD]0: 2825 mg/L BOD5/COD: 0.098 Catalyst: 0.5 g Initial ozone dosage: 10 mg/L Nitrobenzene: 55.9 mg/L Benzoic acid: 67.5 mg/L Nitrobenzene: 6.5 Benzoic acid: 3.5 Catalyst: 2 g/L [TOC]0: 250 mg/L Ozone dosage: 5 mg/L Process performance References Diclofenac removal: 73.3% Yuan et al. (2012) Acid Red B removal: 99.35% Li et al. (2015) COD removal: 70% Teng et al. (2019) COD removal: 67.1% BOD5/COD: 0.330 Chen et al. (2015b) TOC removal: Nitrobenzene: 85.4% Benzoic acid: 88.3% Xu et al. (2019) TOC removal: 90% with addition of NaCl Vittenet et al. (2015) Chapter 11 Fenton- and ozone-based AOP processes Fig. 8 Pathways of microbubbles for •OH formation. increasing rate is sufficiently high, the temperature within the microbubble would rise sharply because of adiabatic compression, leading to the collapse of the microbubbles (Takahashi et al., 2007, 2003). Takahashi et al. (2007) demonstrated the generation of free radicals (especially •OH) from the collapsing of microbubbles. Possible pathways for •OH formation during the collapsing of microbubbles were proposed as following: (1) excess ions trapped on the surface of the microbubble interface; (2) collapsing of the microbubble leading to a sudden disappearance of the gas-liquid interface; (3) significant increase in ion concentration around the shrinking microbubble gas-liquid interface; and (4) generation of radicals through adiabatic compression. Xu et al. (2012) investigated •OH generation during the fewmicrosecond collapse of microbubbles through dynamic stimuli such as ultrasound and shock waves. It was found that dynamic stimuli induced more efficient free radical generation when compared to the process involving microbubble shrinking and collapsing. In recent years, microbubble ozonation has been recognized as a promising AOP technology for industrial effluent treatment, as it could overcome the major drawbacks of conventional ozonation processes. The distinctive physicochemical properties of microbubbles could enhance the ozone gas mass transfer and •OH formation, thereby increasing the ozone utilization rate and promoting organic oxidation. It was reported that smaller ozone microbubbles could induce a larger mass transfer coefficient and higher ozone saturation concentration (Xiong et al., 2018). In the microbubble ozonation process, the reactive oxygen species (especially •OH, HO2 , O2 , and O3 ) could be generated 229 230 Chapter 11 Fenton- and ozone-based AOP processes through two major mechanisms: (1) shrinking and collapsing of O3 microbubbles; and (2) self-decomposition of O3 and radical chain reactions. The additional •OH production from microbubble shrinkage and collapse has huge benefits on the oxidation efficiencies of recalcitrant organic compounds. Xia and Hu (2018) pointed out that the collapse of ozone microbubbles could also induce local turbulence and facilitate the reaction between O3/•OH and organic pollutants, thereby enhancing the oxidation efficiency. Table 8 depicts recent research works on industrial effluent treatment with the microbubble ozonation process. Li et al. (2009) studied the oxidation efficiency of free radicals generated from air, oxygen gas, and nitrogen microbubbles in terms of phenol removal The results showed that with 2 h contact time, the phenol removal rates in the air, oxygen gas, and nitrogen microbubble-mediated reaction system were 36%, 59%, and 83%, respectively. Zheng et al. (2015) compared the performance of macrobubble and microbubble ozonation for treating acrylic fiber wastewater. It was reported that the microbubble ozonation process could enhance the COD, NH3-N, and UV254 removal by 25%, 35%, and 9% when compared to the macrobubble ozonation process. Chu et al. (2008) studied the treatment of textile wastewater with microbubble ozonation and conventional ozonation processes, and it was indicated that the decolorization rate and COD reduction were both significantly improved in the microbubble ozonation process. The literatures shows that a combination of ultrasound and microbubble ozonation could further improve the ozone mass transfer and •OH formation. Ultrasonication could induce several turbulences in the aqueous phase and benefit the mixing of ozone molecules and target pollutants. Additionally, the ultrasound waves could intensify •OH generation via pyrolysis. •OH could be generated inside and/or near the interface of bubble cavity. According to Guo et al. (2016), sulfamethoxazole degradation was mainly induced by the direct oxidation of ozone molecules rather than the •OH reaction. Zhao et al. (2015) demonstrated that ultrasound could intensify the ozone decomposition and accelerate the initiation of •OH generation, thereby enhancing nitrobenzene degradation. 3.3 Heterogeneous catalytic-microbubble ozonation process Similar to the microbubble ozone/ultrasound process, the hybrid technology of combining the heterogeneous catalyticmicrobubble ozonation process could improve both ozone mass Table 8 Recent research works on industrial effluent treatment with the microbubble ozonation process. Wastewater/organics System Operating condition Acrylic fiber wastewater O3 macrobubbles O3 microbubbles (M-O3) O3 dosage: 5 g/h Temperature: 20°C Organic-contaminated wastewater with high salinity O3 micronanobubbles [COD]0: 4500 mg/L Cl: 123,000 mg/L Dimethyl phthalates (DMP) O3 microbubbles Textile wastewater O3 microbubbles Phenol containing synthetic water O3 microbubbles Dimethyl phthalate Microbubble-O3/ ultrasound Reactive Red X-3B dye O3/ultrasound SO4 2 : 58,500 mg/L Na+: 114,000 mg/L O3 gas flowrate: 3.5 g/h Initial pH: 9 Contact time: 1 h [DMP]0: 1.03 mol/m3 [O3]0: 132 mg/L Initial pH: 8.7 [COD]0: 530–600 mg/L BOD5/COD: 0.15–0.22 [O3]0: 20 mg/L [Phenol]0: 0.1 mol/L [O3]0: 1.11 mg/s [DMP]0: 1.029 mol/m3 pH: 7 [Red X-3B]0: 100 mg/L pH: 6.5 Ultrasonic intensity: 200 W L1 Process performance References O3 macrobubbles COD removal: 17% UV254 removal: 7% NH3-N removal: 12% O3 microbubbles COD removal: 42% UV254 removal: 42% NH3-N removal: 21% COD removal: 63% Zheng et al. (2015) DMP removal: 95% Jabesa and Ghosh (2017) COD removal: 70% Color removal: 80% Chu et al. (2008) Phenol removal: 80% Ozone consumption: Microbubble: 10 mg/L Macrobubble: 40 mg/L DMP removal: 95% Wu et al. (2019) Dye removal: 99.2% Jabesa and Ghosh (2017) Xia and Hu (2018) Jabesa and Ghosh (2017) 232 Chapter 11 Fenton- and ozone-based AOP processes transfer and •OH generation for better oxidation efficiency. As previously mentioned, external dynamic stimuli such as ultrasound and shock waves could catalyze microbubble ozonation via the collapsing of microbubbles. Besides dynamic stimuli, incorporating a heterogeneous catalyst into the microbubble ozonation system could also enhance the generation of •OH. Many studies have demonstrated effective recalcitrant organic removal in the catalytic ozonation process (Yong et al., 2005; Gharbani and Mehrizad, 2014; Deng et al., 2015) while it was highlighted that the incorporation of a heterogeneous catalyst in the conventional catalytic ozonation process was not adequate for cost-effective recalcitrant organic degradation (Liu et al., 2018; Cheng et al., 2018). The main mechanisms for enhanced organic degradation in the heterogeneous catalytic-microbubble ozonation process might include: (1) enhanced ozone mass transfer contributed by ozone microbubbles; and (2) the surface-mediated process of a heterogeneous catalyst enhancing •OH formation (Fig. 9). Liu et al. (2018) adopted the activated carbon catalyticmicrobubble ozonation process for treating bio-treated coal. Organics Adsorption Catalyst Organics ·OH Oxidation bypoducts and CO2 Microbubble-catalytic O3 ·OH Oxidation byproducts from M-O3 mechanism Microbubble ozone (M-O3) Oxidation byproducts Fig. 9 Mechanism of heterogeneous catalyticmicrobubble ozonation process. O3,·OH Organics Chapter 11 Fenton- and ozone-based AOP processes 233 The results show that this ozonation process achieved efficient degradation of refractory compounds in bio-treated coal wastewater with a higher ozone utilization rate (98%), and the residual ozone concentration was negligible. Similarly, Ma et al. (2019) adopted Fe3O4 nanoparticles@cow dung ash as the catalyst for carrying out catalytic-microbubble ozonation and treating biologically pretreated leachate. An enhanced generating rate of • OH, effective refractory pollutant degradation, and biodegradability enhancement were observed. Huang et al. (2017b) reported a higher ozone utilization rate during the treatment of biologically treated leachate from municipal solid waste by incorporating activated carbon into a microbubble ozonation system. Table 9 summarizes recent research works on industrial effluent treatment with the heterogeneous catalytic-microbubble ozonation process. Table 9 Recent research works on industrial effluent treatment with the heterogeneous catalytic-microbubble ozonation process. Wastewater/ organics System Operating condition Leachate from municipal solid waste M-O3/ activated carbon Biologically pretreated leachate M-O3/Fe3O4 Bio-treated coal wastewater M-O3/ activated carbon Phenol-containing wastewater M-O3/Ca(OH)2 COD: 817 50 mg/L pH: 8 Color: 350–400 Catalyst dosage: 350 g Ozone dosage: 60 mg/L COD: 1270 50 mg/L TOC: 492 25 mg/L BOD5/COD: 0.05 Catalyst dosage: 0.8 g/L Ozone dosage: 3.0 g/L COD: 283.8 mg/L pH: 8 TOC: 99.8 mg/L BOD5/COD: 0.038 Catalyst dosage: 28% (filling ratio in reactor) Ozone dosage: 30 mg/L [Phenol]0: 450 mg/L Ozone dosage: 65 mg/L Catalyst dosage: 2 g/L TOC: 365 mg/L Process performance References COD removal: 89.9% Huang et al. (2019) COD removal: 53% BOD5/COD: 0.32 Ma et al. (2019) COD removal: 42% Ozone utilization rate: 98% BOD5/COD: 0.30 Liu et al. (2018) Phenol removal: 100% Cheng et al. (2018) Continued 234 Chapter 11 Fenton- and ozone-based AOP processes Table 9 Recent research works on industrial effluent treatment with the heterogeneous catalytic-microbubble ozonation process—cont’d Wastewater/ organics System Operating condition Synthetic dye wastewater (Acid Red 3R) Acid Red 18 wastewater M-O3/ activated carbon M-O3/Ca(OH)2 Catalyst: 2 g/L Ozone dosage: 12.5 mg/min [Acid Red 3R]0: 100 mg/L TOC: 145 mg/L [Acid red 18]0: 450 mg/L Catalyst dosage: 3 g/L Ozone dosage: 65 mg/L Process performance References TOC removal: 75% Zhang et al. (2018) Acid Red 18 removal: 100% TOC removal: 100% Quan et al. (2017) 4 Applications of Fenton and ozone-based AOPs for industrial effluent treatment Fenton- and ozone-based AOPs are versatile technologies for industrial effluent treatment. They can be applied as pretreatment processes for recalcitrant organic abatement and biodegradability enhancement. They can also be applied as tertiary treatment processes for meeting stringent discharge standards. In this section, recent pilot-scale and full-scale applications of Fenton- and ozone-based AOPs for industrial effluent treatment are discussed. 4.1 Fenton-based AOPs 4.1.1 Fenton process The pilot-scale treatment of pharmaceutical wastewater with the Fenton process was studied by Cui et al. (2015). Raw pharmaceutical wastewater had an initial COD level of 4061 mg/L and a target pollutant berberine level of 709 mg/L. The maximum treatment capacity of the pilot system was 5 tons/d while the Fenton process operating conditions were first optimized by response surface methodology (RSM), and the pilot system was continuously operated for 56 days. The RSM results suggested the optimum operating conditions to be pH 3, an H2O2/COD molar ratio of 1.25, an Fe2+/H2O2 molar ratio of 0.1, and a system flow rate of 100 L/h. During the 56-day stable operation, the average removal efficiencies of COD and berberine were 28.3% and 77.7%, respectively. The BOD5/COD ratio of the pharmaceutical wastewater was enhanced from less than 0.1 to 0.3. Chapter 11 Fenton- and ozone-based AOP processes Bae et al. (2015) reported a full-scale application of the Fenton process in a dyeing wastewater pretreatment plant, which receives wastewater from 61 dyeing factories. The total treatment capacity of the plant was 100,000 m3/day, and the plant influent had a pH value of 10–12 and an average soluble COD (SCOD) level of 1100 mg/L. The main treatment processes consisted of primary sedimentation, a pure oxygen-activated sludge process (ASP), the Fenton process, coagulation, and final sedimentation. Plant effluent was discharged to a regional municipal wastewater treatment plant. The Fenton process operating pH was 3.5 and the HRT was 30 min. The adopted H2O2 and FeSO47H2O dosages were 4.0 and 4.2 mM, respectively, and H2O2 was injected with a two-step dosing mode (30% at 12 min and 70% at 16 min). In the coupled biological-AOP processes, pure oxygen ASP achieved 53% SCOD and 13% color removal while the Fenton process removed 66% of SCOD and 73% of color. The effluent COD after final sedimentation was 128 mg/L. A full-scale application of rapid Fenton oxidation for bio-treated dyeing and finishing wastewater (BDFW) treatment was reported by Chen et al. (Chen et al., 2019). The highlight of this study is that the rapid Fenton oxidation process was conducted in second-scale intervals using pipeline reactors. The full-scale plant with a treatment capacity of 400,000 m3/day has been continuously operated in 16 pipeline reactors since 2014. Each pipeline reactor had a length of 13.6 m and a working volume of 18.32 m3; rapid Fenton oxidation, neutralization, and flocculation were carried out in sequence inside the pipeline reactor. The estimated HRT of Fenton oxidation was 24 s, which is significantly shorter than the conventional Fenton process. After Fenton oxidation, the COD, SCOD, and DOC levels in BDFW were reduced from 140, 110, and 35 to 77, 71, and 26 mg/L, respectively. 4.1.2 FBR-Fenton process The FBR-Fenton technology has been exploited in full-scale industrial effluent treatment in Taiwan since 2000. It is usually applied to achieve further COD reduction in bio-treated wastewaters containing recalcitrant organic pollutants. Table 10 summarizes several completed projects from Greentec Environmental Protection Technology (GreenTec, www.biogreentec.com.tw) and EVER-CLEAR Environmental Eng. Corp. (EVER-CLEAR, www.ever-clear.com.tw). These projects demonstrate the fullscale applications of FBR-Fenton in different industrial sectors, including the paper mill, yeast production, leather manufacturing, and electronic industries. 235 236 Chapter 11 Fenton- and ozone-based AOP processes Table 10 Full-scale application of FBR-Fenton technology for treating different industrial effluents. Wastewater Treatment capacity (m3/day) Water characteristics before treatment Water characteristics after treatment Pulp and paper effluent 86,000 Yeast production effluent Leather manufacturing effluent Electronic industry effluent ABS resin production effluent 8300 COD 800 mg/L SS 100 mg/L COD 1000 mg/L COD 100 mg/L SS 40 mg/L COD 200 mg/L 1200 COD 300 mg/L COD 100 mg/L 3000 COD 210 mg/L COD 80 mg/L 5000 COD 140 mg/L COD 60 mg/L 4.1.3 Photo-Fenton process Despite the excellent performance of photo-Fenton reported in recent lab-scale treatability studies, process cost-effectiveness studies in large-scale applications are quite limited. The most promising studies were carried out in at the pilot scale using the solar photo-Fenton process. Ruı́z-Delgado et al. (2019) investigated the degradation of four micropollutants (terbutryn, chlorfenvinphos, pentachlorophenol, and diclofenac) in olive mill wastewater (OMW) with the photo-Fenton process. The polyphenols presented in OMW could act as iron chelators and allow for effective Fenton oxidation without water acidification. The photo-Fenton process was carried out in a compound parabolic collector (CPC) solar pilot plant, with a total irradiation area of 3.08 m2 and a reactor volume of 39 L. With optimum dosages of 0.1 mM Fe2+ and 1.47 mM H2O2, more than 90% removal of the four micropollutants was achieved by the solar photo-Fenton pilot system. Foteinis et al. (2018) conducted a life cycle analysis (LCA) of a semiindustrial solar photo-Fenton system for treating pharmaceutical laboratory effluent. The solar photo-Fenton process was conducted in a CPC reactor with a mean solar intensity of 30 W/m2 and a treatment capacity of 0.7 m3/h, The pharmaceutical wastewater contained 1914 mg/L TOC and 389 mg/L antipyrine, and it was acidified to a pH value of 2.7 before treatment. Under the optimal operation conditions with 73.53 mM H2O2 and 0.36 mM Fe2+, the Chapter 11 Fenton- and ozone-based AOP processes 237 CPC plant achieved 100% removal of antipyrine and 21% mineralization efficiency. The LCA results revealed that chemical reagent consumption (mainly H2O2) was the most significant environmental hotspot for CO2 emission. Also, this semiindustrial solar photo-Fenton system was a sustainable technology for treating micropollutant-containing wastewater. 4.1.4 Electro-Fenton process The Fered-Fenton technology has been exploited in full-scale industrial effluent treatment. A commercial Fered-Fenton system generally consists of an electrolytic reactor, electric supplies, and a control system. The Fered-Fenton system is typically operated in batch mode by continuously recirculating the reaction mixture between the oxidation tank and the electrolytic reactor, wherein Fe2+ regeneration occurs by the cathodic reduction of Fe3+, being returned to the oxidation tank as a catalyst. This cycle is repeated enough to complete the reaction in the oxidation tank. Table 11 summarizes several completed projects from GreenTec Environmental Protection Technology These projects demonstrate the full-scale applications of Fered-Fenton in different industrial sectors, including the printboard manufacturing, fiber production, and electronic industries. Compared to FBR-Fenton, the FeredFenton system is primarily aimed at wastewater treatment with a medium to high organic load, and its treatment capacity is relatively lower. Table 11 Full-scale application of Fered-Fenton technology for treating different industrial effluents. Wastewater Printboard manufacturer wastewater Synthetic fiber production wastewater Electronic industry wastewater Surface treatment wastewater Treatment capacity (m3/day) Water characteristics before treatment Water characteristics after treatment 30 COD 2000 mg/L COD 400 mg/L 100 COD 1000 mg/L COD 100 mg/L 1 COD 18,000 mg/L COD 1800 mg/L 10 COD 10,000 mg/L COD 2000 mg/L 238 Chapter 11 Fenton- and ozone-based AOP processes 4.2 Ozone-based AOPs 4.2.1 Catalytic ozonation process A pilot-scale treatment of coal gasification wastewater with the catalytic ozonation process was conducted by Wei et al. (2019), where a novel catalyst Cu-Co bimetal induced NiCAF (CuCO/ NiCAF) was developed and adopted in the treatment process. The long-term operation of the catalytic ozonation system was carried out with a treatment capacity of 5 m3/day. In the presence of a developed catalyst, the ozone utilization efficiency was increased by 120% with a higher ΔCOD/ΔO3 ratio of 2.12, compared to a ΔCOD/ΔO3 ratio of 0.96 in the conventional ozonation process. Furthermore, 75% power consumption reduction was achieved in the catalytic ozonation process. The total cost for CuCO/NiCAF catalyst preparation was estimated to be USD 1.26/kg and the operating cost for removing 1 kg COD was USD 0.4, whereas the operating cost in the conventional ozonation process was estimated to be USD 1.6/kg COD. The considerable reduction of operating cost was due to lower ozone consumption in the catalytic ozonation process, where the required ozone dosages were 25 and 100 mg/L in the catalytic and conventional ozonation processes, respectively. Additionally, it was highlighted that the developed catalyst was able to achieve both high catalytic activity and excellent structural stability, which are feasible for large industrial-scale applications. Ma et al. (2018) conducted a pilot-scale study on treating bio-treated dyeing and finishing wastewater. Recycled iron shavings were used in the catalytic ozonation system, and the effective reaction volume was 2.9 m3. The influent COD levels ranged from 132 to 148 mg/L, and an average effluent COD level below 80 mg/L was achieved with 30 min HRT. Zhuang et al. (2017) developed a metal-doped activated carbon catalyst (MnOx/activated carbon) for conducting the pilot-scale treatment of coal gasification wastewater. An MnOx/activated carbon-mediated catalytic ozonation process was able to achieve 72% COD removal (average influent COD: 150 mg/L) with an effective ozonation utilization rate (ΔCOD/ΔO3: 1.21). Wu et al. (2017) integrated the catalytic ozonation and persulfate oxidation into a pilot-scale pretreatment technology for dry-spun acrylic fiber wastewater treatment. The optimum operating conditions were identified as 40 g/h ozone dosage, 4.44 h HRT, 61.8°C reaction temperature, and 1.3 kg/ton persulfate. The maximum COD removal efficiency was 44.36%, and the wastewater biodegradability was enhanced from 0.078 to 0.315 in terms of the BOD5/COD ratio. Chapter 11 Fenton- and ozone-based AOP processes 4.2.2 Microbubble ozonation process Khuntia et al. (2015) investigated the degradation of brilliant green dye in a pilot-scale microbubble ozonation system. The observed TOC and dye removal efficiencies were 80% and 90%, respectively. By using 25 μm ozone microbubbles, an effective wastewater treatment performance could be obtained at a very low ozone generation rate due to the enhanced mass transfer of microbubble ozone gas in the aqueous phase. Jabesa and Ghosh (2016) adopted microbubble ozonation technology for the pilot-scale degradation of diethyl phthalate, and a final TOC removal efficiency of 94% was achieved with an ozone generation rate of 1.94 mg/s. Gao et al. (2019) developed a pilot system by combining microbubble ozonation and UV irradiation for removing refractory organics in a secondary wastewater effluent. The combined system enhanced the •OH generation up to 2–6 times higher than that in the conventional ozonation and UV irradiation processes alone. Table 12 summarizes recent pilot-scale studies on industrial effluent treatment with the catalytic and microbubble ozonation processes. 5 Concluding remarks In recent years, many research efforts have been made toward improvement of the Fenton and ozone-based AOPs. The system performances of all developed technologies have been successfully validated through their lab-scale, pilot-scale, and even fullscale applications in treating real industrial effluents. The classic Fenton process has a wide range of applications to various types of industrial effluents, and it is the earliest Fenton technology demonstrated on an industrial scale. The classic Fenton process usually has a simple process design and operation protocol, low capital cost, and good scalability. It also has a number of drawbacks that limit its widespread acceptance, including high chemical consumption, low efficiency with the presence of radical scavengers, requirement for mildly acidic conditions, and the production of ferric sludge. Some of these drawbacks are intrinsic while others could be alleviated through technology development. FBR-Fenton is a successful modification of the classic Fenton process by conducting a homogenous Fenton reaction in a fluidized bed reactor. Both lab-scale and industrial-scale applications show that FBR-Fenton could overcome the problem of excessive sludge generation in classic Fenton oxidation. In spite of encouraging results in this field, more studies are needed to address 239 Table 12 Recent pilot-scale studies on industrial effluent treatment with catalytic and microbubble ozonation processes. Wastewater/organics System Operating condition Performance efficiency References Bio-treated dyeing and finishing wastewater Recycled iron shaving catalyst COD final: 54 5 mg/L DOC final: 16 3 mg/L Ozone utilization efficiency DCOD/DO3: 0.64 Ma et al. (2018) Coal gasification wastewater 1. Ni-induced C-Al2O3 (NiCAF) 2. Cu-Co bimetal induced NiCAF (CuCO/ NiCAF) COD final: 22.1 mg/L DOC final: 6.3 mg/L Ozone utilization efficiency DCOD/DO3: 2.12 75% reduction of energy consumption compared to ozone alone Wei et al. (2019) Coal gasification wastewater MnOx/sewage sludge-based activated carbon [COD]0: 165 20 mg/L [DOC]0: 76 6 mg/L Reactor volume 2.93 m3 pH: 7.08 0.20 Influent flowrates: 2.9–17.6 m3/h HRT: 30 min Ozone concentration: 80 mg/L Catalyst dosage: 2 mg/L Ozone dosage: 10.2 gO3/min Catalyst loading CuCO/NiCAF: 150 kg [COD]0: 70–80 mg/L [TOC]0: 20–25 mg/L pH: 6.5–7.0 Feed flux: 5 m3/day HRT: 30 min Ozone dosage: 25 mg/L [COD]0: 150 25 mg/L [TOC]0: 50 10 BOD5/COD: 0.06 Ozone dosage: 90 mg/L Zhuang et al. (2017) Brilliant green dye Ozone microbubbles COD final: 41 4 mg/L TOC final: 19 1 mg/L BOD5/COD: 0.44 Ozone utilization efficiency DCOD/DO3: 1.21 TOC removal: 80% Dye removal: 90% [Dye]0: 0.0274–0.164 mM Microbubble generator gas intake capacity: 1.7 mL/s Reactor capacity: 20 L Ozone dosage: 6.0 g/h Khuntia et al. (2015) Table 12 Recent pilot-scale studies on industrial effluent treatment with catalytic and microbubble ozonation processes—cont’d Wastewater/organics System Diethyl phthalate (DEP) Ozone microbubbles Recirculating aquaculture wastewater Ti-Mn/TiO2/Al2O3 membrane Pretreatment of dry-spun acrylic fiber wastewater Catalytic ozone-persulfate Biologically treated wastewater (micropollutant removal) Granular activated carbon Secondary effluent from wastewater treatment plant Microbubble ozonation-UV process Operating condition 3 [DEP]0: 0.18 mol/m Reactor capacity: 20 L pH: 7 [TOC]0: 23 mg/L Ozone dosage: 10 g/h [CODMn]0: 2.1–4.1 mg/L pH: 7.7–8.1 UV254: 0.073–0.095 Ozone dose: 52 mg/min Recirculation rate: 4000 L/h [COD]0: 2056 mg/L BOD5/COD: 0.08 pH: 6.9 Ozone dosage: 40 g/h Persulfate: 1.3 kg/ton Catalyst: 120 L Total nitrogen (TN): 452 mg/L Reactor effective volume: 180 L [COD]0: 252.7 60.4 mg/L [DOC]0: 68.3 25.8 mg/L UV254: 62.5 11.6 mg/L Average flow rate: 0.8 m3/h [COD]0: 22.50 0.50 mg/L [TOC]0: 43.79 0.44 mg/L pH: 7.61–8.25 UV254: 0.119 0.03 Reactor volume: 20 L HRT: 30 min Performance efficiency References DEP removal: 78% TOC removal: 53% Jabesa and Ghosh (2016) CODMn removal: 52% Chen et al. (2015c) COD removal: 42.4% BOD5/COD: 0.315 TN removal: 28.5% Wu et al. (2017) COD removal: 91% DOC removal: 85% HRT: 17 3 min Ozone consumption: 0.89 0.29 gO3/gDOC COD removal: 37.50% UV254: 81.15% Knopp et al. (2016) Gao et al. (2019) 242 Chapter 11 Fenton- and ozone-based AOP processes some research gaps. Existing studies have mostly observed the effects of conventional operational parameters (pH, Fenton reagents, HRT, and carrier) on FBR-Fenton system performance. Comprehensive process optimization and modeling are somewhat limited. As the FBR-Fenton is operated in a liquid-solid system, process modeling and optimization could be relatively challenging due to the additional parameters. More studies are needed to address this part and take the system hydrodynamics into consideration. One main concern of the photo-Fenton process is its cost effectiveness, and many lab-scale studies have been conducted to address this issue such as the utilization of heterogeneous catalysts, chelating agents, and solar energy. The heterogeneous photo-Fenton process could overcome pH limitations in a homogenous system. Iron oxides are good candidates for the heterogeneous catalyst due to their wide availability and cheap price. In terms of system scaling up, both the catalyst’s lifetime and the relatively low oxidation efficiency of the heterogeneous system should be carefully considered. Chelating agents could prevent ferric precipitation at near-neutral or even alkaline pH conditions while their addition could also increase the process’s chemical cost and wastewater organic content. Replacing UV irradiation with natural solar irradiation could significantly reduce the process capital cost and power consumption. However, by using this natural resource, the process efficiency is also affected by the location latitudes, atmospheric conditions, and sunshine duration. To achieve an adequate irradiation area and solar intensity, the design of the solar photo-Fenton reactor is relatively complex. Furthermore, the applicability and performance of solar photo-Fenton is subject to the transmissivity properties of treated water. More pilot-scale and full-scale studies are needed to prove the cost-effectiveness of the photo-Fenton process for industrial effluent treatment. The electro-Fenton process is also a successful process improvement by combining the Fenton process with the electrochemical process. Both lab-scale and industrial-scale studies demonstrate that electro-Fenton could enhance Fe2+ regeneration and reduce sludge production. Unlike with other Fentonbased AOPs, the electro-Fenton process is particularly suitable for treating high COD and hardly biodegradable organiccontaining wastewater. Because the electro-Fenton reactors are typically operated in batch mode, their treatment capacities in full-scale applications are relatively lower than those of other Fenton processes. Furthermore, the high electricity cost involved during their operation could reduce the cost effectiveness for large-scale industrial effluent treatment. Chapter 11 Fenton- and ozone-based AOP processes Several achievements of the ozonation process have encouraged researchers to improve the drawbacks of ozonation technology, especially on the enhancement of the ozone utilization rate. The low ozone solubility and instability of ozone molecules in the aqueous phase in the conventional ozonation process lead to the development of technologies such as microbubble ozonation, catalytic ozonation, and combined microbubble ozonation. The literatures reveals that catalytic ozonation processes are feasible ozone AOPs for large-scale industrial effluent treatment while the catalyst selection for practical application becomes crucial, as many parameters such as catalyst leaching, dosage, regeneration, cost, etc., need to be considered. Introducing ozone gas into an aqueous system with microbubbles could facilitate gas-liquid ozone mass transfer and ozone dissolution. The application of microbubble technology in ozonation processes for efficiency improvement has been validated in both lab- and pilot-scale studies. In the context of large-scale industrial effluent treatment, microbubble technology is a straightforward modification method that could be retrofitted into the existing conventional ozonation process with minimal design alteration and additional operating cost. However, its ability for enhancing ozonation efficiency could be relatively limited when the target wastewater exhibits strong radical scavenging effects. Lab-scale studies demonstrated that combined catalyticmicrobubble ozonation exhibited remarkable synergistic effects on ozonation efficiency enhancement and organic pollutant abatement while pilot- or full-scale applications of this combined process are rather limited. More research efforts are needed before its exploitation in large-scale industrial effluent treatment. Some research gaps that should be addressed are the following: (1) the economic feasibility of the combined catalytic-microbubble ozonation process for industrial-scale applications; (2) the reaction mechanisms involved in the combined ozonation process; and (3) the impacts of water quality parameters such as pH, organic matter, and inorganic species. References Abida, O., Mailhot, G., Litter, M., Bolte, M., 2006. Impact of iron-complex (Fe(III)– NTA) on photoinduced degradation of 4-chlorophenol in aqueous solution. Photochem. Photobiol. Sci. 5, 395–402. Alvárez’, P.M., Beltrán, F.J., Masa, F.J., Pocostales, J.P., 2009. A comparison between catalytic ozonation and activated carbon adsorption/ozone-regeneration processes for wastewater treatment. Appl. Catal. B Environ. 92, 393–400. 243 244 Chapter 11 Fenton- and ozone-based AOP processes An, J., Zhu, L., Zhang, Y., Tang, H., 2013. Efficient visible light photo-Fenton-like degradation of organic pollutants using in situ surface-modified BiFeO3 as a catalyst. J. Environ. Sci. 25, 1213–1225. Anotai, J., Chen, C.-M., Bellotindos, L.M., Lu, M.-C., 2012. Treatment of TFT-LCD wastewater containing ethanolamine by fluidized-bed Fenton technology. Bioresour. Technol. 113, 272–275. Avetta, P., Pensato, A., Minella, M., Malandrino, M., Maurino, V., Minero, C., Hanna, K., Vione, D., 2015. Activation of persulfate by irradiated magnetite: implications for the degradation of phenol under heterogeneous photoFenton-like conditions. Environ. Sci. Technol. 49, 1043–1050. Babuponnusami, A., Muthukumar, K., 2012. Advanced oxidation of phenol: a comparison between Fenton, electro-Fenton, sono-electro-Fenton and photoelectro-Fenton processes. Chem. Eng. J. 183, 1–9. Bae, W., Won, H., Hwang, B., de Toledo, R.A., Chung, J., Kwon, K., Shim, H., 2015. Characterization of refractory matters in dyeing wastewater during a full-scale Fenton process following pure-oxygen activated sludge treatment. J. Hazard. Mater. 287, 421–428. Balcik-Canbolat, C., Sakar, H., Karagunduz, A., Keskinler, B., 2016. Advanced treatment of biologically treated medium density fiberboard (MDF) wastewater with Fenton and Fenton enhanced hydrodynamic cavitation process. J. Chem. Technol. Biotechnol. 91, 2935–2941. Bampalioutas, K., Vlysidis, A., Lyberatos, G., Vlyssides, A., 2019. Detoxification and methane production kinetics from three-phase olive mill wastewater using Fenton’s reagent followed by anaerobic digestion. J. Chem. Technol. Biotechnol. 94, 265–275. Barhoumi, N., Labiadh, L., Oturan, M.A., Oturan, N., Gadri, A., Ammar, S., Brillas, E., 2015. Electrochemical mineralization of the antibiotic levofloxacin by electroFenton-pyrite process. Chemosphere 141, 250–257. Barhoumi, N., Oturan, N., Ammar, S., Gadri, A., Oturan, M.A., Brillas, E., 2017. Enhanced degradation of the antibiotic tetracycline by heterogeneous electro-Fenton with pyrite catalysis. Environ. Chem. Lett. 15, 689–693. Barndõk, H., Blanco, L., Hermosilla, D., Blanco, Á., 2016. Heterogeneous photoFenton processes using zero valent iron microspheres for the treatment of wastewaters contaminated with 1,4-dioxane. Chem. Eng. J. 284, 112–121. Bautista, P., Mohedano, A.F., Casas, J.A., Zazo, J.A., Rodriguez, J.J., 2008. An overview of the application of Fenton oxidation to industrial wastewaters treatment. J. Chem. Technol. Biotechnol. 83, 1323–1338. Bello, M.M., Abdul Raman, A.A., Asghar, A., 2019. Fenton oxidation treatment of recalcitrant dye in fluidized bed reactor: role of SiO2 as carrier and its interaction with fenton’s reagent. Environ. Prog. Sustain. Energy 38, 13188–13196. Beltrán, F.J., 2004. Ozone Reaction Kinetics for Water and Wastewater Systems. Lewis Publishers, Boca Raton, FL. Beltrán, F.J., Rivas, F.J., Montero-de-Espinosa, R., 2005. Iron type catalysts for the ozonation of oxalic acid in water. Water Res. 39, 3553–3564. Beltrán, F.J., Pocostales, J.P., Alvarez, P.M., Jaramillo, J., 2009. Mechanism and kinetic considerations of TOC removal from the powdered activated carbon ozonation of diclofenac aqueous solutions. J. Hazard. Mater. 169, 532–538. Boonrattanakij, N., Lu, M.-C., Anotai, J., 2011. Iron crystallization in a fluidized-bed Fenton process. Water Res. 45, 3255–3262. Boonrattanakij, N., Sakul, W., Garcia-Segura, S., Lu, M.-C., 2018. Implementation of fluidized-bed Fenton as pre-treatment to reduce chemical oxygen demand of wastewater from screw manufacture: influence of reagents feeding mode. Sep. Purif. Technol. 202, 275–280. Chapter 11 Fenton- and ozone-based AOP processes Brillas, E., Sir es, I., Oturan, M.A., 2009. Electro-Fenton process and related electrochemical technologies based on Fenton’s reaction chemistry. Chem. Rev. 109, 6570–6631. Briones, R.M., de Luna, M.D.G., Lu, M.-C., 2012. Optimization of acetaminophen degradation by fluidized-bed Fenton process. Desalin. Water Treat. 45, 100–111. Buxton, G.V., Greenstock, C.L., Helman, W.P., Ross, A.B., 1988. Critical review of rate constants for reactions of hydrated electrons, hydrogen atoms and hydroxyl radicals (•OH/•O) in aqueous solution. J. Phys. Chem. Ref. Data Monogr. 17, 513–886. Chen, W.-S., Huang, C.-P., 2014. Decomposition of nitrotoluenes in wastewater by sonoelectrochemical and sonoelectro-Fenton oxidation. Ultrason. Sonochem. 21, 840–845. Chen, C.-Y., Wu, P.-S., Chung, Y.-C., 2009. Coupled biological and photo-Fenton pretreatment system for the removal of di-(2-ethylhexyl) phthalate (DEHP) from water. Bioresour. Technol. 100, 4531–4534. Chen, M., Ren, H., Ding, L., Gao, B., 2015a. Effect of different carriers and operating parameters on degradation of flax wastewater by fluidized-bed Fenton process. Water Sci. Technol. 71, 1760–1767. Chen, C., Yoza, B.A., Wang, Y., Wang, P., Li, Q.X., Guo, S., Yan, G., 2015b. Catalytic ozonation of petroleum refinery wastewater utilizing Mn-Fe-Cu/Al2O3 catalyst. Environ. Sci. Pollut. Res. 22, 5552–5562. Chen, S., Yu, J., Wang, H., Yu, H., Quan, X., 2015c. A pilot-scale coupling catalytic ozonation–membrane filtration system for recirculating aquaculture wastewater treatment. Desalination 363, 37–43. Chen, Y., Cheng, Y., Guan, X., Liu, Y., Nie, J., Li, C., 2019. A rapid Fenton treatment of bio-treated dyeing and finishing wastewater at second-scale intervals: kinetics by stopped-flow technique and application in a full-scale plant. Sci. Rep. 9, 1–11. Cheng, W., Quan, X., Li, R., Wu, J., Zhao, Q., 2018. Ozonation of phenol-containing wastewater using O3/Ca(OH)2 system in a micro bubble gas-liquid reactor. Ozone Sci. Eng. 40, 173–182. Cho, H.-H., Huang, H., Schwab, K., 2011. Effects of solution chemistry on the adsorption of ibuprofen and triclosan onto carbon nanotubes. Langmuir 27, 12960–12967. Chu, L.-B., Xing, X.-H., Yu, A.-F., Sun, X.-L., Jurcik, B., 2008. Enhanced treatment of practical textile wastewater by microbubble ozonation. Process Saf. Environ. Prot. 86, 389–393. Clarizia, L., Russo, D., Di Somma, I., Marotta, R., Andreozzi, R., 2017. Homogeneous photo-Fenton processes at near neutral pH: a review. Appl. Catal. B Environ. 209, 358–371. Cui, X., Zeng, P., Qiu, G., Liu, Y., Song, Y., Xie, X., Han, L., 2015. Pilot-scale treatment of pharmaceutical berberine wastewater by Fenton oxidation. Environ. Earth Sci. 73, 4967–4977. Danckwerts, P.V., 1970. Gas-Liquid Reactions. McGraw-Hill, New York. Davarnejad, R., Sabzehei, M., 2019. Sodium diclofenac removal from a pharmaceutical wastewater by electro-Fenton process. Sep. Sci. Technol. 54, 2294–2303. Deng, F., Qiu, S., Chen, C., Ding, X., Ma, F., 2015. Heterogeneous catalytic ozonation of refinery wastewater over alumina-supported Mn and Cu oxides catalyst. Ozone Sci. Eng. 37, 546–555. Diz, H.R., Novak, J.T., 1998. Fluidized bed for removing iron and acidity from acid mine drainage. J. Environ. Eng. 124, 701–708. El-Ghenymy, A., Rodrı́guez, R.M., Brillas, E., Oturan, N., Oturan, M.A., 2014. Electro-Fenton degradation of the antibiotic sulfanilamide with Pt/carbon-felt and 245 246 Chapter 11 Fenton- and ozone-based AOP processes BDD/carbon-felt cells. Kinetics, reaction intermediates, and toxicity assessment. Environ. Sci. Pollut. Res. 21, 8368–8378. Expósito, E., Sánchez-Sánchez, C.M., Montiel, V., 2007. Mineral iron oxides as iron source in electro-Fenton and photoelectro-Fenton mineralization processes. J. Electrochem. Soc. 154, E116. Expósito, A.J., Monteagudo, J.M., Dı́az, I., Durán, A., 2016. Photo-fenton degradation of a beverage industrial effluent: intensification with persulfate and the study of radicals. Chem. Eng. J. 306, 1203–1211. Fan, D., Wei, J., Song, Y.-H., Zeng, P., Cui, X., Xu, D., 2015. Treatment of reverse osmosis concentrate of petrochemical wastewater by Fered-Fenton process. Chin. J. Environ. Eng. 9, 2653–2659. Fang, F., Han, H., 2018. Effect of catalytic ozonation coupling with activated carbon adsorption on organic compounds removal treating RO concentrate from coal gasification wastewater. Ozone Sci. Eng. 40, 275–283. Faria, P.C.C., Órfão, J.J.M., Pereira, M.F.R., 2008. Catalytic ozonation of sulfonated aromatic compounds in the presence of activated carbon. Appl. Catal. B Environ. 83, 150–159. Farzadkia, M., Dadban Shahamat, Y., Nasseri, S., Mahvi, A.H., Gholami, M., Shahryari, A., 2014. Catalytic ozonation of phenolic wastewater: identification and toxicity of intermediates. J. Eng. 2014, 1–10. , J., 1990. Photolysis of Fe (III)-hydroxy complexes as sources of Faust, B.C., Hoigne OH radicals in clouds, fog and rain. Atmos. Environ. A Gen. Top. 24, 79–89. Faust, B.C., Zepp, R.G., 1993. Photochemistry of aqueous iron(III)-polycarboxylate complexes: roles in the chemistry of atmospheric and surface waters. Environ. Sci. Technol. 27, 2517–2522. Fenton, H.J.H., 1894. LXXIII.—Oxidation of tartaric acid in presence of iron. J. Chem. Soc. Trans. 65, 899–910. Flox, C., Ammar, S., Arias, C., Brillas, E., Vargas-Zavala, A.V., Abdelhedi, R., 2006. Electro-Fenton and photoelectro-Fenton degradation of indigo carmine in acidic aqueous medium. Appl. Catal. B Environ. 67, 93–104. Foteinis, S., Monteagudo, J.M., Durán, A., Chatzisymeon, E., 2018. Environmental sustainability of the solar photo-Fenton process for wastewater treatment and pharmaceuticals mineralization at semi-industrial scale. Sci. Total Environ. 612, 605–612. Ganiyu, S.O., Zhou, M., Martı́nez-Huitle, C.A., 2018. Heterogeneous electro-Fenton and photoelectro-Fenton processes: a critical review of fundamental principles and application for water/wastewater treatment. Appl. Catal. B Environ. 235, 103–129. Gao, Y., Wang, Y., Zhang, H., 2015. Removal of rhodamine B with Fe-supported bentonite as heterogeneous photo-Fenton catalyst under visible irradiation. Appl. Catal. B Environ. 178, 29–36. Gao, Y., Duan, Y., Fan, W., Guo, T., Huo, M., Yang, W., Zhu, S., An, W., 2019. Intensifying ozonation treatment of municipal secondary effluent using a combination of microbubbles and ultraviolet irradiation. Environ. Sci. Pollut. Res. 26, 21915–21924. Garcia-Rodriguez, O., Lee, Y.Y., Olvera-Vargas, H., Deng, F., Wang, Z., Lefebvre, O., 2018. Mineralization of electronic wastewater by electro-Fenton with an enhanced graphene-based gas diffusion cathode. Electrochim. Acta 276, 12–20. Garrido-Ramı́rez, E.G., Marco, J.F., Escalona, N., Ureta-Zañartu, M.S., 2016. Preparation and characterization of bimetallic Fe–Cu allophane nanoclays and their activity in the phenol oxidation by heterogeneous electro-Fenton reaction. Microporous Mesoporous Mater. 225, 303–311. Chapter 11 Fenton- and ozone-based AOP processes Gharbani, P., Mehrizad, A., 2014. Heterogeneous catalytic ozonation process for removal of 4-chloro-2-nitrophenol from aqueous solutions. J. Saudi Chem. Soc. 18, 601–605. GilPavas, E., Dobrosz-Gómez, I., Gómez-Garcı́a, M.Á., 2017. Coagulationflocculation sequential with Fenton or photo-Fenton processes as an alternative for the industrial textile wastewater treatment. J. Environ. Manage. 191, 189–197. Giraldo-Aguirre, A.L., Serna-Galvis, E.A., Erazo-Erazo, E.D., Silva-Agredo, J., Giraldo-Ospina, H., Flórez-Acosta, O.A., Torres-Palma, R.A., 2018. Removal of β-lactam antibiotics from pharmaceutical wastewaters using photo-Fenton process at near-neutral pH. Environ. Sci. Pollut. Res. 25, 20293–20303. Glaze, W.H., Kang, J.-W., Chapin, D.H., 1987. The chemistry of water treatment processes involving ozone, hydrogen peroxide and ultraviolet radiation. Ozone Sci. Eng. 9, 335–352. Gonzalez-Olmos, R., Martin, M.J., Georgi, A., Kopinke, F.-D., Oller, I., Malato, S., 2012. Fe-zeolites as heterogeneous catalysts in solar Fenton-like reactions at neutral pH. Appl. Catal. B Environ. 125, 51–58. Gottschalk, C., Libra, J.A., Saupe, A., 2010. Ozonation of Water and Waste Water: A Practical Guide to Understanding Ozone and Its Applications, second completely rev. and updat ed. Wiley-VCH, Chichester; Weinheim. Guandao, G., Qiaoying, Z., Zhenwei, H., Vecitis, C.D., 2015. Carbon nanotube membrane stack for flow-through sequential regenerative electro-Fenton. Environ. Sci. Technol. 49, 2375. Guo, W.-Q., Yin, R.-L., Zhou, X.-J., Cao, H.-O., Chang, J.-S., Ren, N.-Q., 2016. Ultrasonic-assisted ozone oxidation process for sulfamethoxazole removal: impact factors and degradation process. Desalin. Water Treat. 57, 21015–21022. Guo, Y., Xue, Q., Zhang, H., Wang, N., Chang, S., Wang, H., Pang, H., Chen, H., 2018. Treatment of real benzene dye intermediates wastewater by the Fenton method: characteristics and multi-response optimization. RSC Adv. 8, 80–90. Guzmán, J., Mosteo, R., Sarasa, J., Alba, J.A., Ovelleiro, J.L., 2016. Evaluation of solar photo-Fenton and ozone based processes as citrus wastewater pre-treatments. Sep. Purif. Technol. 164, 155–162. Hermosilla, D., Cortijo, M., Huang, C.P., 2009. Optimizing the treatment of landfill leachate by conventional Fenton and photo-Fenton processes. Sci. Total Environ. 407, 3473–3481. Hou, B., Han, H., Jia, S., Zhuang, H., Xu, P., Wang, D., 2015. Heterogeneous electroFenton oxidation of catechol catalyzed by nano-Fe3O4: kinetics with the Fermi’s equation. J. Taiwan Inst. Chem. Eng. 56, 138–147. Hou, B., Han, H., Jia, S., Zhuang, H., Xu, P., Li, K., 2016. Three-dimensional heterogeneous electro-Fenton oxidation of biologically pretreated coal gasification wastewater using sludge derived carbon as catalytic particle electrodes and catalyst. J. Taiwan Inst. Chem. Eng. 60, 352–360. Huang, Y., Sun, Y., Xu, Z., Luo, M., Zhu, C., Li, L., 2017a. Removal of aqueous oxalic acid by heterogeneous catalytic ozonation with MnOx/sewage sludge-derived activated carbon as catalysts. Sci. Total Environ. 575, 50–57. Huang, Y., Xu, W., Hu, L., Zeng, J., He, C., He, Z., Tan, X., Zhang, Q., Shu, D., 2017b. Combined adsorption and catalytic ozonation for removal of endocrine disrupting compounds over MWCNTs/Fe3O4 composites. Catal. Today 297, 143–150. Huang, X., Cheng, W., Quan, X., Cheng, C., Cheng, Z., Yang, L., 2019. Catalytic ozonation of biologically treated leachate from municipal solid waste in a microbubble reactor. Ozone Sci. Eng. 41, 415–426. 247 248 Chapter 11 Fenton- and ozone-based AOP processes Iglesias, O., Fernández de Dios, M.A., Pazos, M., Sanromán, M.A., 2013. Using ironloaded sepiolite obtained by adsorption as a catalyst in the electro-Fenton oxidation of Reactive Black 5. Environ. Sci. Pollut. Res. 20, 5983–5993. Iglesias, O., Meijide, J., Bocos, E., Sanromán, M.Á., Pazos, M., 2015. New approaches on heterogeneous electro-Fenton treatment of winery wastewater. Electrochim. Acta 169, 134–141. Isarain-Chávez, E., Garrido, J.A., Rodrı́guez, R.M., Centellas, F., Arias, C., Cabot, P.L., Brillas, E., 2011. Mineralization of metoprolol by electro-Fenton and photoelectro-Fenton processes. J. Phys. Chem. A 115, 1234–1242. Jabesa, A., Ghosh, P., 2016. Removal of diethyl phthalate from water by ozone microbubbles in a pilot plant. J. Environ. Manage. 180, 476–484. Jabesa, A., Ghosh, P., 2017. Removal of dimethyl phthalate from water by ozone microbubbles. Environ. Technol. 38, 2093–2103. Jiang, W.-L., Xia, X., Han, J.-L., Ding, Y.-C., Haider, M.R., Wang, A.-J., 2018. Graphene modified electro-Fenton catalytic membrane for in situ degradation of antibiotic florfenicol. Environ. Sci. Technol. 52, 9972–9982. Jothinathan, L., Hu, J., 2018. Kinetic evaluation of graphene oxide based heterogenous catalytic ozonation for the removal of ibuprofen. Water Res. 134, 63–73. Jung, H., Choi, H., 2006. Catalytic decomposition of ozone and para-chlorobenzoic acid (pCBA) in the presence of nanosized ZnO. Appl. Catal. B Environ. 66, 288–294. Kang, Y.W., Hwang, K.-Y., 2000. Effects of reaction conditions on the oxidation efficiency in the Fenton process. Water Res. 34, 2786–2790. Kasprzyk-Hordern, B., Raczyk-Stanisławiak, U., Świetlik, J., Nawrocki, J., 2006. Catalytic ozonation of natural organic matter on alumina. Appl. Catal. B Environ. 62, 345–358. Khuntia, S., Majumder, S.K., Ghosh, P., 2015. A pilot plant study of the degradation of Brilliant Green dye using ozone microbubbles: mechanism and kinetics of reaction. Environ. Technol. 36, 336–347. Kim, S., Yang, Y.L., Christoffersen, R., Jacobson, A.J., 1998. Determination of oxygen permeation kinetics in a ceramic membrane based on the composition SrFeCo0.5O3.25 δ. Solid State Ion. 109, 187–196. Kitsiou, V., Antoniadis, A., Mantzavinos, D., Poulios, I., 2014. Homogeneous photoFenton mineralization of the antibiotic sulfamethazine in water under UV-A, visible and solar irradiation: photo-Fenton mineralization of sulfamethazine. J. Chem. Technol. Biotechnol. 89, 1668–1674. Knopp, G., Prasse, C., Ternes, T.A., Cornel, P., 2016. Elimination of micropollutants and transformation products from a wastewater treatment plant effluent through pilot scale ozonation followed by various activated carbon and biological filters. Water Res. 100, 580–592. Kocot, P., Karocki, A., Stasicka, Z., 2006. Photochemistry of the Fe(III)–EDTA complexes: a mechanistic study. J. Photochem. Photobiol. A Chem. 179, 176–183. Kurt, U., Apaydin, O., Gonullu, M.T., 2007. Reduction of COD in wastewater from an organized tannery industrial region by electro-Fenton process. J. Hazard. Mater. 143, 33–40. Lai, C., Huang, F., Zeng, G., Huang, D., Qin, L., Cheng, M., Zhang, C., Li, B., Yi, H., Liu, S., Li, L., Chen, L., 2019. Fabrication of novel magnetic MnFe2O4/bio-char composite and heterogeneous photo-Fenton degradation of tetracycline in near neutral pH. Chemosphere 224, 910–921. Le, S.T.T., Ngo, T.T., Khanitchaidecha, W., Nakaruk, A., 2015. Synthesis of iron/GAC catalyst for wastewater treatment using heterogeneous Fenton reaction. Bull. Mater. Sci. 38, 1039–1042. Legube, B., Karpel Vel, N., 1999. Leitner, catalytic ozonation: a promising advanced oxidation technology for water treatment. Catal. Today 53, 61–72. Chapter 11 Fenton- and ozone-based AOP processes Leili, M., Moussavi, G., Naddafi, K., 2013. Degradation and mineralization of furfural in aqueous solutions using heterogeneous catalytic ozonation. Desalin. Water Treat. 51, 6789–6797. Li, P., Takahashi, M., Chiba, K., 2009. Degradation of phenol by the collapse of microbubbles. Chemosphere 75, 1371–1375. Li, Z., Zhao, J., Zhong, W., Duan, E., Li, G., Liu, Y., Gao, X., 2015. Efficiency and kinetics of catalytic ozonation of Acid Red B over Cu-Mn/γ-Al2O3 catalysts. Ozone Sci. Eng. 37, 287–293. Li, X., Chen, W., Li, L., 2018. Catalytic ozonation of oxalic acid in the presence of Fe2O3-loaded activated carbon. Ozone Sci. Eng. 40, 448–456. Lima, M.J., Silva, C.G., Silva, A.M.T., Lopes, J.C.B., Dias, M.M., Faria, J.L., 2017. Homogeneous and heterogeneous photo-Fenton degradation of antibiotics using an innovative static mixer photoreactor. Chem. Eng. J. 310, 342–351. Lin, S.H., Lo, C.C., 1997. Fenton process for treatment of desizing wastewater. Water Res. 31, 2050–2056. Lin, S.H., Lin, C.M., Leu, H.G., 1999. Operating characteristics and kinetic studies of surfactant wastewater treatment by Fenton oxidation. Water Res. 33, 1735–1741. Liu, Z.-Q., Ma, J., Cui, Y.-H., Zhang, B.-P., 2009. Effect of ozonation pretreatment on the surface properties and catalytic activity of multi-walled carbon nanotube. Appl. Catal. B Environ. 92, 301–306. Liu, Z.-Q., Ma, J., Cui, Y.-H., Zhao, L., Zhang, B.-P., 2011. Factors affecting the catalytic activity of multi-walled carbon nanotube for ozonation of oxalic acid. Sep. Purif. Technol. 78, 147–153. Liu, J., Li, J., Mei, R., Wang, F., Sellamuthu, B., 2014. Treatment of recalcitrant organic silicone wastewater by fluidized-bed Fenton process. Sep. Purif. Technol. 132, 16–22. Liu, Y., Li, G., Zhang, Z., Gao, X., Niu, J., Zhao, J., Li, Z., 2016. Catalytic ozonation of bisphenol A in aqueous medium by Mn-Fe/Al2O3 catalyst. J. Adv. Oxid. Technol. 14, 358. Liu, Y., Jin, W., Zhao, Y., Zhang, G., Zhang, W., 2017. Enhanced catalytic degradation of methylene blue by α-Fe2O3/graphene oxide via heterogeneous photo-Fenton reactions. Appl. Catal. B Environ. 206, 642–652. Liu, C., Chen, X.-X., Zhang, J., Zhou, H.-Z., Zhang, L., Guo, Y.-K., 2018. Advanced treatment of bio-treated coal chemical wastewater by a novel combination of microbubble catalytic ozonation and biological process. Sep. Purif. Technol. 197, 295–301. € , X., Zhang, Q., Yang, W., Li, X., Zeng, L., Li, L., 2015. Catalytic ozonation of 2,4Lu dichlorophenoxyacetic acid over novel Fe–Ni/AC. RSC Adv. 5, 10537–10545. Luo, M., Yuan, S., Tong, M., Liao, P., Xie, W., Xu, X., 2014. An integrated catalyst of Pd supported on magnetic Fe3O4 nanoparticles: simultaneous production of H2O2 and Fe2+ for efficient electro-Fenton degradation of organic contaminants. Water Res. 48, 190–199. Lyu, C., Zhou, D., Wang, J., 2016. Removal of multi-dye wastewater by the novel integrated adsorption and Fenton oxidation process in a fluidized bed reactor. Environ. Sci. Pollut. Res. 23, 20893–20903. Ma, J., Chen, Y., Nie, J., Ma, L., Huang, Y., Li, L., Liu, Y., Guo, Z., 2018. Pilot-scale study on catalytic ozonation of bio-treated dyeing and finishing wastewater using recycled waste iron shavings as a catalyst. Sci. Rep. 8, 7511–7555. Ma, C., Yuan, P., Jia, S., Liu, Y., Zhang, X., Hou, S., Zhang, H., He, Z., 2019. Catalytic micro-ozonation by Fe3O4 nanoparticles @ cow-dung ash for advanced treatment of biologically pre-treated leachate. Waste Manage. 83, 23–32. Marcinowski, P.P., Bogacki, J.P., Naumczyk, J.H., 2014. Cosmetic wastewater treatment using the Fenton, photo-Fenton and H2O2/UV processes. J. Environ. Sci. Health A 49, 1531–1541. 249 250 Chapter 11 Fenton- and ozone-based AOP processes Martı́nez-Costa, J.I., Rivera-Utrilla, J., Leyva-Ramos, R., Sánchez-Polo, M., Velo-Gala, I., Mota, A.J., 2018. Individual and simultaneous degradation of the antibiotics sulfamethoxazole and trimethoprim in aqueous solutions by Fenton, Fenton-like and photo-Fenton processes using solar and UV radiations. J. Photochem. Photobiol. A Chem. 360, 95–108. Matira, E.M., Chen, T.-C., Lu, M.-C., Dalida, M.L.P., 2015. Degradation of dimethyl sulfoxide through fluidized-bed Fenton process. J. Hazard. Mater. 300, 218–226. Methatham, T., Bellotindos, L.M., Chen, T.E., Lu, M.C., 2016. Factors affecting treatment of TFT-LCD wastewater by fenton and electro-Fenton processes. Environ. Prog. Sustain. Energy 35, 368–373. Muthukumari, B., Selvam, K., Muthuvel, I., Swaminathan, M., 2009. Photoassisted hetero-Fenton mineralisation of azo dyes by Fe(II)-Al2O3 catalyst. Chem. Eng. J. 153, 9–15. Nawrocki, J., Kasprzyk-Hordern, B., 2010. The efficiency and mechanisms of catalytic ozonation. Appl. Catal. B Environ. 99, 27–42. Neyens, E., Baeyens, J., 2003. A review of classic Fenton’s peroxidation as an advanced oxidation technique. J. Hazard. Mater. 98, 33–50. Nidheesh, P.V., Gandhimathi, R., 2012. Trends in electro-Fenton process for water and wastewater treatment: an overview. Desalination 299, 1–15. bana, M.C., Sánchez-López, E., Hidalgo-Carrillo, J., Marinas, A., Ortega-Lie Marinas, J.M., Urbano, F.J., 2012. A comparative study of photocatalytic degradation of 3-chloropyridine under UV and solar light by homogeneous (photoFenton) and heterogeneous (TiO2) photocatalysis. Appl. Catal. B Environ. 127, 316–322. Oturan, M.A., Aaron, J.-J., 2014. Advanced oxidation processes in water/wastewater treatment: principles and applications. A review. Crit. Rev. Environ. Sci. Technol. 44, 2577–2641. Oulton, R., Haase, J.P., Kaalberg, S., Redmond, C.T., Nalbandian, M.J., Cwiertny, D.M., 2015. Hydroxyl radical formation during ozonation of multiwalled carbon nanotubes: performance optimization and demonstration of a reactive CNT filter. Environ. Sci. Technol. 49, 3687–3697. Panizza, M., Cerisola, G., 2005. Application of diamond electrodes to electrochemical processes. Electrochim. Acta 51, 191–199. Park, J.-S., Choi, H., Cho, J., 2004. Kinetic decomposition of ozone and para-chlorobenzoic acid (pCBA) during catalytic ozonation. Water Res. 38, 2285–2292. Perreault, F., Fonseca de Faria, A., Elimelech, M., 2015. Environmental applications of graphene-based nanomaterials. Chem. Soc. Rev. 44, 5861–5896. Qiu, S., He, D., Ma, J., Liu, T., Waite, T.D., 2015. Kinetic modeling of the electroFenton process: quantification of reactive oxygen species generation. Electrochim. Acta 176, 51–58. Quan, X., Luo, D., Wu, J., Li, R., Cheng, W., Ge, s., 2017. Ozonation of acid red 18 wastewater using O3/Ca(OH)2 system in a micro bubble gas-liquid reactor. J. Environ. Chem. Eng. 5, 283–291. Rahim Pouran, S., Abdul Aziz, A.R., Wan Daud, W.M.A., 2015. Review on the main advances in photo-Fenton oxidation system for recalcitrant wastewaters. J. Ind. Eng. Chem. 21, 53–69. Rivas, F.J., Beltrán, F.J., Frades, J., Buxeda, P., 2001. Oxidation of p-hydroxybenzoic acid by Fenton’s reagent. Water Res. 35, 387–396. Rodrı́guez-Chueca, J., Amor, C., Fernandes, J.R., Tavares, P.B., Lucas, M.S., Peres, J.A., 2016. Treatment of crystallized-fruit wastewater by UV-A LED photo-Fenton and coagulation–flocculation. Chemosphere 145, 351–359. Rosal, R., Gonzalo, M.S., Rodrı́guez, A., Garcı́a-Calvo, E., 2009. Ozonation of clofibric acid catalyzed by titanium dioxide. J. Hazard. Mater. 169, 411–418. Chapter 11 Fenton- and ozone-based AOP processes Rosenfeldt, E.J., Linden, K.G., Canonica, S., von Gunten, U., 2006. Comparison of the efficiency of OH radical formation during ozonation and the advanced oxidation processes O3/H2O2 and UV/H2O2. Water Res. 40, 3695–3704. Roshani, B., McMaster, I., Rezaei, E., Soltan, J., 2014. Catalytic ozonation of benzotriazole over alumina supported transition metal oxide catalysts in water. Sep. Purif. Technol. 135, 158–164. € era, A., Malato, S., 2019. Natural Ruı́z-Delgado, A., Roccamante, M.A., Oller, I., Agu chelating agents from olive mill wastewater to enable photo-Fenton-like reactions at natural pH. Catal. Today 328, 281–285. Rusevova, K., Kopinke, F.-D., Georgi, A., 2012. Nano-sized magnetic iron oxides as catalysts for heterogeneous Fenton-like reactions—influence of Fe(II)/Fe(III) ratio on catalytic performance. J. Hazard. Mater. 241–242, 433–440. Sánchez-Sánchez, C.M., Expósito, E., Casado, J., Montiel, V., 2007. Goethite as a more effective iron dosage source for mineralization of organic pollutants by electro-Fenton process. Electrochem. Commun. 9, 19–24. Shahamat, Y.D., Farzadkia, M., Nasseri, S., Mahvi, A.H., Gholami, M., Esrafili, A., 2014. Magnetic heterogeneous catalytic ozonation: a new removal method for phenol in industrial wastewater. J. Environ. Health Sci. Eng. 12, 50. Shemer, H., Kunukcu, Y.K., Linden, K.G., 2006. Degradation of the pharmaceutical metronidazole via UV, Fenton and photo-Fenton processes. Chemosphere 63, 269–276. Soares, O.S.G.P., Gonçalves, A.G., Delgado, J.J., Órfão, J.J.M., Pereira, M.F.R., 2015. Modification of carbon nanotubes by ball-milling to be used as ozonation catalysts. Catal. Today 249, 199–203. Su, C.-C., Pukdee-Asa, M., Ratanatamskul, C., Lu, M.-C., 2011. Effect of operating parameters on the decolorization and oxidation of textile wastewater by the fluidized-bed Fenton process. Sep. Purif. Technol. 83, 100–105. Su, C.-C., Chen, C.-M., Anotai, J., Lu, M.-C., 2013. Removal of monoethanolamine and phosphate from thin-film transistor liquid crystal display (TFT-LCD) wastewater by the fluidized-bed Fenton process. Chem. Eng. J. 222, 128–135. Sui, M., Xing, S., Sheng, L., Huang, S., Guo, H., 2012. Heterogeneous catalytic ozonation of ciprofloxacin in water with carbon nanotube supported manganese oxides as catalyst. J. Hazard. Mater. 227, 227–236. Sychev, A.Y., Isak, V.G., 1995. Iron compounds and the mechanisms of the homogeneous catalysis of the activation of O2 and H2O2 and of the oxidation of organic substrates. Russ. Chem. Rev. 64, 1105–1129. Szpyrkowicz, L., Juzzolino, C., Kaul, S.N., 2001. A comparative study on oxidation of disperse dyes by electrochemical process, ozone, hypochlorite and fenton reagent. Water Res. 35, 2129–2136. Takahashi, M., Kawamura, T., Yamamoto, Y., Ohnari, H., Himuro, S., Shakutsui, H., 2003. Effect of shrinking microbubble on gas hydrate formation. J. Phys. Chem. B. 107, 2171–2173. Takahashi, M., Chiba, K., Li, P., 2007. Free-radical generation from collapsing microbubbles in the absence of a dynamic stimulus. J. Phys. Chem. B 111, 1343–1347. Teng, Y., Yao, K., Song, W., Sun, Y., Liu, H., Liu, Z., Xu, Y., 2019. Preparation and characterization of Cu-Mn-Ce@gamma-Al2O3 to catalyze ozonation in coal chemical wastewater-biotreated effluent. Int. J. Environ. Res. Public Health 16, 1439–1460. Tizaoui, C., Mohammad-Salim, H., Suhartono, J., 2015. Multiwalled carbon nanotubes for heterogeneous nanocatalytic ozonation. Ozone Sci. Eng. 37, 269–278. Trellu, C., Oturan, N., Keita, F.K., Fourdrin, C., Pechaud, Y., Oturan, M.A., 2018. Regeneration of activated carbon fiber by the electro-Fenton process. Environ. Sci. Technol. 52, 7450–7457. 251 252 Chapter 11 Fenton- and ozone-based AOP processes Upadhyayula, V.K., Deng, S., Mitchell, M.C., Smith, G.B., 2009. Application of carbon nanotube technology for removal of contaminants in drinking water: a review. Sci. Total Environ. 408, 1–13. Vittenet, J., Aboussaoud, W., Mendret, J., Pic, J.-S., Debellefontaine, H., Lesage, N., Faucher, K., Manero, M.-H., Thibault-Starzyk, F., Leclerc, H., Galarneau, A., Brosillon, S., 2015. Catalytic ozonation with γ-Al2O3 to enhance the degradation of refractory organics in water. Appl. Catal. Gen. 504, 519–532. Walling, C., Kato, S., 1971. Oxidation of alcohols by Fenton’s reagent. Effect of copper ion. J. Am. Chem. Soc. 93, 4275–4281. Wang, J., Bai, Z., 2017. Fe-based catalysts for heterogeneous catalytic ozonation of emerging contaminants in water and wastewater. Chem. Eng. J. 312, 79–98. Wang, A., Li, Y.-Y., Estrada, A.L., 2011. Mineralization of antibiotic sulfamethoxazole by photoelectro-Fenton treatment using activated carbon fiber cathode and under UVA irradiation. Appl. Catal. B Environ. 102, 378–386. Wang, Y., Xie, Y., Sun, H., Xiao, J., Cao, H., Wang, S., 2016. Efficient catalytic ozonation over reduced graphene oxide for p-hydroxylbenzoic acid (PHBA) destruction: active site and mechanism. ACS Appl. Mater. Interfaces 8, 9710–9720. Wang, B., Zhang, H., Wang, F., Xiong, X., Tian, K., Sun, Y., Yu, T., 2019a. Application of heterogeneous catalytic ozonation for refractory organics in wastewater. Catalysts 9, 241. Wang, W.-L., Hu, H.-Y., Liu, X., Shi, H.-X., Zhou, T.-H., Wang, C., Huo, Z.-Y., Wu, Q.-Y., 2019b. Combination of catalytic ozonation by regenerated granular activated carbon (rGAC) and biological activated carbon in the advanced treatment of textile wastewater for reclamation. Chemosphere 231, 369–377. Wei, K., Cao, X., Gu, W., Liang, P., Huang, X., Zhang, X., 2019. Ni-induced C-Al2O3framework (NiCAF) supported core–multishell catalysts for efficient catalytic ozonation: a structure-to-performance study. Environ. Sci. Technol. 53, 6917–6926. Weller, C., Horn, S., Herrmann, H., 2013. Effects of Fe(III)-concentration, speciation, excitation-wavelength and light intensity on the quantum yield of iron (III)-oxalato complex photolysis. J. Photochem. Photobiol. A Chem. 255, 41–49. Wu, Z.-w., Xu, X.-c., Jiang, H.-b., Zhang, R.-y., Song, S.-n., Zhao, C.-q., Yang, F.-l., 2017. Evaluation and optimization of a pilot-scale catalytic ozonation– persulfate oxidation integrated process for the pretreatment of dry-spun acrylic fiber wastewater. RSC Adv. 7, 44059–44067. Wu, C., Li, P., Xia, S., Wang, S., Wang, Y., Hu, J., Liu, Z., Yu, S., 2019. The role of interface in microbubble ozonation of aromatic compounds. Chemosphere 220, 1067–1074. Xia, Z., Hu, L., 2018. Treatment of organics contaminated wastewater by ozone micro-nano-bubbles. Water 11, 55. Xiao, X., Sun, Y., Sun, W., Shen, H., Zheng, H., Xu, Y., Zhao, J., Wu, H., Liu, C., 2017. Advanced treatment of actual textile dye wastewater by Fenton-flocculation process. Can. J. Chem. Eng. 95, 1245–1252. Xiong, X., Wang, B., Zhu, W., Tian, K., Zhang, H., 2018. A review on ultrasonic catalytic microbubbles ozonation processes: properties, hydroxyl radicals generation pathway and potential in application. Catalysts 9, 10. Xiong, W., Chen, N., Feng, C., Liu, Y., Ma, N., Deng, J., Xing, L., Gao, Y., 2019. Ozonation catalyzed by iron- and/or manganese-supported granular activated carbons for the treatment of phenol. Environ. Sci. Pollut. Res. Int. 26, 21022–21033. Xu, X.-R., Li, X.-Y., Li, X.-Z., Li, H.-B., 2009. Degradation of melatonin by UV, UV/ H2O2, Fe2+/H2O2 and UV/Fe2+/H2O2 processes. Sep. Purif. Technol. 68, 261–266. Xu, Z., Mochida, K., Naito, T., Yasuda, K., 2012. Effects of operational conditions on 1,4-dioxane degradation by combined use of ultrasound and ozone microbubbles. Jpn. J. Appl. Phys. 51. Chapter 11 Fenton- and ozone-based AOP processes Xu, Y., Wang, Q., Yoza, B.A., Li, Q.X., Kou, Y., Tang, Y., Ye, H., Li, Y., Chen, C., 2019. Catalytic ozonation of recalcitrant organic chemicals in water using vanadium oxides loaded ZSM-5 zeolites. Front. Chem. 7, 384–397. Yang, F., Zhao, M., Wang, Z., Ji, H., Zheng, B., Xiao, D., Wu, L., Guo, Y., 2014. The role of ozone in the ozonation process of graphene oxide: oxidation or decomposition? RSC Adv. 4, 58325–58328. Yang, L., Sheng, M., Zhao, H., Qian, M., Chen, X., Zhuo, Y., Cao, G., 2019. Treatment of triethyl phosphate wastewater by Fenton oxidation and aerobic biodegradation. Sci. Total Environ. 678, 821–829. Yip, A.C.-K., Lam, F.L.-Y., Hu, X., 2005. Chemical-vapor-deposited copper on acidactivated bentonite clay as an applicable heterogeneous catalyst for the photoFenton-like oxidation of textile organic pollutants. Ind. Eng. Chem. Res. 44, 7983–7990. Yong, E.L., Lin, Y.-P., 2012. Incorporation of initiation, promotion and inhibition in the Rct concept and its application in determining the initiation and inhibition capacities of natural water in ozonation. Water Res. 46, 1990. Yong, K., Wu, J., Andrews, S., 2005. Heterogeneous catalytic ozonation of aqueous reactive dye. Ozone Sci. Eng. 27, 257–263. Yongrui, P., Zheng, Z., Bao, M., Li, Y., Zhou, Y., Sang, G., 2015. Treatment of partially hydrolyzed polyacrylamide wastewater by combined Fenton oxidation and anaerobic biological processes. Chem. Eng. J. 273, 1–6. Yoon, J., Lee, Y., Kim, S., 2001. Investigation of the reaction pathway of OH radicals produced by Fenton oxidation in the conditions of wastewater treatment. Water Sci. Technol. J. Int. Assoc. Water Pollut. Res. 44, 15–21. Yuan, L., Shen, J., Chen, Z., Liu, Y., 2012. Pumice-catalyzed ozonation degradation of p-chloronitrobenzene in aqueous solution. Appl. Catal. B Environ. 117–118, 414–419. Yuan, L., Shen, J., Chen, Z., Guan, X., 2016. Role of Fe/pumice composition and structure in promoting ozonation reactions. Appl. Catal. B Environ. 180, 707–714. Zeng, P., Du, J., Song, Y., Liu, Y., Liu, R., Zhang, P., Xiao, S., 2015. Efficiency comparison for treatment of amantadine pharmaceutical wastewater by Fenton, ultrasonic, and Fenton/ultrasonic processes. Environ. Earth Sci. 73, 4979–4987. Zhang, T., Lu, J., Ma, J., Qiang, Z., 2008. Fluorescence spectroscopic characterization of DOM fractions isolated from a filtered river water after ozonation and catalytic ozonation. Chemosphere 71, 911–921. Zhang, C., Zhou, M., Ren, G., Yu, X., Yu, F., Ma, L., Yang, J., 2015. Heterogeneous electro-Fenton using modified iron–carbon as catalyst for 2,4-dichlorophenol degradation: influence factors, mechanism and degradation pathway. Water Res. 70, 414–424. Zhang, R.-N., Zhang, L., Zhang, J., Huang, G.-Q., Liu, C., Chen, X.-X., 2018. Synergistic effect of microbubbles and activated carbon on the ozonation treatment of synthetic dyeing wastewater. Sep. Purif. Technol. 201, 10–18. Zhang, L., Su, F., Wang, N., Liu, S., Yang, M., Wang, Y.-Z., Huo, D., Zhao, T., 2019. Biodegradability enhancement of hydrolyzed polyacrylamide wastewater by a combined Fenton-SBR treatment process. Bioresour. Technol. 278, 99–107. Zhao, L., Ma, W., Ma, J., Wen, G., Liu, Q., 2015. Relationship between acceleration of hydroxyl radical initiation and increase of multiple-ultrasonic field amount in the process of ultrasound catalytic ozonation for degradation of nitrobenzene in aqueous solution. Ultrason. Sonochem. 22, 198–204. Zheng, T., Wang, Q., Zhang, T., Shi, Z., Tian, Y., Shi, S., Smale, N., Wang, J., 2015. Microbubble enhanced ozonation process for advanced treatment of wastewater produced in acrylic fiber manufacturing industry. J. Hazard. Mater. 287, 412–420. 253 254 Chapter 11 Fenton- and ozone-based AOP processes Zhou, M., Tan, Q., Wang, Q., Jiao, Y., Oturan, N., Oturan, M.A., 2012. Degradation of organics in reverse osmosis concentrate by electro-Fenton process. J. Hazard. Mater. 215–216, 287–293. Zhuang, H., Han, H., Shan, S., 2017. Advanced treatment of coal gasification wastewater using catalytic ozonation by sewage sludge based activated carbon as catalysts in pilot-scale. Acta Sci. Circumst. 49, pp. 85–91. Zhuang, H., Guo, J., Hong, X., 2018. Advanced treatment of paper-making wastewater using catalytic ozonation with waste rice straw-derived activated carbon-supported manganese oxides as a novel and efficient catalyst. Pol. J. Environ. Stud. 27, 451–457. Zimmermann, S.G., Wittenwiler, M., Hollender, J., Krauss, M., Ort, C., Siegrist, H., von Gunten, U., 2011. Kinetic assessment and modeling of an ozonation step for full-scale municipal wastewater treatment: micropollutant oxidation, by-product formation and disinfection. Water Res. 45, 605–617. Zouboulis, A., Samaras, P., Ntampou, X., Petala, M., 2007. Potential ozone applications for water/wastewater treatment. Sep. Sci. Technol. 42, 1433–1446.