Lista de Verificación Inspección Laboratorio: Seguridad y Cumplimiento

advertisement

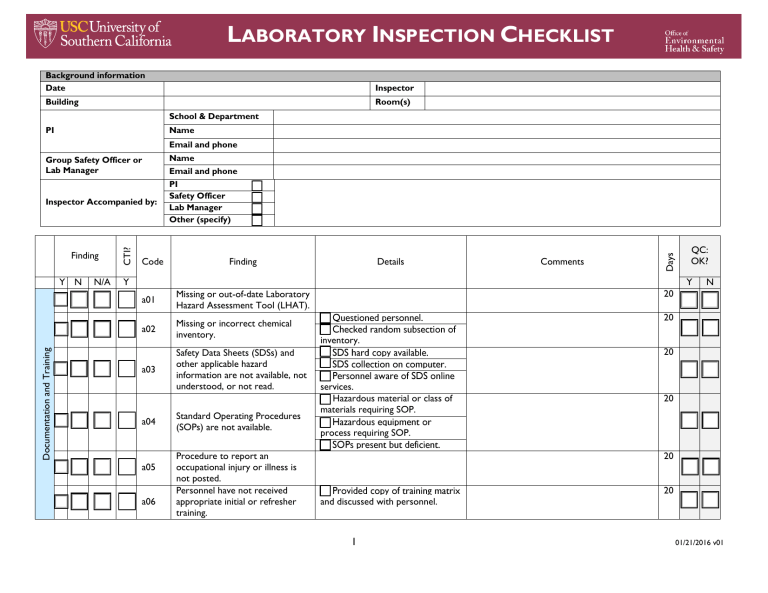

LABORATORY INSPECTION CHECKLIST Background information Date Inspector Building Room(s) School & Department PI Name Email and phone Finding Documentation and Training Y N N/A CTI? Inspector Accompanied by: Code Name Email and phone PI Safety Officer Lab Manager Other (specify) Finding Details Comments Days Group Safety Officer or Lab Manager Y QC: OK? Y a01 Missing or out-of-date Laboratory Hazard Assessment Tool (LHAT). a02 Missing or incorrect chemical inventory. a03 Safety Data Sheets (SDSs) and other applicable hazard information are not available, not understood, or not read. a04 a05 a06 Standard Operating Procedures (SOPs) are not available. Procedure to report an occupational injury or illness is not posted. Personnel have not received appropriate initial or refresher training. N 20 20 inventory. 20 services. Hazardous material or class of materials requiring SOP. 20 process requiring SOP. 20 20 and discussed with personnel. 1 01/21/2016 v01 N/A Finding Details Comments Y QC: OK? Y a07 Other documentation or training deficiency. b01 Defective building feature or defective room fixtures and fittings. b02 Tripping or slipping hazard. b03 Obstructed passageway, entrance, exit, door, or locked exit door. b04 Improperly or defectively signed emergency exit, incorrect or missing directional signage, or non-exit not signed "not an exit". Room Y N Code Days Finding CTI? LABORATORY INSPECTION CHECKLIST sheet not available. Other (specify). N 20 20 building. -related, e.g. defective floor. -related, e.g. extension cords, pipes, spillage. -related. PI-related. -related (e.g. equipment in corridor) 5 5 20 20 Environment b05 c01 Incorrect or missing room number or door sign. Poor housekeeping. (e.g. laser warning) . “PPE must be worn” on door of room where it need not necessarily be worn). Dirt/contamination. Clutter. Excessive storage of combustibles. Heavy items stored too high. Combustibles stacked too close to ceiling. Other (specify). 2 20 01/21/2016 v01 Y N N/A Code Water Comments QC: OK? Y c02 Defective HVAC, too hot/cold, or poor quality of incoming air. c03 Suspected asbestos or ceramic fiber hazard. d02 Insufficient provision for handwashing. Defective plumbing, faucet, or sink. N 20 FMS-related. -related, e.g. furnace, heating mantle. Needs to be at least one sink in lab with soap and paper towels. Look for leaking taps, blocked sinks, etc. 20 20 20 20 d03 d04 e01 Electrical Details Y d01 e02 e03 Fire Equipment Finding Days Finding CTI? LABORATORY INSPECTION CHECKLIST f01 f02 Improvised tubing or equipment poses a flooding risk. Water damage, dampness, condensation, active leak, mold, fungus, or rot. Defective or overloaded electrical outlet and/or inappropriate extension cord usage. Defective or obstructed electrical circuit breaker box (including box with no circuit directory). Other electrical hazard, e.g. exposed wiring, dangerous improvised equipment, electrical installation too close to water Fire extinguisher requires maintenance and/or testing log is not up to date. Fire extinguisher is absent, incorrect type, not visible, not accessible, not hung on the wall, is obstructed, or needs relocation. recirculated flow. -recirculating water pipework not securely fastened. 20 -current devices (e.g. hotplates, furnaces) on extension cords or overloading outlets. 5 20 -related. -related. 20 5 extinguisher (flammable metals). 3 5 01/21/2016 v01 Y N N/A Code Comments QC: OK? Y g01 Safety Equipment Details Y f03 g02 g03 g04 h01 General Equipment Finding Days Finding CTI? LABORATORY INSPECTION CHECKLIST h02 Visibly defective or obstructed smoke detector or sprinkler. Emergency eyewash / shower / drench hose testing log not upto-date. Emergency eyewash / shower / drench hose is defective, obstructed, non-code-compliant, missing, too far from lab, or improperly signed. Chemical spill cleanup supplies are not available. First aid kit / HF burn kit is not available, inaccessible, inappropriate, out of date, or incorrectly signed Improperly guarded, defective, dangerous, poorly-maintained, contaminated, inappropriately sited, or inappropriately used equipment. Hazardous equipment lacks warning signs, "Out of Service" sign, a usage log, instruction manual, SOP, list of trained and approved users, or a maintenance schedule. N 5 20 20 sec distant and/or more than one intervening doorway). 20 no appropriate supplies. 20 missing. Unguarded belt (IDLH). Contaminated. Other (specify). 20 Missing log book. Missing instruction manual. Missing SOP. Missing training records or approved user list. Ultracentrifuge has no maintenance schedule, rotorderating policy, rotor log. Out-of-use equipment not signed “do not use”. Other (specify). 20 4 01/21/2016 v01 Y N N/A Code Comments QC: OK? Y i01 Fridge/Freezer Details Y h03 i02 i03 i04 j01 j02 Fume Hood/BSC Finding Days Finding CTI? LABORATORY INSPECTION CHECKLIST j03 j04 j05 j06 Unsafe discharge of vacuum pump exhaust Defective, excessively iced, inappropriately sited, or inappropriately used refrigerator or freezer. Unacceptably contaminated refrigerator or freezer. Glass container is in a freezer without secondary containment. Unlabeled or incorrectly labelled refrigerator or freezer. Uncontaminated outlet passing to lab without coalescing filter. Contaminated outlet passing to lab. Flammables in a non-explosionproof unit. 20 Check for noxious smell. 20 20 20 Missing “no food or drink” label. Missing “no flammable materials” label. Defective fume hood / biosafety cabinet Fume hood / biosafety cabinet (BSC) internal airflow obstructed by overcrowding, shelf, or equipment; or biosafety cabinet external vent(s) obstructed. Incorrect fume hood / biosafety cabinet usage. N 20 5 5 Sash wide open when working. Sash not pulled down all the way when not working. Items too close to front. Fume hood / biosafety cabinet / biological glove box has not been tested / certified within the last 12 months. Fume hood / biosafety cabinet signage absent or defective. Other fume hood / biosafety cabinet finding 5 20 20 20 5 01/21/2016 v01 Y N N/A Code Details Comments Y QC: OK? Y k01 Hazardous Materials Finding Days Finding CTI? LABORATORY INSPECTION CHECKLIST k02 k03 k04 k05 Incorrect gas cylinder storage. Hazardous materials container or storage cabinet is defective, corroded, contaminated, or emitting an odor or irritant vapors. Corrosive or especially hazardous materials stored above eye level Missing or unsatisfactory secondary containment. Unsafe storage of flammables. k06 Flammable storage cabinet does not have a self-closing door. k07 Over-age or visibly-suspect timesensitive chemicals. k08 k09 Gas cylinders not properly restrained Cylinders in storage missing end caps. Flammables and oxidizers not separated. Cylinders surrounded by flammables/combustibles. Cylinders of hazardous gases not turned off after use. Highly toxic gases outside ventilated enclosures. N 20 20 5 20 Cabinet signed “Non-approved flammables cabinet — does not qualify for MAQ increase.” Peroxide formers. Anhydrous HF cylinders. Other (specify). Highly toxic materials, regulated precursor chemicals, or controlled substances are stored with poor physical security. Deficient labelling of hazardous materials container or storage area. 20 20 5 20 20 6 01/21/2016 v01 Y N N/A Code Comments QC: OK? Y l01 l02 l03 l04 l05 Waste Details Y k010 l06 l07 l08 l09 l010 l011 l012 Sharps/Bro ken Glass Finding Days Finding CTI? LABORATORY INSPECTION CHECKLIST m01 m02 Other unsafe hazardous materials storage practice. Incorrect separation of waste streams. Piranha solution or other hydrogen peroxide-containing material in non-vented container, or mixed with other waste Contaminated material in regular trash. Regular trash in hazardous waste container. Inappropriate, damaged, uncapped, or externally contaminated waste container. Missing or unsatisfactory secondary containment. Free-flowing liquids inappropriately mixed with solid chemical or biohazardous waste. Overfull container or over-large items in small container. Solid waste bags are emitting an odor. Items placed on top of waste containers. Incorrect labelling of hazardous waste. Accumulation start date on the chemical waste label is more than nine months old. Broken glass and/or sharps container is missing. Unattended broken glass or exposed sharps. Incompatible chemicals stored together. N 20 20 Lab has written procedure for hydrogen peroxide disposal. 5 20 20 Un-capped container. 20 20 More than 5 mL free-flowing liquid in a biohazard waste container. 20 20 20 20 20 20 20 0 7 01/21/2016 v01 Y N N/A Code m05 m06 m07 m08 n01 Mercury Comments QC: OK? Y m04 n02 n03 p01 PPE Details Y m03 p02 p03 p04 Practice s Finding Days Finding CTI? LABORATORY INSPECTION CHECKLIST q01 Sharps are being transported improperly. Evidence of needle recapping was found. Incorrect sharps disposal. Incorrect broken glass disposal. Broken glass container appears to contain contaminated material, or is emitting an odor. Broken glass and/or sharps container is missing hazardous waste label if it is being used for contaminated items. Inappropriate mercury thermometer usage or storage. Mercury-containing bottle or device has no or insufficient secondary containment. Mercury bubbler discharges into lab air. PPE is not available, not worn, or is not correctly matched to the hazards. Personnel exit the lab without removing personal protective equipment/clothing (PPE). Incorrect glove usage. N 0 0 0 20 20 20 Hg thermometer in oven, or heating bath. 20 20 20 0 20 Re-use of disposable gloves. Respirator usage outside of the EH&S respirator program. Evidence of food/drink was found in work area containing hazardous materials. 5 20 0 8 01/21/2016 v01 Y N N/A Code Comments QC: OK? Y q03 q04 q05 Seismic Safety Details Y q02 Miscellaneous Finding Days Finding CTI? LABORATORY INSPECTION CHECKLIST r1 s01 s02 s03 Personnel were observed touching potentially hazardous material with bare skin or leaving work area without washing hands. Carcinogenic, cumulatively toxic, sensitizing, or highly toxic materials in chemical inventory, but no evidence of engineering/administrative controls to prevent dispensing/weighing in open lab. Material posing inhalation hazard is used outside of fume hood, or work requiring respiratory protection is being done in a nonapproved area where the respiratory hazard may spread to unprotected persons Bottle carriers not available or hazardous materials observed to be transported in unsafe manner. Tall and/or hazardous items not properly restrained. Lack of signage or labelling (specify). Other hazardous condition or unsafe practice. Congratulations! No safety issues were found during the safety assessment of your area. N 20 5 0 Question personnel. If glass bottles are ever carried from the lab, a bottle carrier must be available. Enter improperly restrained gas cylinders (and Dewars) under k01, not here. Only use this code as a last resort. 20 Only use this code as a last resort. 20 9 20 20 01/21/2016 v01 LABORATORY INSPECTION CHECKLIST QC Inspection by: Accompanied by: Quality Control Date: Comments 10 01/21/2016 v01