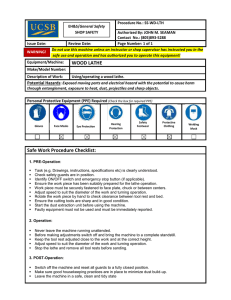

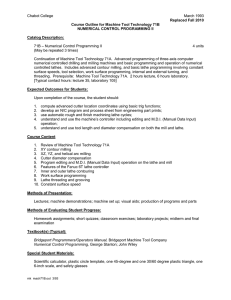

ENGINEERING APPLICATION AND SURVEY EG 233 Prepared by: H. Mupeta Copperbelt University, School of Engineering, Mechanical Engineering Department. 1 MECHANICAL SAFETY 2 Objectives • Understand the risks associated with machinery and equipment. • Understand safe access and egress • Outline and list hazards associated with mechanical machinery and control. • Understand and explain the correct procedure for material handling. 3 MECHANICAL SAFETY • Safety can be defined as the state of well-being for protecting and preserving human and equipment in a workplace. • Mechanical safety is the explicit type of safety evaluation involving the assessment of the health of machinery and equipment. • If safety is not taken into account, accidents occur. • In some instances, these result in work disruptions, permanent disabilities, damage to equipment or environment and catastrophically loss of life 4 HAZARDS AND RISKS v A hazard is anything that has the potential to cause harm or injury. v A risk is the possibility or likelihood that harm will occur due to exposure to a hazard. v For a sound work environment, a risk assessment, which is the careful examination of what can cause harm or danger to anyone at a work place, should always be conducted. 5 HAZARDS & RISKS ASSOCIATED WITH MACHINERY AND EQUIPMENT 6 MACHINERY AND EQUIPMENT vMachinery and equipment have both stationary and moving parts. vThe moving Parts of the machinery and equipment, with its action which can produce adequate force in motion, has the great potential to cause harm or pose danger to human beings. vMachinery and Equipment must be assessed for mechanical hazards. 7 MECHANICAL HAZARDS No. Mechanical Hazard 1. Rotating Parts such as Shafts, Coupling, pully drives, V-belts, gears, feed rolls and sprockets 2. Reciprocating or sliding parts such as dies found in punching presses. 3. Hose and cable connections 4. Liable to fragment of rapture parts such as abrasive wheel 8 ASSOCIATED MECHANICAL RISKS vIf a person is trapped, between a fixed structure and a moving part of a machine, can be crushed. vOn the other hand, if the human being’s fingers or part of the body is trapped between the moving and fixed part of the machine, he/she will experience shearing of that particular part of the body. vAdditionally, getting in contact with a rotating disc, band saw and or any cutting edge can result in cutting or severing. v Furthermore, oil leaks from hoses or cable can lead to falling, slipping and tripping of personnel. 9 HAZARDS AND RISKS CONTROL vMostly, hazards and risks cannot be eliminated completely. vHowever, certain measures should be undertaken to minimize exposure to hazards and risks associated with machinery and equipment. 10 STEPS TO BE TAKEN 1. Hazard assessment: A thorough inspection must be done to identify hazards and deal with them. The aim is to remove or minimize hazards. 2. Risk Evaluation: Risks must be evaluated based on expected damage severity and probability of that damage occurring. 3. Implementation of measure: Only trained personnel must be allowed to operate machinery and equipment. Before operating any machinery, all risk assessment procedures must be concluded. 11 SAFE ACCESS AND EGRESS 12 SCAFFOLDING vScaffolding is a framework that is used to support people and materials temporarily. vThey provide safe access that’s appropriate for work being done. vToday, most scaffolding consist of aluminum or steel tubing and couplers. vTwo distinct types of scaffolds are available: The support and Access type. vFocus in this course is on the access type 13 DIFFERENT ACCESS TYPE SCAFFOLDS 1. Single-Point: This scaffold is suspended by a single rope from an overhead support and easily adjustable. This also has means of moving the platform to a work level desired. 2. Two-point: This is the most common adjustable suspension scaffold. Ropes or cables connected to stirrups are used to hung the platform. 3. Multipoint: This is an adjustable scaffold consisting of a single or multiple platform which are suspended by three or more ropes from overhead supports. The platforms can be raised or lowered to a work level desired. 4. Needle beam: This type of scaffold has the platforms suspended from needle beams, with one end attached to a permanent structural member. 14 SAFETY RULES AND GUIDELINES 1. Job site survey: survey the site for hazards. Check for debris, ditches, high tension wires, untamed earth fills. Where hazards exist, correct the situation before the scaffold is erected. 2. Equipment inspection before use: Equipment that are defective or damaged must never be used. By all means possible, have all defective equipment removed from site, and mark it as defective. 15 SAFETY RULES AND GUIDELINES 3. Scaffold erection: This must be done following the manufacturers recommendations. Erection, altering or dismantling must be done by a competent person. Additionally, continuous inspection of erected scaffolds by users must be done to make sure safe conditions are maintained. 4. Take no chances: if you are in doubt concerning the safety or scaffold use, do not use it and consult the scaffold supplier. 5. Influence of alcohol or drugs: If you are under the influence of alcohol or other illicit drugs, do not work on the scaffolds. 16 SCAFFOLD ERECTION v Scaffolds must be erected, dismantled or altered by a competent person because any mistakes in doing this can lead to injury or accident. v It’s extremely important that during scaffold erection, dismantling and alteration there is adequate bracing in position. v The bracings must be tied to the structure to ensure that there is stability of the scaffold. v Additionally, there should be a safe means to access easily each working platform for all scaffolding. 17 MATERIAL HANDLING 18 MATERIAL HANDLING v Material handling is very common in most industries. v Material handling is the movement of right amount of material to a right place in sequence to reduce cost of production. v Usually, robots, hoists and conveyors are used for material handling. v There main purpose is to raise, lower and transport load over a short distance. v Examples of hoist include but not limited to cranes, winches, manual pullers etc. 19 DIMENSIONS IN MATERIAL HANDLING 1. Quantity: The amount of material per move determines the type of material handling equipment to use. 2. Movement: This involves the actual material transfer form one position to the other. 3. Space: This takes into account the storage space of the material, material handling equipment as well as its movement. 4. Time: This determines the duration of material movement within the facility. 5. Control: This involves management of inventory, identifying and tracking materials. 20 MATERIAL HANDLING v Guards must be incorporated to prevent direct access to dangerous moving parts and gears during operation of material handling equipment. v It’s a good practice to put limit switches on hoisting devices in order to prevent loads from going over the specified distance. v Additionally, hoisting equipment like cranes must be operated by people who have undergone serious training. v In an event that manual loading of conveyors is employed, proper safe load signages should be visibly placed on all loading bays. 21 PROCEDURE FOR LIFTING & CARRYING v In manual material handling, proper training in lifting procedures is fundamental in preventing some musculoskeletal injuries. v These musculoskeletal injuries affects upper limbs, shoulders and lower back. v For manual material handling, the S.M.A.R.T lifting technique is usually ideal and helpful to follow. 22 S.M.A.R.T LIFTING TECHNIQUE 1. Size the load: Assess the load size, it’s weight as well as shape. v All obstacles from the load such as wrapping materials should be removed. v Surface hazards for the material must also be inspected. v Additionally, identify where the load will be placed and make sure that there are no obstacles on the pathway. 2. Move close to the load: The load must be moved close to the body as possible and the person lifting must stay close to the load throughout the lifting process. v In ensuring a firm grip, use the whole hand. v To avoid being pinched, however, hands must be kept away from the end of long objects. 23 S.M.A.R.T LIFTING TECHNIQUE 3. Always bend your knees: Balance must always be maintained. vFeet must be kept in comfortable positions and apart. vPositioning the feet correctly increases balance. vWaist bending must be minimal. vHowever, the knees must be bent to a semi squat position. 24 S.M.A.R.T LIFTING TECHNIQUE 4. Raise the Load: The load must be lifted smoothly avoiding jerking. v The normal spine curve throughout the process of limiting must be maintained always. v Additionally, the abdominal muscles must be tightened as you breath-out while lifting. 5. Turn your feet: You must always turn in the direction that you want to move the load. v All unnecessary twisting, bending and reaching must be avoided at all cost. v To change direction, only your feet not your back should be turned. 25 26 LATHE MACHINE 27 LATHE MACHINE v Considered one of the oldest machine tools. v Widely used in industries. v A machine tool which holds the workpiece between two rigid and strong supports centers or in a chuck or face plate which revolves vThe primary task: Generation of cylindrical workpieces. 28 LATHE MACHINE v Lathes have allowed man to reshape, machine and manufacture many precision cylindrical components v These components are made of various types of metal, wood, plastics and other materials vAll lathes, except the vertical turret type, have one thing in common for all usual machining operation: i.e the workpiece is held and rotated around a horizontal axis while being formed to size and shape by a cutting tool. 29 LATHE MACHINE v The cutter bit is held either by hand or by a mechanical holder, then applied to the workpiece. vPrinciple capabilities: Forming straight, tapered, or irregularly outlined cylinders, facing or radial turning cylindrical sections, cutting screw threads and boring or enlarging internal diameters. 30 LATHE MACHINE PARTS v Bed: Forms the base of the machine. Carries the headstock and tailstock for supporting the workpiece. It also provides a base for the movement of the carriage assembly which carries the tool. vLegs: They carry the entire load of machine and are firmly secured to floor by foundation bolts. 31 LATHE MACHINE PARTS v Headstock: Clamped on the left hand side of the bed. It serves as housing for the driving pulleys, back gears, headstock spindle, live centre and the feed reverse gears. v Headstock spindle is vHeadstock spindle: A hollow cylindrical shaft that provides a drive from the motor to work holding devices. 32 LATHE MACHINE PARTS v Gear box: Placed below the headstock and contains a number of different sized gears. v Tailstock: Movable casting located opposite the headstock. It can slide along the bed to accommodate different lengths of workpiece vHeadstock spindle: A hollow cylindrical shaft that provides a drive from the motor to work holding devices. 33 LATHE MACHINE PARTS v Carriage: Located between the headstock and tailstock on the lathe bed guideways. It has several parts to support, move and control the cutting tool. 34 PARTS OF THE CARRIAGE a) saddle: an H-shaped casting mounted on the top of lathe ways. It provides support to cross-slide, compound rest and tool post. b) cross-slide: mounted on the top of saddle, and it provides a mounted or automatic cross movement for the cutting tool. c) compound rest: fitted on the top of cross slide and is used to support the tool post and the cutting tool. d) tool post: mounted on the compound rest, and it rigidly clamps the cutting tool or tool holder at the proper height relative to the work centre line. e) apron: fastened to the saddle and it houses the gears, clutches and levers required to move the carriage or cross slide. 35 TYPES OF LATHES 1. Speed lathe (Woodworking lathe, Centering lathe, Polishing lathe and Metal spinning lathe). 2. Engine lathes( Belt driven lathe, Individual motor driven lathe and Gear head lathe). 3. Semi-automatic lathes (turret lathes and capstan lathe), 4. Automatic lathes and 5. Special purpose lathes(Wheel lathe, Gap bed lathe, ‘T’ lathe and Duplicating lathe). 36 ENGINE LATHE v The engine lathe is intended for general purpose lathe work and is the usual lathe found in the machine shop. v Most engine lathes are back-geared and high torque, which is required for machining large diameter workpieces and taking heavy cuts. 37 SEMI-AUTOMATIC LATHES v Turret and Capstan lathes are known as semiautomatic lathes. v These lathes are used for production work where large quantities of identical workpieces are manufactured. v They are called semi-automatic lathes as some of the tasks are performed by the operators and the rest by the machines themselves. 38 SPECIAL PURPOSE LATHES v Used for special purposes and for jobs, which cannot be accommodated and conveniently machined on a standard lathe. v Other special purpose lathes are specialized for machining specific items and cannot be adapted to the common types of lathe operations. v Wheel lathe, ‘T’ lathe, duplicating lathe are some examples of special purpose lathe 39 LATHE WORK HOLDING DEVICES 1. Chucks: used to hold Workpieces of short length, large diameter and irregular shapes, which can not be mounted between centres. 2. Face plate: used to hold large, heavy and irregular shaped workpieces which can not be conveniently held between centres 3. Driving plate: used to drive a workpiece when it is held between centres. 4. Catchplate: performs almost as a driving plate. 40 LATHE WORK HOLDING DEVICES 5. Carriers: useful in transmitting the driving force of the spindle to the work by means of driving plates and catch plates. 6. Mandrels: previously drilled or bored workpiece is held on a mandrel to be driven in a lathe and machined 7. Centres: useful in holding the work in a lathe between centres. 8. Rests: A rest is a mechanical device to support a long slender workpiece when it is turned between centres or by a chuck. 41 LATHE OPERATIONS 1. Facing: This is the operation of machining the ends of a piece of work to produce flat surface square with the axis. The operation involves feeding the tool perpendicular to the axis of rotation of the work. 2. Turning: This is the removal of excess material from the workpiece to produce a cylindrical surface of required shape and size. a. Straight turning: The work is turned straight when it is made to rotate about the lathe axis and the tool is fed parallel to the lathe axis. b. Step turning: the process of turning different surfaces having different diameters. (Shoulder turning) 42 LATHE OPERATIONS 3. Chamfering: the operation of bevelling the extreme end of the workpiece. 4. Grooving: Grooving is the process of cutting a narrow goove on the cylindrical surface of the workpiece. 5. Forming: Forming is a process of turning a convex, concave or any irregular shape. 6. Knurling: Knurling is the process of embossing a diamond shaped pattern on the surface of the workpiece 43 LATHE OPERATIONS 7. Undercutting: process of enlarging the diameter if done internally and reducing the diameter if done externally over a short length. It is useful mainly to make fits perfect. Boring tools and parting tools are used for this operation. 8. Eccentric turning: The turning of different surfaces of the workpiece 9. Taper turning: a uniform increase or decrease in diameter of a piece of work measured along its length. 10.Thread cutting: The process of thread cutting is to produce a helical groove on a cylindrical surface by feeding the tool longitudinally. 44 LATHE OPERATIONS 11. Drilling: the operation of producing a cylindrical hole in the workpiece. 12. Reaming: holes that are produced by drilling are rarely straight and cylindrical in form. The reaming operation finishes and sizes the hole already drilled into the workpiece. 13. Boring: the process of enlarging a hole already produced by drilling. 14. Tapping: 45 GET A PIECE OF PAPER 46 QUIZ ONE QUESTION With the aid the aid of a diagram, explain the accident triangle, and also list and explain the 8 principles of safety 47 THANK YOU FOR YOUR ATTENTION Contact Details: Henry.Mupeta@cbu.ac.zm www.cbu.ac.zm Cel: +260-950 423 980 48