Uploaded by

Abdelnasir Abdelrhman

Second Moment of Area: Mechanics of Materials Explained

advertisement

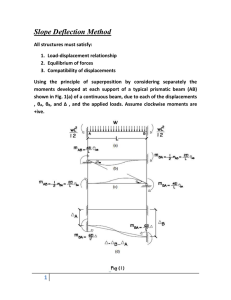

Second Moment of Area Set up axes for second moments of area (horizontal) and product second moments of area (vertical). From: Mechanics of Materials 2 (Third Edition), 1997 Related terms: Bending Moment, Centroid, Neutral Axis, Shear Centre, Beam Section View all Topics Statics Richard Gentle, ... Bill Bolton, in Mechanical Engineering Systems, 2001 Second moment of area The integral y2 dA defines the second moment of area I about an axis and can be obtained by considering a segment of area A some distance y from the neutral axis, writing down an expression for its second moment of area and then summing all such strips that make up the section concerned, i.e. integrating. As indicated in the discussion of the general bending equation, the second moment of area is needed if we are to relate the stress produced in a beam to the applied bending moment. Mathematics in action Second moment of area As an illustration of the derivation of a second moment of area from first principles, consider a rectangular cross-section of breadth b and depth d (Figure 5.4.27). For a layer of thickness y a distance y from the neutral axis, which passes through the centroid, the second moment of area for the layer is:The total second moment of area for the section is thus:(5.4.11) Figure 5.4.27. Second moment of area Example 5.4.9 Determine the second moment of area about the neutral axis of the I-section shown in Figure 5.4.28. Figure 5.4.28. Example 5.4.9 We can determine the second moment of area for such a section by determining the second moment of area for the entire rectangle containing the section and then subtracting the second moments of area for the rectangular pieces ‘missing’ (Figure 5.4.29). Figure 5.4.29. Example 5.4.9 Thus for the rectangle containing the entire section, the second moment of area is given by I = bd3/12 = (50 × 703)/12 = 1.43 × 106mm4. Each of the ‘missing’ rectangles will have a second moment of area of (20 × 503)/12 = 0.21 × 106 mm4. Thus the second moment of area of the I-section is 1.43 × 106 − 2 × 0.21 × 106 = 1.01 × 106mm4. > Read full chapter BENDING E.J. HEARN Ph.D., B.Sc. (Eng.) Hons., C.Eng., F.I.Mech.E., F.I.Prod.E., F.I.Diag.E., in Mechanics of Materials 1 (Third Edition), 1997 Example 4.2 A uniform T-section beam is 100 mm wide and 150 mm deep with a flange thickness of 25 mm and a web thickness of 12 mm. If the limiting bending stresses for the material of the beam are 80 MN/m2 in compression and 160 MN/m2 in tension, find the maximum u.d.l. that the beam can carry over a simply supported span of 5 m. Solution The second moment of area value I used in the simple bending theory is that about the N.A. Thus, in order to determine the I value of the T-section shown in Fig. 4.17, it is necessary first to position the N.A. Fig. 4.17. Since this always passes through the centroid of the section we can take moments of area about the base to determine the position of the centroid and hence the N.A. Thus Thus the N.A. is positioned, as shown, a distance of 109.4 mm above the base. The second moment of area I can now be found as suggested in Example 4.1 by dividing the section into convenient rectangles with their edges in the neutral axis. Now the maximum compressive stress will occur on the upper surface where y = 40.6 mm, and, using the limiting compressive stress value quoted, This suggests a maximum allowable B.M. of 14.5 kN m. It is now necessary, however, to check the tensile stress criterion which must apply on the lower surface, i.e. The greatest moment that can therefore be applied to retain stresses within both conditions quoted is therefore M = 10.76 kN m. But for a simply supported beam with u.d.l., The u.d.l. must be limited to 3.4 kN m. > Read full chapter Bending of Open and Closed, Thin-Walled Beams T.H.G. Megson, in Introduction to Aircraft Structural Analysis, 2010 15.4.4 Product Second Moment of Area The product second moment of area, Ixy, of a beam section with respect to x and y axes is defined by (15.42) Thus, each element of area in the cross section is multiplied by the product of its coordinates, and the integration is taken over the complete area. Although second moments of area are always positive, since elements of area are multiplied by the square of one of their coordinates, it is possible for Ixy to be negative if the section lies predominantly in the second and fourth quadrants of the axes system. Such a situation would arise in the case of the Z-section of Fig. 15.30(a) Fig. 15.30. Product second moment of area. where the product second moment of area of each flange is clearly negative. A special case arises when one (or both) of the coordinate axes is an axis of symmetry so that for any element of area, A, having the product of its coordinates positive, there is an identical element for which the product of its coordinates is negative (Fig. 15.30(b)). Summation (i.e., integration) over theentire section of the product second moment of area of all such pairs of elements results in a zero value for Ixy. We have shown previously that the parallel axes theorem may be used to calculate second moments of area of beam sections comprising geometrically simple components. The theorem can be extended to the calculation of product second moments of area. Let us suppose that we wish to calculate the product second moment of area, Ixy, of the section shown in Fig. 15.30(c) about axes xy when IXY about its own, say, centroidal, axes system Cxy is known. From Eq. (15.42), or which, on expanding, gives If X and Y are centroidal axes, then . Hence, (15.43) It can be seen from Eq. (15.43) that if either Cx or Cy is an axis of symmetry; that is, IXY = 0, then (15.44) Therefore, for a section component having an axis of symmetry that is parallel to either of the section reference axes, the product second moment of area is the product of the coordinates of its centroid multiplied by its area. > Read full chapter Structural Instability Dr.T.H.G. Megson, in Structural and Stress Analysis (Fourth Edition), 2019 21.2 Limitations of the Euler theory For a column of cross-sectional area A the critical stress, CR, is, from Eq. (21.23) (21.24) The second moment of area, I, of the cross section is equal to Ar2 where r is the radius of gyration of the cross section. Thus we may write Eq. (21.24) as (21.25) Therefore for a column of a given material, the critical or buckling stress is inversely proportional to the parameter (Le/r)2. Le/r is an expression of the proportions of the length and cross-sectional dimensions of the column and is known as its slenderness ratio. Clearly if the column is long and slender Le/r is large and CR is small; conversely, for a short column having a comparatively large area of cross section, Le/r is small and CR is high. A graph of CR against Le/r for a particular material has the form shown in Fig. 21.11. For values of Le/r less than some particular value, which depends upon the material, a column will fail in compression rather than by buckling so that CR as predicted by the Euler theory is no longer valid. Thus in Fig. 21.11, the actual failure stress follows the dotted curve rather than the full line. Figure 21.11. Variation of critical stress with slenderness ratio. > Read full chapter Axial Strengthening of RC Members Using FRP Riadh Al-Mahaidi, Robin Kalfat, in Rehabilitation of Concrete Structures with Fiber-Reinforced Polymer, 2018 Step 12. Serviceability checks Modular ratio: Depth of neutral axis: y = 300 mm (section is symmetry) Uncracked section second moment of area: Principal concrete stresses: Since the whole section is in compression, there is no flexural cracking. Longitudinal steel bar stress: Serviceability limits: > Read full chapter Torsion of Beams Dr.T.H.G. Megson, in Structural and Stress Analysis (Fourth Edition), 2019 Torsion of a circular section hollow bar The preceding analysis may be applied directly to a hollow bar of circular section having outer and inner radii Ro and Ri, respectively. Equation (11.2) then becomes Substituting for from Eq. (11.1) we have from which The polar second moment of area, J, is then (11.5) Example 11.1 A hollow shaft of outside diameter 220 mm and thickness 40 mm is required to transmit power at a speed of 80 rpm. If the maximum shear stress in the shaft is limited to 60 N/mm2 determine the power transmitted and the angle of twist in a length of 10 m. Take G = 80000 N/mm2. (Note: Power P (watts)=Torque (Nm)×angular speed (rad/sec)). From Eq. (11.5) From Eq. (11.4) so that Thenor Again, from Eq. (11.4)or Example 11.2 If a solid shaft was used to transmit the same power as the hollow shaft in Ex.11.1 with the same length and limiting stress what would be the percentage increase in weight of the material used. For a shaft diameter of D mm Then, substituting for the torque from Eq. (11.4) in the expression for powerthat iswhich gives D = 207.3 mm Since weight is proportional to cross sectional area the percentage weight increase is given bythat is % weight increase = 49.0%. Example 11.3 Determine the angle of twist and the maximum shear stress in the tapered shaft shown in Fig. 11.6. The shear modulus of the material of the shaft is G. Figure 11.6. Tapered shaft of Ex 11.3. Suppose that the diameter of the shaft at a distance x from the left-hand end is d. Then, from Eq. (11.4), the angle of twist, , over the length x is given by(i) If the change in diameter over the length x is d then Substituting for x in Eq. (i) The angle of twist over the complete length of the shaft is then given bywhich giveswhich simplifies to(ii) From Eq. (11.4) The maximum shear stress therefore occurs at the section where d is a minimum, that is where d = D2. Then > Read full chapter Solutions to Chapter 12 Problems Dr.T.H.G. Megson, in Structural and Stress Analysis (Fourth Edition), 2019 S.12.1The second moments of area of the timber and steel are, respectivelyThen, from Eq. (12.7)which givesFrom Eq. (12.8)from whichTherefore the allowable bending moment is 94.7 kNm. S.12.2The maximum bending moment isAlso, for the timberand for the steelThen, from Eq. (12.7)so thatFrom Eq. (12.8)which gives t = 17.0 mm.Therefore the required thickness of the steel plates is 17 mm. S.12.3The maximum stress in the timber beam is given bywhich givesAlso, since s = 20 t, the steel stress is limiting so that t = 155/20 = 7.75 N/mm2.Referring to Fig. S.12.3Figure S.12.3. which givesNow taking moments about the resultant of the compressive stress distribution in the timberwhich givesTherefore, Ms/Mt = 74.4/27 = 2.76 so that the increase produced by the steel reinforcing plate is 176%. S.12.4From Eq. (12.13) for a critical sectionwhich givesTaking moments about the centroid of the steel reinforcement (see Fig. 12.6)from whichThenso thatThen, equating the tensile force in the steel to the compressive force in the concretewhich gives S.12.5The area of the compression steel is 3 × π × 252/4 = 1472.6 mm2 and of the tensile steel is 5 × π × 252/4 = 2454.4 mm2. Then, from Eq. (12.17)from whichUsing the compatibility of strain condition, i.e. Eq. (12.13)Therefore the limiting stress is the steel stress and c = 125/33.4 = 3.7 N/mm2. Then, taking moments about the compressive steeli.e. S.12.6Assume that the neutral axis is at the base of the flange. The maximum bending moment isThen, taking moments about the resultant compressive force in the concrete flangei.e.The tensile force in the steel is equal to the compressive force in the concrete, i.e.which givesThe required width of the flange is therefore 700 mm. S.12.7 The maximum bending moment isAssume that the neutral axis is 0.45d1 from the top of the beam, i.e. M = Mu. Thenwhich givesFrom Eq. (12.24)from which S.12.8Assume that n = d1/2. Then, taking moments about the compression steeli.e. S.12.9From S.12.6, Mmax = 189 kNm. Assuming the neutral axis to be at the base of the flangefrom whichThen, since the compressive force in the concrete is equal to the tensile force in the steelwhich givesSay a flange width of 304 mm. S.12.10 Equating the compressive force in the concrete to the tensile force in the steelso thatTaking moments about the line of action of the resultant compressive force in the concretei.e. S.12.11 The available compressive force in the concrete isThe available tensile force in the steel isSince the available compressive force in the concrete is less than the available tensile force in the steel the neutral axis of the composite beam section lies within the steel beam. Then, from Eq. (12.30)which givesFrom Steel Tables the flange thickness of the steel beam is 17 mm so that, by inspection, the neutral axis lies within the flange of the beam. Thenfrom whichandFrom Eq. (12.31)which gives > Read full chapter FIFTY-TWO ADDITIONAL APPLICATIONS In Applied Dimensional Analysis and Modeling (Second Edition), 2007 Example 18-40. Deflection of a Simply Supported Beam upon a Centrally Dropped Mass We design and execute a modeling experiment to determine the deflection of a simply supported L1 = 7.3 m long prototype beam upon a mass M1 = 2950 kg dropped on the beam's midpoint from a height of h1 = 3.15 m on the Moon. The arrangement is shown in Fig. 18-43. Figure 18-43. Deflection of a simply supported beam upon a mass dropped on its midpoint The beam is steel, Young's modulus E1 = 2 × 1011 Pa and its cross-sectional second moment of area is I1 = 1.998 × 10−5 m4 (regular American Standard I beam, light series, size 8 × 4 × 0.245 inches). Of course, we build our model on Earth, where we do all the experimentation. For the model we select aluminium E2 = 6.7 × 1010 Pa and a rectangular cross-section of a = 0.2 m width and b = 0.040 m height. What should be the model's length, the mass dropped on it and the height the mass dropped from? Further, how will the measured deflection of the model (on Earth) correlate with the deflection of the prototype (on the Moon)? To proceed in an orderly manner, we first list the relevant variables. Variable Symbol Dimension deflection U m second moment of area I m4 height mass dropped from h m gravitational acceleration g m/s2 length of beam L m mass dropped M kg Young's modulus of beam E kg/(m·s2) We see that there are seven variables and three dimensions, therefore we have 7 − 3 = 4 dimensionless variables furnished by the Dimensional Set Note that U, h, and L have identical dimensions, therefore at the most only one of them may appear in the A matrix (Theorem 14-3 in Art. 14-2). From the above set (a) and the Model Law therefore is (b) where SU is the Deflection Scale Factor; SL is the Length Scale Factor; SI is the Second Moment of Area Scale Factor; Sh is the Height Mass Dropped from Scale Factor; Sg is the Gravitational Acceleration Scale Factor; SE is the Young's Modulus Scale Factor; SM is the Dropped Mass Scale Factor. By the given data of the model's cross-section (c) hence (d) Thus, by the second and third relations of Model Law (b) (e) But SL = L2/L1, therefore the model's length must be Since gravitational acceleration on the Moon is g1 = 1.6 m/s2 and on Earth it is g2 = 9.81 m/s2 (f ) Moreover, by the given data (g) Next, the Mass Scale Factor is now supplied by (e), (f ), (g), and the fourth relation of Model Law (b) (h) But SM = M2/M1, hence from the given data and (h), the mass to be dropped on the model must be (i) Finally, by (e) and the third relation of Model Law (b) (j) Since Sh = h2/h1, by (j), the height from which the mass dropped onto the model must be (k) Now we have all the information necessary to build the model and perform the experiment on Earth. Accordingly, we drop an M2 = 37.2417 kg mass from height h2 = 1.5141 m onto an L2 = 3.509 m long simply supported aluminium beam whose cross-section is a rectangle of 0.2 m width and 0.04 m height. By dropping the mass on this model, we measure on it a deflection of, say, U2 = 0.1180 m. Hence, by (e) and the first relation of Model Law (b) from which the sought-after deflection of the prototype (on the Moon) is All the above input data and results are conveniently summarized in the Modeling Data Table (Fig. 18-44). Note the numerical equivalence (within rounding errors) of the four dimensionless variables defined in (a). This of course is expected and required for a modeling experiment in which the model is dimensionally similar to the prototype. Figure 18-44. Modeling Data Table for the determination, by a modeling experiment, of the deflection of a simply supported beam by a centrally dropped mass (Version 1) Also note that there are four quantities in the table that are determined by the application of Model Law (b). These are designated as Category 2 variables. The Model Law comprises four relations, hence four unknowns can be determined. Actually, the relations constituting the Model Law should be viewed as constraints which are imposed upon the model. Thus, once the cross-section and the material of the model are fixed a priori, we have no control over its other characteristics. It follows, therefore, that the length of the beam, the dropped mass, and the height from which this mass is dropped are prescribed by the conditions of similarity. The question now naturally presents itself: is there a way to increase our freedom in selecting characteristics for the model? Yes, there is: we have to reduce the number of relations in the Model Law. Since the number of such relations equals the number of dimensionless variables, we must reduce the number of dimensionless variables. Some clear-head thinking is now in order (actually, clear-head thinking is always in order, but this diversionary subject shall not be further pursued here!). We note that both I and E appear in the set of relevant variables. Now in problems of statics and dynamics if both I and E are present in a relation, then they most likely do so as the product I·E. This suggests that a new variable—which we call “rigidity” (another name is “flexural stiffness”) (l) can be introduced. The dimension of z is by its definition (ℓ) (m) With “rigidity,” the number of variables is reduced to six, while the number of dimensions remains three. Hence we now have three dimensionless variables, instead of the former four. Accordingly, the new list of variables is Variable Symbol Dimension deflection U m rigidity z m3·kg/s2 height mass dropped from h m gravitational acceleration g m/s2 length of beam L m mass dropped M kg which yields the Dimensional Set from which (n) and the Model Law is (o) where Sz is the Rigidity Scale Factor, and SL, Sg, SM, Sh, and SU are as defined previously for relation (b). By the given data, (p) (q) hence (r) Now we select mass M2 to be dropped on the model. Note that this could not have been done in the previous arrangement, since the value of mass M2 was defined for us by Model Law (b). Since we are now at liberty to choose the mass, we select a relatively smaller value to produce a smaller deflection. We select (s) thus (t) By the second relation of Model Law (o) (u) where scale factors Sz, Sg, and SM are given in (r), (f ), and (t), respectively. Next, we write SL = L2/L1, by which the length of the model beam must be (v) By the third relation of the Model Law (o), Sh = h2/h1 = SL, from which, by (u) (w) from which the sought-after deflection of the prototype is (x) All of the above data are summarized in the Modeling Data Table presented in Fig. 18-45. Note that in this version Category 2 designation appears only three times—instead of four, as in Version 1. Also observe that three is the number of relations in Model Law (o), and the mass for the model is now “selectable,” i.e., Category 1. This is our reward for knowing a priori that I and E appear only as a product in the expression of U. Figure 18-45. Modeling Data Table for the determination, by a modeling experiment, of the deflection of a simply supported beam by a centrally dropped mass (Version 2) Finally, observe again the very close numerical agreement of the dimensionless variables between the prototype and the model. > Read full chapter Bending of Beams Dr.T.H.G. Megson, in Structural and Stress Analysis (Third Edition), 2014 Second moments of area of standard sections Many sections in use in civil engineering such as those illustrated in Fig. 9.2 may be regarded as comprising a number of rectangular shapes. The problem of determining the properties of such sections is simplified if the second moments of area of the rectangular components are known and use is made of the parallel axes theorem. Thus, for the rectangular section of Fig. 9.23 Figure 9.23. Second moments of area of a rectangular section. which gives (9.36) Similarly (9.37) Frequently it is useful to know the second moment of area of a rectangular section about an axis which coincides with one of its edges. Thus in Fig. 9.23, and using the parallel axes theorem (9.38) Example 9.8 Determine the second moments of area Iz and Iy of the I-section shown in Fig. 9.24. Figure 9.24. Second moments of area of an I-section. Using Eq. (9.36) Alternatively, using the parallel axes theorem in conjunction with Eq. (9.36) The equivalence of these two expressions for Iz is most easily demonstrated by a numerical example. Also, from Eq. (9.37) It is also useful to determine the second moment of area, about a diameter, of a circular section. In Fig. 9.25 where the z and y axes pass through the centroid of the section Figure 9.25. Second moments of area of a circular section. (9.39) Integration of Eq. (9.39) is simplified if an angular variable, , is used. Thus i.e. which gives (9.40) Clearly from symmetry (9.41) Using the theorem of perpendicular axes, the polar second moment of area, Io, is given by (9.42) > Read full chapter ScienceDirect is Elsevier’s leading information solution for researchers. Copyright © 2018 Elsevier B.V. or its licensors or contributors. ScienceDirect ® is a registered trademark of Elsevier B.V. Terms and conditions apply.