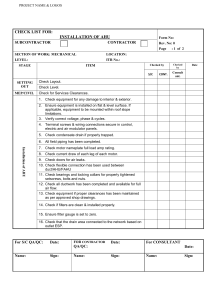

39HQM Central Station Air Handling Units Installation, Operation and Maintenance Instructions Page 1 of 20 Table of Contents 1 – SAFETY CONSIDERATIONS .................................................................................................................................................. 3 1.1. General ............................................................................................................................................................................... 3 1.2 Applications .......................................................................................................................................................................... 3 1.3 Instruction types ................................................................................................................................................................... 3 1.4 Disposal of parts/materials ................................................................................................................................................... 4 2 – TRANSPORT AND LIFTING INSTRUCTIONS ........................................................................................................................ 4 2.1. General ................................................................................................................................................................................ 4 2.2 Transport and Storage.......................................................................................................................................................... 4 2.3 Roof edge protection during transport (outside installation) ................................................................................................. 5 2.4 Offloading and Hoisting ........................................................................................................................................................ 5 2.5 Horizontal transport .............................................................................................................................................................. 5 3 – AHU STORAGE REQUIREMENTS ......................................................................................................................................... 6 4 – STARTUP INSTRUCTIONS ..................................................................................................................................................... 7 4.1 Casing .................................................................................................................................................................................. 7 4.2 Dampers ............................................................................................................................................................................... 8 4.3 Air Filters .............................................................................................................................................................................. 8 4.4 Electric Heaters .................................................................................................................................................................... 8 4.5 Drain Connection.................................................................................................................................................................. 8 4.6 Cooling Coil .......................................................................................................................................................................... 9 4.7 Plate Heat Exchanger........................................................................................................................................................... 9 4.8 Heat Recovery Wheel......................................................................................................................................................... 10 4.9 Fan and Motor .................................................................................................................................................................... 10 4.10 Drive Package .................................................................................................................................................................. 11 5 – MAINTANANCE AND OPERATING INSTRUCTIONS .......................................................................................................... 12 5.1 General ............................................................................................................................................................................... 12 5.2 Casing Panels .................................................................................................................................................................... 12 5.3 Doors and Access Covers .................................................................................................................................................. 12 5.4 Flexible Connections .......................................................................................................................................................... 12 5.5 Earthing .............................................................................................................................................................................. 12 5.6 Dampers ............................................................................................................................................................................. 12 5.7 Outside Air Intake ............................................................................................................................................................... 12 5.8 Filters.................................................................................................................................................................................. 12 5.9 Electric Heaters .................................................................................................................................................................. 12 5.10 Cooling Coil ...................................................................................................................................................................... 12 5.11 Heat Recovery Wheel....................................................................................................................................................... 12 5.12 Plate Heat Exchanger....................................................................................................................................................... 13 5.13 Fan ................................................................................................................................................................................... 13 5.14 Sound Attenuator ............................................................................................................................................................. 13 6 – 39HQM WITH STARTER PANEL .......................................................................................................................................... 14 7 – HYGENIC AIR HANDLING UNITS GUIDELINES .................................................................................................................. 15 8 – MAINTENANCE CHECKLIST ................................................................................................................................................ 16 9 – HYGENIC AHU MAINTENANCE CHECKLIST ...................................................................................................................... 17 10 – AHU TROUBLESHOOTING GUIDE ................................................................................................................................... 18 11 – MANDATORY START-UP CHECK LIST AND RECORD .................................................................................................... 19 Page 2 of 20 1 – SAFETY CONSIDERATIONS Earthing 1.1 – General The 39HQM air handling units (AHUs) has been manufactured in Carrier factory in the Kingdom of Saudi Arabia, under the guidelines and policies of Global Carrier Corporation. In order to guarantee safe operation and use of the unit, please carefully read and observe the instructions in this document and pay special attention to the warnings that apply to this unit. Any modifications in the design and/or installation of the AHU that are carried out without discussion with Carrier Corporation and without advance written agreement will result in the loss of the right to any warranty claims and any claim for injury to personnel as a result of these modifications. Maintenance procedures may only be carried out by qualified personnel. 1.2 – Applications The AHU is designed for the movement and conditioning of air, unless otherwise agreed during the design stage. 1.3 - Instruction Types The following warning labels and labels with text are used. Lifting point This label indicates where the AHU must be earthed and is on one of the support beams beneath the casing in the fan section. - The electrical components in the AHU must be earthed, except for components with double insulation and/or components with a supply voltage below 50 V. - The electrical components must be installed in accordance with national and local regulations. Rotating parts This label indicates that there are rotating parts behind this access cover, door or panel which may cause injury. The components that include rotating parts are the fan and heat recovery wheel. If there are special customer-specific components behind doors, access covers or panels that include rotating parts and pose a potential risk, this is also indicated by this label. Hot surfaces This label shows where the AHU must be lifted and is positioned on the support beam. Forklift Handling All sections are produced with a base frame and optionally can be placed on a wooden block for positioning with a forklift. This label indicates that there are components behind this access cover, door or panel that can cause serious burns when touched. The components that may have hot surfaces are the steam humidifier, steam heater and the electric heater. If there are special customer-specific components behind doors, access covers or panels that have hot surfaces and pose a potential risk, this is also indicated by this label. Electrical voltage - Place the forklift under the center of gravity of the section for equilibrium and maximum safety. - Confirm that the forklift has adequate lifting capacity for each section to be moved. Page 3 of 20 This label indicates that there are electrical components behind this access cover, door or panel that may be dangerous for the user/installer. Only personnel qualified in accordance with NEN 3140 is permitted to carry out work on these components. The label is attached to the access cover for the electric heater control box. Removal of transport brackets This label is located at the bottom of the fan section. It indicates that the transport brackets must be removed during commissioning before the fan is started up. Central data Remove Wooden blocks underneath fan motor base, if any. Unfasten all screws and remove the shipping clamps Sample of rating plate, above, contains the data for the AHU, such as Project Name, Section number, power supply, air flow etc. the Rating Plate is normally located on the access cover or the door of the fan assembly. Opening the fan door Before opening doors, switch off and deenergize the fan, and ensure that it has stopped rotating. (Minimum of 2 minutes) Before starting the unit removes the 4 fan shipping clamps. Untighten spring isolator bolt Partially un-tight (loose) the nut of spring isolator as shown below. Move up the isolator bolt min 25 mm, using Allen or vise grip, this will disconnect the spring bolt from bottom Spring Plate, Tighten again the nut for all spring isolators so that the Fan Motor Base is secured to the top spring isolator plate. Label is located at the inner skin of the access door of the fan section. Partially untie the nut before applying the Allen Key. Loosen the spring bolts (min 25mm) with the help of Allen Key, till you hear a click sound indicating spring bolt being disconnected from bottom spring plate. This label is positioned on the outside of the door or access cover of the fan assembly. This label warns that the fan must have been switched off and deenergized for a minimum of two minutes before the door or access cover is opened. Caution: All doors and access covers must be closed before starting up the AHU. 1.4 - Disposal of Parts/Materials - The packaging material must be disposed of in a responsible manner and in accordance with local regulations. - Components that are replaced must be disposed of as described above. 2 – TRANSPORT AND LIFTING INSTRUCTIONS 2.1 - General Transport and lifting of the AHU must always be in accordance with the instructions below. If these instructions are not observed, irreparable damage may occur to the unit, and people in the immediate vicinity of the unit are also endangered. Carrier does not accept any responsibility if these instructions are not observed. Transport and lifting must be carried out by qualified personnel. Lifting must be carried out in accordance with local regulations and with the help of certified lifting aids. Top Spring Plate 25 mm minimum Bottom Spring Plate 2.2 - Transport and Storage Lifting of the AHU is only permitted under the designated lifting points. This applies to transport as well as storage. Tighten the nut again to secure the fan and motor base frame. Page 4 of 20 2.3 - Roof Edge Protection During Transport (Outside Installation) Evenly positioned spacer bars should be used between the lifting cables to prevent damage to the top of the unit and ensure that no excess pressure is applied to the AHU panels. For hoisting please ensure that the weight is evenly distributed. Bed Truck Roof edge transport protection During transport by truck the units are attached to the loading surface with tie ropes, pulled across the unit towards the side edges of the truck. On external units, to protect the roof edge from distortion by the tie ropes protection plates are added. 2.4 – Offloading and Hoisting Depending on the dimensions of the AHU and the situation on site, the AHUs are supplied in previously agreed transport sections. Before proceeding with the transport and installation of the casing sections, always consult the applicable dimensional drawing which shows the dimensions and weights of the sections, as well as the installation sequence. The weight is given on each transport section. Each transport section is equipped with a sub frame with four lifting points. These points are marked by the label shown below. For offloading as well as hoisting lifting cables can be attached 1) Under the wooden skid OR For hoisting please ensure that the weight is evenly distributed. Ensure that spacer is used in the hoisting properly so no pressure is applied on AHU casing. 2) To the lifting bars. (Lifting bars are not supplied by factory ) Page 5 of 20 2.5 - Horizontal Transport For horizontal movement pallet lifters or transport skids can be placed under the installation frame or under the lifting bars. It is important that these support the lifting points. At no time should the cross beams at the ends of the unit sections be used for jacking or tracking the AHU. For horizontal transport always provide support under the lifting points. - The use of bars / tubes as rollers can result in damage to the installation frame. - Roller should be adequate to support the weight of the AHU section - The roller used for AHU horizontal transport MUST BE FREE ROLLING. - The rollers are not supplied by factory. 3 – AHU STORAGE REQUIREMENTS Store Indoor before Installation 3.2 – Long Term Storage Storage period that took longer than 6 months inside the controlled environment, as explained above in Normal storage, less than 6 months; still require serious and proper preservation actions during the storage period 3.1 – Short Term Storage To properly store the AHU, it is critical to meeting the storage requirements as per the following; 3.2.1 Belts to be removed and kept safe with proper tag of the AHU in conditioned space, belts shipped loose, as standard in production of 39HQM and packed in plastic bag placed inside fan section. 3.1.1 Indoor storage weather: < 70% RH, < 40º C, all AHUs sections are clearly label with sticker mentioning “STORE INDOOR” 3.2.2 Filters to be removed and stored in a proper packed & conditioned space. 3.1.2 Well ventilated store room precaution to prevent internal condensation that can lead to rust. 3.2.3 Every 3 months check fan bearing to see if relubricate is required 3.1.3 Clean and non-corrosive environment. 3.2.4 Every 3 months unload the bearing by turning the fan wheel by hand. This operation prevents bearing corrosion by redistributing the bearing grease. 3.1.4 Storage platform to be smooth with minimum vibration and leveled. 3.1.5 Ensure properly packed or cover the AHU, ensure the openings of the AHUs like the damper, fan and coil opening are closed so that no dust, no external material or animal allow to enter the AHU. After long term storage, grease should be purged from the bearing and fresh grease injected prior to start-up. 3.2.5 Motors should be stored in a clean, dry environment protected from moisture. 3.2.6 Periodically check of the AHU packing to ensure no sand/dust accumulation. Page 6 of 20 4 – STARTUP INSTRUCTIONS 4.1 – Casing A4 Sheet is attached to the unit for the unit data such as project name, section number etc. This usually located on the access cover or door of the fan compartment. 4.1.1 Casing Panels Check the AHU panels for any damage. Any dirt or stains must be removed from the surface to prevent possible long-term damage. Building debris left on the roof must be removed. Dirt can be removed with water and a mild household soap solution. Damage can be repaired by thoroughly cleaning the affected surface, then treat and paint as necessary. If applicable check the sealing joints and repair if required. Before the units are placed against or on top of each other, the sealing tape supplied must be attached between the casing sections. Place the casing sections as close as possible together before assembly. Pull the casing sections towards each other by placing the lifting bars first in one and then in the other casing section. Then pull both parts towards each other using pull ropes. The casing sections are connected with the frames and fixing elements supplied. If the AHU is installed outside, the roof connecting plate provided must be installed on the roof and sealed. 4.1.2 - Doors and Access Covers Check the operation of door handles, locks and movement of the hinges. For outside installation of the AHU check the storm cord. Doors and access covers must always be closed before starting the unit. 4.1.3 - Flexible Connections Check that all flexible connections are attached to the AHU. If necessary, tighten loose screws. 4.1.4 - Earthing Ensure that the AHU has been earthed correctly and in accordance with local regulations. A label on the support frame indicates where the unit should be earthed. 4.1.5.1 - Unit Joining With Half Mullion (For units up to 16 widths) 4.1.5 - AHU Installation and Connection The floor in the room where the AHU is installed must be level and flat to prevent connection problems. Use the pre-mounted corners for the final positioning of the sections and secure the corners with a bolt. The sections must be fully aligned. In case of multi section unit It is highly recommended to install common (single channel base through the AHU) base channel underneath the AHU. Rubber pads/ isolators will be installed underneath this single channel base. Page 7 of 20 Remove the first two corners and mount the GI connection strip to the base. Remove the next two corners and mount the connection strip against the side wall. Repeat this for the other AHU corners. 4.1.5.2 - Unit Joining Corner Posts With Coupling Profile Ensure Coupling profile will be using for units for sections that end with corner posts. Ensure that the sealing tape supplied is fixed to one of the two sections, before moving the sections against each other. Link the sections by connecting the pre-mounted corner posts with bolts and nuts (M6). If there are more than two sections, repeat the procedure above. For an outdoor installation all external joints should be sealed. 4.2 - Dampers - Check if the actuator motor is installed in accordance with the supplier’s instructions. - Check if the correct angle has been set. - Check if the dampers close properly. - Check if the damper can open to the required angle. - Check operation after the power has been restored following a power cut. Some dampers must be open, others must be closed. 4.3 – Air Filters - Check if the correct filters have been installed. - Check if the filters have been installed correctly. - Absolute filters are supplied separately, to prevent contamination during transport and start-up. Insert the absolute filters only after the unit has been cleaned. - Set pressure switches or filter indicators, if used. - Close the inspection door. Filter row can be completely pulled out in one move 4.4 – Electric Heaters - Ensure that the heater has been connected in accordance with the instructions of the supplier. The heater wiring diagram is located on the inside of the connection module. - Check the heater current. Check if the safety devices shown in the wiring diagram have been installed. - Check if the heater has been earthed in accordance with local instructions. - The electric heater will be switched off if there is no air flow rate across the heater exists, air flow switch high pressure side should be connected to atmospheric pressure in draw through arrangement and reverse in-case of blow through arrangement. - Ensure air flow switch is working. - Ensure that no objects have been left in the heater section. - The following warning labels are attached to the panel: electrical voltage and hot surface. 4.5 – Drain Connection When calculating trap depth on draw-thru or blow-thru applications, remember that it is not the total static pressure but the upstream or downstream static resistance that is trapped against. When calculating the trap depth for a cooling coil condensate pan on the draw-thru side, trap against the coil pressure drop in that coil section and any other pressure drops upstream of it (Negative Static Pressure). 4.3 - Air Filters Page 8 of 20 List of SCH40 steel pipes used in 39HQM standard water coil connection. The connection size are as reported in AHU coil’s report, the actual ID and OD SCH40 as references, a guide to select other connection accessories as for example the flanges, reducers etc. NSP = Negative Static Pressure (in Pa) L = Overall trap height A = (NSP/250*25.4) + 50 (mm) B = NSP L = A + B + Pipe diameter Condensate Drain, Draw-Thru Trapping To determine the trap dimensions for blow-thru units, find the coils maximum positive pressure and add 1/2 inch. This figure is normally the fan total static pressure. TSP = Total Static Pressure (in Pa) A = 50 mm (minimum) B = (TSP/250*25.4) + 50 (mm) L = A + B + Pipe diameter Nominal Dia (in) 1 1/2 2 2 1/2 3 3 1/2 4 Actual I D (mm) 40.9 52.5 62.7 77.9 90.1 102.3 Actual OD (in) 48.3 60.3 73.0 88.9 101.6 114.3 Threaded flanges with SAMCO part number that are readily available in market and used with the pipe connection, the exception is for the flange size 2 ½” Condensate Drain, Blow-Thru Trapping - Check the connections in accordance with the dimensional drawing. - Control the connections for leaks. - Check U- trap dimension according to above details. - Insure no damage in fins. Correctly straighten the fins - After several days of cooling operation check the condensate drain and operation of the U trap, if necessary clean it. SAMCO Part Number PIPE-FLANGE-1.5 PIPE-FLANGE-2.0 PIPE-FLANGE-2.5 PIPE-FLANGE-3.0 PIPE-FLANGE-4.0 Descriptions Pipe flange 1.5 inches Pipe flange 2.0 inches Pipe flange 2.5 inches Pipe flange 3.0 inches Pipe flange 4.0 inches For SCH40 pipe 2 ½” diameter, the readily available threaded flange in the market cannot be used to connect with SCH40 coil pipe 2 ½”. Blind Flange type is to be used and to be machined to match the thread with the SCH40 2 ½” coil’s pipe. 4.6 – Cooling Coil All steel pipe connections that are used in 39HQM standard water coil connection are selected from Schedule 40 (SCH40) black steel type and the thread is machined to BST 11 TPI (Taper 1:16). The size of the SCH40 steel pipe connection for the coil is printed as in per AHU selection report. 4.7 - Plate Heat Exchanger Used if dampers are installed. - Check if the actuator motor has been installed in accordance with the instructions of the supplier. - Check if the correct angle has been set. - Check if the dampers close correctly. - Check if the damper can open to the correct position. - Check operation after the power has been restored following a power cut. Some dampers must be open, others must be closed. - Insure no damage in fins. Correctly straighten the fins. Page 9 of 20 4.8 - Heat Recovery Wheel - Check that the wheel is rotating in the correct direction. This is indicated by an arrow on the casing. - Check if the wheel seals are fitting correctly. - Check if belt tension is correct. - Check if the motor has been correctly connected. - Check if the controller has been correctly connected and set in accordance with the instructions of the supplier if any. - Check if the rotor speed has been set correctly. - Heat wheel section is with access door as standard for motor access. data on the motor name plate. Set the motor protection device to the nominal value. The air flow may cause stationary parts to move (even a fan that is switched off) - The following warning label is attached to the panel: rotating parts. - If used check the pressure switch and set the correct pressure. While working on the fan the switch has to be locked open. - Check the operation of the main switch. - The warning label on rotating parts, electrical voltage and opening doors are attached to the door. The label to remove the transport brackets is located on the floor of the fan section. 4.9 – Fan and Motor - Remove the transport brackets. This is indicated by a label on the fan access door. - Untighten spring isolator bolt refer to chapter 1.3. - Check if the fan can move freely without obstructing the frame, flexible connection or wiring. - Insure power connection is star / Delta for motors above 5.5 kW. - Check and/or connect the motor in accordance with local instructions and the data of the supplier. - Check the direction of rotation of the impeller. The direction is indicated on the fan casing by an arrow. - Separately measure the current draw of the electric motor for all phases. The current draw of all phases must be approximately the same and agree with the Page 10 of 20 Before opening doors, switch off and deenergize the fan, and ensure that it has stopped rotating. (Minimum of 2 minutes) 4.10 – Drive Package The data for the belt type, belt tension, number of belts, size and type of pulley is indicated on a label attached to access door of the unit. Belt is not factory installed, supplied loose for site installation. Span length ( mm ) Belt Tension Force ( Kg ) Belt Deflection ( mm ) Using Laser guide device Fan Pulley Motor Pulley Adjustable sheaves: To check the location of adjustable sheave on shaft, make sure that the centerlines of both sheaves are in line and parallel with the bearing support channel. In case of adjustable pitch drives, Carrier recommends that adjustable sheaves should only be used for initial balancing and be replaced with fixed pitch sheaves by the air balancer prior to the final system air balance. Belt Unit Demo Sticker 4.10.1 – Alignment Make sure that fan shafts and motor shafts are parallel and level. The most common causes of misalignment are nonparallel shafts and improperly located sheaves. Where shafts are not parallel, belts on one side are drawn tighter and pull more than their share of the load. As a result, these belts wear out faster, requiring the entire set to be replaced before it has given maximum service. If misalignment is in the sheave, belts enter and leave the grooves at an angle, causing excessive belt and sheave wear. 4.10.1.1 Shaft Alignment Shaft alignment can be checked by measuring the distance between the shafts at 3 or more locations. If the distances are equal, then the shafts are parallel. 4.10.1.2 Sheave Alignment Fixed sheaves: To check the location of the fixed sheaves on the shafts, a straightedge or laser guide device is required. Using Straightedge Straightedge must make contact at 4 distinct points along the outside perimeter of both pulleys Page 11 of 20 Adjustable sheaves should not be used with variable frequency drive Do not exceed maximum fan speed with adjustable sheave 5 – MAINTENANCE AND OPERATING INSTRUCTIONS 5.1 - General The AHU(s) require little maintenance. The smooth inside and outside finish of the panels makes maintenance very simple. For dry sections: once a year thoroughly check the inside and outside of the AHU casing. For maintenance of wet sections (coolers and humidifiers) please refer to the air handling section concerned. 5.2 – Casing Panels 5.2.1 - Inside Installation a) Internal inspection of the casing of double-skin panels and of all dry parts: Remove contamination with water and a mild household soap solution. Where damage of the paint finish has occurred, if necessary remove rust and touch up with good quality anti-corrosive primer and paint. The outside air intake sections can show signs of corrosion as they contain wet parts and are affected by mist, rain and air pollutants. b) Outside inspection of the coating: If damage to the paint treatment has occurred, remove the rust (if necessary), and touch up with good quality anticorrosive primer and paint. 5.2.2 - Outside Installation Check the sealed joints of AHUs installed outside and if required seal again with a UV-resistant and paintable kit. Treat damage as for inside installation. 5.3 - Doors and Access Covers Check locks and hinges of all doors and access covers. 5.4 - Flexible Connections Check the flexible connections for damage. 5.5 - Earthing Ensure that the unit is earthed and installed in the correct manner. 5.6 - Dampers Remove excess contamination by cleaning it with compressed air. Check adjusting bolts and linkage and if necessary tighten. Ensure that the damper blades run free of the casing. 5.7 - Outside Air Intake Especially the outside air intake is contaminated by pollution taken in with the air. The maintenance interval must be observed, as irreparable damage of the panels might otherwise occur. Clean the outside air intake well and repair damage as described in point 5.2.1. Page 12 of 20 5.8 - Filters The filters must be inspected once a month for excess pollution, pressure loss, damage and seating of the slide-in filters or built-in frames. With slide-in filters ensure that the filters have been correctly positioned and have been pushed well against each other from below. When replacing built-in filters you must ensure that the filter has been pushed well against the sealant and that the clips have been correctly installed. Filters must be replaced at the required intervals. The timing of the replacement depends on the type of filter, quality and the degree of contamination of the air. The pressure loss across the contaminated filter can be measured with a pressure differential gauge. Maintenance instructions of special filters are available on request. 5.9 - Electric Heaters Check once a year for contamination, and if necessary clean with compressed air. Check the connections in the control box. Check the operation of the thermostat. The following warning label is located on the panel: electrical voltage and hot surface. 5.10 – Cooling Coil Check once a year for contamination and if necessary clean with compressed air against the direction of the air flow or clean with a vacuum cleaner. Check for leakage. Check the fins of the droplet eliminator after the coil. Clean the siphon and check its operation. Check the condensate pan for contamination and clean if necessary. 5.11 - Heat Recovery Wheel Check the rotor once a year for contamination, and if necessary clean with compressed air. Check the rotor speed and compare it with the design data. Check the rotation of the rotor. Depending on the rotor material the wheel can absorb moisture. When stationary the wheel will become moist on one side and thus heavier. The rotor speed can be set to intermittent in the controller so that the wheel will rotate “x” times per time unit. The rotor bearings are lubricated for life and do not require maintenance. The drive motor is accessible. The belt is automatically tensioned by a spring-loaded rocking base on which the motor is installed. New belts expand a lot in the beginning. Check after two days if the belt still has enough tension. After this check the belt tension weekly during the first month and then check it once a month. For further operation and maintenance details on the heat recovery wheel/controller refer to the documentation provided by the supplier. The following warning label is located on the panel: rotating parts. 5.12 - Plate Heat Exchanger Check the plate heat exchanger once a year for contamination and if necessary clean with compressed air against the direction of the air flow. If dampers are used, follow the instructions in section 7.6 Check condensate pan for contamination and clean if necessary. 5.13 - Fan 5.13.1 – General wear and vibration, if it is too low this can result in belt slippage and belt wear. Sequence for installation of new belts: - Ensure that the pulleys are correctly aligned. If necessary re-align. - Position all belts loosely on the pulleys; do not pull tensioned belts over the pulleys. - Tension the belts and check the tension with a Sonic Tension Meter. - Re-check the alignment. If the fan speed changes or if a motor with different power specifications and/or speed is installed, the manufacturer must be informed. The supplier must recalculate the bearing load as well as the impeller load. If this is not done, irreparable damage to the fan may incur. The supplier does not accept any responsibility for modifications that have not been approved. See chapter 1.1. - The warning pictograms indicating rotating parts, electrical voltage and opening of doors are attached to the door. The air flow may cause stationary parts to move (even a fan that is switched off) While working on the fan the switch has to be locked open. The data for the belt type, belt tension, and number of belts, size and type of pulley is indicated on a label attached to the fan access door. 5.13.2 - Bearings The bearings of the smaller fan types cannot be lubricated. If the larger fans are of the re-lubricated type, then they should be lubricated every six months. For higher temperatures and increased contamination the lubrication interval should be adjusted as required. The standard lubricant is Shell Alvania R3. For higher temperatures and a higher degree of humidity use a lubricant recommended by the supplier. The electric motors are equipped with roller bearings. Depending on the motor size the bearings are lubricated for life or are equipped with a grease nipple. The lubrication interval and type of lubricant are as above. 5.13.3 - Transmission After starting up the unit, but also after replacing the belts the belt tension has to be checked within one week and then after two weeks and further tensioned if required. After that check the belt tension and inspect the condition of the belts every three months. The Correct Belt Tension depends on: - The belt type. - Power to be transmitted. - Belt velocity. The belt tension is calculated for each transmission. If the belt tension is too high this can result in bearing Page 13 of 20 5.14 - Sound Attenuator Under normal conditions the sound dampers are maintenance-free. Nevertheless it is recommended to check the attenuators once a year for possible damage and loose fibers, in order to prevent further contamination of the system. Use the following formula to determine the percentage of voltage imbalance. 6 – 39HQM WITH STARTER PANEL 6.1 - Electrical Connections: Field Power Supply - Before accessing the unit, verify safety procedures are properly followed (LOCKOUT/TAGOUT). - Technicians working on the electrical side of the AHU must be trained in accordance to local national code and other applicable national or international codes. - Unit is factory wired for voltage shown on nameplate. - Motor is factory wired, user is requested not to modify the internal power or control wiring, doing so may lead to Carrier warranty loss - When installing units, provide a disconnect switch of adequate size per NEC (National Electrical Code) requirements, - All field wiring must comply with NEC and local requirements. - Route field power lines to terminal box connections as shown on unit wiring diagram and attached figure. - Operating voltage to motor/s must be within voltage range indicated on unit nameplate. - On 3-phase units, voltages between phases must be balanced within 2% and the current must be balanced within 10%. - Ensure connecting ground cable to factory ground cable which is connected to equipment’s grounding. - Every motor has standard internal thermal overload Percentage of Voltage Imbalance Max voltage de =100x variation from average voltage average voltage EXAMPLE: Supply voltage is 460-3-60. AB = 452 v BC = 464 v AC = 455 v Average Voltage = 455+464+455/3 = 457 Determine maximum deviation from average (AB) 457 – 452 = 5 v (BC) 464 – 457 = 7 v (AC) 457 – 455 = 2 v Maximum deviation is 7 v. Determine percent voltage imbalance: Percentage of Voltage Imbalance = 100 x 7/ 457 =1.53 % This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%. IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electric utility company immediately. Unit failure as a result of operation on improper line Voltage or excessive phase imbalance constitutes abuse and may cause damage to electrical components. Field Control Wiring Route control cables or equivalent single leads of no. 18 AWG (American Wire Gage) colored wire from sub-base terminals through conduit in unit to control connections as shown on unit’s label wiring diagram. Unit Start-Up Switch on the power to the unit, check motor’s operation and direction of rotation, if reversed interchange two of the 3 power phases at terminal box connections. If unit is equipped with VFD, the initial settings for the VFD are factory completed, other settings to be completed at site as per load requirements. Terminal Box Page 14 of 20 7 - HYGIENIC AIR HANDLING UNITS 7.4 Commissioning / Acceptance GUIDELINES: Observe the following: 7.1 - Hygienic AHU Storage Requirements Before switching on fans for the first time, make sure that all parts in contact with the air are clean. Clean, if required. In addition to the 39HQM AHU storage requirement in part 3, the following recommendation by VDI 6022 part1 should be taken care in the consideration for the hygienic unit storage: The packaging and protection of the components shall only be removed immediately prior to assembly. Before installation, the components shall be checked for cleanliness, and shall be cleaned thoroughly if required. Any open ends or accessible surfaces shall be protected against the infiltration of construction site dust and humidity before interruptions of assembly work. 7.2 Outdoor Air Inlet Reference to VDI 6022 part1 outdoor-air inlets shall be so positioned as to minimize any unfavorable effect on the quality of the air taken in by local emission sources such as exhaust air, smoke gas, olfactory, and other disturbing sources (such as roads with heavy traffic, garage doors, parking lots or bus stops, tarmac roofs, open re-cooling plants, impacts emanating from humans, alive and dead small animals). Recirculation of exhaust air into the outdoor-air inlet shall be avoided. Take into account the airflow around the building, wind and meteorological conditions, roof systems (such as attics) and any planned neighboring buildings. The outdoor-air inlet shall not be positioned close to, and not in the main downwind direction behind, wet cooling towers because of the danger of contamination with microorganisms. 7.3 Exhaust-Air Outlet Any short-circuit between exhaust air and outdoor-air inlet shall be avoided. Positioning the exhaust-air outlet above the roof and at a height greater than that of the inlet opening. Sufficiently large distances between air inlet and outlet openings and by blowing the exhaustair flow away from the outdoor-air inlet opening at sufficient velocity Page 15 of 20 Construction progress shall allow for commissioning of the systems. (For instance: Rooms shall be free of dust before the extract-air system is switched on.) It is recommended to connect air-cooled surfaces to the air duct system only after the cleanliness of the completed ventilating and air-conditioning system has been checked and documented in an appropriate manner. Any drainage systems must not be connected directly to the municipal sewage system. Ensure, by means of stepwise shutdown, that the humidifier chamber is blown dry before intended shutdowns. It shall be possible to dimension, install, and inspect or change air filters in such a way that they minimize the carryover of microorganisms and of inorganic and organic dusts to downstream components or into the rooms to which air is supplied; on no account they must increase it. It must be ensured that the filters themselves do not become a source of harmful or odorous substances, especially due to microorganisms in the supply air. Microbial growth on air filters can be prevented or minimized by, e.g., limiting the relative humidity. 8 – MAINTENANCE CHECKLIST The checklist contains a general overview of the planning that facilitates the inspections and maintenance of the AHU. Remember to de-energies all components and to ensure that the fan has stopped rotating, before the doors and access covers are opened before inspections and maintenance take place. Components Panels CASING Doors Actuator General AHU Maintenance Check List Check Points Recommended Maintenance Operations Contamination Damage Operation of Hinges & Locks DAMPER Check for seal span and crack Installation Check if correctly installed to the damper shaft Fitting Opening Rotation Bushing and Linkage Operational Flat Pre-filter FILTER Metallic filter Vee filter Control Fins COIL Check if blades can open and close to require angle Remove dirt from bushing and linkage rod with compressed air Check damper operational once power supply restored Physical condition and seal pressure drop Check filter clip (frame) correctly installed Check and remove pollution and dirt Filter replacement depend to degree of contamination All electrical connection Airflow switch and thermostat sensor Contamination Damage Clean dirt with compressed air and check connection in control box Check the operation of airflow switch and thermostat sensors Clean dirt with compressed air Check fin alignment and comb fins Check gap and seal with silicon sealant to avoid fresh air by-pass Check gap and seal with silicon sealant to avoid fresh air by-pass Air by-pass Headers Seal Water leakage Eliminators Contamination Clean dirt with compressed air Contamination Clean dirt with vacuum cleaner Water Flooding Check and clean U-trap Fan housing Bearing Contamination Lubrication (re-grease type) Wear Blower Contamination Motor Lubrication (re-grease type) Drive (Pulleys & Belts) Belt tensioning Fitting Wear Alignment Isolators Flexible connection HEAT WHEEL Check blades and rod bolts are tight Coil Frames Drain pan FAN Check seal integrity, remove dirt with compressed air Check filter sitting (rail) correctly each other Bag filter ELECTRIC HEATER Check locks and hinges operational function Door Seals Seal and contamination Blades Remove contamination with water and mild house hold soap Remove rust and touch-up with anti-rust primer and paint Rotor Motor and Drive Fixing Contamination Crack and leak Contamination Incase tube leak, braze leak point Check and remove dirt with compressed air Check oil and re-grease every 6 months. Check if physical bearing is good or replace with new bearing Check and remove dirt with compressed air Check oil and re-grease every 6 months. Check pulley fitting tightness to the shaft Check tensioning and tighten the belt if required Check if belt in good condition or replace with good belts Check pulley and belt alignment Check all bolts not loose, tighten the bolts if required For spring isolators, check if rusted and touch-up with anti-rust Check if any damage or air leakage, replace new flexible connector if required Check and remove dirt with compressed air Operational Check rotor rotation Operational Check rotor speed and verify with design rpm Wear and tear Check if belts with enough tension Page 16 of 20 Interval Month 1 3 6 12 9 – HYGENIC AHU MAINTENANCE CHECKLIST The checklist contains a general overview of the planning that facilitates the inspections and maintenance of the Hygienic AHU (Reference VDI 6022 Part 1 - Table 6) which are in addition to the normal maintenance checklist. Components AHU without Humidification Outdoor-Air Inlets Central Air-Handling Units / Unit Housings Hygienic AHU Maintenance Check List Check Points Check for contamination, damage and corrosion Clean and repair Check for contamination, damage and corrosion on the air side Clean and repair Check for water precipitation Check spray nozzles for deposits If number of CFUs > 1000 CFU/mL, clean, rinse and dry the tray; disinfect; test quality of supply water 15 days Clean pump circuit Repair Function-check disinfection facilities Repair Check vapor distribution system for deposits Check spray nozzles for deposits During standstills ** If deposits have formed, extract and clean unit, check region downstream of mist collector Clean and repair Clean and repair steam humidifier Clean Clean or replace nozzles Check drain Clean and repair Determine number of CFUs in the humidifier water; Exception: steam humidifiers If number of CFUs > 1000 CFU/mL, clean, rinse and dry the tray; disinfect; test quality of supply water Function-check control valve Repair Check humidity limiter Repair Check for unacceptable contamination and damage (leakages) and odors Heat Exchanger (Including Heat Recovery Unit) Clean and repair Function-check conductivity sensor Check for contamination, damage, microbial growth and corrosion Check for condensate precipitation in the humidifier chamber Fan Clean and repair Clean or replace nozzles Check circulation pump for contamination and deposits in the intake line, check condition and functioning of filters Check mist collector and flow rectifier for contamination, damage, deposits, and corrosion Silencers 24 Re-adjust Completely empty and dry humidifier unit Air Filters Interval Month 3 6 12 Clean Check empty housings for contamination, damage, and corrosion Check for contamination, damage, microbial growth, and corrosion Determine number of CFUs in the recirculating water Air Humidifiers Operating Without Recirculating Water 1 Routine maintenance possibly 36 months. Function-check shutdown controls Air Humidifiers Operating With Recirculating Water Action, If Required Check differential pressure Change any affected air filters Change filter stage Maximum interval until first filter stage is to be changed Maximum interval until second filter stage is to be changed Check silencers for contamination, damage, and Repair or replace; test with contact corrosion slides, if necessary Clean and repair, check water Check for contamination, damage, and corrosion drain Visual inspection of air-to-air plate heat Clean, repair exchangers for contamination, damage, corrosion Visual inspection of air-to-air rotary heat exchangers for contamination, damage, corrosion, Adjust seals, clean, repair and tightness Visual inspection of directly heated heat Replace seals, clean, repair exchangers for tightness Heaters: Check for contamination, damage, Clean and repair, replace corrosion, and tightness Coolers: Check tube bundles, mist collectors and condensate tray for contamination, corrosion, Clean and repair damage, and tightness Function-check drain and siphon Clean and repair ** During standstills (> 48h) in the absence of suitable disinfection facilities, or during times of operation when no humidification is required for more than 48h. Page 17 of 20 10 - AHU TROUBLESHOOTING GUIDE PROBLEM LESS AIR FLOW PROBABLE CAUSE RECOMMEDED SOLUTION Low fan speed Increase the fan speed by changing the pulleys High external static than design Check if the dampers are open and no block in the air passage Duct layout Ensure that the duct design is proper with no immediate bending /curve after the fan discharge Clogged / dirty coil Clean the cooling coil Clogged / dirty filter Clean and replace filter Overloaded motor Reduce load or replace with larger motor Improper line voltage Check wiring, secure all connections, Check with the electricity supplier MOTOR DRAW HIGH AMPS / Worn bearing OVER HEATS Motor fan is clogged MOTOR FAIL TO START Relace bearing and seal Remove fan cover, clean fan and replace cover Three phase motor has one phase Check wiring , secure all connections. Blown fuse or open circuit braker Replace fuse or reset circuit braker Improper wiring or connection Check wiring diagram supplied on the motor Improper current supply Compare actual power supply with the motor name plate Mechanical failure Determine the motor and drive turn freely without load. Check bearing and lubrication Short-circuited stater Replace blown fuse. motor must be re-winded Overloaded motor Reduce load or replace with larger motor MOTOR STARTS AND THEN Low voltage at motor terminal FAILS OR MOTOR DOES Starter shorts when motor warm up NOT COME UP TO THE Line wiring too small REQUIRED SPEED 60 hz motor connected to 50 hz EXCESSIVE MOTOR NOISE FREQUENT MOTOR BEARING DAMAGE LOOSE FAN BELT OR SHORT BELT LIFE FAN DOESNOT OPERATE Check across ac line and correct voltage if possible Replace starter Relace with large sized wiring Check the require frequency on motor rating plate Motor mounting bolts are loose Tighten motor mounting bolts Rigid coupling connection Replace with flexible connection Worn motor bearing Relace motor bearing and seal Fan rubbing on fan cover Remove and correct the fan housing in the motor Excessive load due to over-tensioned drive Check belt tension and load Excessive load due to smaller motor pulley Relace with large diameter pulley Motor is poorly positioned Adjust the motor to make good tension Worn or damage belt Replace belt and check alignment Worn sheaves Replace pulley Misaligned pulleys Realign the pulleys Greese or oil on belts Check for bearing leaks. clean belts and pulley Belt slipping Adjust tension Electrical Check motor fuses, electrical on-off switch, overload protector and voltage Mechanical failure Looks for broken belt or loose pulleys, make sure that the fan blades are not touching the fan housing Fan hitting inlet cone, cut-off or housing Center fan in inlet cone, secure cut-off in housing. secure fan on shaft, repair or replace the damaged parts Drive belt not operating properly Adjust belt tension, replace worn or broken belts and clean oily or dirty belts. Check if all the belts are of the same size and type. First start after relubrication. (regreasing) Allow machine to cool down and restart Over lubrication Clean surface of grease and purge No lubricants Apply grease and check the bearing for damage Excessive load or fan speed Replace with large bearing / fan Misaligned bearings Correct alignement and check shaft level. Air by-passing the coil Prevent air bypass with blankoff plate NOISY FAN FAN BEARING -VERY HOT LOW COIL CAPACITY/ LESS Coil tubes are blocked Incorrect airflow COOLING / HEATING (CHILLED WATER / HOT Incorrect gpm WATER) Incorrect water temperature LOW COIL CAPACITY- DX COILS ELECTRIC HEATER-NOT OPERATING Clean and unblock the tubes Check fan operating condition Check water pumps,valves and lines for obstruction Provide required water temperature Incorrect airflow direction Ensure that the airflow is in counter flow arrangement. Air by-passing the coil Prevent air bypass with blankoff plate Coil tubes are blocked Clean and unblock the tubes Incorrect airflow Check fan operating condition Expansion valve not operating Check sensing bulb location and the operation Poor refrigerant distribution Check for blockage in distributor and tubes Wrong heater wiring and stages Check the heater wiring and stages Not proper airflow switch connection Check the airflow switch direction, low-pressure & hi-pressure Low voltage Check the voltage Contactors Check the correct contactors and wiring size Page 18 of 20 11 - MANDATORY START-UP CHECK LIST AND RECORD IMPORTANT! This page is a mandatory checklist & record – the check to be executed and data to be recorded for future reference incase of failure. A copy of this checklist data has to be submitted to carrier or carrier representative. Completion of this checklist is a must for any field claim, no field support will be provided for incomplete or blank checklists. Before starting up the AHU ensure that the components have the correct connection voltage and connect them in accordance with the regulations. The doors and access covers must be closed and the AHU must be earthed. 8.1 PRELIMINARY INFORMATION MODEL NO: JOB NAME: SERIAL NO: AHU LOCATION START-UP DATE: Indoor ( ) Outdoor ( ) TECHNICIAN NAME: ADDITIONAL ACCESSORIES: 8.2 PRE-START-UP PRE-START-UP Checklist Yes No NA No NA Review AHU Maintenance and Preservation Record for AHU stored for longer period (> 6 months) as specify in “3.2 Long term storage” Review and record unit cleanliness, and check for corrosion Filters & belts were kept separately indoor and in clean and good condition Check and ensure fan bearing and grease in perfect condition Remove packaging and any construction debris TEAR ALONG THE DOTTED LINE Internal and external panels are in good condition – no damage Are damper operations correct? Are proper air filters in place? Is heating coil, if any, in correct connection side? Is cooling coil, if any, in correct connection side? Is there any leakage in the cooling coil? Is the droplet eliminator, if required, already installed? Has water been placed in drain pan to confirm proper drainage? Insure drain trap connections / dimensions are correct Insure the heat wheel is rotating in correct direction Insure the heat wheel sealing is correctly installed Insure the heat wheel gasket is correctly installed Remove fan transport brackets Untighten spring isolator bolt Check fan bearings, shaft(s) Hand turn fan to ensure no rubbing with housing. Have fan and motor pulleys been checked for proper alignment? Check if fan belts have proper tension and deflection? (Refer to unit sticker for values) Are all wiring terminals to fan motors and heaters tight? Check heater safety devices (airflow switch & auto / manual thermostat) are connected to MCC Ensure air flow switch high pressure side should be connected to atmospheric pressure in draw through arrangement and in-case of blow through arrangement should be connected to negative pressure Check if airflow switch and thermostat sensor are functioning properly Is duct connected to unit in proper way? ( straight duct after fan discharge is 2.5 fan diameter ) Verify wiring is correct for application (voltage, etc.) per component label 8.3 START-UP If this unit is used for construction conditioning without ductwork, ensure balancing is redone and filters replaced once construction is complete. Yes Ensure correct fan rotation. Measure and record actual fan rpm/absorbed motor kW/total fan static pressure and plot on fan curve. Ensure fan and motor operating at designed operating point. Ensure all water inside air handler is in condensate pan. Check for vibration levels. After air and water balance and at least 10 minutes running time, record the following measurements: Check indoor fan speed RPM Air Entering Condition ( DB / RH / WB) Air Leaving Condition ( DB / RH / WB) Entering / Leaving water temp. Page 19 of 20 Manufacturer reserves the rights to discontinue or change at any time, specifications or designs without notice and without incurring any obligations. Supersedes Version: 39HQMIOM-06 Catalog Number: 39HQMIOM-07 Page 20 of 20 Effective Date: 02-02-2021 Phase: 50Hz & 60Hz