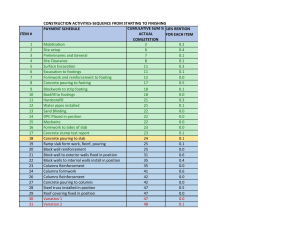

Earthquake Resistant Buildings: Reinforced Concrete Design

advertisement