Financial Analysis & Supply Chain Management Presentation

advertisement

Financial Analysis

& Supply Chain

Management

Leijoy P. Cabanilla | Reynald E. Tomas

Table of Contents

Financial Analysis

Supply Chain Management

Time Value of Money

1a

2a

Overview of SCM

Operational Financial Decisions

1b

2b

Components of SCM

Project Investment Decisions

1c

2c

SCM in a Service Industry

• Randomly shown in the presentation

• Words are related to the topic/s being

discussed

• First 3 correct answers via chat to be

awarded the ff points: 3 pts- 1st

correct, 2 pts- 2nd correct, 1 pt- 3rd

correct

• One top scorer for Financial Analysis

and one top scorer for Supply Chain

Management

01

FINANCIAL

ANALYSIS

TIME VALUE OF MONEY

Albert Einstein

Compound interest is the eighth

wonder of the world. He who

understands it, earns it; he who

doesn’t, pays it.

Benjamin Franklin

Money makes money. And the

money that money makes,

makes money.

Cost of Money

Explicit

Cost of borrowing.

Implicit

Cost of not investing.

I borrowed Php 1M from a bank at 8% interest p.a. to set up a

business that I expect to give me a return of 20% per year.

However, after receiving the loan proceeds, I was tempted to

buy a car, hence, the business did not materialize. During that

time, the average inflation rate is 5%.

Explicit CostThe 8% interest on the loan

Implicit CostThe forgone return of 20% plus the inflation rate

of 5%

Compounding Interest

“Interest on Interest”

Compounding is the process in which an asset's earnings

are reinvested to generate additional earnings over time.

This growth, calculated using exponential

functions, occurs because the investment will generate

earnings from both its initial principal and the accumulated

earnings from preceding periods.

VALUE

Period

Principal

Interest

Book Value

1 1,000,000 200,000

2

200,000

3

200,000

4

200,000

5

200,000

1,200,000

1,400,000

1,600,000

1,800,000

2,000,000

Accumu.

Growth

20%

40%

60%

80%

100%

Thousands

Linear Growth

2,500

100%

2,000

Period

Principal

1

2

3

4

5

1,000,000

Interest

200,000

240,000

288,000

345,600

414,720

Book Value

1,200,000

1,440,000

1,728,000

2,073,600

2,488,320

40%

20%

20%

0

0%

1

Thousands

Accum.

Growth

20%

44%

73%

107%

149%

60%

40%

2

Book Value

Compounding Growth

80%

60%

1,000

500

100%

80%

1,500

3

4

5

Accumulated Growth

149%

3,000

160%

140%

2,500

107%

120%

2,000

100%

73%

1,500

80%

44%

1,000

500

120%

60%

40%

20%

20%

0

0%

1

2

Book Value

3

4

Accumulated Growth

5

Linear Growth

Period

Payment

Interest

Book Value

1

2

3

4

5

1,000

1,000

1,000

1,000

1,000

200

400

600

800

1,000

1,200

2,600

4,200

6,000

8,000

Total

Interest

20%

30%

40%

50%

60%

9,000

8,000

7,000

6,000

5,000

4,000

3,000

2,000

1,000

0

8,000

40%

4,200

30%

2,600

20%

1,200

10%

0%

1

2

3

4

8,930

8,000

Period

Payment

Interest

Book Value

1

2

3

4

5

1,000

1,000

1,000

1,000

1,000

200

440

728

1,074

1,488

1,200

2,640

4,368

6,442

8,930

6,442

6,000

4,368

4,000

2,000

5

Total Interest

10,000

Total

Interest

20%

32%

46%

61%

79%

50%

6,000

Book Value

Compounding Growth

60%

2,640

1,200

0

1

2

Book Value

3

4

Total Interest

5

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

Present and Future Values

Future Value (FV)

FV

Where:

P- principal or periodic payment

r- rate per period

n- number of periods

FVOA

FVAD

Illustration

Future Value

If you deposit Php1,000 in a bank with 10% interest p.a, how much is

the value of the deposit after 5 years?

FV = P * (1 + r) n

FV = Php 1,000 * (1 + 10%) 5

FV = Php 1,000 * 1.61051

FV = Php 1,610.51

Practical Illustration

Business

You are setting up a small online business with initial capital of P10,000. You expect your monthly

income to be 10% per month and you intend to use the income from the business at least for the next

2 years (24 months) before gradually withdrawing for your personal needs. How much is the expected

value of your business after 24 months assuming consistent results per month?

FV = P * (1 + r) n

FV = Php 10,000 * (1 + 10%) 24

FV = Php 10,000 * 9.8497

FV = Php 98,497.33

Compound/

Compounding

Illustration

FV of Ordinary Annuity and Annuity Due

If you deposit Php1,000 in a bank every end of year with 12% interest p.a, how much is the

value of the deposit after 5 years? How about if deposit is made every beginning of the year?

If made every END of month:

FVOA = P * {[(1 + r) n – 1] / r}

FVOA= Php 1,000 * {[(1 + 12%) 5 – 1] / 12%}

FVOA= Php 1,000 * (0.762342/12%)

FVOA= Php 1,000 * 6.352847

FVOA= Php 6,352.85

If made every BEGINNING of month:

FVAD = FVOA * (1 + r)

FVAD= Php 6,352.85 * (1.12)

FVAD= Php 7,115.19

Practical Illustration

Retirement

You are 30 yrs. old and would want to retire at age 50 (after 20 yrs). If you want to have at least 20M

upon retirement to live a somewhat comfortable life afterwards, how much would you need to invest

monthly for the next 20yrs if your investment is consistently earning 24% per year?

FVOA = Php 20,000,000

Php20,000,000 = Pmt * {[(1 + r) n]-1] / r}

Php20,000,000 = Pmt * {[(1 + 24%/12) 20*12 -1] / (24%/12)}

Php20,000,000 = Pmt * {[(1 + 2%) 240 -1] / 2%}

Php20,000,000 = Pmt * (114.88873/2%)

Php20,000,000 = Pmt * 5,744.43676

Pmt = Php20,000,000 / 5,744.43676

Pmt = Php 3,481.63

Takeaways:

•

Because of compounding, the Php

3,481.63 per month for 240 months

(or a total investment of Php835k)

becomes 20M.

•

If without earnings and the power of

compounding, monthly investment

should be Php83,333 to reach 20M in

20 years.

Present Value

PV

Where:

FV- future value

Pmt- periodic payment

r- rate per period

n- number of periods

PVOA

PVAD

Illustration

Present Value

If you want to have exactly Php100,000 after 5 years, how much do you need to have

now invested in a business which you foresee to earn 10% p.a. compounded per year?

PV = FV * (1 + r) –n

PV = Php 100,000 * (1 + 10%) -5

PV = Php 100,000 * 0.62092

PV = Php 62,092.10

Practical Illustration

Present Value of Future Cash Inflows

If you expect your business to generate at least P2,000 worth of cash inflows every month

for the next 5 years, how much is the equivalent value of such inflows assuming 12%

interest per annum?

PVOA = Pmt * {[1- (1 + r) -n] / r}

PVOA = 2,000 * {[1- (1 + 12%/12) -5*12] / (12%/12)}

PVOA = 2,000 * {[1- (1 + 1%) -60] / 1%}

PVOA = 2,000 * (0.44955/1%)

PVOA = 2,000 * 44.955

Pmt = Php 89,910

The total cash flows is 120,000 (2,000 x 5 x 12) but its equivalent value at present is 89,910 due to

compounding.

Operational Financial Decisions

Break Even Point

Sales level where net profit is 0.

Sales = Total VC + Total FxC

Differential Costing

Difference between the cost of 2 or more

alternatives (make or buy, sell or process

further, etc.)

Sensitivity Analysis

Asking “what if?”

Project Investment Decisions

●

Expansion projects

●

Replacement projects

●

Mandatory (compliance projects)

●

Other long term projects (R&D allocations,

patents, etc.)

Evaluating Project Investments

Uniform Annual Cost

Net Present Value (NPV)

Evaluating projects where cost is the most relevant

factor and whether the equal service-period

requirement is met or not.

the difference between the present value of cash

inflows and the present value of cash outflow to

analyze the profitability of a project.

Rate of Return

Payback Period

annual rate of growth an investment is

expected to generate, can be ARR or IRR

the amount of time it takes to recover

the cost of an investment

Uniform Annual Cost Method- Equal Lives

UAC

=

Asset Price___

(1- (1+rate) -n)/rate

Machine A:

UAC =

P105,000

[(1-(1.05) -5]/0.05

+ P11,000

UAC = P35,252.35

Which is better? rate = 5%

Machine A

Machine B

Capital

P105,000

P175,000

Lifespan

5 yrs.

5 yrs.

Annual

Maintenance

P11,000

P8,500

Machine B:

UAC =

P175,000

[(1-(1.05) -5]/0.05

+ P8,500

UAC = P48,920.59

Machine A is better because it has the lower

discounted uniform annual cost of obtaining and

maintaining.

Uniform Annual Cost Method- Unequal Lives

UAC

=

Asset Price___

(1- (1+rate) -n)/rate

Machine A:

UAC =

P105,000

[(1-(1.05) -3]/0.05

+ P11,000

UAC = P49,556.90

Which is better? rate = 5%

Machine A

Machine B

Capital

P105,000

P175,000

Lifespan

3 yrs.

5 yrs.

Annual

Maintenance

P11,000

P8,500

Machine B:

UAC =

P175,000

[(1-(1.05) -5]/0.05

+ P8,500

UAC = P48,920.59

Machine B is better because it has the lower

discounted uniform annual cost of obtaining and

maintaining.

Net Present Value

NPV = PV of Cash Inflows – PV of Cash Outflows

PV of Cash Inflows

PV of Cash Outflows

Net Present Value

Project A

500,000

450,000

50,000

Project B

800,000

1,000,000

-200,000

Project C

950,000

800,000

150,000

If projects are mutually exclusive, which should be selected?

Project C since it yields the largest NPV.

If not mutually

exclusive, Accept?

NPV General Rules

•

•

•

If projects are independent, accept those

with positive NPV.

If projects are mutually exclusive, accept

the project with highest NPV

If NPV is zero, do not proceed with the

project unless required by regulation or for

compliance purposes.

Rate of Return

10%

25%

15%

50%

Total return is 25,000 from an investment

of 100,000. What is the ARR?

Investment must earn at least 10% to

break-even, what is the IRR?

Total inflows was 450,000 from an

outflow of 300,000, what is the rate

of return?

Total inflows is 100,000 and outflows is

100,000 at 15% rate of return, what is

the minimum IRR?

Payback Period

5 years

Investment- 100,000

Annual Cash Inflows- 20,000

4 years

Investment- 100,000

Annual Cash Inflows

Year 1 – 10,000

Year 2 – 20,000

Year 3 – 30,000

Year 4 – 40,000

Year 5 – 30,000

General rule:

The lower the payback period, the better

4.5 years

Investment- 100,000

Annual Cash Inflows

Year 1 – 10,000

Year 2 – 20,000

Year 3 – 30,000

Year 4 – 20,000

Year 5 – 40,000

Decision /

Decision Making

Funding Investment Projects

Personal Investment

Own cash or savings

Venture Capital

Giving up some ownership

or equity in your business

to an external party

Angel Investor & Love Money

Loaned by family or friends

either to be repaid as profits

increase

Bank Loans

Banks or financial companies

providing financing assistance

in exchange for regular

amortization

Loan Amortization – Nominal (Add-On) Interest

If you borrow Php100,000 from a bank with 1% monthly add-on interest and payable monthly for 5 years,

how much shall be the required monthly amortization and the total interest expense/cost of borrowing?

Monthly Amortization = [Principal + (Principal x Rate x Period)] / Period

= [ 100,000 + (100,000 x 1% x 60)] / 60

= (100,000 + 60,000) / 60

= 160,000 / 60

Monthly Amortization= 2,666.67

Total Interest = Total Payments – Total Loans

= 160,000 – 100,000

Total Interest= 60,000

Loan Amortization – Effective Interest

If you borrow Php100,000 from a bank at 12% effective interest per annum and payable monthly for 5

years, how much shall be the required monthly amortization and the total interest expense/cost of

borrowing?

Monthly Amort = Pmt using PVOA Function

PVOA = Php 100,000

Php100,000 = Pmt * {[1- (1 + r) -n] / r}

Php100,000 = Pmt * {[1- (1 + 12%/12) -5*12] / (12%/12)}

Php100,000 = Pmt * {[1- (1 + 1%) -60] / 1%}

Php100,000 = Pmt * (0.44955/1%)

Php100,000 = Pmt * 44.955

Pmt = Php100,000 / 44.955

Required Monthly Amort = Php 2,224.44

Total Interest = Total Payments – Total Loans

= (2,224.44 x 5 x 12) – 100,000

= 133,466 – 100,000

Total Interest= 33,466

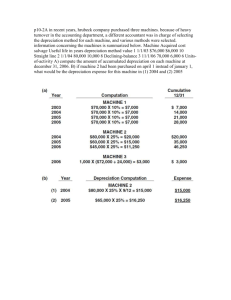

Depreciation

Straight Line Method

Units of Production Method

Sum-of-Years Digit (SYD) Method

Double Declining Balance Method

Straight Line Method

Cost Asset = 300,000

Useful Life = 5 years

Residual Value = 10% of Cost

Monthly Depreciation = ?

Straight Line Monthly Depreciation = (Cost of Asset – Residual Value) / Useful Life

Straight Line Monthly Depreciation = [300,000 – 10% (300,000)] / 60

Straight Line Monthly Depreciation = 270,000 / 60

Straight Line Monthly Depreciation = 4,500

When to use straight line?

a. No particular pattern to the manner in which the asset is being used over time

b. The main reason for decrease in value is passage of time

Units of Production Method

Cost Asset = 300,000

Total Expected Production = 600,000 units

Residual Value = 10% of Cost

Total Expected Production = 600,000 units

Total Actual Production = Yr 1- 50,000, Yr 2- 100,000

Depreciation in Year 1 and 2 = ?

UPM Depreciation = (Cost of Asset – Residual Value) / Total Production x Actual Production

Yr 1 UPM Depreciation = [300,000 – 10% (300,000)] / 600,000 x 50,000

Yr 1 UPM Depreciation = 270,000 / 600,000 x 50,000

Yr 1 UPM Depreciation = 22,500

Yr 2 UPM Depreciation = [300,000 – 10% (300,000)] / 600,000 x 75,000

Yr 2 UPM Depreciation = 270,000 / 600,000 x 75,000

Yr 2 UPM Depreciation = 33,750

When to UPM?

Main reason for decrease in value is use due to production or extraction.

Sum-of-Years Digit (SYD) Method

Cost Asset = 300,000

Useful Life = 5 years

Residual Value = 10% of Cost

Annual Depreciation = ?

SYD = sum of all years , Annual Depreciation Rate = Highest Year Number for Year 1 (and so on) / SYD

SYD = 1 + 2 + 3 + 4 + 5 = 15

Year

Annual Depreciation Rate

Depreciable Amount

(300,000 x 90%)

Annual Depreciation

1

5/15

270,000

90,000

2

4/15

270,000

72,000

3

3/15

270,000

54,000

4

2/15

270,000

36,000

5

1/15

270,000

18,000

SYD Method allows for the likelihood of assets to decline over time, and also to require higher repair and

maintenance costs in later years than when first purchased

Double Declining Balance Method

Cost Asset = 300,000

Useful Life = 5 years

Residual Value = 10% of Cost

Annual Depreciation = ?

Double Declining Rate = 100% / Useful Life x 2

Annual Depreciation = Book Value x Double Declining Rate

Year

Double Declining Rate

Book Value

Annual Depreciation

1

40%

300,000

120,000

2

40%

180,000

72,000

3

40%

108,000

43,200

4

40%

64,800

25,920

5

40%

38,880

8,880

Notes:

a. Disregard residual value in the depreciation computation.

b. Last year’s depreciation is the remaining BV after deducting the residual value

c. Ideal for assets that quickly lose their values or inevitably become obsolete

02

Supply Chain

Management

Supply Chain Management

management of the flow of goods

and services and includes all

processes that transform raw

materials into final products

Objective of SCM

Procurement

Integration

Operations Management

Logistics and IT

creating value

through this

chain of key

processes and

activities

01

Improve Quality

Improve Efficiency

Minimization of waste either

materials, man hours, delivery

time, etc.

Improve Stability

Maintaining strong relationships

making sure that the business

continues to run smoothly

02

04

Making sure that the product

and customer experience are as

positive and effective as they

can be

Risk Management

03

Taking steps to alleviate and

mitigate the negative impacts of

risks

Components of the Supply Chain

01

04

Planning

02

Sourcing

03

Logistics &

Distribution

Production

05

Return System

01

Planning

02

Sourcing

03

Production

04

Logistics and Distribution

05

Return

Planning

Developing an overall strategy for the supply chain

Demand Planning

Sales and Operations

Planning

Inventory Planning

Supply Planning

External Analysis

Plan Development

Synchronize forecast

and financial outlook

Develop sales and

operations plan

Portfolio Assessment

Conduct portfolio review

Internal Analysis

Implementation

Synchronize supply and

capacity

Conduct of Executive

S&Op Meeting

Procurement /

Purchasing /

Buying

01

Planning

02

Sourcing

03

Production

04

Logistics and Distribution

05

Return

Sourcing

Purchasing & Outsourcing

Partner & Vendor

Management

Sourcing a product or service

from an outside supplier rather

than producing it in house

SERVICES

Deepening

the buyer-supplier

relationships to achieve a

mutually beneficial goal and

establish trust

The ‘5 rights’ of Purchasing

Right Price

Right Quality

Buying Goods &

Services

Right Time

Right Place

Right Quantity

Low

Supply Risk

High

‘Kraljic’ Supply Matrix

Bottleneck Items

•

Monopolistic market

• Secure supply

•

Non-critical Items

• Large product variety

• Simplify and automate

Low

•

•

Strategic Items

Dependence on supplier

• Form partnerships

Leverage Items

Alternative sources of

supply available

Exploit purchasing power

and minimize cost

Profit Impact

High

Outsourcing

Possible loss of

competitive knowledge

Economies of scale

Reduced process and

quality control

Risk pooling

Reduced capital

investment

Focus on core

competency

Increased flexibility

Pros

Cons

Limits innovation

Possible conflict of

objectives

Privacy and

confidentiality issues

Make or Buy?

•

•

•

•

•

•

•

•

Make

Cost of making is cheaper

Desire to integrate plan

operations

Excess plant capacity

Desire to exert to direct control

over production and quality

Design secrecy

Unreliable suppliers

No suitable supplier quotation

Desire to maintain a stable

workforce

•

•

•

•

•

•

Cost of buying is cheaper

Suppliers research and

specialized know how

Small volume requirements

Limited production facilities

Desire to maintain multiple

source policy

Monopoly items on which the

buyer has no option

Buy

Make or Buy Decision

Illustration

You need 5,000 units of a part of the final product and the

cost of internal manufacturing per unit is as follows:

Solution:

Direct Materials

Direct Labor

Variable Overhead

Avoidable Fixed Overhead Unavoidable Fixed Overhead-

Relevant cost of making

= DM + DL + VoH + Avoidable FxOH

= 2.50 + 2.50 + 1.50 + 1.00

= 7.50

Relevant cost of buying = 7.75

2.50

2.50

1.50

1.00

1.00

8.50

If you can buy an unlimited quantities of the part from

outside supplier at 7.75 and disregarding qualitative

considerations, should you make or buy the part? How

much is the net benefit of the better option?

Decision: MAKE

Net Benefit to make = 7.75 – 7.50 = 0.25

= 0.25 x 5,000

= 1,250

Vendor Management

Sourcing Continuum

Basic Provider

Model

Approved

Provider

Model

Preferred

Provider

Model

Performance

Based/

Managed

Services

Vested

Business

Model

Shared

Services

Model

Equity

Partnerships

Approaches to Vendor Management

01

Reactive

Managing the supplier

relationships is handled in

response to when negative

situation occurs

02

Strategic

Supplier relationship

management is planned and

starts even before an agreement

with supplier is signed.

01

Planning

02

Sourcing

03

Production

04

Logistics and Distribution

05

Return

Production Process

Customization

Considering customer preferences or

introducing differentiated feature

Production & Assembly

Conversion of the materials

into desired output

Quality Control

Checking if final output passes

the minimum standards

Packing & Labeling

Preparing the product for selling

distribution

‘Just in Time’ (JIT) System

Materials arrive exactly as they are needed for each stage in the production process. Nothing is

produced until it is needed. Demand triggers every step and ‘pulls’ a product through production.

Organized in manufacturing

work cells

Multiskilled workers

Reduced set up and

manufacturing lead times

Reliable supplier

‘Just in Time’ (JIT) System

01

02

Lower cost of handling and

carrying, lower risk of

obsolescence and shrinkage

01

Inventory

02

Supplier

03

Supply Chain

Space

Lower investment in space

03

Limitations

Inventory

Revenues

Higher revenues resulting from a

quicker response time to

customers

Benefits

No buffer inventory and potential

stockouts

High reliance on suppliers to maintain

adequate stock to meet unpredictable

demands

Highly dependent on supply

chain

Use of ‘Kanban’ in JIT

Kanban is a Japanese term that describes a visual record or card oftenly used in JIT systems. It signals

the need of specified quantity of materials or parts to move from one work cell operation to another, in

sequence.

Benchmarking

Internal Benchmarking

identifying best practice within a group and

sharing it resulting in cross-functional

and/or cross-site teams

Competitor Benchmarking

comparisons with competitors and their

best practices

Functional Benchmarking

compare specific functions (e.g.,

logistics); the comparison is with the best

in class or best in the industry

Planning

01

Identifying benchmark outputs, best competitors

and data collection method

02

Analysis

Determining current competitive gap and project

future performance levels

Integration

05

Benchmarking

Process

04

03

Establishing functional goals and developing

functional plans

Action

Implementing specific actions and monitoring

results

Maturity

Recalibrating benchmarks

Benchmarking /

Benchmark

01

Planning

02

Sourcing

03

Production

04

Logistics and Distribution

05

Return

Logistics

01

Sourcing and

Procurement

Creating strategic alliances

with suppliers

04

Distribution

Facilitating business

transactions between trading

partners or to end-customers.

02

Transport

connecting one side of the supply

chain to another by carrying vital

resources to the entire supply

chain

03

Warehousing &

Materials Handling

moving, storing, protecting,

sequencing, and picking the right

material in the right condition at the

right time and at the right place

Transport

Considerations for Transportation

Regulations

LTO, LTFRB and DOTr rules and regulations

Carrier Management Activities

Carrier selection, scheduling, dispatching,

staffing, delivery arrangements, tracking,

handling, safety, etc

Intermodalism as Transport

Management Strategy

Transportation of cargo or passengers using

multiple modes (truck, rail, air, ship) under a

single freight bill

1

2

3

Warehousing & Materials Handling Activities

Pre-packaging

Receiving

Cross docking

Put-away

Unitizing

Warehouse Layout

Static Shelving

Mobile Shelving

Pallet Racking

Warehouse Layout

Multi Tier Racking

Mezzanine Flooring

Wire Partitions

Distribution Intermediaries

1

2

Own Stores/Branches

4

3rd party logistics

providers (3PLs)

3

Agents

5

Wholesalers

6

Retailers

Brokers

Just in Time

01

Planning

02

Sourcing

03

Production

04

Logistics and Distribution

05

Return

The Return System

Post-delivery customer support process that is associated with all kinds of returned products. Aims to

minimize potential deterioration of relationships with customers.

SCM in Manufacturing Industry

Supplier

Storage

Production

Distribution

Retailer

Customer

SCM in Service Industry

02

01

Supplier

04

03

Storage

Service

Customer

Thanks

Do you have any questions?

CREDITS: This presentation template was created by

Slidesgo, including icons by Flaticon, infographics &

images by Freepik and illustrations by Stories

Please keep this slide for attribution