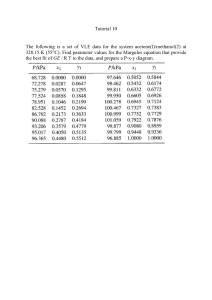

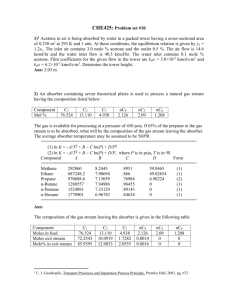

i College of Mechanical Engineering Technology/Benghazi Chemical Engineering Department PROCESS DESIGN FOR A SYNTHESIS UNIT OF METHANOL PRODUCTION A PROJECT REPORT Submitted by SANAD JOUMAH HAMAD 132168 MOHANAD ABDULLAH ALSAITY 161036 Fall 2021 ii College of Mechanical Engineering Technology / Benghazi Department of Chemical Engineering Technology PROCESS DESIGN FOR A SYNTHESIS UNIT OF METHANOL PRODUCTION A project submitted in partial fulfillment of the requirements for the degree of Chemical Engineering SANAD JOUMAH HAMAD MOHANAD ABDULLAH ALSAITY Supervisor Dr. Ali. H.ElHudayri Fall 2021 132168 161036 iii CERTIFICATE The project work entitled: PROCESS DESIGN FOR A SYNTHESIS UNIT OF METHANOL PRODUCTION Which is being submitted by students : SANAD JOUMAH HAMAD 132168 MOHANAD ABDULLAH ALSAITY 161036 In partial fulfillment of the requirements for the award of BA. Tech degree in Chemical Engineering has been carried out under my supervision and accepted for Presentation / examination Supervisor: Date: ….../..…./……….. Signature: …………….. Corrected approved copy for records Examiner 1: Examiner 2: Date: ….../..…./……….. Date: ….../..…./……….. Signature: ……………… Signature: ……………… Supervisor: head of chemical department Date: ….../..…./……….. Date: ….../..…./……….. Signature: ……………… Signature: ……………… iv ACKNOWLEDGEMENT We dedicate our graduation to the father and mother who were the greatest reasons for success and excellence in our academic and scientific career. We also express our thanks and gratitude to our virtuous teacher who supervised our project and contributed to its completion. We also thank all the teachers and everyone who supported me in these years on the path to success. I thank you all from the bottom of my heart, I ask May God Almighty reward you on our behalf and bless you in your work. v شكر وتقدير نهدد ت رجنا ددو لد ولدد دول ولدد ولدددعظم أونددو لنجدد للددوو ول سددون دولدردد ة وددع ميدد،نر و ول ولدد ،دول د ،دد أ دددو نجدددك ولالدددان دوعمد دددوف ل د دددو ولروىدددر ولدددعت ل دددن ندددد مالدددندن و دلدددوف ودددع إر ومددد دنالدددان لظضدددو أووددد ول د ددد،م دأدددر مدددم لدددون نو ودددع فدددعي وليددد ،م ودددع ،نظدددر ول سدددون وع دددانأ ا ،دددو مدددم لن دددوة قدوع للعل هللا ّ نز دا ّر لف ظسزظا ن و خ،ن ولسزوء دلف ظوو ك لا وع ن دا . vi ABSTRACT Preliminary process design of synthesis unit for methanol , was established with a production rate of 1000 ton/yr of crude methanol , in the first chapter a general review of methods of methanol Production was presented , low pressure method was adopted for this project , this methanol is used in sirte oil company , Brega. A material and energy balance calculations for each unit was carried out , based on a data from sirte oil company , Brega. A process design for the cooler , was established based on the design results of the cooler it is recommended to split the cooler into tow coolers at lest , either in series or parallel. vii الخالصة ظدض م ول الندع رص ،مو ئع ل ح رص ،ع ول ،ثون ل ل إندوج ، 1000م/ل لد ،ثون ل ولجوم ص نوم ر ردج،ك ولطنة لد ولدق ،وت ول يدج م وع فعو ول سول در حيو أر مم ول وزن ول ودظ دولحنو ظ ل ح وت منحد ولدص ،ع در رص ،ول وودل ول وند دولعت ظق م دونظ غوزوت ول دج ولجو ج مم ول رونر. ر ولدج وم ض ولو،ونوت مم مصود وء ند ندوئج رص ،ول وند ظ ص نأ لنت لد رط ول ص ع ولجوص إندوج ول ،ثون ل دسزئ ول وند إل وث ،م لد لأثن ل وء ند ولد ولع لد ند ولد وزت viii TABLE OF CONTENTS Title i CERTIFICATE iii ABSTRACT vi List of Figures x List of Tables xi List of Symbols xii Chapter 1 : Introduction 1.1 Introduction 1.1.1 History of Methanol 1 2 3 1.2 Methanol Uses 4 1.3 Production Processes 5 1.4 Methanol production technologies 6 1.5 Methanol synthesis loop 6 1.5.1 Process description 6 1.5.2 Process Flow Diagram 7 Chapter 2 : Material Balance Chapter 3 : Energy Balance 3.1 Process design of cooler Chapter 4 : Safety 4.1 Methanol Safety Data Sheet 2 11 40 27 45 4.1.1 Potential Health Effects 45 4.1.2 First Aid Measures 46 4.1.3 Accidental Release Measures 46 4.1.4 Storage And Handling 46 4.1.5 Exposure Controls/Personal Protection 47 ix 4.1.6 Stability And Reactivity 47 Reference 48 Appendices 49 x List of Figures Figure (1.1) : Global Methanol Fuel Demand ...............................................................4 Figure (1.2) : Basic steps of methanol production ........................................................5 Figure (1.3) : Process Flow Diagram ...........................................................................7 Figure (2.1) : Process Flow Diagram ............................................................................9 Figure (2.2) : mole balance for the reactor and separator ..........................................10 Figure (2.3) : Mole Balance for the 2nd separator SV2 .............................................14 Figure (2.4) : Balance at SV1 .....................................................................................14 Figure (2.5) : Balance at SV2 .....................................................................................14 Figure (3.1) : Energy Balance for the Mug compressor ..............................................30 Figure (3.2) : Energy Balance for the mixing point ....................................................31 Figure (3.3) : Energy Balance for the compressor K-02 ...........................................33 Figure (3.4) : Energy Balance for reactor ..................................................................34 Figure (3.5) : Energy Balance for Heat exchanger .....................................................36 Figure (3.6) : Energy Balance for the Cooler ..............................................................37 Figure (3.7) : Design of Cooler .................................................................................39 xi List Of Tables Table (1.1) history of methanol .....................................................................................3 Table (2.1) composition stream S1 ................................................................................9 Table (2.2) composition stream S9 ..............................................................................18 Table (2.3) Summary of all stream rate (Kmol/hr) .....................................................23 Table (2.4) Mole fraction of Components in each stream ..........................................24 Table (2.5) : actual stream flow rate each stream must be multiplied by the scale factor : 124.67 ............................................................................................................25 xii List of symbols S : feed stream (mol/hr) P : pressure (Pa) V : volume (m3) ρ : Density (Kg/m3) μ : Viscosity (Pa.s) K : thermal conductivity (W/m.K) T : temperature (K°) ∆H : Enthalpy (KJ/hr) Cp : Heat capacity (Kj/Kmol.K) ∆T : temperature difference (K°) ∆Tm : Log mean temperature difference (K) A0 : Heat transfer area (m2) a0 : Area of one tube (m2) d0 : tube outside diameter (m) di : inside diameter tube (m) L : Length (m) Nt : number of tube Db : tube bundle diameter Ds : shell-side diameter (m) As : shell-side cross flow area (m2) LB : baffle spacing (m) de : triangle tube pitch, equivalent diameter (m) Gs : shell-side mass velocity (Kg/s.m2) xiii Ws : mass flow rate of shell-side fluid (Kg/s) us : shell-side velocity (m/s) Re : Reynolds number Pr : Prandtl number At : flow area in tube side (m2) Wt : mass flow rate of water in the tube (Kg/s) ns : molar flow rate (mol/hr) Z : mole fractions Mwav : average molecular weight (Kg/Kmol) Q cooler : Heat transferred in the cooler (KJ/hr) ∆H: Latent heat (KJ/hr) W : watt (J/s) Chapter 1 Introduction 2 1.1 Introduction Methanol is an alcoholic chemical compound that is considered to be the simplest alcohol. It is a light, colorless, flammable liquid at room temperature, and contains less carbon and more hydrogen than any other liquid fuel. The chemical formula for methanol is CH3OH (often abbreviated as MeOH). Methanol appears naturally in the environment. Methanol is often called wood alcohol because it was once produced chiefly as a byproduct of the destructive distillation of wood. Today, the most common feedstocks for its production are natural gas and coal. This simple alcohol can be made from virtually anything that is, or ever was, a plant. This includes common fossil fuels – like natural gas and coal – and renewable resources like biomass, landfill gas. To produce methanol, synthesis gas needs to be created from the feedstock first. Through gasification, synthesis gas can be produced from anything that is or ever was a plant, which includes biomass, agricultural and timber waste, solid municipal waste, recycled carbon dioxide and a number of other feedstocks in addition to natural gas and coal. In a typical facility, methanol production is carried out in two steps. The first step is to convert the feedstock into a synthesis gas consisting of CO, CO2, H2O and H2. This is usually accomplished by the catalytic reforming of feed such as SMR (Steam methane reforming), POX (Partial oxidation), ATR (Auto thermal reforming) and Combined Reforming. The second step is the catalytic synthesis of methanol from the synthesis gas. Since the 1800s, methanol has been widely used as an industrial chemical compound to produce a variety of traditional chemical derivatives, including formaldehyde, acetic acid, dimethyl terephthalate, methyl methacrylate, and methyl chloride to manufacture a wide range of end products. With its diversity of feedstocks and array of applications, methanol is one of the world’s most widely used industrial chemical. Currently, approximately 60% of the global demand for methanol comes from the industrial chemical market demand and 40% comes from fuels applications demand. 3 1.1.1 History Of Methanol Methanol was first produced by destructive distillation of wood in 1830. The process prevailed for about a century until the first synthetic methanol plant was introduced by Badische Anilin und Soda Fabrik (BASF) in 1923. DuPont introduce the synthetic methanol plan in the United States in 1927. In late 1940, natural gases replaced the water gas as a source of syngas (i.e. CO and H2). Imperial Commercial Industry (ICI) announced that a low pressure methanol process in 1966 using a copper based catalyst. This operates at 5-10 Mpa (50-100 atm) compared with 35 Mpa (345.42314 atm) for the older high pressure process. The Arab oil embargo in 1973 first generated much interest in methanol as an alternative automobile fuel. In 1989, the us administration proposed a clean air regulations that would mandate the use of cleaner alternative automobile fuels. The amended Clean Air Act, passed in 1990, requires a reduction in ozone layer and carbon monoxide emissions, although it does not mandate used of the alternative fuel. Currently, methyl-tert-butyl ether derived from isobutene and methanol is the most widely used oxygenated in reformulated gasoline, and automakers, and local government authorities have announced plans to introduce methanol-fueled vehicles. The interest in methanol fuel applications has shifted from the economic considerations in the 1970’sto environmental considerations in the 1990s. this environmental impact will continue into the next century and could have a strong effect on demand for methanol. Furthermore, it was recently discovered that some crops treated with methanol or nutrient supplement methanol showed significant increases in crop yields. This has opened up another area of research and the development for the methanol and provide another opportunity for future methanol growth. Table (1.1) history of methanol Year 1830 1905 1923 1927 Late 1940s 1966 1970 1973 1989 1990 Early 1990s Events First commercial methanol process by destructive distillation Synthetic methanol route suggested by French chemist Paul First synthetic methanol plant commercialized by BASF Synthetic methanol process introduced in United States Conversion from water gas to natural gas as source of synthetic methanol reactors Low pressure methanol process announced by ICI Acetic acids process by methanol carbonylation introduced Arab oil-embargo reassessment for alternative fuels Clean Air regulations proposed by Bush Administration Passage of the amended Clean Air Act in the United States Discovery of enhanced crop yields with methanol treatment 4 1.2 Methanol Uses The major methanol end-uses in fuels applications include : Gasoline Blend stock: In some countries, methanol is blended directly with gasoline. Methanol has attractive properties as a fuel blending component; it has a high octane number, combusts efficiently, emits fewer harmful byproducts than gasoline, and is relatively low-cost. Dimethyl Ether (DME): DME can be used to blend into LPG4, as a replacement for LPG fuel in heating and cooking applications, as a transportation fuel in modified diesel engines, and for power generation. Methyl Tert-Butyl Ether (MTBE): MTBE (an oxygenate) is added to gasoline to increase its octane number. Use of MTBE in a gasoline blend also allows for a cleaner combustion process, emitting less pollution. Biodiesel: Biodiesel is the product obtained when vegetable oil or animal fat is chemically reacted with an alcohol - methanol, for example - to produce a compound known as a fatty acid alkyl ester. When methanol is used, the product is fatty acid methyl ester (FAME). Methanol-to-Gasoline (MTG): MTG refers to the process of making gasoline via a methanol route. In some ways, MTG is a misnomer, because methanol is often an intermediate in the process, and units are back-integrated to coal or natural gas. Some MTG units in China may run on merchant methanol. Others: Methanol can also be used as a fuel in power generation plants and in methanol fuel cells. Figure (1.1) : Global Methanol Fuel Demand 5 1.3 Production Processes Methanol is manufactured using a proven technology based predominantly on natural gas, with a small portion of the world capacity being based on petroleum fractions and process off-gases. , when using natural gas as the feedstock, comprises the following process steps : desulphurization of natural gas synthesis gas generation synthesis gas compression methanol synthesis methanol distillation Figure(1.2) : Basic steps of methanol production (Figure 1.2) shows the various options available for the individual process steps. The option selected as the most suitable and, consequently, the plant configuration depends on the customer’s requirements and local conditions. In addition, high pressure steam (HPS) and medium pressure steam (MPS) are usually produced by cooling the high temperature synthesis gas and methanol synthesis reactor, respectively. The main reactions for methanol production are: CO + 2 H2 → CH3OH CO2 + 3 H2 → CH3OH + H2O Therefore, the following ratio is ideal for methanol production : (H2 - CO2) / (CO + CO2) = 2 6 The synthesis of carbon oxides to methanol is based on a CuO/ZnO based catalysts, e.g. Synetix catalysts. This catalyst type has proved its performance in adiabatic as well as in isothermal reactors. The conversion of carbon oxides to methanol is an exothermic process which takes place at high pressures and low temperatures. The synthesis unit operates at 40 - 110 bar and around 200 to 300 °C. The aim is to achieve a relatively high carbon efficiency so as to minimize the amount of synthesis gas to be processed. Carbon eff. = [moles methanol produced / moles (CO + CO2) in syngas] × 100% 1.4 Methanol production technologies there are several of Methanol production technologies in the world. All of the processes have their own advantages and disadvantages. It is important to choose the most efficient process in order to have a good and almost perfect production of methanol. Here are the lists of the technologies in producing the methanol : Methanol production based on one step reforming. Methanol production based on two step reforming. Methanol synthesis loop. Methanol distillation 1.5 Methanol synthesis loop 1.5.1 Process description Feed gas comprising of hydrogen & carbon monoxide is compressed to 3000-5000 psi, mixed with recycle gas, then fed to a high pressure converter. Internal preheat is usually employed. The reactor is copper lined steel & contains a mixed catalyst of zinc,chromium,manganese, or aluminium oxides.The temperature is maintained at 300-375 °C by proper space velocity & heat exchanger design. Exit gases from the reactor are cooled by heat exchange with reactants, then with water. Methanol condenses under full operating pressure to maximize yields-50%.The liquid methanol is depressurized, then sent to the separator then to another tower to minimize the water content. 7 1.5.2 Process Flow Diagram Figure (1.3) : Process Flow Diagram Chapter 2 Material Balance 8 Take a basic of 100 Kmol/hr in stream S1 , the composition of the make-up gas stream S1 is given as following , based on sub oil Table (2.1) composition stream S1 Composition Mol % CO 11.77 CO2 11.865 H2 69.885 H2O 0.408 CH4 5.804 N2 0.25 CH3OH 0.0216 Total 100 Figure (2.1) : Process Flow Diagram The main reactions are taken place in the reactor : CO + 2 H2 → CH3OH CO2 + 3 H2 → CH3OH + H2O 9 The given date from sirte oil company is : CO conversion is 54.77% CO2conversion is 20.88% The mole balance will be taken for the reactor and separator Figure (2.2) : mole balance for the reactor and separator According to the date from sirte oil company, the following information will be used: 1- The recycle stream SR is 76% of Stream S10 2- The purge stream is 24% of S10 3- The dissolved gases in stream S9 is 5 mol% of the exit stream from the reactor except methanol and water and 95 mol% in S10 Balance of CO Take Y as mole of CO in stream S5 Conversion of CO is 0.5477 CO in S6 = CO in S5 – CO converted CO output from the reactor in S6 = Y – 0.5477Y CO in S10 = 0.95 [Y – 0.5477Y] CO in purge stream S11 = 0.24 S10 CO in S11 = 0.24 × 0.95[Y – 0.5477Y] CO Recycled in SR = 0.76 × [Y – 0.5477Y] CO in S9 = 0.05[Y – 0.5477Y] Note the S9 is the bottom stream of the separator SV1 10 Balance at the mixing point B for CO will be : Y = CO in S1 + CO SR Y = 11.77 + 0.76 × [Y – 0.5477Y] Solve for Y Y = 11.77 + 0.722Y – 0.3954Y Y = 36.037 Kmol/hr CO in S10 = 0.95 [36.037 – 0.5477 × 36.037] = 15.48 Kmol/hr CO in purge stream S11 = 0.24 × 15.48 = 3.76 Kmol/hr CO in SR = 0.76 × 15.48 = 11.768 Kmol/hr CO in S9 = 0.05 (36.037 – 0.5477 × 36.037) = 0.814 Kmol/hr CO in S6 = 36.037 (1 – 0.547) = 16.3 Kmol/hr Balance of CO2 Make CO2 in S5 = X CO2 (exit from the rector in S6 = X - CO2 converted = X – 0.2088 × X CO2in purge stream S11 = 0.24 × 0.95[X – 0.2088 × X] CO2in SR = 0.76 × 0.95[X – 0.2088 × X] CO2in S9 = 0.05 [X – 0.2088 × X] Balance at the mixing point B for CO2 will be : 11 X = CO2in S1 + CO2 in SR X = 11.865 + 0.76 × [X – 0.2088 × X] X = 11.865 + 0.722 X – 0.15 X Solve for X X = 27.72 Kmol/hr CO2 in S9 = 0.05 × 0.95[27.72 – 0.2088 × 27.72] = 1.096 Kmol/hr CO2 in S6 = 27.72 (1-0.2088) = 21.9 Kmol/hr CO2 in S11 = 0.24 × 0.95 (27.72 - 0.2088 × 27.72) = 5 Kmol/hr CO2 in S10 = 0.95 × [27.72 (1- 0.2088)] = 20.83 Kmol/hr CO2 in recycled SR = 15.8 Kmol/hr Balance of H2 Make H2 in S5 = Z Total hydrogen converted = H2 converted in rector 1 + H2 converted in rector 2 ∴ Total hydrogen converted = 2 (0.5477Y) + 3(0.2088X) Y = 36.037 , X = 27.72 = 2(0.5477 × 36.037) + 3(0.2088 × 27.72) = 56.83 Kmol/hr H2 in S6 (exit from the rector) = Z - H2 reacted = Z – 56.83 = 103.81 – 56.83 = 46.98 Kmol/hr 12 H2 in S10 = 0.95[Z – 56.83] H2 in the purge stream S11 = 0.24 × 0.95[Z – 56.83] H2 Recycled in SR = 0.76 × 0.95[Z – 56.83] H2 in S9 = 0.05 [Z – 56.83] Balance at the mixing point B for Hydrogen will be : Z = H2 in S1 + H2 in SR Z = 69.8855 + 0.76 × 0.95 [Z – 56.83] Solve for Z Z = 103.81 Kmol/hr X = 27.72 Kmol/hr H2 in S9 = 0.05 [103.81 – 56.83] = 2.349 Kmol/hr H2 in S10 = 0.95[103.81 – 56.83] = 44.631 Kmol/hr Balance for CH4 Make CH4 in S5 equal to M Kmol/hr According to the given date , 95 mol% of gases leaving the reactor goes to S10 for the 1st separator SV1 while 5mol% dissolve in the bottom stream S9 CH4 gas in considered as inert (it doesn't participate in the reaction ) CH4 in S10 = 0.95M CH4 in S9 = 0.05M CH4 in the purge stream S11 = 0.24 [ 0.95M] CH4 Recycled in SR = 0.76 [ 0.95M] CH4 in SR = 15.03 Kmol/hr 13 Balance at the mixing point B will be : CH4 in S1 + CH4 in SR = S5 5.784 + 0.76 (0.95M) = M Solve for M M = 20.82 Kmol/hr CH4 in S10 = 19.78 Kmol/hr CH4 in S9 = 1.041 Kmol/hr CH4 in S11 = 0.24 (0.95 × 20.82) = 4.74 Kmol/hr CH4 in S12 = 0.76 (0.95 × 20.82) = 15.03 Kmol/hr Balance for N2 Nitrogen is inert gas (it doesn't react) Put N2 in S5 (Reactor feed = N) N2 in S5 = N2 in S6 N2 in S10 = 0.95N N2 in S9 = 0.05N N2 in SR = 0.76 [0.95N] N2 in S11 = 0.24 [0.95N] Balance at the mixing point B will be : N2 in S1 + N2 in SR = S5 0.25 + 0.76 (0.95N) = N Solve for N N = 0.899 ≈ 0.9 Kmol/hr 14 N2 in S10 = 0.855 Kmol/hr N2 in S9 = 0.045 Kmol/hr Calculation of the mole fraction of water and methanol in the gas stream of the separator SV1 (S10) using the following relation : PV = PT × y PV : vapor pressure , PT : Total pressure y : mole fraction of the component temperate = 40 C° using Antonio's equation , the vapor pressure of water and methanol is obtained at 40 C° ln 𝑃𝑉 = 𝐴 − 𝐵 𝐶+𝑇 A , B and C are constants T : temperate in Kelvin PV for water = 7375 Pa PV for methanol = 39182 N/m2 𝑦𝑤𝑎𝑡𝑒𝑟 = 𝑃𝑉 7375 = = 0.0013 𝑃𝑇 5591700 𝑦𝑚𝑒𝑡ℎ𝑎𝑛𝑜𝑙 = 𝑃𝑉 39182 = = 0.007 𝑃𝑇 5591700 mole fractions of water + methanol will be 0.0013 + 0.007 = 0.0083 mole fractions of gases in S10 (except water and methanol) is : 1 – 0.0083 = 0.9917 Total molar flow rate in S10 will be : 𝑆10 = 𝑚𝑜𝑙𝑒𝑠 𝑜𝑓 𝑔𝑎𝑠𝑒𝑠 𝑤𝑖𝑡ℎ𝑜𝑢𝑡 𝑤𝑎𝑡𝑒𝑟 𝑎𝑛𝑑 𝑚𝑒𝑡ℎ𝑎𝑛𝑜𝑙 𝑚𝑜𝑙𝑒𝑠 𝑓𝑟𝑎𝑐𝑡𝑖𝑜𝑛 𝑜𝑓 𝑔𝑎𝑠𝑒𝑠 𝑤𝑖𝑡ℎ𝑜𝑢𝑡 𝑤𝑎𝑡𝑒𝑟 𝑎𝑛𝑑 𝑚𝑒𝑡ℎ𝑎𝑛𝑜𝑙 moles of gases without water and methanol 15 = CO moles + CO2 moles + H2 moles + CH4 moles + N2 moles = 15.48 + 20.93 + 136.86 + 19.78 + 0.955 = 193.8 Kmol/hr The mole fraction of the gases of CO + CO2 + H2 + CH4 + N2 is = 0.9917 Total mole in 𝑆10 = 193.8 0.9917 = 195.4 Kmol/hr Balance for water for the reactor and separator units H2O moles in S10 = 0.0013 * S10 = 0.0013 × 195.4 = 2.54 Kmol/hr H2O moles in S11 (purge stream) = 0.24 (2.54) = 0.609 Kmol/hr H2O moles in SR (Recycle) = 0.79 (2.54) = 1.93 Kmol/hr From the reaction the produced water will be estimated as follows : CO2 +3H2 → CH3OH +H2 H2O produced = CO2 reacted = (CO2 in S5) × conversion CO2 CO2 in S5 = X = 27.72 CO2 conversion = 0.2088 H2 produced = 27.72 × 0.2088 = 5.787 Kmol/hr Balance at the mixing point B will be : Water in S1 + Water in SR = Water in S5 0.408 + 1.93 = 2.338 Kmol/hr Water in S6 (output from the reactor) = Water input to the reactor + Water produced due to reaction 16 H2O in S6 = 2.338 + 5.787 = 8.125 Kmol/hr Water in the bottom stream of the separator SV1 (S9) = H2O in S6 – H2 in S10 = 8.125 – 2.54 = 5.585 Kmol/hr Balance for methanol (reactor and separator loop) The main reactions for methanol Production is given : CO + 2 H2 → CH3OH CO2 + 3 H2 → CH3OH + H2O CH3OH produced in 1st reaction : = (CO in S5) * (CO conversion) = 36.037 * 0.5477 = 19.737 Kmol/hr CH3OH produced in 2nd reaction : = (CO2 in S5) * (CO2 conversion) = 27.72 × 0.2088 = 5.787 Kmol/hr Total methanol produced = 19.737 + 5.787 = 25.5 Kmol/hr 17 Balance at the mixing point B : Figure (2.4) : Balance at SV1 CH3OH in S5 = CH3OH in SR + CH3OH in S1 CH3OH in SR = S10 × 0.76 × 0.007 = 195.4 × 0.76 × 0.007 = 1.039 Kmol/hr CH3OH in S5 = 1.039 + 0.0216 = 1.411 Kmol/hr CH3OH in S6 = CH3OH in S5 + Total CH3OH produced in the reactions CH3OH in S6 (output from the reactor) = 1.411 + 25.5 = 26.91 Kmol/hr CH3OH Balance separator SV1 : S6 = S9 + S10 CH3OH in S9 = S6 – S10 = 26.91 – (195.4 × 0.07) = 13.23 Kmol/hr CH3OH in S11 (purge) = CH3OH in S10 × 0.24 CH3OH in S11 (purge) = (195.4 × 0.0007) × 0.24 18 = 0.328 Kmol/hr Mole Balance for the 2nd separator SV2 : Figure (2.3) : Mole Balance for the 2nd separator SV2 The temperature and pressure data are obtained from sirte oil company , according to the the previous calculation, component in S9 is given : Table (2.2) : composition stream S9 composition Kmol/hr CO 0.814 CO2 1.069 H2 2.349 CH4 1.041 N2 0.045 H2O 5.585 CH3OH 13.23 Total (S9) 24.16 According to the date from sirte oil company , 99 mol% of gases in the feed S9 goes into the vapor –phase S12 , and 1 mol% an dissolved in liquid-phase (S13) The mole fractions of H2O and CH3OH in the vapor –phase will be obtained as following : 𝒚 𝑯𝟐 𝑶 = 𝑷𝑽 (𝒇𝒐𝒓 𝑯𝟐𝑶) 𝑷𝑻𝒐𝒕𝒂𝒍 PV : for water vapor at the given Temperature and pressure (40 C° and 343350 Pa) = 7375 Pa 19 ∴ 𝑦𝐻2 𝑂 (𝑚𝑜𝑙𝑒 𝑓𝑟𝑎𝑐𝑡𝑖𝑜𝑛 𝑜𝑓 𝑤𝑎𝑡𝑒𝑟 𝑖𝑛 𝑆12 ) = 7375 343350 𝒚𝑯𝟐 𝑶 = 0.02 mole fractions of methanol in the vapor –phase will be obtained : 𝑦𝐶𝐻3 𝑂𝐻 = 𝑃𝑉 (𝑓𝑜𝑟 𝐶𝐻3 𝑂𝐻) 𝑃𝑇𝑜𝑡𝑎𝑙 PV : for CH3OH at 40 C° and 39182.7 Pa ∴ 𝑦𝐶𝐻3 𝑂𝐻 = 39182.7 343350 ∴ 𝑦𝐶𝐻3 𝑂𝐻 = 0.114 Mole fraction of the gases in S12 (except H2O and CH3OH) = 1- (0.02 + 0.114) = 0.866 Total stream S12 = S12 = 𝑚𝑜𝑙𝑒𝑠 𝑜𝑓 (CO + CO2 + H2 + CH4 + N2 ) ×0.99 0.866 (0.814+1.096+2.349+1.041+0.245) ×0.99 0.866 S12 = 6.11 Kmol/hr Mole fraction of the composition in S12 will be : 𝑦𝐶𝑂 = 𝑦𝐶𝑂2 = 𝑦𝐻2 = 𝑦𝐶𝐻4 = 𝑦𝑁2 = 𝐶𝑂 𝑜𝑛 𝑆9 ×0.99 𝑆12 = 𝐶𝑂2 𝑜𝑛 𝑆9 ×0.99 𝑆12 𝐻2 𝑜𝑛 𝑆9 ×0.99 𝑆12 = 𝐶𝐻4 𝑜𝑛 𝑆9 ×0.99 𝑆12 𝑁2 𝑜𝑛 𝑆9 ×0.99 𝑆12 = 0.814 ×0.99 6.11 = 1.096 ×0.99 6.11 2.399 ×0.99 6.11 = = 0.1318 = 0.3806 1.041 ×0.99 6.11 0.045 ×0.99 6.11 𝑦𝐻2 𝑂 = 0.02 , 𝒚𝑪𝑯𝟑 𝑶𝑯 = 0.114 = 0.1775 = 0.1686 = 0.0073 20 flow rate of the liquid-phase Stream S13 will obtained by the following balance : Figure (2.5) : Balance at SV2 S9 = S12 + S13 S13 = S9 – S12 = 24.16 – 6.11 = 18.05 Kmol/hr Composition flow in S13 will be : H2O in S13 = H2O in S9 - H2O in S12 = 5.585 – (6.11 × 0.02) = 5.46 Kmol/hr CH3OH in S13 = CH3OH in S9 - CH3OH in S12 = 13.23 – (6.11 × 0.114) = 12.533 Kmol/hr Gases in S13 will be 1 mol% of the gases in S9 (except H2O and CH3OH) will be : 21 [CO + CO2 + H2 + CH4 + N2] × 0.01 = [0.814 + 1.196 + 2.349 + 1.041 + 0.045] × 0.01 = 0.05345 Kmol/hr H2O in S13 = H2O in S9 - H2O in S12 = 5.585 – (6.11 × 0.02) = 5.46 Kmol/hr CH3OH in S13 = CH3OH in S9 - CH3OH in S12 = 13.23 – (6.11 × 0.119) = 12.533 Kmol/hr Total flow rate of S13 = 5.46 +12.533 + 0.05345 S13 = 18.04 Kmol/hr Identical Value was obtained total balance Component mole fractions in S13 will be : 𝑚𝑜𝑙𝑒 𝑜𝑓 𝐶𝑜 𝑦𝐶𝑂 = 𝑇𝑜𝑡𝑎𝑙 𝑚𝑜𝑙𝑒 𝑜𝑓 𝐶𝑂2 𝑦𝐶𝑂2 = 𝑦𝐻2 = 𝑇𝑜𝑡𝑎𝑙 𝑚𝑜𝑙𝑒 𝑜𝑓 𝐻2 𝑇𝑜𝑡𝑎𝑙 = 𝑚𝑜𝑙𝑒 𝑜𝑓 𝐶𝐻4 𝑦𝐶𝐻4 = 𝑦𝑁2 = = 𝑇𝑜𝑡𝑎𝑙 𝑚𝑜𝑙𝑒 𝑜𝑓 𝑁2 𝑦𝐻2 𝑂 = 𝑇𝑜𝑡𝑎𝑙 𝑜𝑙𝑒 𝑜𝑓 𝐻2 𝑂 𝑇𝑜𝑡𝑎𝑙 𝑦𝐶𝐻3 𝑂𝐻 = = 0.814 ×0.01 18.04 = 1.096 ×0.01 18.04 2.349 ×0.01 18.04 = = 0.00045 = 0.0006 = 0.0013 1.041 ×0.01 18.04 0.045×0.01 18.04 = 0.00057 = 0.000024 5.46 = 18.04 = 0.302 𝑚𝑜𝑙𝑒 𝑜𝑓 𝐶𝐻3 𝑂𝐻 𝑇𝑜𝑡𝑎𝑙 = 12.535 18.04 = 0.694 Calculation of the scale factor for methanol balance : Required production rate for methanol is 4 × 108 Kg/year (based on 8000 working hours per year) 22 The required rate = 4 ×108 8000 = 50000Kg/year Molecular weight of CH3OH = 32 Kg/Kmol production rate in Kmol/hr = 50000 32 = 1562.5 Kmol/hr the production of methanol in S13 = 12.533 Kmol/hr (based on 100 Kmol/hr of S1) scale factor for material balance = 1562.5 12.533 = 124.67 This number must multiplied to all streams. 23 Table (2.3) : Summary of all stream rate (Kmol/hr) Streams S1 S2 S3 S4 S5 S6 S7 S8 S9 SR S10 S11 S12 S13 CO 11.77 11.77 23.53 23.53 23.53 16.3 16.3 16.3 0.814 11.76 15.48 3.72 0.805 0.00814 CO2 11.865 11.865 27.695 27.695 27.695 21.9 21.9 21.9 1.096 15.83 20.83 4.99 1.085 0.01096 H2 69.885 69.885 103.785 103.785 103.785 46.98 46.98 46.98 2.349 33.9 44.631 10.71 2.325 0.02349 H2O 0.408 0.408 2.338 2.338 2.338 8.125 8.125 8.125 5.585 1.93 2.54 0.609 0.122 5.46 CH4 5.804 5.804 20.834 20.834 20.834 20.82 20.82 20.82 1.041 15.03 19.78 4.74 1.03 0.01041 N2 0.25 0.25 0.899 0.899 0.9 0.9 0.9 0.045 0.649 0.855 0.205 0.0445 0.00045 CH3OH 0.0216 0.0216 1.0606 0.9 ≈ 0.9 ≈ 26.91 26.91 26.91 13.23 1.039 1.37 0.328 0.696 12.533 Total 100 100 180.146 1.0606 1.0606 141.9 141.9 141.9 24.16 80.138 105.48 25.3 6.11 18.04 Component 0.899 ≈ 0.9 24 Table (2.4) : Mole fraction of Components in each stream Streams S1 S2 S3 S4 S5 S6 S7 S8 S9 SR S10 S11 S12 S13 CO 0.117 0.117 0.13 0.13 0.13 0.1148 0.1148 0.1148 0.0336 0.1467 0.146 0.1470 0.1317 0.0004 CO2 0.1186 0.1186 0.15 0.15 0.15 0.1543 0.1543 0.1543 0.045 0.1975 0.1974 0.1972 0.177 0.0006 H2 0.698 0.698 0.57 0.57 0.57 0.331 0.331 0.331 0.097 0.4231 0.4231 0.4233 0.3805 0.00130 H2O 0.004 0.004 0.0129 0.0129 0.0129 0.057 0.057 0.057 0.2311 0.0240 0.00240 0.0240 0.01996 0.3026 CH4 0.058 0.058 0.1156 0.1156 0.1156 0.146 0.146 0.146 0.0430 0.1875 0.1875 0.1873 0.1685 0.0005 N2 0.002 0.002 0.0049 0.0049 0.0049 0.006 0.006 0.006 0.00186 0.0081 0.0081 0.008 0.0072 0.00002 CH3OH 0.0002 0.0002 0.0058 0.0058 0.0058 0.1896 0.1896 0.1896 0.5475 0.0129 0.0129 0.0129 0.11391 0.6947 Component 25 Table (2.5) : actual stream flow rate each stream must be multiplied by the scale factor : 124.67 Streams S1 S2 S3 S4 S5 S6 S7 S8 S9 SR S10 S11 S12 S13 CO 1467.37 1467.37 2933.49 2933.49 2933.49 2032.1 2032.1 2032.1 101.48 1466.12 1929.89 463.77 100.36 1.0148 CO2 1479.2 1479.2 3452.7 3452.7 3452.7 2730.3 2730.3 2730.3 136.6 1973.5 2526.88 622.1 135.27 1.37 H2 8712.56 8712.56 12938.9 12938.9 12938.9 5856.99 5856.99 5856.99 292.8 4226.3 5564.15 1335.22 289.86 2.93 H2O 50.87 50.87 291.48 291.48 291.48 1012.94 1012.94 1012.94 696.28 240.6 316.66 75.92 15.21 680.7 CH4 723.58 723.58 2597.4 2597.4 2597.4 2595.6 2595.6 2595.6 129.78 1873.79 2465.97 590.9 128.4 1.298 N2 31.168 31.168 112.2 112.2 112.2 112.2 112.2 112.2 5.61 80.9 106.59 25.558 5.55 0.056 CH3OH 2.69 2.69 132.23 132.23 132.23 3354.87 3354.87 3354.87 1649.38 129.5 170.8 40.89 86.77 1562.49 Total 12467.44 12467.44 22458.395 22458.395 22458.395 17694.9997 17694.9997 17694.9997 3011.9 9990.71 13150.94 3154.358 761.42 2249.8 Component Chapter 3 Energy Balance 27 Heat capacity data Heat capacity for the mixture will be estimated an additional property. 𝑛 𝐶𝑝𝑚𝑖𝑥𝑡𝑢𝑟𝑒 = ∑ 𝑦𝑖 𝐶𝑝𝑖 𝑖=1 𝑦𝑖 : mole fraction for ith component 𝐶𝑝𝑖 : Heat capacity for ith component An average value of Component heat capacity will be taken. Enthalpy for each stream in Kj/hr will be : 𝐻𝑠𝑖 = 𝑆𝑖 . 𝐶𝑝𝑠𝑖 (𝑇𝑠𝑖 − 𝑇𝑅 ) 𝑇𝑠𝑖 : temperature of ith stream. 𝐶𝑝𝑠𝑖 : Heat capacity for ith stream. 𝑇𝑅 : reference temperature = 298K Composition Cp (Kj/Kmol K) gas-phase CO 29.5 CO2 38.07 H2 29 H2O 34.04 CH4 38.14 N2 29.5 CH3OH 44.76 Table (3.1) : average value of Component heat capacity Heat capacity for liquid-phase for water and CH3OH will be : 𝐶𝑝𝐻2𝑂 (liquid) = 75 Kj/Kmol K 𝐶𝑝𝐶𝐻3𝑂𝐻 (liquid) = 90 Kj/Kmol K 𝐶𝑝 for gas-phase as a function of temperature 𝐶𝑝𝐶𝑂 = 30.8 − 0.013𝑇 + 2.79 × 10−5 𝑇 2 𝐶𝑝𝐶𝑂2 = 19.8 + 0.073𝑇 − 5.6 × 10−5 𝑇 2 28 𝐶𝑝𝐻2 = 14.5 𝐶𝑝𝐻2𝑂 = 32.2 + 0.013𝑇 + 1.92 × 10−3 𝑇 + 1.055 × 10−5 𝑇 2 𝐶𝑝𝐶𝐻4 = 19.2 + 0.052𝑇 + 1.2 × 10−5 𝑇 2 𝐶𝑝𝑁2 = 31.1 − 0.0135𝑇 + 2.68 × 10−5 𝑇 2 𝐶𝑝𝐶𝐻3𝑂𝐻 = 21.1 + 0.07𝑇 + 2.58 × 10−5 𝑇 2 Heat capacity for the mixture in each stream : 𝐶𝑝𝑠1 = 𝑦𝐶𝑂 . 𝐶𝑝𝐶𝑂 + 𝑦𝐶𝑂2 . 𝐶𝑝𝐶𝑂2 + 𝑦𝐻2 . 𝐶𝑝𝐻2 + 𝑦𝐻2𝑂 . 𝐶𝑝𝐻2𝑂 + 𝑦𝐶𝐻4 . 𝐶𝑝𝐶𝐻4 + 𝑦𝑁2 . 𝐶𝑝𝑁2 + 𝑦𝐶𝐻3𝑂𝐻 . 𝐶𝑝𝐶𝐻3𝑂𝐻 Neglect the small value of mole fraction 𝐶𝑝𝑠1 = 0.1177 (29.5) + 0.1186 (38.07) + 0.696 (29) 𝐶𝑝𝑠1 = 26.07 Kj/Kmol K 𝐶𝑝𝑠3 = 0.13 (29.5) + 0.15 (38.07) + 0.57 (29) 𝐶𝑝𝑠3 = 26.17 Kj/Kmol K 𝐶𝑝𝑠6 = 0.1148 (29.5) + 0.1543 (38.07) + 0.331 (29) + 0.2 (44) 𝐶𝑝𝑠6 = 27 Kj/Kmol K 𝐶𝑝𝑠𝑅 = 0.1467 (29.5) + 0.1975 (38.07) + 0.4230 (29) 𝐶𝑝𝑠𝑅 = 24.11 Kj/Kmol K 𝐶𝑝𝑠10 = 0.146 (29.5) + 0.1975 (38.07) + 0.42310 (29) 𝐶𝑝𝑠10 = 14.24 Kj/Kmol K 𝐶𝑝𝑠11 = 0.1470 (29.5) + 0.1974 (38.07) + 0.4233(29) 𝐶𝑝𝑠11 = 24.13 Kj/Kmol K 𝐶𝑝𝑠12 = 0.1317 (29.5) + 0.1770 (38.07) + 0.38050 (29) 𝐶𝑝𝑠12 = 21.66 Kj/Kmol K 29 𝐶𝑝𝑠9 = 𝑦𝐻2𝑂 . 𝐶𝑝𝐻2𝑂 + 𝑦𝐶𝐻3𝑂𝐻 . 𝐶𝑝𝐶𝐻3𝑂𝐻 𝐶𝑝𝐻2𝑂 (liquid) = 75 Kj/Kmol K 𝐶𝑝𝐶𝐻3𝑂𝐻 (liquid) = 90 Kj/Kmol K 𝐶𝑝𝑠9 = 0.23 (75) + 0.547 (90) 𝐶𝑝𝑠9 9 = 66.48 Kj/Kmol K 𝐶𝑝𝑠13 = 0.3026 (75) + 0.6947 (90) 𝐶𝑝𝑠13 = 85.21 Kj/Kmol K 𝐶𝑝𝑠5 = 0.186 (29.5) + 0.143 (38) + 0.537 (29) + 0.012 (34) + 0.1 (38) 𝐶𝑝𝑠5 = 32 Kj/Kmol K 𝐶𝑝𝑠6 = 0.115 (29.5) + 0.15 (38) + 0.33 (29) + 0.057 (34.9) + 0.146 (38) + 0.2 (44) 𝐶𝑝𝑠6 = 35 Kj/Kmol K 30 Energy balance around the mug compressor : Figure (3.1) : Energy balance around the mug compressor ∆ 𝐻𝑆1 = 𝑆1 𝐶𝑝𝑠1 (𝑇1 − 𝑇𝑅 ) , 𝑇𝑅 = 298 𝐾 ∆ 𝐻𝑆1 = 1246.4 × 26.07 (313 − 298 ) ∆ 𝐻𝑆1 = 4875376 Kj/hr The out let stream temperature Tś2 will be calculated using the following relation for a diabetic compression 𝐶𝑝 K = constant = 𝐶 = 1.4 𝑣 Data from sirte oil company : Ps1 = 1716 KPa Ps2 = 5791 KPa For a diabetic compression , we have : 𝑇2 𝑇1 𝑃2 = (𝑃 ) 1 𝛾−1 𝛾 ,𝛾= 𝐶𝑝 𝐶𝑣 T1 = Ts1 = 313K P1 = Ps1 = 1716 KPa P1 = Ps1 = 1716 KPa = 1.39 31 P2 = Pś2 = 5791 KPa Tś2= T2 = unknown 𝑇2 5791 =( ) 313 1716 1.39 −1 1.39 Tś2= 440.3 K Work done by compressor : 𝑊𝐾−01 = ∆ 𝐻ś2 − ∆ 𝐻𝑆1 ∆ 𝐻ś2 = ś2 𝐶𝑝ś2 (𝑇ś 2 − 298) ∆ 𝐻ś2 = 12467.4 × 26.07 (440 − 298 ) ∆ 𝐻ś2 = 46251074.29 𝐾𝑗/ℎ𝑟 ∆ 𝐻𝑆1 = 𝑆1 𝐶𝑝𝑆1 (𝑇1 − 𝑇𝑅 ) = 4875376 𝐾𝑗/ℎ𝑟 𝑊𝐾−01 = 41375698 𝐾𝑗/ℎ𝑟 Energy balance around the mixing point as shown below : TsR= 313 K S3 Ts2= ? K Tś2= 440.3 K Figure (3.2) : Energy balance around the mixing point Make energy balance will be : ∆ 𝐻𝑆𝑅 + ∆ 𝐻ś2 = ∆ 𝐻𝑆3 ∆ 𝐻𝑆𝑅 = 𝑆𝑅 𝐶𝑝𝑅 (𝑇𝑆 𝑅 − 298) 32 ∆ 𝐻ś2 = ś2 𝐶𝑝ś2 (𝑇ś 2 − 298) ∆ 𝐻𝑆3 = 𝑆3 𝐶𝑝3 (𝑇𝑆 3 − 298) 𝑆𝑅 𝐶𝑝𝑅 (𝑇𝑆 𝑅 − 298) + ś2 𝐶𝑝ś2 (𝑇ś 2 − 298) = 𝑆3 𝐶𝑝3 (𝑇𝑆 3 − 298) 𝑆𝑅 = 9990.7 𝐾𝑚𝑜𝑙/ℎ𝑟 , Ś2 = 𝑆1 = 12467 𝐾𝑚𝑜𝑙/ℎ𝑟 , 𝑆3 = 22458.4 𝐾𝑚𝑜𝑙/ℎ𝑟 𝐶𝑝𝑅 = 24.11 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 , 𝐶𝑝ś2 = 𝐶𝑝𝑠1 = 26.07 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 𝐶𝑝𝑠3 = 26.17 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 Solve for 𝑇𝑆 3 3612883 + 46152085 = 58772690 (𝑇𝑆 3 − 298) 0.8467 = 𝑇𝑆 3 − 298 𝑇𝑆 3 = 382.9 𝐾 33 Energy balance around the compressor K-02 : The mixed stream S3 is compressed from 5687.9 KPa to 6377.625 KPa. Figure (3.3) : Energy balance around the compressor K-02 For a diabetic compression , we have : 𝑇𝑠 4 𝑇𝑠 3 𝑃𝑠 4 𝛾−1 𝛾 = (𝑃 ) 𝑠3 , 𝛾 = 1.39 1.39 −1 1.39 𝑇𝑠 4 6377.625 =( ) 382.9 5687.8 𝑇𝑠 4 = 395.36 K Work done by compressor K-02 will be : 𝑊𝐾−02 = ∆ 𝐻𝑠4 − ∆ 𝐻𝑠3 ∆ 𝐻𝑠4 = 𝑆4 𝐶𝑝4 (𝑇𝑆 4 − 298) ∆ 𝐻𝑠4 = 22458.39 × 26.17 (395.36 − 298 ) ∆ 𝐻𝑠4 = 57221983 𝐾𝑗/ℎ𝑟 ∆ 𝐻𝑆3 = 𝑆3 𝐶𝑝3 (𝑇𝑆 3 − 298) ∆ 𝐻𝑆3 = 22458.39 × 26.17 (382.9 − 298 ) ∆ 𝐻𝑆3 = 49898792 𝐾𝑗/ℎ𝑟 34 𝑊𝐾−02 = 57221983 − 49898792 𝑊𝐾−02 = 7323191 𝐾𝑗/ℎ𝑟 Energy balance around the reactor Figure (3.4) : Energy balance around reactor To calculate the temperature of the steam , we need to make energy balance 𝑄 = ∆ 𝐻𝑠6 − ∆ 𝐻𝑠5 + ∆ 𝐻𝑅1 (𝑐𝑜𝑛𝑠𝑢𝑚𝑒𝑑 𝑚𝑜𝑙𝑒 𝑜𝑓 𝐶𝑂) + ∆ 𝐻𝑅2 (𝑐𝑜𝑛𝑠𝑢𝑚𝑒𝑑 𝑚𝑜𝑙𝑒 𝑜𝑓 𝐶𝑂2 ) ∆ 𝐻𝑅1 (𝑎𝑡 298𝐾) = −90700 𝐾𝑗/ℎ𝑟 ∆ 𝐻𝑅2 (𝑎𝑡 298𝐾) = −49500 𝐾𝑗/ℎ𝑟 From material balance : Consumed mole of CO = 4493 × 0.5477 = 2461 𝐾𝑚𝑜𝑙/ℎ𝑟 Consumed mole of CO2 = 3456 × 0.2088 = 721.6 𝐾𝑚𝑜𝑙/ℎ𝑟 35 ∆ 𝐻𝑠6 = 𝑆6 𝐶𝑝6 (𝑇𝑆 6 − 298) 𝑆6 = 17695 𝐾𝑚𝑜𝑙/ℎ𝑟 𝐶𝑝6 = 35 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 𝑇𝑆 6 = 533𝐾 ∆ 𝐻𝑠6 = 17695 × 35 (533 − 298 ) ∆ 𝐻𝑠6 = 145541375 𝐾𝑗/ℎ𝑟 ∆ 𝐻𝑠5 = 𝑆5 𝐶𝑝5 (𝑇𝑆 5 − 298) 𝑆5 = 24066 𝐾𝑚𝑜𝑙/ℎ𝑟 𝐶𝑝5 = 32 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 𝑇𝑆 5 = 473𝐾 ∆ 𝐻𝑠5 = 24066 × 32 (473 − 298 ) ∆ 𝐻𝑠6 = 134769600 𝐾𝑗/ℎ𝑟 Heat removed from the reactor : 𝑄 = 145541375 − 134769600 + (−90700)(2461) + (−49500)(721.6) 𝑄 = −248160125 𝐾𝑗/ℎ𝑟 36 Energy balance around the heat exchanger (E) : Figure (3.5) : Energy balance around heat exchanger 𝐶𝑝𝑠4 − 𝐶𝑝𝑠5 = 35 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 𝐶𝑝𝑠6 − 𝐶𝑝𝑠7 = 35 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 To estimate 𝑇𝑠 7 , an energy balance will be taken : 𝑄𝑔𝑎𝑖𝑛𝑒𝑑 = 𝑆4 𝐶𝑝4 (𝑇𝑆 5 − 𝑇𝑆 4 ) 𝑄𝑔𝑎𝑖𝑛𝑒𝑑 = 24066 × 35 (473 − 395.3) = 65447487 𝐾𝑗/ℎ𝑟 65447487 = 𝑆6 𝐶𝑝6 (533 − 𝑇𝑆 7 ) 65447487 = 17695 × 35 (533 − 𝑇𝑆 7 ) 105.67 = 533 − 𝑇𝑆 7 𝑇𝑆 7 = 427.3 𝐾 37 Energy balance around the cooler (C) : Figure (3.6) : Energy balance around the cooler Heat removed by Cooling water : 𝑄𝑐𝑜𝑜𝑙𝑒𝑟 = 𝑆7 𝐶𝑝7 (𝑇𝑆 7 − 𝑇𝑆 8 ) 𝐶𝑝𝑠7 = 35 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 𝑄𝑐𝑜𝑜𝑙𝑒𝑟 = 17695 × 35 (427.3 − 313) 𝑄𝑐𝑜𝑜𝑙𝑒𝑟 = 70788847𝐾𝑗/ℎ𝑟 Cooling water flow rate 𝑚𝐻2 𝑂 = 𝐶𝑝 𝑄 𝐻2 𝑂 ∆𝑇 𝐶𝑝𝐻2 𝑂 = 75 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 ∆𝑇 = 25 𝐶° = 25𝐾 𝑚𝐻2 𝑂 = 70788847 75 × 25 𝑚𝐻2 𝑂 = 37754 𝐾𝑚𝑜𝑙/ℎ𝑟 = 10.5 𝐾𝑚𝑜𝑙/𝑠 𝑚𝐻2 𝑂 = 188 𝐾𝑔/𝑠 Enthalpies of streams S10 , S9 , S12 and S13 will be calculated as following : ∆ 𝐻𝑠10 = 𝑆10 𝐶𝑝10 (𝑇𝑆10 − 298) ∆ 𝐻𝑠9 = 𝑆9 𝐶𝑝9 (𝑇𝑆 9 − 298) ∆ 𝐻𝑠12 = 𝑆12 𝐶𝑝12 (𝑇𝑆12 − 298) 38 ∆ 𝐻𝑠13 = 𝑆13 𝐶𝑝13 (𝑇𝑆13 − 298) 𝑆10 = 13150 𝐾𝑚𝑜𝑙/ℎ𝑟 𝑆9 = 3012 𝐾𝑚𝑜𝑙/ℎ𝑟 𝑆12 = 760 𝐾𝑚𝑜𝑙/ℎ𝑟 𝑆13 = 2249.2 𝐾𝑚𝑜𝑙/ℎ𝑟 𝐶𝑝10 = 31.4 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 𝐶𝑝9 = 35.2 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 𝐶𝑝12 = 33 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 𝐶𝑝13 = 85.5 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 Temperature of streams S10 , S9 , S12 and S13 at 313K ∆ 𝐻𝑠13 = 2249.2 × 85.9 (313 − 298) ∆ 𝐻𝑠10 = 13150 × 31.4 (313 − 298) ∆ 𝐻𝑠9 = 3012 × 35.2 (313 − 298) ∆ 𝐻𝑠12 = 760 × 33 (313 − 298) Chapter 4 Process design of cooler 40 4.1 Process design of cooler Figure (3.7) : Design of cooler Counter – Current flow arrangement Tube – Side fluid : cooling water. Shell – Side fluid : Stream S7 and S8. ∆𝑇𝑙𝑚 = (313 − 298) − (427.3 − 323) 15 − 104.3 = 313 − 298 15 ln (427.3 − 323) ln (104.3) ∆𝑇𝑙𝑚 = 46 𝐾 = 46 𝐶° Physical properties of tube – side fluid (water) : Heat capacity 𝐶𝑝 = 75 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 = 4.2 𝐾𝑗/𝐾𝑔 𝐾 Viscosity 𝜇 = 0.8 × 10−3 𝑃𝑎. 𝑠 Thermal conductivity 𝐾 = 0.6 𝑊/𝑚𝐶° Density 𝜌 = 1000 𝐾𝑔/𝑚3 Mass flow rate 𝑚𝐻2𝑂 = 188 𝐾𝑔/𝑠𝑒𝑐 Physical properties of Stream S7 (shell – side fluid) : 𝐶𝑝 = 35 𝐾𝑗/𝐾𝑚𝑜𝑙 𝐾 = 1.85 𝐾𝑗/𝐾𝑔 𝐾 𝜇 = 1 × 10−5 𝑃𝑎. 𝑠 41 𝐾 = 0.11 𝑊/𝑚𝐶° 𝜌 = 34 𝐾𝑔/𝑚3 𝐴𝑣𝑒 𝑀𝑤𝑡 = 18.9 𝐾𝑔/𝐾𝑚𝑜𝑙 Physical properties are taken at an average temperature of shell – side fluid = 427.3+313 2 = 370𝐾 Assume overall heat transfer coefficient 𝑢0 = 300 𝑊/𝑚2 𝐾 𝑄 = 𝑢0 𝐴0 ∆𝑇𝑙𝑚 𝑄 = 70788847 𝐾𝑗/ℎ𝑟 = 19663568 𝑗/𝑠 Heat transfer area 𝐴0 = 𝑢 𝑄 0 ∆𝑇𝑙𝑚 𝐴0 = 19663568 = 2137 𝑚2 300 × 46 Select tube dimensions : Length 𝐿 = 6 m 𝑑𝑖 = 16 𝑚𝑚 𝑑0 = 20 𝑚𝑚 Area of one tube 𝑎0 = 𝜋𝑑0 𝐿 𝑎0 = 𝜋(0.02)(4.88) = 0.3066 𝑚2 𝑡𝑜𝑡𝑎𝑙 𝑎𝑟𝑒𝑎 Number of tubes 𝑁𝑡 = 𝑎𝑟𝑒𝑎 𝑜𝑓 𝑜𝑛 𝑡𝑢𝑏𝑒 2137 𝑁𝑡 = (3.14)(20×10−3 )(6) = 5671 𝑡𝑢𝑏𝑒 shell – side calculation : 𝑁 1 Bundle diameter 𝐷𝑏 = 𝑑0 (𝐾 𝑡 )𝑛1 1 For one tube pass and triangle pith 42 𝐾1 = 0.319 , 𝑛1 = 2.142 , Ref (4) 𝐷𝑏 = 20( 3782 1 )2.142 0.319 𝐷𝑏 = 1.6 𝑚 Cross –flow area 𝐴𝑠 = (𝑃𝑡 −𝑑0 )𝐷𝑠 𝐿𝐵 𝑃𝑡 𝐿𝐵 : Baffle spacing Choose baffle spacing 𝐿𝐵 = 𝐷𝑠 5 𝑃𝑡 = 12.5𝑑0 = 1.25 × 25 𝑚𝑚 𝐷𝑠 = 𝐷𝑏 + 20 𝑚𝑚 𝐷𝑠 = 1927 + 20 = 1947 𝑚𝑚 = 1.947 𝑚 𝐴𝑠 = (𝑃𝑡 − 𝑑0 ) 𝐷𝑠 . 𝐷𝑠 × 𝑃𝑡 5 (25 − 20) (1.947)2 𝐴𝑠 = . 25 5 𝐴𝑠 = 0.07788 𝑚2 Equivalent diameter 𝑑𝑒 = 1.1 2 (𝑃𝑡 − 0.917𝑑0 2 ) 𝑑0 𝑑𝑒 = 1.1 (252 − 0.917(20)2 ) 20 𝑑𝑒 = 14.201 𝑚𝑚 = 0.0142 𝑚 Mass velocity 𝐺 = 𝑚𝑎𝑠𝑠 𝑓𝑙𝑜𝑤 𝑟𝑎𝑡𝑒 𝑖𝑛 𝑠ℎ𝑒𝑙𝑙 𝑡𝑢𝑏𝑒 𝑆7 𝐴𝑠 𝑆7 = 17695 𝐾𝑚𝑜𝑙/ℎ𝑟 = 17695 × (𝑎𝑣𝑒𝑟𝑎𝑔𝑒 𝑀𝑤𝑡) = 17695 × 18.9 𝐴𝑣𝑒 𝑀𝑤𝑡 = 18.9 𝐾𝑔/𝐾𝑚𝑜𝑙 𝑆7 = 334435.5 𝐾𝑔/ℎ𝑟 = 92.9𝐾𝑔/𝑠𝑒𝑐 43 𝐺= 92.9 = 1192.8608 𝐾𝑔/𝑚2 . 𝑠 0.07788 Reynolds number for shell – side fluid 𝑅𝑒 = 𝐺𝑒 𝑑𝑒 × 0.0142 = 𝜇 1 × 10−5 𝑅𝑒 = 1694060 Prandtl number 𝑃𝑟 = 𝐶𝑝𝜇 𝐾 = (1.85×10−5 )(1×10−5 ) 0.11 𝑃𝑟 = 0.168 From fig (1) , shell – side heat transfer factor (for 25% baffle cut) 𝑅𝑒 = 1694060 𝑗ℎ = 7 × 10−4 Convection heat transfer coefficient ℎ𝑠 𝑑𝑒 = 𝑗ℎ . (𝑅𝑒). (𝑃𝑟)0.33 𝐾 7 × 10−4 (1694060)(0.168)0.33 × 0.11 ℎ𝑠 = 0.0142 ℎ𝑠 = 5099 𝑊/𝑚2 𝐾 tube – side calculation : 𝜋 𝑎𝑡 total tube cross flow area = 4 𝑑𝑖 2 × 𝑁𝑡 = 𝜋 (0.016)2 × 5671 4 = 1.342 𝑚2 𝐺𝑡 = 𝑅𝑒 = 𝑚𝑎𝑠𝑠 𝑓𝑙𝑜𝑤 𝑡𝑎𝑡𝑒 𝑜𝑓 𝑤𝑎𝑡𝑒𝑟 𝑎𝑡 𝐺𝑡 𝑑𝑖 140.1 × 0.016 = 𝜇 0.8 × 10−3 𝑅𝑒 = 2802 188 = 1.342 = 140.1 𝐾𝑔/𝑚2 . 𝑠 44 Water linear velocity 𝑢𝑡 = Prandtl number 𝑃𝑟 = 𝐶𝑝𝜇 𝐾 𝐺𝑡 𝜌 = = 2808 1000 = 2.802 𝑚/𝑠 (4.2×103 )(0.8×10−3 ) 0.6 𝑃𝑟 = 5.6 𝐿 6 = = 375 𝑑𝑖 0.016 Convective heat transfer coefficient for tube - side : ℎ𝑖 𝑑𝑖 = 𝑗ℎ . (𝑅𝑒). (𝑃𝑟)0.33 𝐾 𝐿 𝑗ℎ , from fig (2) , for (𝑑𝑖 ) = 375 𝑖 ℎ𝑖 = 𝑗ℎ . (𝑅𝑒). (𝑃𝑟)0.33 𝐾 𝑑𝑖 ℎ𝑖 = 3.9 × 10−3 (2802)(5.6)0.33 × 0.6 0.016 ℎ𝑖 = 482 𝑊/𝑚2 𝐶° Overall heat transfer coefficient : 𝑑0 1 1 1 𝑑0 ln( 𝑑𝑖 ) 𝑑0 1 1 𝑑0 = + + + × + × 𝑢0 ℎ𝑠 ℎ0 2𝐾𝑤 𝑑𝑖 ℎ𝑖 ℎ𝑖 𝑑𝑖 20 0.02 ln (16) 20 1 1 1 1 1 1.25 = + + + × + × 𝑢0 1.279 5000 2 × 50 16 5000 2129 20 1 = 340 𝑢0 Since the estimated u higher then the assumed value, then the heat transfer will be taking place successfully. Chapter 5 Safety 45 5.1 Methanol Safety Data Sheet 5.1.1 Potential Health Effects Eye : may cause painful sensitization to light. Methanol is a mild to moderate eye irritant. Inhalation, ingestion or skin absorption of methanol can cause significant disturbance in vision, including blindness. Skin : causes moderate skin irritation. May be absorbed through the skin in harmful amounts. Prolonged and or repeated contact may cause defatting of skin and dermatitis. Methanol can be absorbed through the skin, producing systemic effects that include visual disturbances. Ingestion : may be fatal or cause blindness if swallowed. Aspiration hazard. Cannot be made nonpoisonous. May cause gastrointestinal irritation with nausea, vomiting and diarrhea. May cause systematic toxicity with acidosis. May cause central nervous system depression, characterized by excitement, followed by headache, dizziness, drowsiness, and nausea. Advanced stages may cause collapse, unconsciousness, coma, and possible death due to failed respiratory failure. May cause cardiopulmonary system effects. Inhalation : methanol is toxic and can very readily form extremely high vapor concentrations at room temperature. Inhalation is the most common route of occupational exposure. At first, methanol causes cns depression with nausea, headache, vomiting, dizziness and incoordination. A time period with no obvious symptoms follows (typically 8-24 hrs). This latent period is followed by metabolic acidosis and severe visual effects which may include reduced reactivity and/or increased sensitivity to light, blurred, doubt and/or snowy vision, and blindness. Depending on the severity of exposure and the promptness of treatment, survivors may recover completely or may have permanent blindness, vision disturbances and/or nervous system effects. Chronic : prolonged or repeated skin contact may cause dermatitis. Chronic exposure may cause effects similar to those of acute exposure. Methanol is only very slowly eliminated from the body. Because of this slow elimination, methanol should be regarded as a cumulative poison. Though a single exposure may cause no effect, daily exposures may result in the accumulation of a harmful amount. 46 5.1.2 First Aid Measures Eyes : in case of contact, immediately flush eyes with plenty of water for a t least 15 minutes. Get medical aid. Skin : in case of contact, immediately flush skin with plenty of water for at least 15 minutes while removing contaminated clothing and shoes. Get medical aid immediately. Wash clothing before reuse. Ingestion : potential for aspiration if swallowed. Get medical aid immediately. Do not induce vomiting unless directed to do so by medical personnel. Never give anything by mouth to an unconscious person. If vomiting occurs naturally, have victim lean forward. Inhalation : if inhaled, remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Get medical aid. Notes to physician : effects may be delayed. Antidote : ethanol may inhibit methanol metabolism. 5.1.3 Accidental Release Measures Spills/leaks : use water spray to disperse the gas/vapor. Remove all sources of ignition. Absorb spill using an absorbent, non-combustible material such as earth, sand, or vermiculite. Do not use combustible materials such as sawdust. Use a spark-proof tool. Provide ventilation. A vapor suppressing foam may be used to reduce vapors. Water spray may reduce vapor but may not prevent ignition in closed spaces. 5.1.4 Storage And Handling Handling : wash thoroughly after handling. Remove contaminated clothing and wash before reuse. Ground and bond containers when transferring material. Use spark-proof tools and explosion proof equipment. Avoid contact with eyes, skin, and clothing. Empty containers retain product residue, (liquid and/or vapor), and can be dangerous. Keep container tightly closed. Do not ingest or inhale. Do not pressurize, cut, weld, braze, solder, drill, grind, or expose empty containers to heat, sparks or open flames. Use only with. 47 Storage : keep away from heat, sparks, and flame. Keep away from sources of ignition. Store in a cool, dry, well-ventilated area away from incompatible substances. Flammables-area. Keep containers tightly. 5.1.5 Exposure Controls/Personal Protection Engineering controls : use explosion-proof ventilation equipment. Facilities storing or utilizing this material should be equipped with an eyewash facility and a safety shower. Use adequate general or local exhaust ventilation to keep airborne concentrations below the permissible exposure limits. Osha vacated pels: methanol: 200 ppm twa; 260 mg/m3 twa Personal protective equipment : Eyes : wear chemical splash goggles. Skin : wear butyl rubber gloves, apron, and/or clothing Clothing : wear appropriate protective clothing to prevent skin exposure. Respirators : follow the osha respirator regulations found in 29 cfr 1910.134 or european standard en 149. Use a niosh/msha or european standard en 149 approved respirator if exposure limits are exceeded or if irritation or other symptoms are experienced. 5.1.6 Stability And Reactivity Chemical stability : stable under normal temperatures and pressures Conditions to avoid : high temperatures, ignition sources, confined spaces. Incompability (materials to avoid) : oxidizing agents, reducing agents, acids, alkali metals, potassium, sodium, metals as powders (e.g. Hafnium, raney nickel), acid anhydrides, acid chlorides, powdered aluminum, powdered magnesium. Hazardous decomposition products : carbon monoxide, irritating and toxic fumes and gases, carbon dioxide, formaldehyde. Hazardous polymerization : will not occur. Reference 1- Hansen, J.B. and Nielsen, P.E.H., ―Methanol Synthesis‖, in: Ertl, G., Knözinger, H., Schûth, F., Weitkamp, J., Handbook of Heterogeneous Catalysis, Second Edition 2008, Vol. 6, p. 2920, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. 2- Huang, P., Ju, H., Tan, S., Wang, H., and Zhao, T., The Future of Methanol Fuel, Project Report, 2015 3- . Hansen, J. B., Methanol Production Technology, Methanol Workshop, Lund University, March 2015. 4- Chemical Engineering , Volume 6 , Coulson and Richardson. Figure (1). Shell-side heat-transfer factor, (for 25% baffle cut) , Ref (4) Appendices APPENDIX . A Figure (2). Tube-side heat-transfer factor - Ref (4) APPENDIX . B