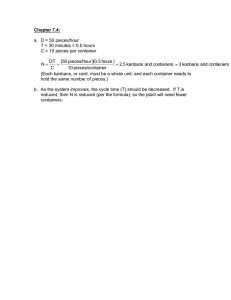

Offshore Container Certification Standard - DNV 2.7-1

advertisement