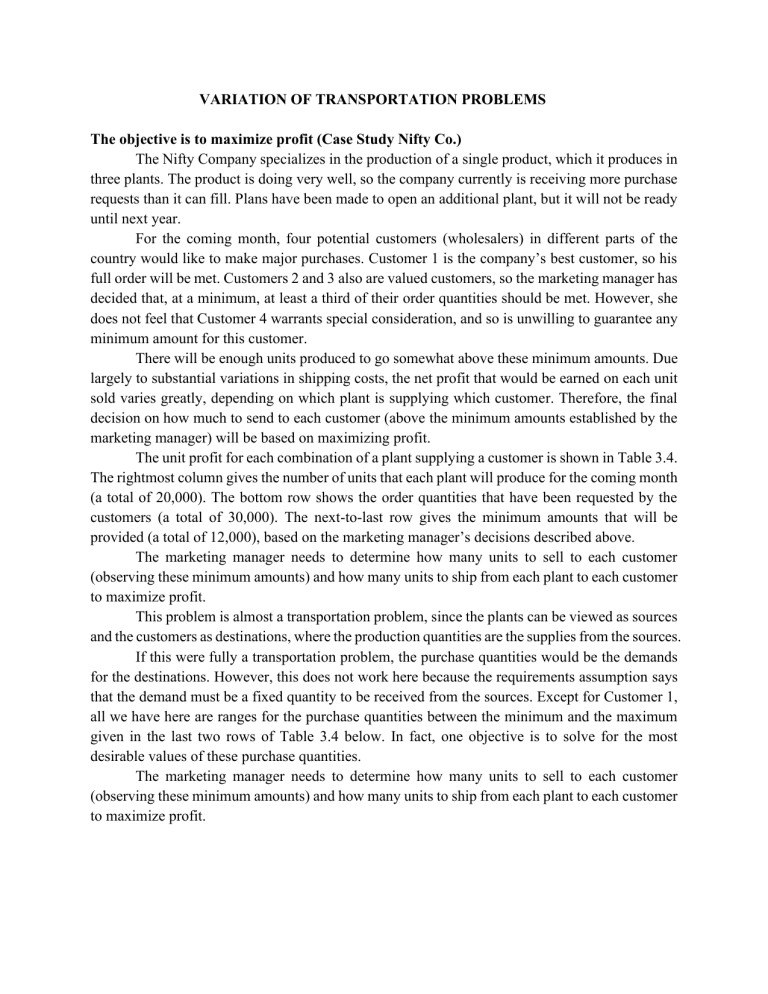

VARIATION OF TRANSPORTATION PROBLEMS The objective is to maximize profit (Case Study Nifty Co.) The Nifty Company specializes in the production of a single product, which it produces in three plants. The product is doing very well, so the company currently is receiving more purchase requests than it can fill. Plans have been made to open an additional plant, but it will not be ready until next year. For the coming month, four potential customers (wholesalers) in different parts of the country would like to make major purchases. Customer 1 is the company’s best customer, so his full order will be met. Customers 2 and 3 also are valued customers, so the marketing manager has decided that, at a minimum, at least a third of their order quantities should be met. However, she does not feel that Customer 4 warrants special consideration, and so is unwilling to guarantee any minimum amount for this customer. There will be enough units produced to go somewhat above these minimum amounts. Due largely to substantial variations in shipping costs, the net profit that would be earned on each unit sold varies greatly, depending on which plant is supplying which customer. Therefore, the final decision on how much to send to each customer (above the minimum amounts established by the marketing manager) will be based on maximizing profit. The unit profit for each combination of a plant supplying a customer is shown in Table 3.4. The rightmost column gives the number of units that each plant will produce for the coming month (a total of 20,000). The bottom row shows the order quantities that have been requested by the customers (a total of 30,000). The next-to-last row gives the minimum amounts that will be provided (a total of 12,000), based on the marketing manager’s decisions described above. The marketing manager needs to determine how many units to sell to each customer (observing these minimum amounts) and how many units to ship from each plant to each customer to maximize profit. This problem is almost a transportation problem, since the plants can be viewed as sources and the customers as destinations, where the production quantities are the supplies from the sources. If this were fully a transportation problem, the purchase quantities would be the demands for the destinations. However, this does not work here because the requirements assumption says that the demand must be a fixed quantity to be received from the sources. Except for Customer 1, all we have here are ranges for the purchase quantities between the minimum and the maximum given in the last two rows of Table 3.4 below. In fact, one objective is to solve for the most desirable values of these purchase quantities. The marketing manager needs to determine how many units to sell to each customer (observing these minimum amounts) and how many units to ship from each plant to each customer to maximize profit. Table 3.4 – Data for the Nifty Co. Problem Unit profit Customer 1 2 3 4 Production quantity Plant 1 55 42 46 53 8,000 2 37 18 32 48 5,000 3 29 59 51 35 7,000 Minimum purchase 7,000 3,000 2,000 0 Requested purchase 7,000 9,000 6,000 8,000