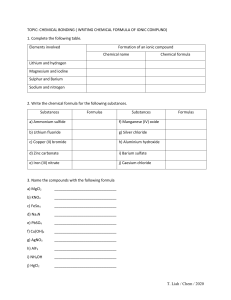

7th Semester Project Report On PURIFICATION Of LEAD CONTAMINATED WATER Submitted to Department of Chemical Engineering By AKHTAR ALI (CHE/18/242) KIRTI KAMAL RONGHANG (CHE/18/292) JITU HALOI (CHE/18/402) ABINASH BHUYAN (CHE/18/206) In partial fulfilment for the award of the degree of BACHELOR OF TECHNOLOGY IN CHEMICAL ENGINEERING DEPARTMENT OF CHEMICAL ENGINEERING Assam Engineering College, Jalukbari, Session-2022 1 Certificate This is to certify that Jitu Haloi( Roll no : CHE/18/402 ) , Akhtar Ali ( Roll no : CHE/18/242) , Kirti Kamal Ronghang ( Roll no : CHE/18/292 ) , Abinash Bhuyan (Roll no :CHE /18/206 ) of B.E. 7th Semester have jointly carried out the project “Purification of lead contaminated water ” under my supervision and submitted the report in partial fulfillment of the requirement of degree of Bachelor in Engineering in Chemical Engineering of Assam Science Technology University, Guwahati which may be accepted . Date: ………………………… Dr. Kabita Chakrabarty Department of Chemical Engineering Assam Engineering College 2 Declaration We ,students of B. Tech, 7th semester Chemical engineering department of Assam Engineering College sincerely declare that: 1. The manuscript is not an exact copy from any source. 2. All the information contained in this report is correct to the best of my knowledge. Thanking you Akhtar Ali (18/242) Jitu Haloi (18/402) Kirti Kamal Ronghang (18/292) Abinash Bhuyan (18/206) 7th semester (B.Tech) Assam engineering college, Jalukbari, Ghy-13 3 Acknowledgment We the students of B.Tech 7th semester, Department of Chemical Engineering, Assam Engineering College, Guwahati would like to take this opportunity to extend gratitude to all the people associated with this project for their kind cooperation and encouragement which help us in completion of this project. We extend our heartiest gratitude to Dr. Kabita Chakrabarty and Miss Mousumee Das ma’am, for providing us with necessary inputs as and when needed. We would like to appreciate and acknowledge the efforts of our Chemical Department. In spite of their busy schedule, they were always eager to help us out and share their vast experiences with us. 4 Abstract Enormous increase in the application of various heavy metals including lead for commercial and noncommercial purposes has also led to their enhanced occurrence in the effluents from industries and domestic discharge creating substantial environmental concerns. The existing techniques for removal of these contaminants such as reverse osmosis and ion exchange suffer a few disadvantages and hence, thrust to develop efficient techniques for the removal have been ever increasing. Adsorption based on the use of adsorbents is promising being cost effective and based on the ease of operation. The present work furnishes a detailed overview on adsorbents for removal of lead from water. The various adsorbents covered in the analysis include coconut coir , coconut shell , banana peels , rice husk , egg shell , activated carbon , saw dust of jackfruit and mango . The review also gives an insight into the synthesis and characterization of adsorbents followed by guidelines on optimum operating parameters to be used in the removal process for maximizing the extent of removal. The typical optimum conditions established based on the critical analysis of literature are pH<6, contact time>60 min and optimum adsorbent dose dependent on the materials.The sequestration was mainly dependent on adsorbent dose that has to be kept optimum to yield adequate surface area and number of adsorption sites. Overall, adsorbents have been established to yield efficient removal of lead from water. 5 Contents Topic Page No 1. Introduction 7 2. Absorption process 7 3. Sources 8 4. Health impact 8 5. Material used 9 6. Experimental procedures 9 a. Preparation of calibration curve 9-10 b. Preparation of adsorbent 10-16 7. Observation 10-16 8. Calculation 16-18 9. Conclusion 18 10. Reference 18 6 Introduction Lead ions are very common pollutants in water which have dangerous potential causing serious diseases and health problems to human , so lead contaminated water should be purified by removing the lead for making it drinkable. Lead is a recognized environmental pollutant that acts as a cumulative poison. Inorganic Pb2+ is an enzyme inhibitor, which also affects the nervous system. The major environmental sources of metallic lead and its salts and oxides are paints and pigments, battery industries, lead smelters, etc. Once mobile in the environment in ionic form, like many other toxic elements it finds its way into the human body through drinking water, food and air. Limit values of lead in drinking water and surface water intended for drinking, as set by EU, USEPA and WHO, are 10, 50 and 10mg/l, respectively . However, more recently an EPA document prescribes a zero lead value in national primary drinking water standard . In India, limit value of lead in drinking water is 0.01mg/l . Removal of lead from contaminated water bodies has been attempted by several researchers employing a wide variety of techniques. Majority of these are adsorption on various surfaces like activated carbon , peat , goethite mineral, hydrated iron and aluminium oxide , granular iron oxide , synthetic anionic clay, biopolymers, industrial wastes like red mud, granulated blast furnace slag, naturally occurring and treated zeolites and coral sand . Other lead removal techniques include hydrocerrusite precipitation , precipitation with sodium di-(n-octyl) phosphinate , precipitation with recycled alum sludge , ion exchange , electrokinetic decontamination and use of microorganism .But among all the method we will use the adsorption process to remove lead from the contaminated water Adsorption process It is a process where attractive forces associates a solute (adsorbate) to a solid surface (adsorbent). It is a surface phenomenon in which adsorbate molecules adhere to the adsorbent surface. The size of adsorbent molecules that interact may vary from microns to nanometer. Adsorption of pollutants on sorbents is generally explained by two mechanisms classified as physical and chemical sorption. Physical adsorption is the simplest immobilization method in which the biomolecules are attached to the surface through weak bonds such as van der waals forces , hydrogen bonding etc. 7 Chemisorption is chemical adsorption phenomenon that involves exchange of electrons between adsorbent and metal rather than focusing on the ions, as in the case of complexation and ion-exchange . Why we are using adsorption process ? These process has certain advantages over the other process of lead removers. Like these process is technically easy to design and operate. It works at a mild operation condition and at a wide pH range and the process also doesn’t produce any toxic by product. It has certain other advantages. 1. It is very much effective at a very low concentration of contaminant. 2. It can work selectively . 3. Regenerability of used adsorbents. Sources of lead in water 1. Industrial wastes . 2. Use of lead solder with copper pipes in household connections . 3. From the sockets present in water tanks . As lead is completely soluble in water, hence heating the lead contaminated water make lead more mixed in water. Lead is more dangerous metal specially for the children below 6 years. Drinking of lead contaminated water can cause slow poisoning to the child and pregnant woman. Hence government has passed certain norms. According to the bureau of indian standard the maximum desirable limit of lead in the drinking water is 0.05 mg/l and as per environmental protection act is 0.01 mg/l. Health Impact of Lead Exposure Impact of lead exposure in humans has been known to cause wide variety of health problems such as • Various forms of blood disorders and Anemia . • Rapid deterioration of brain and the nervous system. • Reduced fertility both in men and women . • Failure of the kidney . 8 • Alzheimer disease. Materials used 1. Lead nitrate salt 2. Activated carbon 3. Acetone 4. Aluminium sheet 5. Test tubes 6. Conical flasks (250 ml) 7. Beakers 8. Magnetic Stirrers 9. Tissue paper 10. Rice husk 11. Coconut shell 12. Coconut coir 13. Wood ashes 14. Egg shell 15. Banana peels 16. Jackfruit and mango Experimental procedures Preparation of calibration curve Calibration curve are should draw between concentration of lead and adsobence. We have made 10 samples of 250 ml Millipore water and leadnitrate as a source of lead in the sample. The concentration of lead is [5,10,15,20, 25, 30, 35, 40, 45, 50] ppm per 250 ml of millipore water. The findings and results are given bellow in the uvspectrometer. Sample Adsorption 5 ppm 0.123 10 ppm 0.237 15 ppm 0.375 20 ppm 0.501 25 ppm 0.625 9 Preparation of adsorbent We have selected 8 adsorbent such as pure activated carbon, rice husk, coconut shell, cocobnut coir, egg shell, banana peels, sawdust of jackfruit-mango . 1. Experimental procedures for activated carbon a. firstly we made a solution of 250ml milipore water and 10 ppm lead nitrate. b. Then we added the prepared adsorbent of activated carbon . c. Then mixed with the help of magnetic stirrer . d. 4 sample mixture is taken from the main sample at a time gap of 10 mins till 40 mins continuously. e. Then these sample tested with the help of uv spectrometer . Observation Table For wavelength = 208 nm (activated carbon) Sample (10 ppm) 10 ppm 5 minutes 10 minutes 20 minutes 30 minutes 35 minutes 40 minutes Absorption 1.231 0.838 0.824 0.763 0.644 0.601 0.523 10 2. Preparation of coconut coir adsorbent a. Coconut coir is first washed and dried and then soak it overnight with 10% potassium hydroxide solution . b. Then it is washed again to remove free from potassium hydroxide and then dried at 110 degree celcius for 24 hours . c. Then it was subjected to activation at 900 degree celcius for 30 minutes . d. The obtained carbon washed and dried at 110 degree celcius again for 24 hours. Then the carbon is grounded to finer size and our coconut coir activated carbon is ready to use. Experimental procedures for coconut coir a. firstly we made a solution of 250ml milipore water and 10 ppm lead nitrate. b. Then we added the prepared adsorbent of coconut coir . c. Then mixed with the help of magnetic stirrer . d. 4 sample mixture is taken from the main sample at a time gap of 10 mins till 40 mins continuously. e. Then these sample tested with the help of uv spectrometer. Observation Table For wavelength = 208 nm (coconut coir ) Sample (10 ppm) 10 ppm 5 minutes 10 minutes 20 minutes 30 minutes 35 minutes 40 minutes Absorption 1.331 0.074 0.135 0.38 0.135 0.008 0.066 3. Preparation of absorbent from rice hush a. The raw rice hush is prepared by immersing rice husk in 1N HCl aquous solution for 4 hours. b. Then it was washed with water and air dried at room temperature. c. A sample of rice hush is converted into an adsorbent rice hush by treating the rice hush at 700 degree celcius for 4 hours. 11 Experimental procedures for rice husk a. firstly we made a solution of 250ml milipore water and 10 ppm lead nitrate. b. Then we added the prepared adsorbent of rice husk . c. Then mixed with the help of magnetic stirrer . d. 4 sample mixture is taken from the main sample at a time gap of 10 mins till 40 mins continuously. e. Then these sample tested with the help of uv spectrometer . Observation Table For wavelength =208 nm (rice husk ) Sample (10 ppm) 10 ppm 5 minutes 10 minutes 20 minutes 30 minutes 35 minutes 40 minutes Absorption 1.145 0.005 0.007 0.010 3 3 3 4. Preparation of egg shell adsorbent a. Firstly the egg shells were washed with tap water several times and afterwards with distilled water . b. Then they were transferred to the oven at 80 degree celcius to dry. c. The dried egg shell were crushed and milled to a average size of 100 nm. d. A weight of 33.33 gm of egg shell powder was vigorously added to 46.16 ml of nitric acid and stirred at room temperature for 1 hour. e. Then a solution of phosphoric acid which is obtained by dilution of 13.70 ml phosphoric acid in 130 ml of distilled water is slowly added to the egg solution. f. Then the solution was maintained at ebullition temperature for 1 hour and at room temperature for 24 hour. g. Lastly the suspension was filtered , dried , and ground into a powder to get the sample. h. Small amount of powder were heated at 600 degree celcius for 3 hour and furnace cooled to improve crystallinity and to check the purity . 12 . Experimental procedures for egg shell adsorbent a. firstly we made a solution of 250ml milipore water and 10 ppm lead nitrate. b. Then we added the prepared adsorbent of egg shell. c. Then mixed with the help of magnetic stirrer . d. 4 sample mixture is taken from the main sample at a time gap of 10 mins till 40 mins continuously. e. Then these sample tested with the help of uv spectrometer . Observation Table For wavelength =208 nm (egg shell) Sample (10 ppm) 10 ppm 5 minutes 10 minutes 20 minutes 30 minutes 35 minutes 40 minutes Absorbent 1.267 0.275 1.760 1.952 2.308 3 3 5. Preparation of banana peel adsorbent a. Firstly , banana peel that can be obtained from local market is separated slowly from the fruit . b. Then it was washed using distilled water to avoid contamination. c. Clean banana peel was dried in the sun for 2 consecutive days and continued with drying in the oven at 80 degree celcius for 18 hours until it was completely dry . d. After that dried banana peels are smoothed and heated at 900 degree celcius for 2 hours . Experimental procedures for banana peel adsorbent a. firstly we made a solution of 250ml milipore water and 10 ppm lead nitrate. b. Then we added the prepared adsorbent of banana peel . c. Then mixed with the help of magnetic stirrer . d. 4 sample mixture is taken from the main sample at a time gap of 10 mins till 40 mins continuously. e. Then these sample tested with the help of uv spectrometer . 13 Observation Table For wavelength =208 nm (banana peel ) Sample (10 ppm) 10 ppm 5 minutes 10 minutes 20 minutes 30 minutes 35 minutes 40 minutes Absorption 1.311 0.291 1.785 1.973 2.328 3 3 6. Preparation of coconut shell adsorbent a. Firstly the collected coconut shells were cut into small pieces followed by washing with tap water for removal of dust adhere to it. b. Then it was dried in the sunlight for 5 days . c. Dried materials were kept inside the furnace at 150 degree celcius for 24 hours for removal of moisture and other volatile impurities. d. Then the sample were kept inside a muffle furnace for 1 hour at 650 degree celcius. e. Then it was cooled and dried . f. The dried material was washed with 0.5 N HCl for 2-3 times and then washed with warm distilled water to remove different residual organic and mineral matter . g. Then it was finally washed with cold water till the solution becomes neutral . h. Finally the sample was dried for 24 hours at 100 degree celcius inside an oven. Experimental procedures for coconut shell adsorbent a. firstly we made a solution of 250ml milipore water and 10 ppm lead nitrate. b. Then we added the prepared adsorbent of coconut shell . c. Then mixed with the help of magnetic stirrer . d. 4 sample mixture is taken from the main sample at a time gap of 10 mins till 40 mins continuously. e. Then these sample tested with the help of uv spectrometer . 14 Observation Table For wavelength =208 nm (coconut shell ) Sample (10 ppm) 10 ppm 5 minutes 10 minutes 20 minutes 30 minutes 35 minutes 40 minutes Absorption 1.296 0.147 0.148 0.148 0.147 1.148 0.432 7. Preparation of jackfruit- mango adsorbent a. First we have taken the sawdust of mango and jackfruit wood . b. The sawdust is dried at 80 degree celcius in the oven for 2 hours . c. The dried sawdust is heated at 350 degree celcius for 3 hours continuously. d. The heated material is then cooled by keeping it for 24 hours in room temperature . e. Then the cooled material is grinded to small size . f. Then the small size material is dipped in lemon juice for 1 day which is extracted from the fresh lemons . g. After 24 hours the material is filtered with the filter paper and dried at 80 degree celcius in oven for 2 hours . Experimental procedures for jackfruit –mango adsorbent a. firstly we made a solution of 250ml milipore water and 10 ppm lead nitrate. b. Then we added the prepared adsorbent of jackfruit –mango . c. Then mixed with the help of magnetic stirrer. d. 4 sample mixture is taken from the main sample at a time gap of 10 mins till 40 mins continuously. e. Then these sample tested with the help of uv spectrometer. 15 Observation Table For wavelength =208 ( jackfruit-mango adsorbent ) Sample (10 ppm) 10 ppm 5 minutes 10 minutes 20 minutes 30 minutes 35 minutes 40 minutes Absorbtion 1.262 1.530 1.701 1.565 1.632 1.668 2.221 Calculations Molecular Mass of Pb (NO3)2 =331.2gm Molecular weight of Pb = 207.2gm Molecular weight of N = 14gm Molecular weight of O3= 3×16= 48gm For Sample 1: (10ppm) 207.2 gm of Pb present in= 331.2gm of Pb (NO3)2 ∴ 5 gm of Lead present in= 5×331.2/207.2 gm of Pb (NO3)2 = 7.992gm of Pb (NO3)2 ∴ 5mg of Lead present in = 7.992gm of Pb (NO3)2 Now 100ml of Pb (NO3)2 solution contains = 7.992mg of Pb (NO3)2 ∴ 250ml of Pb (NO3)2 solution contains =7.992/1000×250 =1.998mg of Pb (NO3)2 . For sample 2: (10ppm) 10mg of Pb present in= 15.984 mg of Pb (NO3)2 ∴ 250ml of Pb (NO3)2 solution contains = 15.984/4 mg of Pb (NO3)2 = 3.996 mg of Pb (NO3)2 16 For sample 3 (15ppm) 15mg of Pb Present in = 23.976 mg of Pb (NO3)2 ∴ 250ml of Pb (NO3)2 solution contains = 23976/4 mg of Pb (NO3)2 = 5.994 mg of Pb (NO3)2 For sample 4 (20ppm) 20mg of Pb Present in = 31.969 mg of Pb (NO3)2 ∴ 250ml of Pb (NO3)2 solution contains = 31.969/4 mg of Pb (NO3)2 =7.992 mg of Pb (NO3)2 For sample 5 (25ppm) 25mg of Pb Present in =39.969 mg of Pb (NO3)2 ∴ 250ml of Pb (NO3)2 solution contains = 39.961/4 mg of Pb (NO3)2 =9.990 mg of Pb (NO3)2 For sample 6 (30ppm) 30mg of Pb Present in=47.953mg of Pb (NO3)2 ∴ 250ml of Pb (NO3)2 solution contains = 47.953/4 mg of Pb (NO3)2 =11.988 mg of Pb (NO3)2 For sample 7 (35ppm) 35mg of Pb Present in= 55.945 mg of Pb (NO3)2 ∴ 250ml of Pb (NO3)2 solution contains = 55.945/4 mg of Pb (NO3)2 =13.986 mg of Pb (NO3)2 For sample 8 (40ppm) 40mg of Pb Present in= 63.938 mg of Pb (NO3)2 17 ∴ 250ml of Pb (NO3)2 solution contains = 63.938/4 mg of Pb (NO3)2 =15.984 mg of Pb (NO3)2 For sample 9 (45ppm) 45mg of Pb Present in= 71.930 mg of Pb (NO3)2 ∴ 250ml of Pb (NO3)2 solution contains = 71.930/4 mg of Pb (NO3)2 = 17.982 mg of Pb (NO3)2 For sample 10 (50ppm) 45mg of Pb Present in= 79.922 mg of Pb (NO3)2 ∴ 250ml of Pb (NO3)2 solution contains = 79.922/4 mg of Pb (NO3)2 =19.980 mg of Pb (NO3)2 Conclusion There are various methods for the removal of lead from the lead contaminated water.But the best and cheapest method is to use the bio adsorbent produced from the natural thing like coconut shell ,coconut coir banana peel egg shell etc .we have prepared the adsorbent by the method of physical activation mainly by heating .For the activation of adsorbent by heating there is a minimum requirement of atleast 700- 900 degree Celsius temperature . But due to some of the technical problem we are forced to do the activation at 350 degree Celsius temperature so that we are not able to get the desired results .But we are working on it to get the appropriate desired results Reference 1. Source : www.researchgate.net 2. Source : www.googlescholers.com 3. Source : www.sciencedirect.com 4. Lead, Pollution prevention and abatement handbook. World Bank Group, http://wbln0018.worldbank.org/essd.nsf/GlobalView/PPAH/$File/37lead.pdf. 5. Current drinking water standards, http://www.epa.gov/safewater/mcl.html. 18 2002, EPA. Office of water, 19