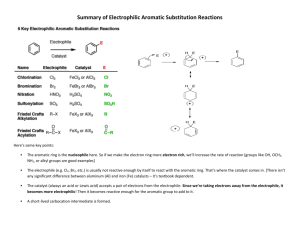

Study of Friedal-Crafts Acylation reaction

Rabiya Javed Awan

Contribution from Department of Chemistry, SBA School of Science and Engineering, Opposite U

Block, 54792, DHA

Received March 5, 2021; Email: 20130026@lums.edu.pk

ABSTRACT: Friedel craft acylation involves the preparation of functionalized aromatic ketones

by the electrophilic substitution reaction of benzene derivative with acetyl chloride in the

presence of a Lewis acid catalyst. In this experiment, p-methyl acetophenone was synthesized

by the electrophilic substitution reaction of toluene and acetyl chloride in presence catalyst

AlCl3. Product (methyl acetophenone) was obtained in a form of viscous liquid in a moderate

yield. TLC was taken to signify that the reaction is complete. IR spectrum, GC-MS data showed

close correspondence with literature values, ascertaining the formation and purity of the

product.

INTRODUCTION

Friedel–Crafts (FC) reaction is a fundamental

method for obtaining functionalized aromatic

ketones. It follows electrophilic aromatic

substitution mechanism. Traditionally, the FC

acylation of benzenes with acid chlorides has

been carried out in the presence of protic acids

or strong Lewis acid catalyst. When an alkyl

halide is treated with a Lewis acid in the presence

of an aromatic ring, the alkyl group can be added

to the ring (forming C-C) with the loss of a C-H

bond. This electrophilic aromatic substitution

reaction is known as the Friedel-Crafts

alkylation reaction. A process related to the

Friedel-Crafts alkylation, called Friedel-Crafts

acylation, also was discovered by Friedel and

Crafts. A Friedel-Crafts acylation is an

electrophilic aromatic substitution reaction that

introduces an acyl group onto an aromatic ring.

The electrophile is an acyl cation that is often

coupled to a Lewis acid catalyst, such as

aluminum chloride. For the reaction to take

place, the aromatic ring system must be very

electron rich and thus cannot contain any

electron withdrawing groups. The reaction was

discovered around the same time (1877) when

Friedel Crafts worked on alkylation 1.

Friedal craft acylation has few limitations such as

the halide must be an alkyl halide. Vinyl or aryl

halides do not react (their intermediate

carbocations are too unstable). Alkylation

reactions

are

prone

to

carbocation

rearrangements. Polyalkylation can be a problem

since the product is more reactive than the

starting material. This can usually be controlled

with an excess of the benzene. The Lewis acid

catalyst AlCl3 often complexes to aryl amines

making them very unreactive 2.

Traditionally, the FC acylation of benzenes with

acid chlorides has been carried out in the

presence of protic acids or strong Lewis acid

catalysts. Lewis acids such as AlCl3, BF3, TiCl4,

Rabiya Javed Awan, LUMS School of Science and Engineering

ZnCl2, SbCl5, Fe2(SO4)3 and strong protic acids

such as HF and H2SO4 have been employed in

these reactions. In particular, the use of metal

halides causes problems 1) associated with the

strong complex formed between the ketone

product and the metal halide itself which

provokes the use of more than stoichiometric

amounts of catalyst. The workup commonly

requires hydrolysis of the complex, leading to the

loss of the catalyst and giving large amounts of

corrosive waste streams. 2) Moreover, these

Lewis acids are moisture sensitive and cannot be

recovered and reused after the reactions are

complete. Due to these draw backs, during the

past decade, the setting up of more ecocompatible Friedel-Crafts acylations has become

a fundamental goal of the general “green

revolution” that has spread in all fields of

synthetic chemistry3. Moreover, following are the

few limitations of Friedel craft acylation:

Acylation can only be used to give

ketones. This is because HCOCl

decomposes to CO and HCl under the

reaction conditions.

Deactivated benzenes are not reactive to

Friedel-Crafts conditions

The Lewis acid catalyst AlCl3 often

complexes to aryl amines making them

very unreactive.

Amines and alcohols can give competing

N or O acylations rather than the require

ring acylation.

Besides its limitation, Friedel craft acylation is has a

significant importance in the field of chemistry,

Vitamin D, DNA, and many other important

compounds in our bodies all includes an aromatic

portion 4 5. But it is very difficult for an aromatic ring

to react with other compounds because it is so stable.

So, to add an aromatic ring to the rest of the molecule

to form these important molecules in our body,

Friedel-Crafts Acylation method is used by

scientist. The reaction is used commonly in food

additives6 and fragrances among other uses.

Development of new catalytic transformations

with easy separation and recyclability of the

catalyst is an essential task in chemical synthesis

due to a very high importance of the aromatic

ketones which are key intermediates in several

fields

including

fine

chemicals

and

7

pharmaceuticals . Friedel–Crafts acylation of

substituted benzenes proceeded smoothly in the

presence of a catalytic amount (5–20%) of

lanthanide triflates. Aluminium, titanium and

ytterbium bis(triflate)imides were found to be

highly effective in acylation reactions of anisole

and diphenyl ether. Aromatic ketones can also be

prepared by the reaction of carboxylic acids with

aromatic compounds catalyzed by Brønsted

acids

such

as

methane-sulfonic

acid,

polyphosphoric

acid,

NafionH,

trifluoromethanesulfonic acid and combinations

of Lewis acids–Bronsted acids 3.

Another important factor is regioselectivity.

Regioselectivity is a process that favors

bond formation at a particular atom over other

possible atoms. The selectivity of the reaction is

determined by the the ability of existing

functional groups on the benzene ring to stabilize

the high energy arenium intermediate in the

reaction. The arenium ion formed by ortho paraattack is more stabilized due to complete octet.

Moreover, the arenium ion formed by Meta

attack is in return slightly stabilized than benzene

because charge is slightly reduced by electronRabiya Javed Awan, LUMS School of Science and Engineering

donating character of the group. Electron

donating stabilizes the arenium ion by dispersing

the positive charge 8.

Electron donating groups (EDG) with lone pairs

(e.g. -OMe, -NH2) on the atoms adjacent to the π

system activate the aromatic ring by increasing

the electron density on the ring through a

resonance donating effect 9. The resonance only

allows electron density to be positioned at the

ortho- and para- positions. Hence these sites are

more nucleophilic, and the system tends to react

with electrophiles at these ortho- and paraposition.

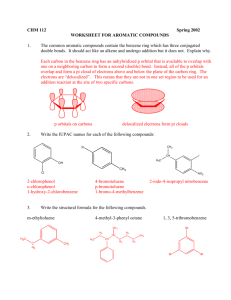

Figure 1: Resonating structure

substituted with activating group.

for

benzene

Electron withdrawing groups (EWG) with π bonds

to electronegative atoms (e.g. -C=O, -NO2)

adjacent to the π system deactivate the aromatic

ring by decreasing the electron density on the

ring through a resonance withdrawing effect. The

resonance only decreases the electron density at

the ortho- and para- positions 10. Hence these

sites are less nucleophilic, and so the system

tends to react with electrophiles at the Meta

sites.

Figure 2: Resonating structure

substituted with deactivating group.

for

benzene

Halogen’s substitutions are little unusual as they

are very electronegative. This means that

inductively they are electron withdrawing.

However, due to their ability to donate a lone

pair of electrons in resonance forms, they are

activators and ortho/para directing. The

inductive effect lowers the reactivity, but the

resonance effect controls the regio-chemistry

due the stability of the intermediates. Because

they are electron withdrawing, halogens are very

weak activators. Friedel Craft acylation of

benzene produces both orth para directing

acetophenone.

Figure 3 (a): p- methylacetophenone and (b): omethylacetophenone

This investigation aims at acylation of aromatic

compound according to the following reaction:

First step is the formation of acylium ion to form

strong electrophile by reaction with lewis acid 5.

Rabiya Javed Awan, LUMS School of Science and Engineering

EXPERIMENTAL SECTION

Chemicals and materials:

Chlorobenzene,

Dichloromethane,

Acetyl

chloride, aluminum chloride, heptane, and

ethanol.

Figure 4: Synthesis of Acylium ion.

Acylium ion formed is resonance stabilized.

Figure 5: Resonance structure of acylium ion.

This acylium ion is then attacked by the benzene

ring.

Figure 6: Mechanism for acylation of Toluene

Glassware and equipment:

Round bottom flask (100 mL), stir bar, reflux

condenser, hot plate, stem funnel, beaker (100

mL +250 mL), extension clamps and fasteners,

grease, aluminum foil, watch glass, ice bath,

melting point capillaries, oil bath and Buchner

funnel.

Procedure:

Anhydrous aluminum chloride (27.17 mmol) was

suspended in methylene chloride (7 ml) in a twoneck round-bottomed flask suspended in an ice

bath. A solution of acetyl chloride (27.17 mmol)

in methylene chloride (5 ml) was added dropwise

to the flask using a syringe at 0οC and the

resulting mixture was stirred for 10 minutes

followed by the addition of a solution of the

aromatic compound (5.43 mmol) in methylene

chloride (5 ml) using a syringe. Once the addition

was completed, heat the reaction to a gentle

reflux for 1 hour. A small quantity of the product

was used to be spotted on a TLC plate, along with

the reactants and standard. TLC was run in a

solvent system of ethyl acetate and hexane in 7:

13 ratios to analyze the completion of reaction.

Isolation of Product: After that the reaction

mixture was poured slowly to three-fold water.

Extraction process in this experiment was carried

out by separating funnel. By carefully planning

out and washing sequences (using DCM and

water), the desired products was separated from

most of the unwanted impurities. The solution

Rabiya Javed Awan, LUMS School of Science and Engineering

was then dried on MgSO4, filtered and solvent

was evaporated on rotary evaporator to get the

final product. The yield of final product was

calculated. Finally, product was analyzed using IR

spectrum and GC-MS.

Mass of product obtained

(Actual Yield)

Percentage yield of product

𝐴𝑐𝑡𝑢𝑎𝑙 𝑦𝑖𝑒𝑙𝑑

𝑇ℎ𝑒𝑜𝑟𝑒𝑡𝑖𝑐𝑎𝑙 𝑦𝑖𝑒𝑙𝑑

RESULTS AND DISCUSSION

0.54 g

0.54

× 100

0.72

= 75 %

× 100 %

The percentage yield obtained is around 75 %.

The loss of product in yield could be due to

improper handling.

GC-MS:

Figure 7: Balanced equations for the reactions

C:\Xcalibur\...\AM-LAB-4_200305112641

3/5/2020 11:26:41 AM

RT: 0.00 - 31.10

7.67

100

Physical properties of reactants:

NL:

3.60E8

TIC MS

AM-LAB4_2003051

12641

90

Relative Abundance

80

Table 1: Physical properties of reactants

70

60

50

40

30

20

10

Toluene

Molar

mass

Density

g/cm3

Melting/boiling

point °C

92.14

0.865

g/mL

110.6

3.60 3.92

4.47 5.81

0

1.104

g/mL

52

Aluminum

chloride

133.34

-

190

2

3

4

5

6

7

9.66

8

9

10

10.76

11.82

11

12

13.14 13.63

13

14

15.08 15.60 16.44

15

16

Time (min)

17

18.11 18.86

18

19

20.77 21.29 22.44 23.26

20

21

22

23

24

24.89

26.09

25

26

27.36

27

28.72 29.24

28

70

Moles of acetyl chloride

0.02717

Limiting Reagent

Toluene

Moles of product expected

0.00543

Mass of product expected

(Theoretical Yield)

= 0.00543

× 134.17

= 0.72 𝑔

31

91.17

60

50

40

134.17

30

65.15

90.33

77.14

92.16

136.20

0

50

100

176.25

150

207.22

200

245.99 267.17 280.88

250

300

327.10 340.78

383.90 398.81

350

400

425.87

466.33

450

504.08

500

528.41

595.12 611.41

550

600

m/z

Figure 3: GC-MS of methyl acetophenone

Table 2: Percentage yield of (methyl)acetophenone

0.00543

30.74

30

80

Percentage yield of the product:

Moles of toluene used

29

90

10

78.5

1

AM-LAB-4_200305112641 #250 RT: 7.67 AV: 1 NL: 1.18E8

T: {0,0} + c EI Full ms [50.00-700.00]

119.16

100

20

Acetyl

chloride

7.57

0

Relative Abundance

Reagent

Figure 4: MS fragmentation pathway for p-methyl

acetophenone

The spectrum attached shows that retention time

for sample is 31.10 minutes.

Molecular ions peak at m/z = 134.17

Rabiya Javed Awan, LUMS School of Science and Engineering

665.69

650

813

Para

substitution

Out-of-Plane

C-H Bending

735

Ortho

substitution

Out-of-Plane

C-H Bending

IR Spectrum:

The C=O stretching peak in acetophenone is

lower than the C=O peak of ketone due to

conjugation. The large intense peak at 813 cm-1

shows that the para methyl acetophenone is

obtained as major product while ortho is minor

product. This is due to the steric hindrance effect.

As methyl group, which is already substituted on

benzene, slightly creates steric hindrance on the

close carbons making the attack difficult for the

acylium ion on the adjacent positions (ortho

position) of substituent. The IR spectrum was in

consonance with those reported in literature 6.

4000

3500

3000

2500

Wavenumber cm-1

2000

1500

813.57

735.70

672.17

636.54

590.69

566.73

1429.92

1405.65

1356.98

1265.63

1181.44

1112.56

1075.09

1044.86

953.28

1736.67

1678.98

1605.39

1573.63

1933.58

3030.67

3003.15

2924.33

2872.19

30

40

50

Transmittance [%]

60

70

80

90

100

The base peak at m/z =119.21

The fragment ion peak at m/z = 91.17: elucidate

the structure of toluene (loss of acetyl group)

while the peak at 77.13 elucidates the pattern of

benzene.

1000

500

Figure 5: IR spectrum of 4-methylacetophenone.

C:\PROGRAM FILES\OPUS_65\MEAS\Am-503-EXP4.0

Am-503-EXP4

ATR platinum Diamond 1 Refl

28/02/2020

Post Lab Questions

Page 1/1

The major peaks obtained in the IR spectrum of

Product methyl acetophenone are interpreted as

follow:

Table 3: The peaks and associated groups with methyl

acetophenone

Frequency (cm-1)

Functional

Group

Vibration

1679

C=O (sp2)

Stretching

1429 - 1605

C=C (sp2)

Aromatic

Stretching

3000 - 3030

C-H (sp2)

Stretching

2872.19 -3003

C-H (sp3)

Stretching

1356 - 1405

C-H (sp3)

Bending

1. Discussion of the lab report related to

this experiment should encompass the

directing ability of substrate, electronic

and steric effects of preexisting

substitutes on the benzene ring.

The pre-existing functional substituents are any

functional group which is already attached to

benzene ring before it undergoes Friedel craft

reaction. The groups determine the reaction

direct by resonance and induction effect.

Resonance effect is the conjugation between the

ring and the substituent, which means the

delocalizing of the ππ electrons between the ring

and the substituent. Inductive effect is the

withdraw of the sigma (the single bond) electrons

away from the ring toward the substituent, due

to the higher electronegativity of the substituent

compared to the carbon of the ring.

Rabiya Javed Awan, LUMS School of Science and Engineering

The reaction of a substituted ring with an

activating pre-existing group is faster than

benzene. On the other hand, a substituted ring

with a deactivated group is slower than benzene.

The activating group directs the reaction to the

ortho or para position, which means the

electrophile substitute the hydrogen that is on

carbon 2 (ortho) or carbon 4 (para). The

deactivating group directs the reaction to the

meta position, which means the electrophile

substitute the hydrogen that is on carbon 3

(meta) except for the halogens that is a

deactivating group but directs the ortho or para

substitution.

intermediate step, thus; the activation energy is

increased which slows down the reaction.

Figure 7: Substate with activating group or electron

donating group.

Ortho and Para products produces a resonance

structure which stabilizes the arenium ion. This

causes the ortho and para products for form

faster than meta. Generally, the para product is

preferred because of steric effects. As Existing

groups can provide steric hindrance on the

positions in close carbons making the attack of

adjacent positions by the substituents difficult.

Figure 6: Products of activating and deactivating

group.

The substrate has a huge role to determine the

reactivity of benzene ring and moreover the

possible product to come out. Activating groups

speed up the reaction because of the resonance

effect. The presence of the unpaired electrons

that can be donated to the ring, stabilize the

carbocation in the transition state. Thus,

stabilizing the intermediate step, speeds up the

reaction; and this is due to the decrease of the

activating energy. On the other hand, the

deactivating groups, withdraw the electrons

away from the carbocation formed in the

Figure 8: Substrate with deactivating group or

electron withdrawing group.

Whereas. Electron withdrawing groups are resonance

deactivators. Ortho and para-attack on such

substrates produces a resonance structure which

places the arenium cation next to and additional

cation. This destabilizes the arenium cation and slows

down ortho and para reaction. Hence, the meta

product forms faster because it lacks this destabilizing

resonance structure.

CONCLUSIONS

Rabiya Javed Awan, LUMS School of Science and Engineering

Methyl acetophenone was synthesized in

moderate yield (75%) by the reaction of toluene

with acetyl chloride in the presence of Lewis acid

as a catalyst, through Friedel craft acylation

reaction. The reactants along with catalyst were

moderately heated with gentle reflux for 1 hr.

The product was extracted through separating

funnel with dichloromethane and dried through

rotavap. Around 75% of the product yield was

obtained. The product was successfully

characterized through IR, GCMS and NMR. The

peak at 1678 cm-1 in IR spectrum depicts the

presence of C=O of acetophenone in product.

The peak at 813 cm-1 shows that para methyl

acetophenone is obtained as major product. The

results of GCMS and IR are in accordance with

the literature value.

6.

7.

8.

9.

10.

REFERENCES

1.

2.

3.

4.

5.

Parella, R.; Kumar, A.; Babu, S. A., Catalytic

Friedel–Crafts

acylation:

magnetic

nanopowder CuFe2O4 as an efficient and

magnetically separable catalyst. Tetrahedron

Letters 2013, 54 (13), 1738-1742.

Mayr, H.; Striepe, W., Scope and limitations of

aliphatic Friedel-Crafts alkylations. Lewis acid

catalyzed addition reactions of alkyl chlorides

to carbon-carbon double bonds. The Journal

of Organic Chemistry 1983, 48 (8), 1159-1165.

Posternak, A. G.; Garlyauskayte, R. Y.;

Yagupolskii, L. M., A novel Brønsted acid

catalyst

for

Friedel–Crafts

acylation.

Tetrahedron Letters 2009, 50 (4), 446-447.

Park, S.; Ikehata, K.; Watabe, R.; Hidaka, Y.;

Rajendran, A.; Sugiyama, H., Deciphering

DNA-based asymmetric catalysis through

intramolecular Friedel–Crafts alkylations.

Chemical communications 2012, 48 (84),

10398-10400.

Nia, A. H.; Amini, A.; Taghavi, S.; Eshghi, H.;

Abnous, K.; Ramezani, M., A facile Friedel–

Crafts acylation for the synthesis of

polyethylenimine-grafted multi-walled carbon

nanotubes as efficient gene delivery vectors.

International journal of pharmaceutics 2016,

502 (1-2), 125-137.

Deng, Q.; Qin, Z.; Yang, Y.; Song, W.,

Synthesis, characterization of triphenyltin

grafted on SBA-15 mesoporous silica and its

catalytic performance for the synthesis of 4methylacetophenone. Chinese Journal of

Chemical Engineering 2015, 23 (2), 384-388.

Patel, J. J.; Karve, M.; Patel, N. K., A novel

approach to synthesize carboxymethyl guar

gum via friedel craft acylation method.

MMAIJ 2014, 10 (1), 18-22.

Sartori, G.; Maggi, R., Use of solid catalysts in

Friedel− Crafts acylation reactions. Chemical

reviews 2006, 106 (3), 1077-1104.

Jaimol, T.; Pandey, A.; Singh, A., Selective

acetylation

of

toluene

to

4methylacetophenone over zeolite catalysts.

Journal of Molecular Catalysis A: Chemical

2001, 170 (1-2), 117-126.

Gopalakrishnan, M.; Sureshkumar, P.;

Kanagarajan, V.; Thanusu, J., Aluminium

metal powder (atomized) catalyzed Friedel–

Crafts acylation in solvent-free conditions: A

facile and rapid synthesis of aryl ketones

under microwave irradiation. Catalysis

Communications 2005, 6 (12), 753-756.

Rabiya Javed Awan, LUMS School of Science and Engineering