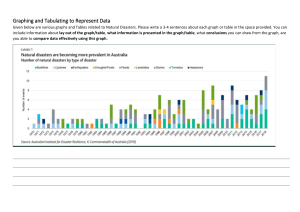

Supply Chain Mindmapping Mindmap for Supply Chain Risk Management green & ethical seals norms ISO90001 revision standards Globalization is increasing the frequency with which supply chains are affected by disruptions such as natural disasters and epidemics at some link in the chain. Such risk events can have far-reaching consequences and long-lasting impact. Companies must ensure that their supply chains are prepared for such risks. Together with software vendor Riskmethods, Supply Chain Movement has created this mindmap for supply chain risk management, outlining the route with road signs indicating the potential hazards along the way. products services higher natural disasters oil disasters nuclear disasters smog/air pollution ecological disasters Brexit North Korea SCM Impact on companies natural risks avoid issues sanction control EU sustainability regulation UK slavery act conflict minerals strikes civil unrest terrorist attacks political uncertainty supply chain design supply chain planning supplier relationship management structured data unstructured data suppliers logistic hubs own plants countries own customers detect patterns with AI/Deep Learning implement Integrated Business Planning through big data monitoring global scope risk as part of ethical compliance multi-tiered supply networks Diagnose geopolitical exposures Diagnose Supply Act Review improve internal collaboration criteria for awarding business part of audits ongoing supplier qualification incentives to share sub-suppliers Review visibility risk beyond Tier-1 network collaboration needed new skills & talents required Chain Risk Plan Management Plan Do Plan supply chain entities risk scoring lack of sub-tier visibility to unknown logistics service providers (Hanjin) dependency on outsourcing foreseeable disruptions elimination of reputational impacts quick response to unpredictable crisis inherent/latent threat detection cumulative risks along regions, tiers and commodities identification of supply threats Check Execute impact evaluation Execute early warning detection leading indicators’ patterns onboarding of risky partners best-price procurement lack of supplier development procurement focus on savings Execute create sub-tier visibility understanding of focus understanding of mitigation levers building product redundancy improve anticipation & mitigation capabilities financially Risk management solutions derive impact quality impact parameters to solve challenge to detect impact patterns to cancel noise generate workflows automated relevance checks 4 supply chain challenges 3 trade-offs justification of investments in risk management fast crisis response prevention activities skills development individual metrics prepared plans ready preventive risk mitigation support experts available Mindmap manual As supply chains become ever-more global in nature, there is a corresponding increase in the likelihood of them being affected by risk events – not only natural disasters, but also financial volatility, disruptions to infrastructure, political instability and man-made risks. But there are other unknown threats in addition to these familiar ones. Companies must be prepared for every possible risk: Plan. Supply chain risks have a fairly broad impact on an organization. From a financial perspective, companies must evaluate the business at risk they are willing to take or mitigate. To limit damage to their reputation and further knock-on effects, companies must make plans to withstand the potential for product recalls and PR campaigns. Risks invariably lead to an increase in rules. Analyzing the impact of threats gives insight into the possible consequences, which can then translate into impli- cations for its supply chains: Do. Supply chain risks create a need for better planning and place greater pressure on delivery reliability. Upstream supply chain disruptions could definitely cause production interruptions and distribution delays. The dependence on IT is not only an operational risk, but is also crucial in gaining an overview of, and responding to, disasters. It is necessary to carefully analyze the implications and the operational bottlenecks in the supply chain: Check. There are several different approaches to mitigate supply chain risk. Supply chain visibility enables companies to monitor possible dangers. Developing a number of scenarios can provide insight into causes and effects. Flexibility and buffers to soften the blow of disruptions can be created in various ways, savings risk mitigation costs and supply chain collaboration could also offer solutions. Tighter controls may be necessary. By taking these precautionary measures, companies will be better prepared to act appropriately when faced with a wide variety of supply chain threats. Act. performance bonus structure S U P P LY C H A I N M O V E M E N T, N o . 2 7 , Q 4 2 0 1 7 S U P P LY C H A I N M O V E M E N T, N o . 2 7 , Q 4 2 0 1 7 28 Time To Recovery (TTR) alternative sourcing relocation times relocation time/lead times total time to recovery inventory levels products/customers affected procurement logistics manufacturing CSR department quality lack of internal collaboration between on category level revenue profit Plan bribery human rights gender equality Execute Diagnose regulatory pressures working conditions workers safety Review Plan infrastructural risks bankruptcy carriers fire at suppliers Diagnose secure environmental compliance brand protection across E2E supply chain human risks Review SUPPLY CHAIN movement high fines market exclusions blocker to win new business shareholder concern zero-tolerance for non-compliance IT system breakdowns closure of logistics hubs Creators mindmap: short lead times smaller delivery slots costly manufacturing stoppage lack of total visibility costly activation of 2nd source 2 The perfect storm tsunami storms floodings volcano eruption draught wildfires Hanjin 1 customer behavior expectations JIT JIS vulnerable supply chains child labor disease outbreaks image- & reputation damage by social media harbor airports distribution centers warehouses boarders Lean low inventory buffers requirements sustainable products ethical compliance service level differentiation demanding service levels 29