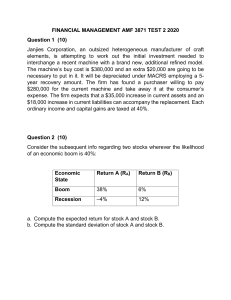

Mobilkrane TECHNICANS MANUAL SLI-System DS350C <X>DEMAC. ·� S.Weinberger 8333.2 • Technical Training SLI DS350C Service Manual This manual was produced by the technical troining department. lt is designed for customer service specialists who possess working knowledge of the SLI functions; for this reason are functional descriptions kept to a minimum. 2nd revised edition 711994 S. Weinberger r:":mannes;f;ärfn Dematic - Mobile Cranes Technical Training NDS350Cl SLI DS350C Manual Table of Contents lmportant Notes 3 Description of System Hardware and Interface AC95 Hardware and Interface AC155 Hardware and Interface AC205 5 6 7 Functions -Settings -lnspections 8 Operating/Display Console LCD, Function of Display Sections Keyboard 9 13 Keypad A, Push-Button and Indicator Light Function 13 Keypad B, Functions 16 18 View of Keypad A and Keypad B Setting the Operating Mode Checks before Starting Work Troubleshooting 19 20 21 Notes on Programming Programming the DS350C 22 Transducers Pressure Transducer - Type DAVS301 23 1st Length/Angle Transducer - LWG220/3 Angle Transducer - Type WG103 24 25 2nd Length Transducer - Type LG152 3rd Length Transducer - Type LG208 26 27 28 Hoist Limit Switch (A-2-B) Error-Code Chart Error-Code Numbers and Designations 29 31 Error Code Indication Glossary 39 Abbreviations and Specialist Terms AppendixA AC95, Telescoping Sequences AC155, Telescoping Sequences AC205, Telescoping Sequences Example of a Load Chart Print-out of Operating Modes SLI Standard Terminal Diagram Al A2 A3 AS A7 A9 AppendixB Central Unit Contents - System Description Central Unit with Printed Circuit Boards Bl BI B2 Appendix C - Miscellaneous Cl Using the DEMAG-Testadapter Notes SLI\.DS350Cl 1140 SLI DS350C Manual Important Notes Description of System The system DS350C as used by us is made up of a central microprocessor unit and an operating/display console, both housed in a sheet metal casing which is built into the instrument panel one lengthlangle transducer one (AC95) or several (AC155/AC205) length transducers one pressure transducer and one or more hoist limit switches The SLI works according to the principle of comparison between desired value and actual value The desired value corresponds to the load curve and is preselected on the computer using the contents ofthe loaddata-EPROM; it changes when the length or the angle of the boom is altered when the operating mode is adjusted. The actual value is determined by force and/or pressure determination. The microprocessor constantly compares desired value and actual value: if the actual value is equal to the desired value, the overload cut-off device is actuated, resulting in all crane movements which increase the Ioad torque being shut down. Boom length and angle are determined by length and angle transducers. These are located in cable drums on the side of the basic boom section. The length of telescopic boom is recorded by the cable which is also used to transmit signals from hoist limit switch, electrics in main boom head and main boom extension. Angle of telescopic boom is determined by means of an angle transducer; angle and length of main boom extension, if fitted, are entered with the code for the operating mode. Loading of crane is determined by means of a pressure transducer which measures the pressure in piston side of luffing cylinder. When ignition is switched on, the SLI-computer automatically begins a sequence to test its system; following items are tested: Contents ofMemory (EPROM) for valid data Electronic Components Reference Voltages Output State of Relays Limiting Value ofTransducers An error-code nurnber is displayed if a fault is recognised during test sequence. SLI\DS350Cl 3/40 SLI DS350C Manual lmportant Notes After successful completion oftest sequence, the operator must enter following on operating/display console: operating mode corresponding to operating status; number of rope falls and telescoping sequence If signals given by the crane's electrical system via transducers and controls correspond to these settings, they are acknowledged by the computer and the system is ready for operation; otherwise a fault reading will be given. Figure 1 shows central unit and arrangement of boards --r----�-24 :lllt JIOtU------../;---.;---, r-__ ,_.........,. =��-=%: ..---r----t:uu:r1,.. -----+-""!le ;T!:.�.„c1 „„ ,,„,.,..,"',„. " '"' 1 -'fll.---24 ..i. - =...:; ;:. _,, ... 11---....J 4/40 ._____„ SLI\DS350Cl SLI DS350C Manual lmportant Notes Hardware and Interface - AC 95 Compact SLI DS350C shared housing for operating/display console and central unit System Modules in eurocard layout Connectingboard with six 2 amp fuses, one connecting plug each for transducers and crane electrics on rear of housing Power supply board Analogboard CPU main board with CPU module, processor 80C537 Display unit Dot-Matrix-LCD, with background illumination Keyboard module, foil-keyboard with short-stroke keys Data-EPROM module with one EPROM (256 KB) each for crane data and load data Connectingboard Serial interface (=plug) for connecting the programming device Force Measurement in piston side of luffingcylinder with pressure transducer 0 - 300 bar, type DAV8 301 Angle Measurementfor telescopic boom with angle transducer WG103, 0° - 90°, located in length/angle transducer housing LWG220/3 Length Measurementfor extended boom sections entire telescopic boom with length transducer located in length/angle transducer housing LWG220/3; basic boom length f telescopic boom retracted - with proximity switch B51 l Slewing Range Measurementfor superstructure locked over rear with proximity switch B43 Pilot-Pressure 1l'leasurement when extending boom sections in pilot line, by means of pressure switch B703 - 2.5 bar Hoist Limit Switch (A-2-B) for hoist on main boom head and/or main boom extension 3 Relay Outputs 1. Overload By-pass possible with key-operated switch 8700 2. Hoist Limit Switch (A-2-B) By-pass possible with key-operated switch 8701 3. Telecylinder Release, dependent on software By-pass possible with key-operated switch 8703 SLI\DS350Cl 5/40 Manual SLI DS350C Important Notes Hardware and Interface - AC 155 Compact SLI DS350C shared housing for operating/display console and central unit System Modules in eurocard layout Connectingboard with six 2 amp fuses, one connecting plug each for transducers and crane electrics located on rear of housing Power supply board Analogboard CPU main board with CPU module, processor 80C537 Display unit Dot-Matrix-LCD, with background illumination Keyboard module, foil-keyboard with short-stroke keys Data-EPROM module with one EPROM (256.KB ) each for crane data and load data Connectingboard Serial interface (=plug) for connecting the prograrnming device Force Measurement in piston side of luffingcylinder with pressure transducer 0 - 300 bar, type DAVS 301 Angle Measurement for telescopic boom with angle transducer WG103, 0° - 90°, located in length/angle transducer LWG220/3 Length Measurement for extended boom sections entire telescopic boom with length transducer located in length/angle transducer LWG220/3 1 st boom section extended with length transducer LG152 1 st boom section retracted with proximity switch B511 2nd boom section retracted with proximity switch B512 Slewing Range Measurementfor superstructure locked over rear with proximity switch B43 Pilot-Pressure Measurement when extendingboom sections in pilot line, by means of pressure S\\<itch B703 - 2.5 bar Pilot-Pressure Measurement when raisingmain boom with luffingcylinder for EC acceptance Hoist Limit Switch (A-2-B) on main boom head and/or main boom extension 5 Reiay Outputs 1. Overload, by-pass possible with key-operated switch S700 2. Hoist limit switch, by-pass possible with key-operated switch S701 3. 1 st Telecylinder release, and 4. 2nd Telecy/inder release, dependent on software by-pass of #3. and 4. functions possible with key-operated switch S703 5. Control of telescopic boom, locking Ist telecylinder, dependent on software 6140 SLI'\DS350Cl Manual SLI DS350C lmportant Notes Hardware and Interface - AC 205 Compact SLI DS350C shared housing for operating/display console and central unit System Modules in eurocard layout Connecting board with six 2 amp fuses, one connecting plug each for signals of transducers and crane electrics located on rear of housing Power supply board Analog board CPU main board with CPU module, processor 80C537 Display unit Dot-Matrix-LCD, with background illumination Keyboard module, foil-keyboard with short-stroke keys Data-EPROM module with one EPROM (256 KB) each for crane data and load data Connecting board Serial interface (=plug) for connecting a prograrnming device Force Measurement in piston side of luffing cylinder with pressure transducer 0 - 300 bar, type DAVS 301 Angle Measurement for telescopic boom with angle transducer WG103, 0° - 90°, located in length/angle transducer L WG220/3 Length Measurement for extended boom sections entire telescopic boom with length transducer in L WG1, B702, type L WG220/3 Ist boom section extended with length transducer 2, B705, type LWG152 1 st boom section retracted with proximity switch B511 2nd boom section axtended with length transducer 3 , 8706, type 208 2nd boom section retracted with proximity switch B512 3rd/4th/5th boom section retracted with proximity switch B513 Slewing Range Measurement for superstructure locked over rear with proximity switch B43 Piiot Pressure 1vleasurement when extending boom sections in pilot line, by means of pressure switch 8703 - 2.5 bar Pilot Pressure Measurement when raising main boom for EC acceptance Hoist Limit Switch (A-2-B) on boom head and/or main boom extension 5 Relay Outputs 1. Overload, by-pass possible with key-operated switch S700 2. Hoist Limit Switch, by-pass possible with key-operated switch 8701 3. Ist Telecylinder Release, and 4. 2nd Telecylinder Release, dependent on software By-pass of #3. and 4. possible with key-operated switch 8703 5. Control ofTelescopic Boom, locking l st telecylinder, dependent on software SLI'\DS350Cl 7/40 Manual SLI DS350C Functions - Settings - Inspections Operating/Display Console with two important tasks: Input through keypads, for instructions to the system Display of important information and data on a sectioned LCD and indicator lights DEMAG K J B C Hoioi0� 88 88 ""''l"G ! L p G es L'\ - 5 ·--··· ·���' H- AB80808 ···-··· G .t"':I.� LCD -Anzeige �w_rmoooo�m1rrnoocooou�uuwoo1 i0ss �& :� 0,,s-� 0 a� o[iJ a:a F A Error ----t-M =BB OBJ3 ..: · 0 D · Limit Information N 1 E Tastenfeld B Tastenfeld A (�� � �'i n�m � @l'; Lampe! Taste5 Taste9 Lampe2 Taste6 Taste!O Lampe3 Taste7 Tastell � [Q] : [ill [QJ] [illJ J J ��[Q] 1[Q]J�� '\ [iJ � [Q] ) \ � [illJ � � Lampe4 Taste8 1 1 Taste12 Fig. 2 Operating/Display Console DS350C, LCD in test sequence mode 8/40 SLI\DS350C2 Manual SLI DS350C Functions - Settings - Inspections LCD with sectioning displaying all necessary information: --- ····-------- K . - ------ ·1 - ---- J c B 0 A ! ,·---'- M D BHHBBBBB Limit Infonnation V i - N E Fig 3, LCD in test sequence mode Function of Displp,y Sections ,--�·--1 L _� .. ,---& � · ! -�-. ! A Overload Symbol red background, flashes when 100% of rated load is exceeded and if an error occures. '0' appears simultaneously in section M B Prewarning Symbol amber background, flashes when 9 0% of rated load is reached and if an error occures. 'P' appears simultaneously in section M C Hoist Lim it Symbol appears when a hoist limit switch has been tripped or when there is a fault in the electrical circuit of the hoist limit switch. 'H' appears simultaneously in section :M: and indicator light and audible alarm are switched on. SLI\DS350C2 9/40 Manual SLI DS350C Functions - Settings - Inspections I__ 8ft8,8 .. . · · · · · j i=J : __ -_ D Grane Data Display selected data is given in connection with crane symbol E, or pressure in piston side of luffing cylinder ( 13) or actual load moment (8): code of desired info is entered on keypad B and is acknowledged with C E Grane Sym bol 5 displays crane dimensions which can be selected. The dimensions are designated with arrows and code numbers [1,2,3, 4,5, 9 ]; select the desired code on keypad B and acknowledge with push-button C. Data is displayed on section D. The selected dimension is indicated by a flashing dimensional arrow. F Load Display for normal crane operation the total load is displayed; if tare symbol G appears, net load is displayed G Tare Sym bol appears, when the lifting tackle is tared by pressing tare button 7 on keypad A, in order to have the net load displayed on F; if radius is changed or ignition is switched off briefly, this function is erased and F displays the total load again Note: Total load includes weight of hook block, hoist rope and all lifting tackle Net load is the load on hook without any lifting tackle; Display faults may occur due to external factors such as, for example, wind which affects crane and load H Load Display shows rated load (capacity) corresponding to present operating status 10/40 SLl\DS350C2 Manual SLI DS350C Functions - Settings - Inspections J Load Mom ent Display (Bargraph display) shows what proportion of the presently permissible load moment is being exploited. The load moment fluctuates constantly when the boom is moved and therefore the load moment display also fluctuates; this display is divided into three coloured sections green, safe working range,0 - 90% of load moment am ber, prewarning range, 90 - 100% of load red, overload range, above 100% of load moment K Operating Mode Display and Sym bol shows the code of operating mode. This code must correspond to the number valid for the current operating status and load curve. Check that this is the case! These numbers are given in operating mode table, which is supplied with every central unit. When an operating mode is automatically altered, e.g. for various boom lengths, the change is displayed here. If the computer selects a rigging program, a 9 appears as second digit and the amber prewarning indicator light flashes simultaneously. EEEE appears simultaneously to fault display E04 before acknowledgement is given. The code to be set can be found in the load chart: Press function key, enter code and acknowledge pushing C. L Reeving Display displays reeving number (= number of rope falls) to which the SLI is set; to enter: actuate push-button 6 in section A, enter number of falls on keypad B and 1E�i�J!§J !n1 acknowledge with push-button C .. � 1 Limit Informatio 1 BBBB.B.BB��J SLI\DS350C2 M Fault Display if the system recognises malfunction, an error code number will be displayed; fault and remedy is given :i.."1 an error-code table N Text Display Code number for extension sequence or extension length in% 11140 Manual SLI DS350C Functions - Settings - Inspections 0 Display "On Outriggers" or "On Rubber" 1-h symbol is displayed when operating mode "crane on outriggers" is selected, r-h symbol is displayed when operating mode "crane on rubber" is selected. P we do not use this function. 12/40 SLI\DS350C2 Manual SLI DS350C Functions - Settings - Inspections Keyboard The keyboard is divided into two sections: Keypad A, left-hand side: function keys, indicator lights for prewarning, overload, and hois Keypad B, right-hand side: input of codes and acknowledgement Always acknowledge operating mode after switching on ignition: press push-button 5 on pad A, then push-button C on pad B. Keypad A, Push-Button and Indicator Lights Panel, Function: Tastenfeld A I I��� 1 il 00 [Qj Leuchte 2 Taste6 Taste 10 3 Taste7 Tastell Leuchte 4 Taste8 Tastel2 ��[QJ Leuchte ·,......_ ,_ _ - ___ i ) ,/ __ Indicator Light 1, Red: Hoist Limit Switch Alarm comes on when a hoist limit switch opens or when an error occurs in its electric circuit, an audible alarm is given at same time and crane movements: raise hoist, extend telesections and lower boom are cut off 'H' appears as an error display in section M Indicator Light 2, Amber: Prewarning comes on when 90% of currently permissible load molllent is reached and overload situation is imminent; " P " appears as an error display in section M; flashes when an erecting program is selected Indicator Light 3, Red: Overload Alarm comes on when 100% of currently permissible load moment is exceeded; Crane movements: raise hoist, extend telesections and lower boom are shut down. '0' appears as an error display in section M SLI'\DS350C2 13/40 an SLI DS350C Manual Functions - Settings - Inspections Indicator Light 4: no function assigned Push-Button 5: Clearance for Operating Mode Input always actuate before entering an operating mode number; lights up when pressed confi.rming clearance. Enter operating mode on keypad B. The display comes up in section K of LCD. The operating mode entered must always correspond to operating status of crane. Setting the Code 1. 2. 3. 4. 5. Determine operating status using valid load chart Assign code for operating status Actuate push-button 5, keypad A, button lights up Enter code on keypad B, e.g. 1 Acknowledge with push-button C, keypad B. The light in push-button 5 goes out Push-Button 6: Clearance for Setting Number of Rope Falls (Rope Reeving Number) always actuate before entering number of falls; lights up when pressed confirming clearance. Enter number of falls on keypad B. The display comes up in section L of LCD. The enterediactual number of falls must correspond to that specified for operating status (exception: special lifts). Setting Number of Falls: 1. 2. 3. 4. Determine number of falls for operating status using load chart Actuate pltsh-button 6, keypad A, button lights up Enter number of falls on keypad B Acknowledge with push-button C, keypad B. The light in push-button 6 goes out Push-Button 7: TARE for switching on tare function, which deducts weight of lifti..'1.g tackle, hook and hoist rope from load display: After push-button has been pressed, load display F is set to zero = tared. The tare symbol appears in section G of LCD. A flashing "O" appears on load display F for net load. If a load is then raised, F flashes the resultant weight. This function is switched off when the radius is altered or by switching ignition off and on again. Push-Button 8: Horn Acknowledge for switching off audible alarm 14/40 SLI\DS350C2 SLI DS350C Manual Functions - Settings - Inspections Push-Button 9: Input of Wanted Extension Boom Sequence identical boom lengths can be achieved with different extension sequences of boom sections : 1. Determine code for extension sequence using load chart 2. Actuate push-button 9, button lights up 3. Enter code on keypad B 4. Acknowledge with push-button C. Button 9 goes out. Subsequently actuate boom section as detailed in operating manual. The selected boomlength appears in section M for approx. 2 seconds. lf 100% of boom are extended MX will be displayed. Push-Button 10: no Function Assigned Push-Button 11: no Function Assigned Push-Button 12: no Function Assigned SLI\DS350C2 15/40 SLI DS350C Manual Functions - Settings - Inspections Keypad B, Functions: Tastenfeld B '"\ �� [Eill : 1 [ill] [ill] � 1 1 ��� 1 1 1 Codes for operating mode, rope reeving and extension sequence are entered after the desired function has been preselected on keypad A. The functions do not need to be preselected for purposes of displaying crane data. After inputting and acknowledging with push-button C, section Don LCD displays the desired information. Codes are explained on crane symbol in section E and in the followlng table. Input Display 1 2 3 Length of main boom Angle of main boom Working radius 4 5 8 9 13 Angle of main boom extension Tip-Height Current load moment Length of boom extension Pressure in luffing cvlinder in bar, piston side Push-Button ''.Asterix": no function assigned Push-Button "C": Acknowledge button, used to acknowledge input of crane data, operating mode, rope reeving and extension sequence 16/40 SLI\DS350C2 SLI DS350C Manual Functions - Settings - Inspections DEMAG K fl�M�m 88 88 � � s.s G F - J B C A 6 g nfü1iillliiürn nonrnmrn�an�&1n j 1 f 1"'-?fG ßß 09. 8-'- CJlLJ bd (jJ 0 -0 5 u - -- - _____ __J .t-:1..� LCD -Anzeige Error 1sE1s . __ 0 M _ =Ü[] q 800 )tJw D ·=- � ====a=a�-os:-_ ,G_a-2����-=,_e=i=·ei=i=ie="e�� H t::: / .,,.-·- Tastenfeld A - - :� (� � Lampe! � Taste5 . · ----- .... ,,...-.,. -- \ / ......._ - Tastenfeld B --·- -········ --- --....... \ �il[ill) [illJ �; ·- Taste9 : � (00] [QJ : : � [illJ [illJ : : i � [gJ : ; [illJ [illJ @J 1 Lampe3 Taste? Taste II 1 1 1 � ßill � : �� � [QJ:� \ ) \ La.mpe4 -...__ SLI\JJS350C2 __ - Taste8 -- - Tastel2 ----- ,/ ___ '----- -- 17/40 - -------- ------ ---- --- _ ) __„ Manual SLI DS350C Functions - Settings - Inspections View of Keypad A and Keypad B Tastenfeld B Tastenfeld A (� � �': � 00 g: 1 J Taste5 Leuchte 2 Taste6 Leuchte 3 Taste7 Taste 11 : Leuchte 4 Taste8 Tastel2 J Leuchte 1 \ Taste9 Taste ! 1 ·---- -- - - _ . - - - - --"\ ! [illJ [QJJ rmJ [Q]J [illJ [illJ 1 1 ���I 10 1 ��[QJ1 � � [QJI ·"--··-· [illJ [Im [ill] //' ' \.,"--- --- _../· 18/40 SLI\DS350C2 Manual SLI DS350C Functions - Settings - Inspections S etti ng Operating Mode The SLI must always be set corresponding to operating status ofcrane. The SLI will otherwise neither cut off correctly nor display correct data. Codes must always be entered when the operating status of crane has been altered. Following data is required: 1. Operating Mode 2. Reeving of Hook Block 3. Extension Sequence of Boom Sections Setting procedure is identical for all functions: 1. Press Preselect Button, this must light up 2. Enter Code Number 3. Acknowledge with Button C, the p reselect button must then go out, indicating that computer has accepted the setting. Settin g Operating Mode 1. Press push-button 5 on keypad A, preselect operating mode, button lights up. The previously selected operating mode is displayed an section K of LCD 2. Enter operating mode (from load chart) on keypad B, checking entry on section K of LCU 3. Press push-button C to acknowledge setting which has just been entered. Pre-select button goes out Always acknowledge operating mode after switching on ignition: press push-button 5 on keypad A, then push-button C on keypad B Setting Rope Reeving 1 . Press push-button 6 on keypad A, preselect rope reeving, button lights up. The previously selected rope reeving arrangement is displayed an section L of LCD 2. Enter rope reeving on keypad Bin accordance with load chart, checking entry on section L of LCD. 3. Press push-button C to acknowledge setting which has just been entered, pre-select button goes out. Setting Extension Sequence 1. Press push-button 9, preselect extension sequence, button lights up. The previously selected extension sequence is displayed on section N of LCD. 2. Euter code for extension sequence on keypad Bin accordance with load chart. The desired extension sequence is briefly displayed in% in section N of LCD, display returns to actual extended length. 3. Press push-button C to acknowledge setting which has just been entered, pre-select button goes out, SLI is ready for operation. SLI\DS350C2 19/40 SLI DS350C Manual Functions - Settings - Inspections Checks before starting Work Hoist Limit Switch (A-2-B) Position of shift weight: with even number of rope falls - on dead end of rope with uneven number of rope falls - on the fall wich moves slowest. If a main boom extension has been fitted: hoist limit switch must be removed from main boom head and located on main boom extension. Cable must be connected and by-pass plug inserted in terminal box on boom head. The system does not function if hoist limit switch and shift weight are not changed over and connected Hoist Limit Switch Indicator Light and Audible Alarm, for this purpose, lift shift weight: Carefully pull hook block up against shift weight. As soon as the hook block lifts the weight, the alarm must sound, indicator light come on and "raise hoist" function be shut down. Lower hook block slightly to alleviate this condition. Next, lower or extend boom to reproduce a hoist limit condition. When the hook g or telescoping procedure be shut down. block subsequently raises the shift weight, the alarm must sound, indicator light come on and luffin If indicator lamp or alarm do not function as described and crane movements are not shut down, the system is not in füll working order. Fin d and rectify the fault. Check: all Gable Connections for damage Gable Drum for smooth rotation, pretensioning and correct winding in of electric cable Displayed Boom Length must correspond to actual boom length Displayed Angle must correspond to actual boom angle Displayed Working Radius must correspond to actual working radius Pressure Transducer and Connecting Hoses for oil leaks All faults must be rectified before work with crane is started 20/40 SLI\DS350C2 Manual SLI DS350C Functions - Settings - lnspections Troubleshooting If the CPU recognises malfunction, the LCD displays an error code number (E .....) on section M. All possible code numbers are listed in an error code chart, where reference to the cause is given. Faults and corresponding remedies are described. Faults on central unit and transducers must be rectified by specialist qualified personnel as the system can only be checked thoroughly using a programming unit. If errors occur, inform our after sales service departement immediately. Faults due to Operating Mistakes Faults caused by specified operating ranges being exceeded or by operating mistakes, (error reading EOl, E02, etc.) can be rectified directly by the crane operator. SLI\DS350C2 21140 Manual SLI DS350C Notes on Programming Programming the DS350C This system is programmed differently to SLI-systems otherwise used by DEMAG. The ready fitted telescopic boom is set on a test stand at 2° and weighed in 7 or 11 different sectional lengths (corresponding to standard and special extension sequences). A "master" pressure transducer is used to make measurements whilst the pressure transducer which is subsequently to be fitted on the crane makes measurements in parallel. This second pressure transducer is adjusted if a tolerance of 2 bar is exceeded. Measured values are recorded by a PC and the corresponding program is written into an EEPROM*. The ready assembled crane is tested with loads on the test bed. Any program adjustments which are found to be necessary are then carried out, including adjustments to basic setting of transducers. After testing is completed, data are converted from the programmed EEPROM into an EPROM*, which is placed into the computer. All program corrections pass through a data logger into the original program, producing an increasingly accurate data program. This means that fewer corrections are required with time. *Info on EEPROM 'and EPROM: an EEPROM is erased using voltage, an EPROM using UV light. 22/40 SLI\DS350C3 Manual SLI DS350C Transducers Pressure Transducer Type DAVS 301 A pressure transducer is used for determination of force. lt measures pressure in piston side of luffing cylinder. In a body shaped as a steel pipe is fitted an amplifier from one side and from the other side there is inserted another steel pipe which is connected to hydraulic circuit to be measured. On outside of this second steel pipe there are four strain gauges fitted. These are connected to a füll bridge circuit and wirde to an amplifier which has been calibrated by the manufacturer. The pipe is filled with plastic compound tö protect electronics against moisture, vibration or shock. The strain gauge bridge circuit is supplied with a stabilised voltage. When depressurized, diagonal voltage (signal) equals zero. When pressure in luffing cylinder builds up, resistance of strain gauges changes resulting in a voltage which is amplified and fed to central unit. A transducer must not be fixed with a tight clamp as this leads to incorrect ! measurements. Electrical Connection: -·-·-·-·-·-·-·-·-·- 4-pin cannon plug, double-shielded cable Hydraulic Connection: _jfli��if--�_,��ilr-� f rr 'E ' mo.T1 Inner thread M16 x 1 .5 __ Measured Value: Power Supply : 0 to 300 bar !101 +/-5.000 V Signal: � 0 to -1 .000 V linear Checks: release all hydraulic pressure from transducer unfasten pipes; load moment or pressure must not be displayed on LCD, Signal 0.000 V constant, tolerance 20 mV Balancing: only possible with software Important: always replace if accident damage has occured to the boom. '' ' ' '' ' ''' '' 1 s A B C l . 1·-t-.-1.. .J._.L.-1, . . 8701.1 L --'1 -·-·-·-·-· SLI\DS350C4 23/40 0 „. Manual SLI DS350C Transducers lst Length/Angle Transducer Type LWG 22013 fitted on left-hand side of basic boom section. The upper edge of housing is :flush with upper edge of basic boom section. The cable of the reeldrnm is secured to the sheave head. Each extending or retracting movement of boom drives a lOk0-1 0-turn potentiometer via two plastic gears; the larger gear wheel slips on the shaft of potentiometer if too much force occures, thus avoiding any damage. Pre-Tensioning: of cable reel drum approx. 5 turns Zero Setting, Mechanical: fully retract all boom sections, turn setscrew (=potentiometer shaft) a small amount to the right and then carefully to the left stop Voltage Supply: 5.000 V across two protective resistors; interuptions and short circuits in measuring system can thus be identified. Balancing: Connect a digital voltmeter across potentiometer, balance to 4.000 V Signal voltage at basic boom length 0.500 V, if necessary adjust with trimming potentiometer on PCB Test: fully extend all boom sections, compare display with actual length Fine Balancing: only possible with software · SCHIRH· A+SV LGI A-Gt.D l/Gf SCHIRH -·-v- 1i911r·rr·-rn·-·,-r·- �J�.N. r r r r . ... -·---,.. - 1D C A 2_ 8 1_·4uo ., � 1 - ..______. - 24/40 i _J · · - - - ·-·-·-· - · · · SLI'-DS350C4 Manual SLI DS350C Transducers Angle Transducer (WG) Type WG103 fitted inside housing of LWG 220/3, it must be set in a way that its upper edge is flush with upper edge of basic boom section. The potentiometer of angle transducer is housed in an aluminium casing which is filled with liquid silicone to dampen oscillating movements. The axle of potentiometer is moved by a pendulum. Potentiometer Range: 5 kQ, 356° Subarea 90°: used to measure boom angle; residual winding is used as series resistance for monitoring of range. Voltage Supply: 5.000 V Signal Voltage: 9 0° 0° 45° �„„ -- -'*"""- 1 .875 V 3.1 25 V 2.500 V Fine Balancing: only possible with software . . . . . ·-·-.-· ' . . . 1 ·-· 1 1 -·-·-·-·-·-·-·-·-· SLI\DS350C4 25/40 _J SLI DS350C Manual Transducers 2nd Length Transducer, for AC155 and AC205 TypeLG152 fitted on left-hand side of basic boom section, the length measuring cable is secured on collar of first boom section and measures its extending/retracting movements. A 10 kO 1,0-turn potentiometer is driven through turning of reel drum. Zero Setting, Mechanical: Fully retract Ist boom section, turn pot shaft a small amount to the left and then carefully to the right stop, looked from outside on potentiometer; if necessary loosen clamping screw of friction coupler. Pre-Tensioning: of cable reel drum approx. 5 turns. Voltage Supply: 5.000 V across two protective resistors; interuptions and short circuits in measuring system can thus be identified. Balancing: Connect a digital voltmeter on potentiometer, balance to 4.000 V Signal voltage at basic boom length 0.500 V, if necessary adjust with trimming potentiometer on PCB Control test: fully, extend lst boom section, Compare display with actual length s.oov Fine Balancing: 1 only possible with software ·-·-·-·-·-·-·-·-·- � �-1i�-s2ii- '1L ·- · · ·-· _,X700,�,rrrr ll .. . -·-+-· e H J.G 8 7 3 E F ·-·-1 ·-·-·-·-·-·-·-·-· 26/40 i _j J SLI\DS350C4 Manual SLI DS350C Transducers 3rd Length Transducer, for AC205 TypeLG208 fitted on left-hand side of basic boom section, the length measuring cable is secured on 2nd boom section and measures its extending/retracting movements. A 10 kn 10-turn potentiometer is driven from turning of reel drum. Zero Setting, Mechanical: Fully retract first boom section, turn pot shaft a small amount to the right and then carefully to the left stop, as looked on potentiometer. Pre-Tensioning: of the cable reel drum approx. 5 turns Voltage Supply: 5.000 V across two protective resistors; interuptios and short circuits in measuring system can thus be identified Balancing: Connect a digital voltmeter to the potentiometer, balance to 4. 000 V Signal voltage at basic boom length 0.500 V, if necessary adjust with trimming potentiometer on PCB Control test: fully extend lst boom section Compare display with actual length Fine Balancing: only possible witli. software 11 /10 ,„ Jun rai SLI\DS350C4 27/40 SLI DS350C Manual Transducers Hoist Limit Switch (A-2-B) A circuit is wired: from computer, A700, terminal 23 across transducer B705. 7 Length transducer B702.7, interference PCB Slip ring E702.2 Length transducer cable, brown Hoist limit switch X550.6, with two protective resistors 4.7 k.Q and 1 k.Q connected in parallel back across shield slip ring E702. 1 interference board, length transducer B702.8, length transducer B705.8 back to computer, A700, terminal 22 A comparator on PCB recognises broken circuit, short circuit or hoist limit switch open/closed; on terminal 23: 7.1 5 V closed circuit, 4.6 V open circuit. 1.403 kn resistance with closed circuit, hoist limit switch relay picked up; 24 V from terminal 16 to K701/coil; with open circuit a hoist limit switch-actuated-signal is given. Hoist limit switch and by-pass plug with 826.Q resistor are connected in series. The hoist limit switch is always mounted on the boom head currently in use, the by-pass plug is closing open circuit, otherwise the device will not function. 1 A700 1 ·-·-·-· -pJ-·-·-·-·-·-·--""' vz ·-·-·-·'lT · 1 r-air· rr · -.n·-·SCllIRH -.r·- ·-·-·-·-·-L·-·-·-·-·-·-·-·-·-·-·-·-·-·-·-·-·-·-·- x�.2 lf<-IUSSE lfS 8705 X700 , --·-· r r LGI A-� llGI 1 0 C A 8 ·-·-·-·:· . 1 ' -·-·---·+-· ·-·-·-· L • S IB •••. l� ; r xsso., r -·-·-·-·�· L.-·-· ! A+SV 6El� 'N r r r I" l K 8702 , --·-· SCHIRlf r L ·��-: 1 .l550.l r.,..�:1..-.-----� ,Pf ! l � r ·-·-·-·-·-·-·-·-·-- � .1550·3 ��- L . .. .. .. oder I or � i · .------· ········: : 1 2: :„„„„„„„„„ „„„„„„„: .rsso.a � t1 JSS'll', XSSO-• L ,Pf rf-----f , xsso .2 L.......... � . : IS50.1 10 .••• ISSO-� 1 Jn xsso.1 J -·-·-·-·-·-·-·-·-· : \_ 1k '2 'Pf tt 4: f� rsso.s "- ·-·:ito·--· � 'PE oll hitr Sdli,.. lhitld •tcrts htrt } l j Mil i FlEll HI.V G!TTfliMSTTEr!. Mil FIER HI.V tASIDISPITlr :. „ ..: : 1ta 1 : L_„„„„.„„�„„ .J • • 28/40 SLI\DS350C4 SLI DS350C Manual Error Code Chart Error-Code Numbers and Designations This table is valid only for cranes with SLI type DS350C A large proportion of possible faults is diagnosed by the computer and is listed here. If an error number is displayed which is not given in the table, contact our Service Department. Please note that an electronics specialist is needed to rectify mahy of the faults listed. CodeNumber 0 p H EEEE Error Designation Overload, 100%, safe working load exceeded Prewarning at 90% to 100% of safe working load Hoist limit switch tripped (A-2-B) Operating Mode not acknowledged, see also E04 EOl Radius range fallen short/angle range exceeded E02 E04 Radius range exceeded/angle range fallen short Operating mode not acknowledged E05 Illegal length range E06 Angle range fallen short with luffing fly jib E07 Nq remote indication from overload relay E08 No remote indication from limit switch relay(A-2-B) E09 No remote indication from relay 2 EU Telescopic boom length: signal below lower limiting value E12 Luffing cylinder piston side: signal below lower limiting value E13 Luffing cylinder rod side: signal below lower limiting value E14 Luffing fly jib force: signal below lower limiting value E15 Main boom angle: signal below lower limiting value E16 Luffing fly jib angle: signal below lower limiting value E17 2nd length input: signal below lower limiting value E18 E19 New DAT-EPROM (chanel level switch off) Reference voltage defect E20 Analog voltages not present E21 Telescopic boom length: upper limiting value exceeded Luffing cylinder piston side: upper limiting value exceeded E22 E24 Luffing cylinder rod side: upper limiting value exceeded Luffing fly jib force: upper limiting value exceeded E25 Main boom angle: upper limiting value exceeded E23 E26 Luffing fly jib angle: upper limiting value exceeded E27 2nd length input: upper limiting value exceeded SLI'-DS350C5.DOC 29/40 SLI DS350C Manual Error Code Chart Code Number Error Designation E29 E31 E38 E39 E41 E42 E 43 E 45 E 46 E47 E49 Reference voltage defect Error in system program Programs in EPROM's not compatible System program and load chart-EPROM not compatible Error in internal RAM of CP 80C537 Error in Ist section of external RAM Error in 2nd section of external RAM Redundancy error in A/D converter (ADC) E51 Error in crane data-EPROM or -EEPROM E52 E56 E57 E58 Error in load chart EPROM Error in crane data EPROM Error in serial crane data EPROM Error in serial EPROM of analog PCB E72 E73-E77 Error in ADC uPD7004 Buffered RAM disturbed Wrang data with online operation Error with relay K2 Error with relays K3 to K7 E83 E84 E86 incorrect telescoping sequence incorrect operating mode incorrect percentage for at least one boom section E88 incorrect main boom angle with luffing fly jib operation 30/40 SLI\DS350C5.DOC Manual SLI DS350C Error Code Chart Error Code Indication System Message 0 'Overload', Crane overloaded, 100% exceeded P 'Prewarning', Prewarning at 90% to 100% H a) Hoist limit switch tripped (A-2-B) b) c) d) Interuption in hoist limit switch circuit Short circuit in hoist limit switch circuit Accidental ground/earth in hoist limit switch circuit EEEE Operating mode not acknowledged or not present (see also E04) Error Messages Error EOl Radius range fallen short Cause Remedy Boom raised to far Move main boom to radius or angle corresponding to load chart or angle range exceeded with main boom operation E02 Radius range exceeded or angle range fallen short with main boom operation Boom lowered to far Move main boom to radius or angle corresponding to load chart E04 Operating mode not acknow ledged a) Operating mode not acknowledged after selftest of SLI-device b) SLI adjusted to wrong operating mode c) Digital input missing a) Carry out acknowledging striking of keys always after switching on power or seiftest of SLI resp. b) Set operating mode corresponding to crane status and carry out acknowledging c) Check digital inputs for correct function SLI\DS350C5. DOC 31/40 SLI DS350C Manual Error Code Chart Error E05 Illegal length range Cause Remedy a) Boom is extended to far or not fart enough e.g. with Operating modes 'on wheels' where maxim um boom length is limited or with Operating modes for luffing fly jib w here the boom has to be extended to a certain length a) Move boom sections to length corresponding to operating mode b) Retract boom completely and check initial tension of reel drum, the cable must be tight; open housing of length transducer and adust poti to basic boom length with turning shaft with a srewdriver carefully ccw to its stop c) Check coupler or change b) Adjustment of length-poti is wrong because cable was fallen off from reel drum c) Coupler between drive and poti defective or gear is sliding on shaft of poti d) 5 V supply for . E06 Angle range fallen short with luffing fly jib operation transducers missing because of a short in one of the cables to the transducers e) Cable defective or loose from CPU to length transducer f) Poti of length transducer defective g) Digital input of basic boom length is switched on despite boom being extended gear/0-ring, clean shaft of poti from oil and adjust basic boom length as described in para b) d) Check all voltages, if they are correct change computer; if voltages are not present or will break down with a load of 50 n check cables to transducers for a short and replace if required e) Check cables and plugs and change them if required f) Check poti and change it if required, adjust basic boom length as described in para b) g) Check cable and switch for digital input and change if required Angle of luffing fly jib fallen short because radius is to big. Correct radius or angle Move luffing fly jib in working range corresponding with load is given in load chart of actual status of crane chart of actual status of crane E07 No remote indication from overload relay Blackout of overload relay, defective or not actuated Check relay; replace connecting board if required EOS No remote indication from hoist limit switch relay (A-2- Blackout of relay, defective or not actuated Check relay; replace connecting board if required B) 32/40 SLI\DS350C5.DOC Manual SLI DS350C Error Code Chart Error E09 EU No remote indication from relay 2 Signal i n measuring channel 1 for telescopic boom length is below lower limit Remedy Cause Blackout of relay 2, defective or not actuated Change relay; if no success change connecting board a) Cable from central unit to a) Check cable and plug length transducer defective or water in plug connector connector and replace if b) Lenght-poti defective b) Check length-poti and required if required, adj ust c) Elektronic component in change measuring channel defective basic boom length afterwards El2 Signal i n measuring channel c) Chanrre analof! PCB a) Cable from central unit to a) Check cable and plug connector and replace if pressure transducer 2 for pressure transducer on luffing cylinder piston side is defective or water in plug below lower limit connector b) Check pressure b) Pressure transducer transducer and replace if defective required c) Elektronic component in measuring channel defective E13 Signal in measuring channel 3 for pressure transducer on luffing cylinder rod side is below lower limit Change analog PCB a) Cable from central unit to a) Check cable and plug connector and replace if defective or water in plug required connector b) Check pressure b) Pressure transducer transducer and replace if defective c) Elektronic component in required c) Change analog PCB Signal i n measuring channel a) Measuring channel open, a) Connect load cell below lower limit e.g. load cell not connected b) Cable from central unit to connector and replace load cell defective or water required 4 for load on luffing fly jib is in plug connector c) Load cell defective d) Elektronic component in measuring channel defective E15 c) pressure transducer measuring channel defective E14 required Signal i n measuring channel 5 for angle of main boom is below lower limit if c) Check load cell and replace if required c) Change analog PCB a) Cable from central unit to a) Check cable and plug connector and replace if length/angle transducer defective or water in plug required connector b) Check angle transducer b) Angle transducer and replace defective c) Elektronic component in measuring- channel defective SLI\DS350C5. DOC b) Check cable and plug 33/40 c) if required Change analog PCB E18 New DAT-EPROM (chanel level switch off) SLI DS350C Manual Error Code Chart Error E23 Remedy Cau se a) Cable from central unit to a) Check cable and plug Signal in measuring channel 3 for pressure transducer on pressure transducer connector and replace if luffing cylinder rod side defective or water in plug required exceeded upper limit connector b) Check pressure defective c) Elektronic component in transducer and replace if required c) Change analog PCB b) Pressure transducer measurinir channel defective E24 Signal in measuring channel 4 for load cell on luffing fly jib exceeded upper limit e.g. load cell not connected a) Connect load cell b) Check cable and plug load cell defective or water required a) Measuring channel open, b) Cable from central unit to connector and replace in plug connector c) Load cell defective d) Elektronic component in c) if Check load cell and replace if required d) Change analog PCB measurinir channel defective E25 Signal in measuring channel a) Cable from central unit to a) Check cable and plug exceeded upper limit length/angle transducer defective or water in plug 5 for angle of main boom connector b) Angle transducer defective c) Elektronic component in connector and replace if required b) Check angle transducer and replace if required c) Change analog PCB measuring- channel defective E26 Signal in measuring channel 6 for angle of luffing fly jib exceeded uppf(r limit a) Cable from central unit to a) Check cable and plug angle transducer defective or connector and replace if water in plug connector b) Angle transducer defective c) Elektronic component in required b) Check angle transducer and replace if required c) Change analog PCB measurinl.? channel defective E27 Signal in measuring channel 7 for 2nd length input exceeded upper limit a) Cable from central unit to a) Check cable and plug 2nd length transducer defective or water in plug connector b) Check 2nd length defective required b) 2nd length transducer c) Elektronic component in measuring channel for 2nd length inout defective E29 Reference voltage defective connector and replace if required a) Total of supply and reference voltages on measuring point (MP) 10 is >3.3V b) A/D- Converter (ADC) defective transducer and replace if c) Change analog PCB a) Check supply voltages; if one of this voltages is not present a short in cable to a transducer might be the reason, check cables and plug connectors, replace if required b) Change p ower supply board with ADC SLI\DS350C5.DOC 35/40 SLI DS350C Manual Error Code Chart Error Cause Remed_y Replace system programm EPROM E31 Data in system programm Wrong system program EPROM does not match data EPROM in central unit in data EPROM E38 Programs do not match Wrong EPROM in central unit Check version numbers of EPROM's and insert EPROM's corresponding to type of crane and serial number E39 System program and load chart program do not match Wrong EPROM in central unit Check version numbers of EPROM's and insert EPROM's corresponding to type of crane and serial number E41 Error in internal RAM o f CP 80C537 E42 Error in Ist section of external RAM of CP 80C537 E43 Error in 2nd section of external RAM of CP 80C537 E45 Redundancy error in AJDconverter (ADC) a) Replace CP 80C537 b) Replace main board with CPU module a) Replace CMOS-RAM b) Replace main board with CPU module a) Replace CMOS-RAM b) Replace main board with CPU module • E46 Error in AJD-converter (ADC) uPD7004 No remote indication from ADC E 47 Buffered RAM disturbed CRC giving faulty result E49 Wrong data with online No valid data in RAM after operation programming with online interface E51 1 ADC on CPU module and ADC of CP 80C357 are giving different results probably because of a short in cables to a transducer or water in plug connector a) Check supply voltages; if one of this voltages is not present a short in cable to a transducer might be the reason, check cables and plug connectors, replace if required b) Replace main board with CPU module a) Replace power supply board b) Replace main board with CPU module a) Retract boom completely, error will possibly be reset b) Check buffer battery, replace if required c) replace main board with CPU module Error in crane data EPROM or E EPROM a) No valid data in EPROM b) Jumpers located wrong on Data EPROM module c) Data EPROM defective a) Replace RAM extension b) Replace online interface c) Replace main board with CPU module a) Load valid data into crane data EPROM b) Locate jumpers corresponding to type of E PROM c) Reolace data EPROM 36140 SLI\DS3 50C5.DOC Manual SLI DS350C Error Code Chart Error Remed_y Cause E52 Error in load chart EPROM E56 Errar in crane data EPROM E57 Error in serial crane data EEPROM a) No valid data in serial crane data EEPROM b) Data EPROM module defective a) Copy valid testprogram data into EEPROM and restart SLI b) Replace data EPROM module Error in serial EPROM of a) No valid data in serial analog board data EPROM b) Analog board defective a) Capy valid testprogram data into EEPROM and restart SLI b) Replace data EPROM module E58 E72 Remote indication of relay K2 gives error-message; Monitoring contact gives message 'relay off' despite relay should have picked up, or vice versa E73/ E77 E83 Likewis E 72 but for relays K3 ta K7 Load chart EPROM defective a) Reset SLI b) Replace laad chart EPROM a) Jumpers wrang located an a) Locate jumpers corresponding to type of Data EPROM module b) Data EPROM defective EPROM b) Reolace data EPROM a) Relay K2 or connecting board defective b) Main board defective a) Check relay and connecting board, replace if required b) Replace main board see E72 see E72 Incorrect telescoping a) Telescoping sequence a) Select valid telescoping sequence selected is not in programmed load chart of crane b) Digital inputs da not correspond with selected telescooin� seouence seqence b) Check digital inputs, replace switches if required a) Select valid operating mode ' E84 Wrang operating mode Operating mode selected is not programmed for this crane E86 Incorrect percentage displayed for at least one telesection Displayed percentage is <-2% or > 106% E88 \Vrong main boom angle with luffing fly jib operation a) Main boom is not in angle position for luffing fly jib operation b) Angle determination of main boom defective Check all length transducers, retract telescopic boom completely, error will than be reset SLI\DS350C5.DOC 37/40 a) Move main boom in angle position prescribed for luffing fly jib b) Check angle transducer and reolace if reouired Manual SLI DS350C Glossary Abbreviations and Specialist Terms AID Analog/Digital ADC Analog/Digital Converter Basic boom section Root section of a telescopic boom B asic length Length of a fully retracted telescopic boom CMOS Complementary Metal-oxide Semiconductor, high-resistance, medium-fast CPU Central Processing Unit, central unit, microprocessor, arithmetic and control Wlit of a computer CRC Cyclic RedWidancy Check, intemal independent test procedure for data transmission/processing DAVS Type designation for pressure transducers used DMS Strain gauge EEPROM Electric Erasable Read Only Memory, programmable with voltage eraseable read-only memory EPROM Erasable Read Only Memory, programmable, with UV-light erasable read-only memory LCD Liquid Crystal Display LG Length transducer LWG Length/angle transducer MP Measuring Point PC Personal Computer PCB Printed Circuit Board Pot, Poti Potentiometer RAM Random Access Memory, read/write memory can be inscribed and erased as desired ?range exceeded defined voltage value which indicates incorrect or correct ?range fallen short defined voltage value which indicates incorrect or correct SLI Safe Load Indicator Transducer Designation for LG, WG, DAV or load cell UV Ultra Violet WG Angle transducer SLI\DS350C6 39/40 = Load limit device