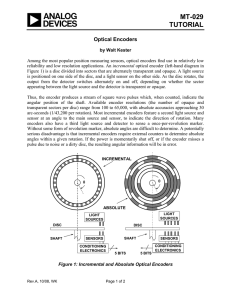

INCREMENTAL ENCODER INTERFACE Incremental rotary encoders generate an output signal each time the shaft rotates a certain angle. The number of signals (pulses) per turn defines the resolution of the device. The incremental encoder does not output an absolute position, which makes the internal components of the encoder much simpler and more economical. Besides position tracking, incremental encoders are often used to determine velocity. The position in relation to the starting point can be calculated by counting the number of pulses. The velocity can be retrieved by dividing the number of pulses by the measured time interval BEI type GHU 930 2048 009 encoder with output signal in HTL & TTL working principle.docx. TYPE GHU 930// 5G 29 //2048//G5R// **D4** as shown in the data sheet. . ORDERING REFERENCE (Contact the factory for special versions, ex: shaft size, resolution, connection) Shaft IP Supply Output stage Output signals Resolution Connection Orientation Reduction hub Anti-rotation GHU9 X 30: 30mm Reduction hub available 01: IP66 Digital signals: 2G2, 5G2, 5G5 2048 max G6: M23 12 pins CW G8 : M23 12 pins CCW R : radial ** : No reduction hub U2 : Reduction hub DW**: 9445/045 2:5Vdc 5:11 to 30Vdc G2: driver 5Vdc RS422 G5 : push-pull 9: AA/ BB/ ZZ/ Sine-wave signals: 2WT, 5WT GP: PUR cable 12 wires G3: PVC cable 8 wires Example : R020 : radial cable 2m 2: 5Vdc 5:11 to 30Vdc WT: sine 1Vpp N: SS/ CC/ ZZ/ Ex: GHU 9X 30 / 01 / 5 G2 9 // 01024 // GP R050 // ** DW** Made in France Changes possible without further notice - Version 140604 BEI Sensors SAS Espace Européen de l’Entreprise 9, rue de Copenhague B.P. 70044 Schiltigheim F 67013 Strasbourg Cedex Tél : +33 (0)3 88 20 80 80 Fax : +33 (0)3 88 20 87 87 Mail : info@beisensors.com Web : www.beisensors.com Basic Principle Incremental Encoder Incremental rotary encoders provide a serial output signal on a single transmission line. One sensor must be connected to one controller. An incremental encoder has at least 1 output signal “A” or typically 2 output signals, called “A” and “B”. These 2 signals are set up with a 90° offset, which is required for the detection of the encoder’s rotation. By turning the encoder clockwise, the “A” pulse is rising 90° ahead of the “B” pulse, by turning the shaft counterclockwise, the “B” pulse is rising ahead of the “A” pulse. Additionally some incremental encoders output a “Z” signal. Once every rotation, this Z signal is rising for typically 90°, on the exact same position. This can be used as an accurate reference point. Some incremental encoders also have additional differential signals, called “/A”, “/B” and “/Z”. These signals are inverted “A”, “B” and “Z” signals. Controllers can compare each pair (“A” must be equal to inverted “/A”) to ensure that there is no error during the transmission. Additionally the transmission sensitivity is improved by transmitting the differential signals through a twisted pair cable. Typical pulse diagram Encoder Characteristics Pulses per revolution (PPR): An incremental rotary encoder outputs a certain amount of Pulses per Revolution. The higher this PPR number, the smaller the angle between each pulse. This PPR number is fixed for ordinary incremental encoders. Programmable incremental encoders can adjust this value to a desired number by a software change. Output drivers: Today most incremental encoders have a Push-Pull (HTL) or RS422 (TTL) output driver, these have replaced most of the older output circuits like Open Collector NPN, Open Collector PNP, Voltage Output. A) Push-Pull (HTL) Push-Pull (HTL) circuits, also known as Totem Pole, provide a signal level which corresponds to the applied supply voltage. The supply voltage typically ranges from 8 to 30 VDC. With proper connections you can use the Push Pull interface to replace true open collector circuits by using an external diode connected in a way to limit the direction of the current for B) RS422 (TTL) RS422 (TTL) circuits provide a constant 5 V signal level that is not dependent on the supply voltage. Two supply voltage ranges can be selected: From 4.75 to 5.5 VDC (can be used to replace open collector output drivers) or from 8 to 30 VDC. Using differential signals the output fully complies to the RS422 standard. The differential outputs have the highest frequency response capability and the best noise immunity. To ensure this the receiver should also be a differential. Replacement of Older Output Drivers 1) PNP open collector replacement (Current source) 2) NPN open collector replacement (Current Sink) Programmable Incremental Encoder Non programmable incremental encoders can only be configured at the factory to the customer’s specs. However, if application requirements change, with programmable incremental encoder it is very simple to adjust some key characteristics. By changing certain parameters in the software with the help of an external configuration tool (UBIFAST Configuration Tool), customers can modify the PRODUCTS INDUSTRIES NEWS ABOUT US CONTACT ________________________________________ Products Communication Interface Incremental INCREMENTAL ENCODER INTERFACE Incremental rotary encoders generate an output signal each time the shaft rotates a certain angle. The number of signals (pulses) per turn defines the resolution of the device. The incremental encoder does not output an absolute position, which makes the internal components of the encoder much simpler and more economical. Besides position tracking, incremental encoders are often used to determine velocity. The position in relation to the starting point can be calculated by counting the number of pulses. The velocity can be retrieved by dividing the number of pulses by the measured time interval. Basic Principle Incremental Encoder Incremental rotary encoders provide a serial output signal on a single transmission line. One sensor must be connected to one controller. An incremental encoder has at least 1 output signal “A” or typically 2 output signals, called “A” and “B”. These 2 signals are set up with a 90° offset, which is required for the detection of the encoder’s rotation. By turning the encoder clockwise, the “A” pulse is rising 90° ahead of the “B” pulse, by turning the shaft counterclockwise, the “B” pulse is rising ahead of the “A” pulse. Additionally some incremental encoders output a “Z” signal. Once every rotation, this Z signal is rising for typically 90°, on the exact same position. This can be used as an accurate reference point. Some incremental encoders also have additional differential signals, called “/A”, “/B” and “/Z”. These signals are inverted “A”, “B” and “Z” signals. Controllers can compare each pair (“A” must be equal to inverted “/A”) to ensure that there is no error during the transmission. Additionally the transmission sensitivity is improved by transmitting the differential signals through a twisted pair cable. Typical pulse diagram Encoder Characteristics Pulses per revolution (PPR): An incremental rotary encoder outputs a certain amount of Pulses per Revolution. The higher this PPR number, the smaller the angle between each pulse. This PPR number is fixed for ordinary incremental encoders. Programmable incremental encoders can adjust this value to a desired number by a software change. Output drivers: Today most incremental encoders have a Push-Pull (HTL) or RS422 (TTL) output driver, these have replaced most of the older output circuits like Open Collector NPN, Open Collector PNP, Voltage Output. A) Push-Pull (HTL) Push-Pull (HTL) circuits, also known as Totem Pole, provide a signal level which corresponds to the applied supply voltage. The supply voltage typically ranges from 8 to 30 VDC. With proper connections you can use the Push Pull interface to replace true open collector circuits by using an external diode connected in a way to limit the direction of the current for B) RS422 (TTL) RS422 (TTL) circuits provide a constant 5 V signal level that is not dependent on the supply voltage. Two supply voltage ranges can be selected: From 4.75 to 5.5 VDC (can be used to replace open collector output drivers) or from 8 to 30 VDC. Using differential signals the output fully complies to the RS422 standard. The differential outputs have the highest frequency response capability and the best noise immunity. To ensure this the receiver should also be a differential. Replacement of Older Output Drivers 1) PNP open collector replacement (Current source) 2) NPN open collector replacement (Current Sink) Programmable Incremental Encoder Non programmable incremental encoders can only be configured at the factory to the customer’s specs. However, if application requirements change, with programmable incremental encoder it is very simple to adjust some key characteristics. By changing certain parameters in the software with the help of an external configuration tool (UBIFAST Configuration Tool), customers can modify the Incremental output driver – set the output driver to Push-Pull (HTL) or RS422 (TTL) Pulses per revolution – program the PPR to a defined value Incremental pulse direction – choose “A before B“ or “B before A“ Device programmability is very significant for distributors, system integrators or machine builders since it helps them reduce inventories. Now, they can hold a relatively small stock of ‘standard’ models and set them up for specific applications on an as-needed basis. Specifications Voltage Output Levels: A logic gate interprets certain input voltages as high (logic 1) or low (logic 0). TTL (transistor-transistor-logic): A signal above 2 V is interpreted as logic 1 and a signal less than 0.8 V is interpreted as logic 0. The output voltage ranges between 0-5 V. HTL (high-threshold-logic): A signal above 3 V is a logic 1 and a signal less than 1 V is a logic 0. The high output signal level is dependent from the supply voltage. Because of the higher voltage difference between logic 0 and 1, the HTL logic is more immune to interference and more resistant against electrical noise. Logic Signal Level Supply Voltage Output Voltage TTL HTL High Low High Low 4.75-30 V 4.75-30 V 4.75-9 V 9-30 V 4.75-30 V min 3 V max 0.5 V min 3 V min Supply Voltage - 3 V max 0.5 V Table 1: Output levels of POSITAL incremental rotary encoders (I=50 mA per channel) Electrical and Mechanical Degree: Mechanical degree is the actual rotation of the shaft in degrees. Electrical degree is used for electrical signals. The required time for completing one alternating voltage/current cycle is defined as 360 electrical degrees (el°). For incremental encoders, one cycle is equal to one complete pulse. With a given PPR the electrical degree can be converted to mechanical degree for any incremental encoder. Quadrature: Every 90 el° the incremental encoder outputs a rising or falling edge on the “A” or “B” output that can be interpreted as a count. If an encoder outputs 1000 PPR, a counter can interpret 4000 counts (4 counts each pulse). Phase Angle: The phase angle states the length between 2 edges, given in el°. This parameter is typically specified with a defined constant phase angle value and phase angle error (also called quadrature error). Accuracy (DNL): The DNL accuracy is the phase angle error as an absolute value given in (mechanical) degrees. Accuracy (INL): An incremental encoder outputs a defined amount of pulses per revolution, so that every pulse is expected to be on a defined mechanical position. The maximum deviation between this ideal position and the actual position is called integral non linearity (INL). The INL accuracy is an important value if the incremental encoder is used for positioning tasks. Duty Cycle: The duty cycle describes the ratio between “high” time to “low” time of an incremental encoder. Typically this ratio is 50/50, which is equivalent to 180 el° high and 180 el° low. The performance of magnetic incremental encoders increases with higher PPR settings and higher rotation speeds (RPM). This is in contrast to optical encoders where the performance decreases. The DNL and INL accuracy that are stated in our datasheets are worst case values, a better performance can be expected for higher PPR and RPM. Frequency Response: This is the maximum frequency that the encoder is able to output via the output lines. For example, the frequency of a 200 PPR encoder that rotates at 600 RPM is 2000 Hz Device programmability is very significant for distributors, system integrators or machine builders since it helps them reduce inventories. Now, they can hold a relatively small stock of ‘standard’ models and set them up for specific applications on an as-needed basis. Specifications Voltage Output Levels: A logic gate interprets certain input voltages as high (logic 1) or low (logic 0). TTL (transistor-transistor-logic): A signal above 2 V is interpreted as logic 1 and a signal less than 0.8 V is interpreted as logic 0. The output voltage ranges between 0-5 V. HTL (high-threshold-logic): A signal above 3 V is a logic 1 and a signal less than 1 V is a logic 0. The high output signal level is dependent from the supply voltage. Because of the higher voltage difference between logic 0 and 1, the HTL logic is more immune to interference and more resistant against electrical noise. Logic Signal Level Supply Voltage Output Voltage TTL High Low 4.75-30 V 4.75-30 V min 3 V max 0.5 V HTL High Low 4.75-9 V 9-30 V 4.75-30 V min 3 V min Supply Voltage - 3 V max 0.5 V Table 1: Output levels of POSITAL incremental rotary encoders (I=50 mA per channel) Electrical and Mechanical Degree: Mechanical degree is the actual rotation of the shaft in degrees. Electrical degree is used for electrical signals. The required time for completing one alternating voltage/current cycle is defined as 360 electrical degrees (el°). For incremental encoders, one cycle is equal to one complete pulse. With a given PPR the electrical degree can be converted to mechanical degree for any incremental encoder. Quadrature: Every 90 el° the incremental encoder outputs a rising or falling edge on the “A” or “B” output that can be interpreted as a count. If an encoder outputs 1000 PPR, a counter can interpret 4000 counts (4 counts each pulse). Phase Angle: The phase angle states the length between 2 edges, given in el°. This parameter is typically specified with a defined constant phase angle value and phase angle error (also called quadrature error). Accuracy (DNL): The DNL accuracy is the phase angle error as an absolute value given in (mechanical) degrees. Accuracy (INL): An incremental encoder outputs a defined amount of pulses per revolution, so that every pulse is expected to be on a defined mechanical position. The maximum deviation between this ideal position and the actual position is called integral non linearity (INL). The INL accuracy is an important value if the incremental encoder is used for positioning tasks. Duty Cycle: The duty cycle describes the ratio between “high” time to “low” time of an incremental encoder. Typically this ratio is 50/50, which is equivalent to 180 el° high and 180 el° low. The performance of magnetic incremental encoders increases with higher PPR settings and higher rotation speeds (RPM). This is in contrast to optical encoders where the performance decreases. The DNL and INL accuracy that are stated in our datasheets are worst case values, a better performance can be expected for higher PPR and RPM. Frequency Response: This is the maximum frequency that the encoder is able to output via the output lines. For example, the frequency of a 200 PPR encoder that rotates at 600 RPM is 2000 Hz