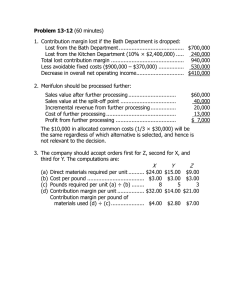

Exercise 3-2 1. The direct materials and direct labor costs listed in the exercise would have been recorded on four different documents: the materials requisition form for Job W456, the time ticket for Jamie Unser, the time ticket for Melissa Chan, and the job cost sheet for Job W456. 2. The costs for Job W456 would have been recorded as follows: Materials requisition form: Blanks Nibs Quantity 20 480 Unit Cost $15.00 $1.25 Total Cost $300 600 $900 Time ticket for Jamie Unser Started Ended 11:00 AM 2:45 PM Time Completed 3.75 Rate Amount Job Number Rate Amount Job Number $9.60 $36.00 W456 Time ticket for Melissa Chan Started Ended 8:15 AM 11:30 AM Time Completed 3.25 Job Cost Sheet for Job W456 Direct materials............ Direct labor: Jamie Unser .............. Melissa Chan ............. $900.00 36.00 39.65 $975.65 $12.20 $39.65 W456 Exercise 3-5 a. Raw Materials .................... Accounts Payable .......... 80,000 b. Work in Process ................. Manufacturing Overhead .... Raw Materials ............... 62,000 9,000 c. Work in Process ................. Manufacturing Overhead .... Wages Payable ............. 101,000 11,000 d. Manufacturing Overhead .... Various Accounts .......... 175,000 80,000 71,000 112,000 175,000 Exercise 3-9 1. Actual direct labor-hours........................... × Predetermined overhead rate ................ = Manufacturing overhead applied ............ Less: Manufacturing overhead incurred ..... Manufacturing overhead underapplied ....... 11,500 $18.20 $209,300 215,000 $ (5,700) $5,700 2. Because manufacturing overhead is underapplied, the cost of goods sold would increase by $5,700 and the gross margin would decrease by $5,700. Exercise 6-3 1. The profit graph is based on the following simple equation: Profit = Unit CM × Q − Fixed expenses Profit = ($16 − $11) × Q − $16,000 Profit = $5 × Q − $16,000 To plot the graph, select two different levels of sales such as Q=0 and Q=4,000. The profit at these two levels of sales are -$16,000 (=$5 × 0 − $16,000) and $4,000 (= $5 × 4,000 − $16,000). Profit Graph $5,000 $0 Profit -$5,000 -$10,000 -$15,000 -$20,000 0 500 1,000 1,500 2,000 2,500 3,000 3,500 4,000 Sales Volume in Units Exercise 6-5 1. The following table shows the effect of the proposed change in monthly advertising budget: Sales With Additional Current Advertising Sales Budget Difference Sales .............................. $180,000 $189,000 Variable expenses ........... 126,000 132,300 Contribution margin ........ 54,000 56,700 Fixed expenses ............... 30,000 35,000 Net operating income ...... $ 24,000 $ 21,700 $ 9,000 6,300 2,700 5,000 $ (2,300) Assuming no other important factors need to be considered, the increase in the advertising budget should not be approved because it would lead to a decrease in net operating income of $2,300. Alternative Solution 1 Expected total contribution margin: $189,000 × 30% CM ratio.................. Present total contribution margin: $180,000 × 30% CM ratio.................. Incremental contribution margin ........... Change in fixed expenses: Less incremental advertising expense . Change in net operating income............ $56,700 54,000 2,700 5,000 $ (2,300) Alternative Solution 2 Incremental contribution margin: $9,000 × 30% CM ratio ..................... Less incremental advertising expense .... Change in net operating income............ $2,700 5,000 $ (2,300) Exercise 6-5 (continued) 2. The $2 increase in variable expense will cause the unit contribution margin to decrease from $27 to $25 with the following impact on net operating income: Expected total contribution margin with the higher-quality components: 2,200 units × $25 per unit ..................... Present total contribution margin: 2,000 units × $27 per unit ..................... Change in total contribution margin........... $55,000 54,000 $ 1,000 Assuming no change in fixed expenses and all other factors remain the same, the higher-quality components should be used. Exercise 6-6 1. The equation method yields the break-even point in unit sales, Q, as follows: Profit = $0 = $0 = $3Q = Q= Q= Unit CM × Q − Fixed expenses ($15 − $12) × Q − $4,200 ($3) × Q − $4,200 $4,200 $4,200 ÷ $3 1,400 baskets 2. The equation method can be used to compute the break-even point in dollar sales as follows: CM ratio = = Unit contribution margin Unit selling price $3 = 0.20 $15 Profit = $0 = 0.20 × Sales = Sales = Sales = CM ratio × Sales − Fixed expenses 0.20 × Sales − $4,200 $4,200 $4,200 ÷ 0.20 $21,000 3. The formula method gives an answer that is identical to the equation method for the break-even point in unit sales: Unit sales to break even = = Fixed expenses Unit CM $4,200 = 1,400 baskets $3 4. The formula method also gives an answer that is identical to the equation method for the break-even point in dollar sales: Dollar sales to break even = = Fixed expenses CM ratio $4,200 = $21,000 0.20 Exercise 8-3 Activity Cost Pool Caring for lawn .................... Caring for garden beds– low maintenance ............... Caring for garden beds–high maintenance ..................... Travel to jobs....................... Customer billing and service . Estimated Overhead Cost Expected Activity $72,000 $26,400 150,000 20,000 $41,400 15,000 $3,250 $8,750 12,500 25 square feet of lawn square feet of low maintenance beds square feet of high maintenance beds miles customers Activity Rate $0.48 per square foot of lawn $1.32 per square foot of low maintenance beds $2.76 per square foot of high maintenance beds $0.26 per mile $350 per customer The activity rate for each activity cost pool is computed by dividing its estimated overhead cost by its expected activity. Exercise 8-4 K425 Activity Cost Pool Supporting direct labor ......... Machine processing .............. Machine setups .................... Production orders ................. Shipments ........................... Product sustaining ................ Total ................................... M67 Activity Cost Pool Supporting direct labor ......... Machine processing .............. Machine setups .................... Production orders ................. Shipments ........................... Product sustaining ................ Total ................................... $6 $4 $50 $90 $14 $840 $6 $4 $50 $90 $14 $840 Activity Rate per per per per per per direct labor-hour machine-hour setup order shipment product Activity Rate per per per per per per 80 100 1 1 1 1 direct labor-hour 500 machine-hour 1,500 setup 4 order 4 shipment 10 product 1 Activity ABC Cost Activity ABC Cost direct labor-hours machine-hours setups order shipment product direct labor-hours machine-hours setups orders shipments product $ 480 400 50 90 14 840 $1,874 $ 3,000 6,000 200 360 140 840 $10,540 Exercise 8-5 Sales ($1,850 per standard model glider × 20 standard model gliders + $2,400 per custom designed glider × 3 custom designed gliders) Costs: Direct materials ($564 per standard model glider × 20 standard model gliders + $634 per custom designed glider × 3 custom designed gliders) ..... Direct labor ($19.50 per direct labor-hour × 26.35 direct labor-hours per standard model glider × 20 standard model gliders + $19.50 per direct labor-hour × 28 direct labor-hours per custom designed glider × 3 custom designed gliders)............................................... Supporting direct labor ($26 per direct labor-hour × 26.35 direct labor-hours per standard model glider × 20 standard model gliders + $26 per direct labor-hour × 28 direct labor-hours per custom designed glider × 3 custom designed gliders)............................................... Order processing ($284 per order × 4 orders) ....... Custom designing ($186 per custom design × 3 custom designs) Customer service ($379 per customer × 1 customer) ...................................................... Customer margin.................................................... $44,200 $13,182 11,915 15,886 1,136 558 379 43,056 $ 1,144 Exercise 12-2 1. Margin = = 2. Net operating income Sales $600,000 = 8% $7,500,000 Turnover = = Sales Average operating assets $7,500,000 = 1.5 $5,000,000 3. ROI = Margin × Turnover = 8% × 1.5 = 12% Exercise 12-3 Average operating assets ...................... £2,800,000 Net operating income............................ Minimum required return: 18% × £2,800,000 ............................. Residual income ................................... £ 600,000 504,000 £ 96,000 Exercise 12-4 1. Throughput time = Process time + Inspection time + Move time + Queue time = 2.7 days + 0.3 days + 1.0 days + 5.0 days = 9.0 days 2. Only process time is value-added time; therefore the manufacturing cycle efficiency (MCE) is: MCE = Value-added time 2.7 days = = 0.30 Throughput time 9.0 days 3. If the MCE is 30%, then 30% of the throughput time was spent in value-added activities. Consequently, the other 70% of the throughput time was spent in non-value-added activities. 4. Delivery cycle time = Wait time + Throughput time = 14.0 days + 9.0 days = 23.0 days 5. If all queue time is eliminated, then the throughput time drops to only 4 days (2.7 + 0.3 + 1.0). The MCE becomes: MCE = Value-added time 2.7 days = = 0.675 Throughput time 4.0 days Exercise 13-3 1. Cost of purchasing ....................... Direct materials ............................ Direct labor .................................. Variable manufacturing overhead .. Fixed manufacturing overhead, traceable1.................................. Fixed manufacturing overhead, common.................................... Total costs ................................... Difference in favor of continuing to make the carburetors ................. 1 Per Unit Differential Costs Make Buy $14 10 3 $35 2 $29 $35 15,000 units Make Buy $210,000 150,000 45,000 $525,000 30,000 $435,000 $525,000 $6 $90,000 Only the supervisory salaries can be avoided if the carburetors are purchased. The remaining book value of the special equipment is a sunk cost; hence, the $4 per unit depreciation expense is not relevant to this decision. Based on these data, the company should reject the offer and should continue to produce the carburetors internally. 2. Make Buy Cost of purchasing (part 1) ............................ $525,000 Cost of making (part 1) ................................. $435,000 Opportunity cost—segment margin foregone on a potential new product line ................... 150,000 Total cost...................................................... $585,000 $525,000 Difference in favor of purchasing from the outside supplier .......................................... $60,000 Thus, the company should accept the offer and purchase the carburetors from the outside supplier. Exercise 13-4 Only the incremental costs and benefits are relevant. In particular, only the variable manufacturing overhead and the cost of the special tool are relevant overhead costs in this situation. The other manufacturing overhead costs are fixed and are not affected by the decision. Total for 20 Per Unit Bracelets Incremental revenue ............................. $169.95 $3,399.00 Incremental costs: Variable costs: Direct materials ............................... $ 84.00 1,680.00 Direct labor ..................................... 45.00 900.00 Variable manufacturing overhead ..... 4.00 80.00 Special filigree ................................. 2.00 40.00 Total variable cost .............................. $135.00 2,700.00 Fixed costs: Purchase of special tool ................... 250.00 Total incremental cost........................... 2,950.00 Incremental net operating income ......... $ 449.00 Exercise 13-5 1. (1) (2) (3) (4) (5) Contribution margin per unit........................... Direct material cost per unit ........................... Direct material cost per pound........................ Pounds of material required per unit (2) ÷ (3) . Contribution margin per pound (1) ÷ (4) ......... A B $54 $108 $24 $72 $8 $8 3 9 $18 $12 C $60 $32 $8 4 $15 2. The company should concentrate its available material on product A: Contribution margin per pound (above) . Pounds of material available.................. Total contribution margin ...................... A B C $ 18 $ 12 $ 15 × 5,000 × 5,000 × 5,000 $90,000 $60,000 $75,000 Although product A has the lowest contribution margin per unit and the second lowest contribution margin ratio, it is preferred over the other two products because it has the greatest amount of contribution margin per pound of material, and material is the company’s constrained resource. 3. The price Barlow Company would be willing to pay per pound for additional raw materials depends on how the materials would be used. If there are unfilled orders for all of the products, Barlow would presumably use the additional raw materials to make more of product A. Each pound of raw materials used in product A generates $18 of contribution margin over and above the usual cost of raw materials. Therefore, Barlow should be willing to pay up to $26 per pound ($8 usual price plus $18 contribution margin per pound) for the additional raw material, but would of course prefer to pay far less. The upper limit of $26 per pound to manufacture more product A signals to managers how valuable additional raw materials are to the company. If all of the orders for product A have been filled, Barlow Company would then use additional raw materials to manufacture product C. The company should be willing to pay up to $23 per pound ($8 usual price plus $15 contribution margin per pound) for the additional raw materials to manufacture more product C, and up to $20 per pound ($8 usual price plus $12 contribution margin per pound) to manufacture more product B if all of the orders for product C have been filled as well. Exercise 14-4 1. The project profitability index for each proposal is: Proposal Number A B C D Net Present Value (a) $36,000 $38,000 $35,000 $40,000 Investment Required (b) $90,000 $100,000 $70,000 $120,000 Project Profitability Index (a) ÷ (b) 0.40 0.38 0.50 0.33 2. The ranking is: Proposal Project Profitability Number Index C A B D 0.50 0.40 0.38 0.33 Note that proposal D has the highest net present value, but it ranks lowest in terms of the project profitability index. Exercise 14-5 1. The payback period is determined as follows: Year Investment Cash Inflow 1 2 3 4 5 6 7 8 9 10 $15,000 $8,000 $1,000 $2,000 $2,500 $4,000 $5,000 $6,000 $5,000 $4,000 $3,000 $2,000 Unrecovered Investment $14,000 $20,000 $17,500 $13,500 $8,500 $2,500 $0 $0 $0 $0 The investment in the project is fully recovered in the 7th year. To be more exact, the payback period is approximately 6.5 years. 2. Because the investment is recovered prior to the last year, the amount of the cash inflow in the last year has no effect on the payback period. Exercise 14-6 This is a cost reduction project, so the simple rate of return would be computed as follows: Operating cost of old machine .................... Less operating cost of new machine ........... Less annual depreciation on the new machine ($120,000 ÷ 10 years)............... Annual incremental net operating income ... $ 30,000 12,000 12,000 $ 6,000 Cost of the new machine ........................... Scrap value of old machine ........................ Initial investment ...................................... $120,000 40,000 $ 80,000 Simple rate = Annual incremental net operating income of return Initial investment = $6,000 = 7.5% $80,000